It’s hard to imagine a home craftsman’s arsenal without such a popular power tool as an angle grinder or an angle grinder (popular name). The angle grinder gained its popularity due to its versatility, since this tool can be used for cutting, grinding, sawing, polishing, stripping, sharpening and other work. Moreover, absolutely any materials can be processed. During the operation of the tool, various breakdowns occur, and one of the most common is sparking brushes on angle grinders. Not many people know why brushes on an angle grinder spark, so let’s look into this issue, and also find out why they burn out and how to replace them.

Purpose of brushes on angle grinders

Before you find out the reasons for sparking brushes on an angle grinder, you need to understand their purpose. Commutator brushes are used not only in the design of angle grinders, but also in the design of all modern power tools - drills, hammer drills, jigsaws and others. In the design of grinders and other power tools, 2 brushes are used, which have a simple design. This design is based on the following elements:

- The main part is rectangular in shape and made of coal or graphite

- A contact is a wire core of the appropriate diameter through which electric current flows. The contact connects the wire to the graphite part

- A spring is a mechanism that ensures the main part is pressed against the collector. There may be no spring on the element, and this indicates that such a brush is intended for installation in a power tool, where the brush holders have a built-in pressing mechanism in the form of a curved plate

The devices are designed to transmit electric current to the rotor of a power tool. The voltage removed from the stator is supplied to the rotor, which is reproduced using carbon brushes and a commutator. Supplying current to the collector ensures its rotation. When the rotor rotates, the devices come into contact with the collector (copper lamellas are the leads of the armature windings), thereby ensuring the continuous flow of electric current.

During the use of devices, they wear out, so they are classified as consumables. The service life of brushes depends not only on the working life of the power tool, but also on the materials from which they are made. The wear of brushes is affected not only by mechanical impact due to friction, but also by thermal impact. Electric current passing through a conductor causes it to heat up. The higher the current, the higher the heating temperature. When current passes through the graphite brushes, they also heat up. The higher the load on a power tool, the higher the current, which means the temperature increases, which negatively affects the integrity of consumables.

This is interesting!

There are no differences between the brushes for the corresponding power tools (except for the method of fastening), since they are selected solely according to such a parameter as the dimensions of the main part.

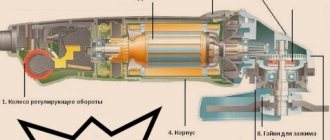

Angle grinder device

To understand the operation of the mechanism and why breakdowns are possible, you need to have an idea, at least schematically, of the main components of the tool.

Regardless of the model, manufacturer and technical characteristics, any angle grinder has the following details:

- The moving part of an electric motor is called an armature, or, what would be technically correct, a rotor. As a rule, this element is combined with a working shaft that transmits torque.

- Contacts of the collector, which is a switching board, through which the voltage is removed from the current collectors.

- Brushes pressed against it provide electrical contact. When pressed lightly, they begin to spark strongly.

- The internal stationary winding is the stator. The rotation of the armature in it is achieved due to electromagnetic induction.

- Mechanical reduction gearbox for speed regulation.

- Other components: housing, usually plastic, handles, start button, power cable.

As a working tool, an angle grinder is subjected to high loads and increased continuous operation time. Despite the maximum tightness, dust, small fragments of processed materials, and scale periodically get inside the housing. This negatively affects both the mechanical parts and the electrical part.

As a result, the conductive parts become contaminated and the collector lamellas gradually burn out due to overheating. In turn, this leads to destruction of the current collecting brushes, which will be signaled by increased sparking.

What are they made from?

Brushes for grinders and other power tools are made from different materials, but the main ones are coal and graphite. This material has a low coefficient of friction and also has increased abrasion resistance. To improve contact, various impurities are added to the composition of graphite or carbon during the manufacture of brushes. Depending on the impurities used, the following types of brushes are distinguished:

- Coal

- Copper plated

- Carbon-graphite

- Graphite

- Copper-coal

- Copper-graphite

The composition of the main part affects not only the service life or wear, but also such a parameter as signs of sparking. The amount of brush sparking depends on the composition from which they are made. When purchasing them, you need to pay attention to the composition, and not purchase equipment of unknown origin and dubious quality.

This is interesting!

The design of the brushes contains a ceramic tip, which performs one of the important tasks. When the graphite layer is abraded to the limit, the tip begins to contact the copper lamellas of the commutator. Ceramics do not conduct electricity, so when the brushes wear out, the grinder will work intermittently or will not turn on at all until the devices are replaced.

Selecting consumables according to the rules

All brushes are divided into soft and hard. This is perhaps the most important selection criterion, since collector copper also has different hardness levels. If these indicators do not meet, the equipment quickly loses its functionality. But the most unpleasant fact is the rapid wear of parts. In this case, precision finishing work is impossible in principle. The same can be said about the safety of the most complex processes at height.

Before ordering, you should inquire about the active resistance indicators of the elements. Without this, a smooth start is impossible, and most importantly, speed control is impossible. Such equipment characteristics make it possible to achieve accurate processing of materials with different densities and hardnesses. At the same time, the latter do not lose their integrity, which is especially important for the external decoration of the facade.

And since all structural elements are a single whole of one complex mechanism, the calculated clamping of the part is important. For example, with intense “pressure” the brush assembly may overheat. If the clamp is too weak, the equipment will constantly spark, and the springs will completely leave their seats. This contributes to premature breakdowns, many of which can only be fixed at a service center.

Reasons why brushes spark

Very often you can notice how the brushes on an angle grinder sparkle. Signs of sparking are detected through the ventilation holes in the body of the power tool. Craftsmen are interested in why the brushes on an angle grinder spark, even after they have been directly replaced. There are many reasons for this, and to understand this, you need to have an understanding of the structure of a power tool. If you know how the angle grinder works inside, then understanding why the brushes spark strongly will not be difficult.

The reasons for strong sparking of brushes on grinders are the following factors:

- Faulty armature winding. If a violation of the insulation of the armature winding occurs, then this ultimately contributes to the development of an interturn short circuit, as well as a short circuit to the core. In addition, a winding break may occur, which will ultimately cause an increase in load. A characteristic sign of a faulty armature winding is a decrease in speed, an increase in noise and a drop in power

- The brushes do not press well to the commutator. A spring is responsible for pressing the main part, which, over time, loses its original springing properties.

- The rotor winding has broken off from the copper plate of the commutator - this phenomenon is extremely rare, however, if the power tool is overloaded, it may well occur

- The centering of the electric motor armature is disrupted, which ultimately contributes to strong sparking of the brush on the angle grinder

- The shape of the collector is broken. The collector, consisting of copper lamellas, has a cylindrical shape, which can be broken when the rotor is rewinding. At the slightest deformation of the commutator shape, sparking of the brushes will occur

- Violation of insulation between the collector lamellas. Each collector plate is insulated from each other, and if the micanite insulating layer is damaged, sparking occurs. The insulation between the plates may also be compromised due to the settling of the graphite layer in the grooves

- When the armature bearings are worn. If the bearings are faulty, then a beating of the rotating armature occurs, and as a result, signs of sparking appear

- Curvature of the rotor shaft. It is difficult to bend it, but if this happens, the engine begins to work under load. To prevent the tool from malfunctioning, it is recommended to replace the rotor

- If the ends of the armature windings are soldered incorrectly to the copper plates of the collector. Such errors are not allowed at the factory, but they can be made by the wrapper who rewinds the armature of the power tool.

- Inappropriate composition of graphite brushes. The parts in question are made from coal and graphite, adding different types of impurities. This is done for a reason, but in order to use brushes depending on the voltage and shaft rotation speed. Graphite can be soft or hard. The lower the supply voltage, the softer the grade of graphite selected. For high-voltage power tools, it is necessary to take hard brushes that do not contain copper.

- Deformation of the lamellas due to their heating. If the angle grinder experiences excessive loads, deformation of one or more lamellas of the collector may occur. The plates rise relative to the others, resulting in the contact being broken. This malfunction causes strong sparking of the brushes when operating the power tool.

- Poor contact at the brush connection point. If the terminal is loosely connected to the device, the result of this contact failure may manifest itself in the form of excessive sparking

- Presence of carbon deposits on copper plates - periodically or regularly it is recommended to clean the surface of copper lamellas from carbon deposits. Carbon deposits usually appear due to wear of the brushes, so if blackening is detected on the surface of the commutator, it should be wiped with alcohol

Often, after changing the brushes on an angle grinder, craftsmen observe the phenomenon of excessive sparking. Based on the factors described above, you can identify the cause and eliminate it before the tool fails. The elements in question are inexpensive, but due to their incorrect selection and use, the power tool may break. To find out what malfunction is causing strong sparking, you will need to disassemble the power tool and inspect it, as well as ring the rotor winding.

Care and proper operation of the grinder

To make the grinder work for a long time, follow the rules:

- Monitor the integrity of the insulation of the wire and plug. Don't remove your protection.

Lubricate and clean the entire tool.

After turning off the grinder, wait until the circle stops rotating, then place it on the ground. When the engine stops, the tool, through the ventilation holes, sucks in, along with the air flow, particles of earth and other hard fractions that hit the motor windings. As a result, a break or short circuit occurs.

Try not to use an angle grinder outside in the winter. While you are running, the engine gets hot. The air is icy. As a result, condensation forms. Moisture is harmful to the engine. Always use the circles recommended by the tool manufacturer. If the angle grinder is 180 mm, do not put more than 200 mm there. The larger the circle, the lower the revolutions should be. You will have to remove the protection, and the speed will be exceeded. Vibrations and vibrations will increase. As a result, the circle will break into pieces. This is not only fraught with serious injuries. The gearbox bearing breaks and the gears wear out.

Post Views: 10

Why do brushes burn out on angle grinders?

In addition to sparking, power tool owners often encounter brushes on their grinders burning. This phenomenon differs from sparking in that rapid wear of the main part of the element occurs. Immediately after installing new elements, they wear out immediately when using the power tool for the first time. We have to figure out why the brushes on the grinder burn.

The main reason lies not in the brushes themselves, but in the commutator. If the lamellas fall out or wear out on the collectors, this leads to an increase in load. This load is experienced by graphite elements, which, when the angle grinder is turned on, begin to wear out quickly - this process of accelerated wear is called combustion. Elements literally burn due to the passage of large current. Many people call this process abrasion, but in reality brushes cannot quickly wear out due to mechanical stress. The cause of combustion is strong sparking, as a result of which the graphite literally simply burns out.

The reasons why brushes on an angle grinder burn are as follows:

- Loss or wear of the copper lamellas of the collector. What wear on the collector lamellas looks like is shown in the video. The material also shows how you can try to eliminate such a malfunction.

- An interturn short circuit between the lamellas or the rotor winding helps to increase the current, from which the brushes heat up and begin to burn. To identify the cause, you will need to ring the anchor

- If the power tool is heavily overloaded - if you use the grinder for a long time without breaks, the result of such use will manifest itself in the form of brushes burning out in 5-10 seconds

There is also such a thing as all-round fire. This phenomenon occurs during large impulses of the armature current, for example, during overloads, short circuits, and also when the network voltage decreases. A circular fire appears when the arc is re-ignited. An increase in load and even a short circuit occurs when using an angle grinder to cut wood. When processing wood, the cutting disc becomes clamped, thereby increasing the current by 15-25 times the nominal value. Most often, the commutator is the cause of element combustion, so if you had to change 2-3 pairs of brushes in a month, then it’s time to diagnose the power tool.

Replacement instructions

At home, this operation is carried out according to the following scheme: first you need to clean the collector from dust. For this purpose, experienced users recommend gasoline. As soon as there is no trace of dirt left, you need to try to rub the new element into the collector. Sandpaper will help to cope with unevenness.

Even if the degree of wear is different, all elements need to be replaced. Their average shelf life is determined by the operating hours of the equipment. So, if the tool is used once a month, 90 hours is the minimum, which can be quite realistically increased to 125 hours. With frequent use of equipment in different weather conditions, 85 hours is the ceiling.

How to understand that you need to change the brushes

Many people change brushes only after they notice strong sparking from the tool, as well as the appearance of a burning smell. Many craftsmen are not stopped even by these signs, and they continue to use the tool until it stops turning on. When is it necessary to change carbon brushes so as not to damage the structure of the power tool? There are the following signs for this:

- Strong sparking - if signs of strong sparking appear, then it is necessary to disassemble the tool and inspect the consumables. Sparking is the first sign that consumables need to be replaced.

- The appearance of a burning smell - if the smell of soot is heard when using the tool, it is recommended to disassemble the grinder and replace the graphite brushes

- When the wear of the main part is over 30% -40%. However, it is almost impossible to determine their initial length, unless you measure it before installing the elements

- When signs such as jerking or “growling” of the power tool appear

Devices are also subject to replacement if they have uneven wear and do not correspond to quality.

This is interesting!

It is not recommended to buy copper-plated brushes for a home grinder, as they will quickly damage the armature commutator due to the high copper content in the composition. Copper-plated elements can be used on grinders that have a special coating on the collector plates.

Homemade electric brushes

We find a suitable material, cut it to size with a margin of 2 mm. Then we sand it down to the desired size. It is recommended to use the contacts of old brushes as the top contact on the wire, soldering them to the contact wire if there is one.

If there is no contact group, to secure the wire, a hole with a smaller diameter than the diameter of the copper braid is drilled in the electric brush. The braid is twisted, inserted into the drilled hole and wedged on the opposite side with copper wire. Everything is ready, install and check for sparking.

How to replace it yourself

What could be easier than replacing the brushes on an angle grinder? However, here there are some nuances that should be taken into account so as not to damage the power tool. First you need to choose the right consumables. When choosing, you should rely on the model of the grinder or remove the installed brushes and measure their dimensions. Buy new elements using these sizes. It makes no sense to talk about how much such devices cost, since this is mere nonsense.

After the consumables are purchased, the brushes are replaced. In this case, first you need to look at the model of the grinder. Some manufacturers equip their power tools with special shafts for quickly replacing brushes. They are a plastic cap that is screwed in and out with a screwdriver.

If it is an angle grinder that does not have a special shaft for quickly replacing brushes, then you will need to disassemble the body to get to the consumables. When access is gained to replace consumables, further actions are performed in the following sequence:

- Having gained access to the brush holder, it is necessary to disconnect the contact wire from it

- Disconnect the contact wire, which is also connected to the brush holder

- Retrieve erased element

- Clean the area where the brush is installed, as it should move freely and without jamming

- Install the new part in the reverse order of removal

- Before installing the brush holder in place, it is necessary to inspect the commutator. If there are signs of carbon deposits, they should be eliminated

- Carry out the replacement procedure on the other side in the same way.

Knowing how to change brushes on an angle grinder, you should immediately replace them. The more sparking devices on power tools are, the sooner they need to be replaced. When replacing, you must also take into account that devices need to be replaced in pairs, but not one at a time.

Summing up the work done, it is worth noting that there are many reasons for sparking brushes on an angle grinder, and in each specific case you need to look for your own breakdown. If it is not possible to determine the causes of sparking, then the tool must be shown to a specialist who will identify the breakdown and fix it. This is better than continuing to work with a faulty tool, which could burn out or short out at any moment. Only with the right approach to the repair and maintenance of power tools can you achieve long-term operation.

Checking the contacts of the brush-collector unit

The reason for sparking of serviceable parts of the block may be poor contact due to insufficient contact with the collector lamellas. During operation of the vacuum cleaner, roughness forms on the surfaces of the engine's switching parts, which prevent the necessary contact. Grinding with fine sandpaper – “zero” – will help eliminate bumps, grooves and scratches on the commutator.

Advice! If the brushes spark excessively, then they should be pressed more tightly to the commutator using springs. In this case, the free movement of the block elements must not be disrupted.