It is no coincidence that the vortex pump, used for pumping liquid media, is so popular both in production and in everyday life. Modern manufacturers offer various types of vortex pumps, differing from each other both in their design features and operating principle, but what is common to all such devices is the presence in their design of an impeller equipped with special blades.

Vortex pump DAB KP-60/6, designed for use in domestic and small industrial systems

Where is a vortex pump used?

Vortex pumps are used to move liquids, but they are suitable for pumping gas.

Their fundamental feature is the ability to produce strong pressure with a small volume of water. This makes them popular for use in domestic conditions. They are widely used in individual water supply, where they operate in automatic mode.

The main purpose is as follows:

- for water supply of country farmsteads, complete with automatic pumping station;

- when pumping flammable mixtures to gas stations;

- for supplying power to low-power boiler systems.

Due to its design and principle of operation, a vortex pump is often used in various industries when working in aggressive environments. The simplicity of the design makes it possible to manufacture components from refractory alloys with increased reliability.

Tips for choosing

When choosing a specific model, you must remember that the vortex pump must perform 2 main functions - ensure an uninterrupted supply of fluid from the well and at the same time have a reliable design.

Many models on the market meet these parameters. But in order to choose the optimal one, it is recommended to adhere to the following recommendations:

- Optimal power indicator and volume of pumped liquid. Depending on the needs, it is necessary to select a model so that its technical characteristics fully comply with the required ones - the volume of liquid from the well should not be less than the minimum consumption rate.

- Calculation of pressure. It depends on the depth of the source of water intake and horizontal pipelines. The manufacturer indicates this data in the equipment passport.

- Pump operation warranty.

Taking these factors into account and using a systematic approach, you can choose the optimally suitable equipment model that will fully meet the requirements of the water supply system.

Design and principle of operation

The main design element of a vortex pump is an impeller that rotates around its axis. It has the appearance of a steel disk, where there are pits on the outer diameter that form blades of different types.

Such an impeller rotates around its axis in a durable chamber shaped like a cylinder. The principle of operation of a vortex pump is the effect of sucking water through the inlet pipe and spinning it into a vortex due to the rotation of the impeller. As a result, it is pushed out under great pressure. Thus, at low energy costs, the power of the water flow is increased several times.

It should be noted that both pipes are located at the top of the housing. This ensures a suction effect already at the start.

A special feature of the device is the presence of a drainage channel between the holes for the inlet and outlet of the pumped water, and a special partition that covers several blades with a gap of no more than 0.2 mm. As a result, centrifugal force is created, increasing the water pressure. As a result, the efficiency of this design has become several times greater than the operation of a centrifugal apparatus.

Structure and principle of operation

According to the method of operation, a self-priming pump can be vortex and centrifugal. In both, the key link is the impeller, only it has a different structure and is installed in a housing of different dimensions. This changes the principle of operation.

Centrifugal

Centrifugal self-priming pumps have an interesting working chamber structure - in the form of a snail. The impellers are fixed in the center of the housing. There can be one wheel, then the pump is called a single-stage, or there can be several - a multi-stage design. Single-stage ones always operate at the same power, multi-stage ones can change performance depending on conditions, and accordingly are more economical (consuming less electricity).

Self-priming centrifugal pump device

The main working element in this design is a wheel with blades. The blades are bent in the opposite direction relative to the movement of the wheel. When moving, they seem to push the water, squeezing it towards the walls of the body. This phenomenon is called centrifugal force, and the area between the blades and the wall is called a “diffuser”. So, the impeller moves, creating an area of increased pressure at the periphery and pushing water towards the outlet pipe.

Diagram of water movement in a centrifugal pump

The principle of operation of centrifugal pumps is associated with their disadvantage: the impeller cannot create centrifugal force from air, so the housing is filled with water before operation. Since pumps often operate in intermittent mode, so that water does not flow out of the housing when stopped, a check valve is installed on the suction pipe. These are the features of the operation of centrifugal self-priming pumps. If the check valve (it must be present) on the supply pipeline is at the bottom, the entire pipeline has to be filled, and this will require more than one liter.

| Name | Power | Pressure | Maximum suction depth | Performance | Housing material | Connection dimensions | Price |

| Caliber NBC-380 | 380 W | 25 m | 9 m | 28 l/min | cast iron | 1 inch | 32$ |

| Metabo P 3300 G | 900 W | 45 m | 8 m | 55 l/min | cast iron (stainless steel drive shaft) | 1 inch | 87$ |

| BISON ZNS-600 | 600 W | 35 m | 8 m | 50 l/min | plastic | 1 inch | 71$ |

| Elitech NS 400V | 400W | 35 m | 8 m | 40 l/min | cast iron | 25 mm | 42$ |

| PATRIOT QB70 | 750 W | 65 m | 8 m | 60 l/min | plastic | 1 inch | 58$ |

| Gilex Jumbo 70/50 Ch 3700 | 1100 W | 50 m | 9 m (built-in ejector) | 70 l/min | cast iron | 1 inch | 122$ |

| BELAMOS XI 13 | 1200 W | 50 m | 8 m | 65 l/min | stainless steel | 1 inch | 125$ |

| BELAMOS XA 06 | 600 W | 33 m | 8 m | 47 l/min | cast iron | 1 inch | 75$ |

Vortex

The vortex self-priming pump is distinguished by the structure of its casing and impeller. The impeller is a disk with short radial baffles located at the edges. It's called an impeller.

Structure of a vortex pump

The housing is made in such a way that it quite tightly covers the “flat” part of the impeller, and there is a significant lateral gap in the area of the partitions. When the impeller rotates, water is carried along by the bridges. Due to the action of the centrifugal force, it is pressed against the walls, but after some distance it again falls into the zone of action of the partitions, receiving an additional portion of energy. Thus, in the gaps it also twists into vortices. This results in a double vortex flow, which is what gave the equipment its name.

Due to the peculiarities of their operation, vortex pumps can create a pressure 3-7 times higher than centrifugal pumps (with the same wheel sizes and rotation speed). They are ideal when low flow and high pressure are required. Another plus is that they can pump a mixture of water and air, sometimes even creating a vacuum if they are filled only with air. This makes it easier to put it into operation - there is no need to fill the chamber with water or a small amount is enough. The disadvantage of vortex pumps is their low efficiency. It cannot be higher than 45-50%.

| Name | Power | Pressure (lifting height) | Performance | Suction depth | Housing material | Price |

| LEO XKSm 60-1 | 370 W | 40 m | 40 l/min | 9 m | cast iron | 24$ |

| LEO XKSm 80-1 | 750 W | 70 m | 60 l/min | 9 m | cast iron | 89$ |

| AKO QB 60 | 370 W | 30 m | 28 l/min | 8 m | cast iron | 47$ |

| AKO QB 70 | 550 W | 45 m | 40 l/min | 8 m | cast iron | 68 $ |

| Pedrollo PKm 60 | 370 W | 40 m | 40 l/min | 8 m | cast iron | 77$ |

| Pedrollo RK 65 | 500 W | 55 m | 50 l/min | 8 m | cast iron | 124$ |

Advantages and disadvantages

The operating principle of a vortex pump has many advantages:

- the possibility of forming a significant pressure at the outlet of the device;

- presence of liquid self-suction function;

- the ability to transport liquids and gases.

Submersible versions of this design can be effectively operated at a depth of 20 meters.

The disadvantages include:

- low efficiency of 45%;

- impossibility of pumping water with the presence of small fractions of solid matter;

- not recommended for transporting viscous liquids.

As you can see, this design is capable of delivering the necessary water pressure for an individual household and can be used when pumping a septic tank.

Technical and functional features

The design of vortex models of pumping equipment also does not particularly offer modern functionality. Technological control automation is rare and only in premium series produced at the level of Grundfos and Marina-Speroni, however, even budget manufacturers, like the domestic one, strive to maximize the basic design capabilities of their products in this segment. For example, you can note the benefit of the built-in ejector, which increases the suction depth.

Vortex pumps also have regulatory abilities, thanks to which the mechanics find the optimal combination between pressure indicators and wheel operating frequency. Among the safety devices, one can note the presence of casings to protect internal parts, as well as developed external forced cooling systems. At the same time, a significant drawback of many designs is the lack of automatic protection in case of idling, that is, a shutdown function in case of harmful operation “dry”, without water.

Open vortex and closed vortex + video

Features of the open vortex design are as follows:

- blades on a longer wheel;

- the width of the wheel is significantly less than the width of the channel for draining liquid;

- the looped channel is connected only to the output channel.

In closed designs, the blades are much shorter, located at different angles, the width of the impeller is similar to the width of the chamber, and the channel connects its inlet and outlet.

The difference between a vortex pump and its operating principle:

- Initially, water passes into the main chamber;

- swirled in a vortex-shaped state, it falls into the connecting channel;

- after which it leaves the pump under high pressure.

In closed structures, due to the same diameter of the impeller and working chamber, the liquid is immediately directed into the connecting channel, where it is formed into a vortex and an increased pressure is created.

Ejector

The greatest depth from which surface vortex and centrifugal pumps can lift water is 8-9 meters; it is often located deeper. To “get” it from there, an ejector is installed on the pumps. This is a specially shaped tube that, when water moves through it, creates a vacuum at the inlet. So such devices also belong to the category of self-priming. An ejector self-priming pump can lift water from a depth of 20-35 m, and this is more than enough for most sources.

Connection diagram for a remote ejector for wells of different diameters - two-inch on the right, four-inch on the left

The disadvantage is that in order to ensure operation, part of the water must be returned, therefore, productivity is significantly reduced - such a pump may not provide a very large water consumption, but no less electricity is spent to ensure operation. When installing an injector in a well or well of sufficient width, two pipelines are lowered into the source - one supply of a larger diameter, the second, return, of a smaller diameter. An ejector is connected to their outputs, and a filter and check valve are installed at the end. In this case, the disadvantage is also obvious - double pipe consumption, which means a more expensive installation.

In small-diameter wells, one pipeline is used - the supply one, and instead of the return line, the well casing pipe is used. In this way, a rarefaction zone is also formed.

Submersible and surface models

The difference between these designs lies in their name. Thus, submersible models are operated in a liquid environment and are capable of moving liquids with low viscosity. Surface - pump only filtered water for watering the garden or home water supply.

- Combined options.

Free vortex structures are capable of pumping contaminated liquid in drainage systems and sewers.

Centrifugal vortex structures have greater efficiency compared to classical versions and can pump liquids heated to a temperature of + 105 °C. A vortex and centrifugal wheel are installed here at the same time.

Vortex-type vacuum pumps are designed to distribute air of different temperatures and can create a slight vacuum.

Main varieties

Vortex pumps according to their design are divided into two categories:

- open-vortex;

- closed-vortex.

Pumps of the first type are distinguished by the following design features.

- The blades with which the impeller is equipped have an elongated shape.

- The impeller, when compared with the lumen of the working channel, has a reduced diameter.

- The annular channel is connected to the pressure pipe.

Diagram of a vortex pump with an open channel

Electric pumps of the closed-vortex type also have certain design features.

- The blades of pumps of this type, when compared with similar elements of open-vortex devices, are shorter and are located on the surface of the impeller at different angles.

- The cross section of the inner chamber is equal to the diameter of the impeller.

- The annular channel of closed-vortex pumps is connected to both the receiving pipe and the output pipe.

Diagram of a vortex pump with a closed channel

Naturally, the differences affect not only the design of pumping equipment of these types, but also the operating principle of such devices. Open-vortex type pumps operate as follows.

- The pumped liquid enters the internal working chamber through the receiving pipe.

- Captured by the rotating impeller, the pumped medium enters the annular channel.

- The vortex flow of the pumped liquid, moving along the annular channel, contributes to the formation of a pressure flow, which is directed to the outlet pipe.

Since the diameter of the impeller in closed-vortex pumps, as mentioned above, is equal to the cross-section of the working chamber, the liquid from the inlet pipe immediately enters the annular channel, where a pressure flow is created.

Open Type Multistage Vortex Pump

Vortex type pumps are classified according to their location relative to the pumped medium. So, depending on this parameter, they distinguish:

- submersible-type devices, which, as their name implies, during operation are located in the thickness of the pumped medium (such pumps are used for both domestic and industrial purposes, pumping with their help clean liquids of not too high viscosity);

- surface-type pumps, which are located in close proximity to a reservoir with a liquid medium or a well, reliably protecting their housing from liquid ingress (equipment of this type is equipped with irrigation systems and water supply systems for domestic purposes).

Surface vortex pump for domestic use, designed to supply clean water from wells or wells

In addition to vortex pumps of classical design, modern industry produces combined devices.

- Free-vortex pumps have a design that allows them to pump highly contaminated liquid media. These devices are used as drainage and sewage pumps, as well as for equipping treatment facilities and in the mining industry (without the help of such equipment, drilling wells from which it is necessary to pump out liquid media is not possible).

- Centrifugal-vortex pumps are capable of working with liquid media whose temperature reaches 105°. A design feature of such pumps is that they are equipped with two impellers at once: centrifugal and vortex. Due to this design feature, this equipment is characterized by significantly higher efficiency (compared to classic vortex devices).

- Vortex vacuum pumps can be used as a blower or for pumping out air - creating a shallow vacuum. Such pumps are easy to use and do not require complex maintenance. They are widely used as a thermal apparatus, which ensures the supply and distribution of the required amount of warm or cold air. In particular, such equipment is successfully used for drying glass containers; it is used to aerate artificial and natural reservoirs.

Unit Maintenance

After the first hours of operation, it is necessary to carry out a preventive inspection of the pump. Further, such inspections must be performed every 100 hours, as recommended by the manufacturers. Units that are not in use must also be inspected every quarter. Particular attention should be paid to the condition of the vortex pump impeller, the degree of wear of mechanical parts and the quality of electrical connections. The housing must be maintained in good condition, cleaned and correctly assembled. During testing, the structure cannot be tilted, as in this case productivity will be reduced by 25-30%. The same rule applies to the normal operational process.

Operating rules

The described unit is installed on a hard surface strictly horizontally and, if possible, closer to the source of water intake. In case of vibrations, it is also advisable to secure the structure with a metal frame or bolted frames. The pump is connected to the network through the RCD fuse block. Grounding can be provided with a steel wire about 6 mm thick. In this case, one end of it is attached to the body, and the other to a ground electrode in the form of a metal pipe from a well or any structure leading into the ground.

Next, you can begin direct operation of the vortex pump, checking its tightness and the correctness of the connections made. First, the suction pipe and pump part are filled with liquid. To do this, you can use a funnel and a filler outlet in the structure. When the pumping part is completely filled, you can put the equipment into operation.

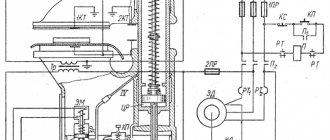

Unit design

In a broad sense, vortex pumps are hydraulic equipment that converts mechanical drive energy into force. The generated force ensures the movement of liquid flows. The typical composition of the design of such units is formed by a pump part, an electric motor (usually asynchronous), a starting unit, a group of filler and outlet holes, mounting infrastructure, etc.

The key element in the design of vortex pumps is the impeller, provided with blades and placed on a shaft. Due to its movement, the main effort required for water circulation is performed. By the way, to determine the direction of rotation of the wheel, you should pay attention to the markings. Usually, an arrow directly on the body indicates in which direction the rotation is made.

The body itself is made of high-strength stainless steel. Unlike many other types of pumps, plastic is practically not used in this case. The minimum insulation protection class of vortex models rarely corresponds to a level less than IP44.

Application area

Devices of this type are primarily used for pumping various liquids and emulsions. Moreover, they can be used in the presence of a large amount of coarse impurities, since a grinder is included in the design.

Scope of application of vortex centrifugal pumps:

- Firefighting. The design is reliable and can work for a long period.

- Water purification systems. As previously noted, the pump can operate at high concentrations of impurities.

- Water supply from a well to the house.

- Irrigation systems. The simplicity of the design determines its small overall dimensions and relatively low cost. Therefore, if necessary, you can install it to create pressure in the system.

Based on the operating principle of a centrifugal vortex pump, other equipment is also created that is used for installation in a ventilation or gas supply system.