Linoleum attracts with its high performance characteristics, reasonable price, durability, and abundance of design options. However, if a piece of roll does not cover the entire volume of the room and several pieces have to be combined, the seams spoil the picture. Even with the best quality and professional installation, it begins to lift up at the joints of the material. Cold or hot welding of linoleum will help eliminate this unpleasant moment by creating a solid surface.

Types of welding: what's the difference?

Options for connecting linoleum joints:

- Cold welding. It is performed using a special glue that melts the edges of the canvases, which, when dry, are combined into a single whole. It is used primarily to get rid of unaesthetic joints that appear during the installation of household linoleum. Depending on the size of the gap and the type of material, adhesives of types “A”, “C” and “T” are used. This method is suitable for restoring damaged coating.

- Hot. The role of a welding tool is played by a construction hair dryer, which heats the material to 350–400 °C during operation. Due to the high cost and complexity of implementation, it is rarely used at home; it is used to connect commercial linoleum in public and industrial premises with high traffic.

When deciding which method to weld linoleum, you need to rely on the characteristics of the coating, the complexity and geometry of the joints.

Cold welding

The joints of linoleum sheets are made using a special glue for cold welding. This method is convenient for sealing defects: breaks, cracks, stains. The coating is replaced in small sections: a new fragment is laid on a continuous section. The adhesive composition has a high binding force and forms a strong connection.

Cold welding technology is economical. To work you will need:

- metal ruler;

- corner;

- stationery knife;

- construction tape 3 cm wide;

- special glue.

Advantages and disadvantages

The cold method of joining joints using a special adhesive composition is considered optimal due to a number of advantages:

- a complete sealed seam is formed;

- the glued joint is almost invisible;

- the connection does not require special machining with tools or consumables;

- the cost of glue is not comparable to the price of a cold welding tool;

- the work does not require professional skills;

- minimal time spent on preparing the work area.

The disadvantage is the toxicity of the glue and volatile compounds formed at the point of contact of the glue with the polymers. In enclosed spaces it is necessary to use personal protective equipment to avoid toxic damage.

Cold welding of linoleum

Choosing adhesive for cold welding linoleum

There are several types of adhesive mixtures. They differ in structure and amount of solvent. Each allows you to get a reliable connection.

Welding for type A linoleum is the most liquid, it contains the least solvent, and it is used to connect even joints. For loose joints with gaps between sheets of up to 2 mm, uneven cuts typical for repair work, this glue is not suitable: the seam will be unreliable. For convenience, the glue packaging is equipped with a needle attachment. This composition can be used to glue light ceiling plinths.

Type C glue has a thick consistency. It forms a dense polymer structure in a gap of up to 4 mm. Suitable for repair work, fragmentary replacement of areas. They can be used to seal small cracks in linoleum. The cold seal tube fits conveniently into the glue gun. A strip similar to heat shrink cord is formed.

Specifics of hot welding

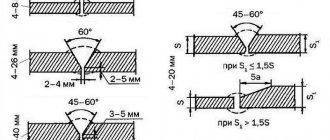

Hot welding for linoleum involves creating a hermetically sealed seam. To ensure a smooth connection, the coating strips are laid overlapping and cut along the line with a sharp knife.

Welding should begin after the linoleum material is securely attached to the floor with adhesive. Due to the need to quickly complete the procedure, the master requires some experience and skill. Trimming and sanding the joining cord is done before it cools, otherwise the resulting surface will look unpresentable. In this case, an ordinary soldering iron, as in the old fashioned way, is not enough.

Advantages of the technique:

- High tightness of the resulting connection.

- Greater reliability than cold welding.

USEFUL INFORMATION: Screed for heated floors: subtleties of doing it yourself

The limitation on performing such gluing is the possibility of using it only for hard types of coatings, the decorative appeal of which will not decrease under the influence of elevated temperatures. Usually this is commercial linoleum, including felt-based. Disadvantages also include the need to use a specialized tool.

Hair dryers for welding linoleum seams

A functional component of a soldering station for working with plastic and polymer alloys, the parameters of which also determine the welding capabilities. This is a kind of welding gun-hair dryer, available on the market in the form of manual and automatic models. In the context of supplementing a soldering station with a heat gun, it is important to note the difference in functional tasks. If the main base technically organizes the conditions for the formation of hot flows in a certain range, then the welding gun directly adjusts the parameters of the thermal air stream, directs it and allows you to regulate the temperature regime. Thus, when hot welding linoleum seams with a hairdryer, medium heating modes are used in the range from 350 to 400 °C.

Tools and materials

In addition to the flooring itself, you will need:

- Welded cord for filling the seam, similar in composition to linoleum. Under the influence of high temperature, the edge melts and the tow penetrates into the material. To guarantee a high-quality result, you should purchase the cord in specialized stores.

Cord (rod) for welding

Using a cord to match the color of the coating

- A construction hair dryer equipped with a thermostat to control the heating temperature. High-quality models of hot air guns can heat the air to 600–700 °C.

- Special attachments for hair dryers.

- Groove chisel.

- Sickle knife. Can be replaced with scissors with arcuate blades. The tool is used to remove excess deposits.

If you have no experience “communicating” with a hot air gun, it is recommended to give preference to cold welding, which is suitable for both household and commercial linoleum.

Soldering stations for welding linoleum

To implement hot welding, special equipment is used in the form of welding or soldering stations. They are based on a rigid frame with a generator set and auxiliary equipment that directly directs the hot air. The standard device also provides a drum for winding the suture rod, which will be used to seal the seam. As for working qualities, an average-performing machine for welding linoleum seams operates at temperatures up to 600-700°C. The connection is usually made to a single-phase 220 V network. The choice should also take into account the performance of the equipment and the rotation speed of the pressure roller. It is determined by the power of the generator and indicates the maximum possible rate of work. For example, a power potential of 3400 W provides a speed range of about 12 m/min. These are average figures for semi-professional equipment.

Hot welding process technology

Work order:

- We carefully lay the material so that we get a uniform seam of minimal thickness. Using a chisel, we widen the joint, using it to prepare a groove for subsequent laying of the cord.

- Using a powerful vacuum cleaner, we thoroughly clean the future joint area of debris.

- We install a special nozzle on the hair dryer.

- We fill the welding rod, then connect the tool and heat it to 350–400 °C.

- Using the tip of a hair dryer, press the cord into the groove made earlier. The formation of a monolithic connection takes a couple of seconds.

- We fill in the entire connecting line in the same way. At the correct speed, the melting of the cord and filling of the groove will occur evenly.

- Having completed welding, we remove excess deposits using a sickle-shaped knife and special attachments designed for cutting cords.

- We carefully monitor the removal of deposits. In order not to deform the surface of the canvas, the nozzle is installed parallel to the floor material.

- Having removed the excess cord, we begin the process of sanding the seam. For this purpose, “zero” sandpaper glued to a wooden block is used.

USEFUL INFORMATION: Insulation of floor screed with penoplex: implementation technology

To understand the principles of hot welding, we recommend watching a training video.

Progress

"Cold" welding of seams

- When the linoleum has already been rolled out, we combine two sheets of paper seam-to-joint. We turn one of the sheets so that its reverse side is visible. Mark a line on the floor at the joint with a marker or pencil.

- After this, you can bend the second sheet of linoleum, then glue double tape over the mark.

- Now we return the folded sheet of linoleum to its place and glue it to the tape, smoothing the canvas to the joint so that waves do not form. Press the sheet with your hand.

- Then we unscrew the second part of the linoleum and also glue it to double tape. We should get an even joint. Now you can start welding: to do this, stick masking tape on top of the seam. The joint should be in the center of the tape.

- Using a construction knife, we cut through the place where the joint is located, so that a small strip remains. In this case, care must be taken not to cut through the material itself. “Cold” welding should not come into contact with the linoleum, as in this case the surface will be damaged, which is why masking tape is needed.

If the “cold” welding is in a tube with a needle, then the masking tape can not be cut, but pierced and guided along the joint.

- When the mixture has hardened, the tape can be removed.

Welding linoleum with overlap

There are situations when it is not possible to combine the factory joints of the sheets; in these cases, an overlap remains.

- We lay the rule on top of both canvases and press it.

- At this stage we need to cut through both sheets with a construction knife. This will result in two short cuts - one from the top sheet, the other from the bottom. We remove them and get a smooth joint that can be welded, as in the case of factory edges.

Repairing old joints with type C glue

- If the linoleum is torn at the joint, then the old edges must be cut off with a construction knife.

- As in the previous case, we paste double-sided tape under the sheets and masking tape at the joint.

- We put a flat nozzle on the tube of glue and begin to fill the gap.

- Over time, the composition shrinks as a result of absorption into the linoleum, so refilling may be necessary.

The drying time of the composition takes from two hours to a day.

Hot welding

To glue joints using this method, you will need specialized tools and consumables.

- Bevel Knife

- Hot welding cord

- Hair dryer with nozzle

- Seam stripping knife

Initially, the progress of work does not differ from the option with the cold gluing method.

- Two sheets are laid seam to seam, then one is folded back and a line is marked on the floor.

- Double tape is glued to the center of the line. Both edges are glued to tape.

- According to the rule, chamfers are removed with a special knife.

- The cord is installed in a holder under the nozzle of the hair dryer. The device processes the material with hot air during the process of filling the seam.

- Excess composition is cut off with a knife to clean the seams of linoleum.

You can read more about laying linoleum on a concrete floor with a backing in a separate article.

Expected difficulties

Having familiarized yourself with the main stages of hot joining linoleum, you can decide that this process is a very simple undertaking. However, professionals point out some difficulties:

- Low prevalence of welding cords. The sale of such building materials is carried out in a limited number of retail outlets.

- A specialized tool (heat gun) has a high cost (from 20 thousand rubles). For one-time procedures, it makes more sense to rent it.

- The likelihood of damage to the coating due to ignorance of the principles of equipment operation and lack of practical experience.

Considering the above, let us summarize: it is not recommended for beginners to undertake hot welding with their own hands, without the help of a specialist, even after watching training videos. After all, without the proper experience gained over the years, there is a risk of simply ruining the floor covering.

Useful tips

Hot welding is not recommended for use in apartments: you can burn through not only the thin top layer, but also the substrate. Cold is more practical. For dense polymer coatings, type C glue is used. In this case, do not use adhesive tape; the thick glue does not spread.

When choosing an adhesive, take into account the amount of PVC in the composition. Repairing old finishes requires a large percentage, while installing new ones requires a low percentage. Glue consumption depends on the thickness of the linoleum.

The glued coating is completely ready only after 1-2 hours; it is not recommended to walk on it before.

Why does sports linoleum need to be welded?

Fixing the joint sections of the material with glue and mastic, which is common in the usual practice of construction work, is not permissible when equipping sports halls. Even the reliable and considered durable cold welding method will not work.

For active activities, linoleum of heavy-duty and wear-resistant brands is used. But the above methods are intended for ordinary material, and they are not able to guarantee the integrity of the coating.

Only the technology of hot welding of linoleum will ensure reliable fixation of its individual parts relative to each other.

This method has the following advantages:

- The connection can withstand vertical loads. On the surface you can exercise with additional equipment: dumbbells, barbells, exercise machines;

- Reliability of horizontal tension. During training, the load vector may not be directed vertically, but at an angle or even horizontally. For example, when doing fitness and especially team sports, during sudden braking, falling, using special techniques;

- The seam is in a flat plane with the rest of the area. The special method of forming the connection leaves no gaps and does not form bumps;

- Great looks. A correctly selected color cord for welding linoleum and a professionally executed joint are almost invisible, which is important when marking the playground.

There is no better way to install this coating. Underestimating the importance of high-quality installation of linoleum can lead to rupture of the joint and, as a consequence, to injuries and damage to athletes during training.

Cord cutting technique

Removal of excess welded cord is carried out with a special sickle-shaped knife. It is advisable to do this procedure no later than 15 minutes after welding in a specific area. Otherwise, the seam will simply cool down and lose its pliability, thanks to which the cut can be made neatly and cleanly. The first cut is made so that there is approximately 1/32 inch of seam above the surface. The second approach is made at an angle - so that the cutting edge of the tool takes an inclined position along the entire cutting line. Laying linoleum this way with welding the seams will provide the effect of a concave gap. After completion of the procedure, polishing is performed with a special mastic for linoleum. It will reveal possible shortcomings of the seam, making its texture clearer.

Options for connecting linoleum to each other

Before soldering linoleum, you need to choose the appropriate type of welding in specific conditions. All types of joining modern linoleum can be divided into two main types:

- Thermal;

- Mechanical.

Mechanical methods include joint processing, which does not use chemicals or methods of hot melting of the coating. One such option is to install a metal threshold. A metal or plastic threshold is used in cases where it is necessary to seal linoleum seams in short areas and in places where linoleum transitions to another type of coating. It is certainly not suitable for joining long seams.

The second common option is double-sided tape for linoleum. However, this joining option is not durable and over time the adhesive tape loses its adhesive qualities, the seams begin to separate, and the edges of the coating begin to curl. Even if you make the joint very carefully, it will still be visible on the surface of the coating and dirt will gradually accumulate in it.

Thermal methods include the following:

- Cold welding, where the gluing process is carried out at the molecular level by chemically melting the edges of linoleum;

- Hot welding, in this case the gluing of linoleum is carried out by heating using low-melting components.

Important. To carry out hot welding, it is advisable to invite competent specialists who have experience and the appropriate tools. To carry out such work, a special hair dryer for linoleum is used, which you need to know how to use.

Types of linoleum glue by composition

Recipes vary, but acrylic or polyurethane are most often used as bases. From a structural and technical point of view, polyurethane is more advantageous, since its ability to adhesion allows you to lay and join linoleum on almost any surface. They also perform repair operations on synthetic floor coverings. As for acrylic compounds, they cannot boast of the same high adhesion ability, but they benefit from environmental friendliness.