Engraving has been around for many years, and to be more precise, even cave paintings and hieroglyphs of cavemen were essentially nothing more than engraving. It is believed that engraving as a craft evolved from jewelry. Many tools and techniques were learned from jewelers. Since ancient times, various inscriptions and drawings were applied to the armor and weapons of warriors. Many museums around the world exhibit antiquities found during excavations, decorated by skilled engravers. These include dishes, military weapons, and even books in settings made of precious metals.

Engraving is considered one of the most ancient methods of finishing materials. With the help of engraving, any item from an ordinary, ordinary one can become spectacular and original. Carvings are applied to gifts, souvenirs, awards, and jewelry. Engraving is possible on glass, leather, stone, metal, wood. Sometimes the most insignificant touch brought by a master to a model makes any product unique, original, inimitable - one that can be compared to a work of art. Laser engraving could well be a similar touch. Applying a drawing, pattern, inscription or even a small symbol can radically change the perception of an object.

What are the ways to engrave metal?

There are several types of metal engraving. Let's look at each of them.

Manual cutting

This method involves applying an image to the surface of an object using a steel cutting tool. This creates lines and indentation points on the material. In other words, hand cutting is called artistic engraving. This is a very long and labor-intensive process. But there are faster ways to engrave.

Sandblasting

Its essence lies in the fact that the surface of the material is damaged by sand or other powdery substance, which is sprayed with a strong air flow. When sand hits the surface of the metal, a matte is formed. The granularity of the sand allows you to create various effects and apply designs using a stencil. The advantages of sandblasting are versatility, high speed and smooth engraving edges.

Mechanical engraving

It is carried out with a sharpened milling cutter. There are two types of mechanical engraving equipment - pantograph and computerized. Jewelry and family decorations are engraved on the pantograph. Using a computerized method, you can engrave any metal product.

Mechanically, you can create three-dimensional images, but the disadvantage is low productivity.

Laser sublimation

This is the application of color images using a printer or sublimation cartridge. First you need to make a transfer - print an image that is placed on top of the product. And when exposed to high temperatures, the paint transfers to the material, leaving an image on it.

Laser sublimation is used to engrave many metal products - bracelets, pendants, watches and coasters.

Laser engraving

This is the most common method of engraving on metal. The design is applied to the product using a focused laser beam. Engraving occurs due to the evaporation of material particles.

Unlike other methods, laser engraving can be done on an industrial scale due to its high speed.

There are several types of laser engraving equipment, but we will talk about this later.

Links

- F. F. Petrushevsky, A. I. Somov.

Engraving // Encyclopedic Dictionary of Brockhaus and Efron: in 86 volumes (82 volumes and 4 additional). - St. Petersburg, 1890-1907. - [dumatao.ru Engraving]

- [eau-forte.blogspot.com/2009/10/blog-post_29.html Engraving]

| : Incorrect or missing image | To improve this article it is desirable:

|

Why is laser engraving better?

- High accuracy and detail of the image.

- Aesthetics of the drawing.

- Durability. Engraving made using other methods will wear off over time.

- No risk of item deformation.

- Possibility to fulfill mass orders thanks to production automation.

- Versatility, because laser can engrave not only metal.

How does raster engraving differ from contour engraving?

Contour engraving is suitable for applying printed text and numbers to products at high speed.

The speed of raster engraving is lower, but it gives a better quality drawing when applying images.

How to make color engraving?

Color engraving has a more complex technological process, and it is only possible on metals prone to oxidation, such as

- titanium,

- stainless steel,

- zirconium,

- aluminum,

- nickel,

- brass,

- silver.

The color appears as a result of tarnish, which occurs due to the interference of light in the oxide film. The hue and color saturation depend on several factors:

- duration of exposure to the laser beam,

- metal thickness,

- thermophysical parameters of the material,

- radiation power,

- thickness of the oxide film.

For example, on a titanium plate with a pulse duration of 80 nanoseconds, a beam speed of 24 mm/s, a pulse frequency of 95-100 kHz and a radiation power of 4.5 W, a purple engraving was obtained.

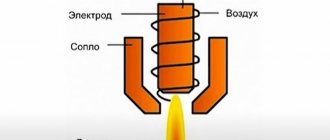

Review of equipment for laser engraving of metal

Laser engraving is possible either using a fiber optic marker or a CO2 engraver. Let's look at each of these methods.

Fiber optic marker

A laser marker is considered a universal equipment for engraving and marking metal.

It has several advantages over other methods:

- No consumables.

- High quality.

- Easy to operate.

- Low energy costs.

- High speed.

- No special knowledge required for setup.

- Contactless engraving on the product.

- Possibility of installing a rotating device.

- Small dimensions.

- Lack of heat treatment in the cutting area.

- Various materials can be engraved.

What products can be engraved?

A laser marker can be used to engrave both piece items and be used for mass production. Let's list the main ones:

- decorations,

- barcodes,

- application of logos,

- serial numbers,

- nameplates,

- branding of souvenir products,

- signs,

- business cards and more.

What industries are fiber markers used in?

- advertising,

- jewelry production,

- medicine,

- defense production,

- dentistry,

- trade,

- shipbuilding,

- Automotive industry,

- tool production,

- production of electrical equipment.

How to choose a laser marker?

In order to decide on the choice of a laser marker, you first need to consider its main technical characteristics.

Emitter power

The main thing is the emitter, because a laser beam appears in it. Lasercut offers three types of laser emitters - Raycus, Max Photonics, IPG.

Max Photonics is the most budget-friendly, but is only suitable for applying simple images.

In contrast, Raycus holds power better and provides uniform pouring. A marker with a Raycus emitter can be used to engrave complex and three-dimensional designs and geometric shapes. Some may require filling.

And the IPG emitter allows you to make color images on metals. In addition, it can perform tasks at high speeds and has built-in anti-reflection protection.

When choosing an emitter, you need to decide on the tasks.

For example, with Max Photonics it is much more difficult to obtain a black tint on stainless steel than with IPG. But it's possible.

Working field size

The size of the working field of laser markers on average ranges from 75/75 to 300/300 mm. Its choice depends on the size of the product being processed.

There are markers with a lifting table, for example, Wattsan FL LT, with a removable handle and focus stop, such as Wattsan FL HH, with a stationary table - Wattsan FL ST.

Each of them has its own functional features. For example, the FL TT marker is suitable for engraving large items.

Setup and maintenance

Before purchasing a machine, Lasercut can provide commissioning. It includes installation of equipment, configuration of the control system, testing of electronics and mechanics, connecting security systems and much more. Our qualified engineers can provide training to your staff.

In addition, service, diagnostics, adjustment, warranty, post-warranty service and repair are possible.

Price

As standard, fiber optic markers cost on average from 300 to 700 thousand rubles, depending on the emitter power and functionality. But it is also possible to modernize the machine, for example, increasing power or installing a rotary device.

LASER MARKER WATTSAN FL HH

Is the CO2 machine suitable for metal engraving?

CO2 laser machines are designed to engrave many materials other than metal.

It is very difficult to apply high-quality engraving on metal using an engraver, but it is only possible if it is coated with a special spray or paste KTP-8. And not every metal can be worked with on a CO2 machine, but only ferrous ones - steel and ferroalloys, stainless steel.

If you specialize in making metal products, then, of course, you need to focus on a fiber marker.

But if working with metals is not your main focus or you use the machine for amateur purposes, then it is possible to engrave on a CO2 machine.

WATTSAN 0503

Is it possible to do engraving at home?

If we are talking about mechanical or manual engraving, then, of course, yes. It is enough to purchase only cutters and a drill.

But if you are planning to engage in laser engraving, then it is worth considering that the equipment for it is much more expensive, so it will only pay off if the craft becomes your business. Of course, for mass production it is better to allocate a special room, at least for safety reasons. After all, to work on laser equipment you will need voltage stabilization and grounding.

But we have several clients who use fiber markers at home for small production. Desktop markers with small dimensions are suitable for this.

Guide to preparing files for laser engravers and cutters

There are particularly important rules that you must follow when it comes to laser engraving. A very popular aspect of laser engraving is text engraving. When text is sent to the controller, the machine automatically adds a border around the letters, so it's important to remember:

- Make sure letters are spacing correctly

- Minimum text size 2 mm

- Narrow fonts are preferred

Laser cutting programs

Engraving examples

Engraving on different objects has its own characteristics. Let's look at a few product examples.

Engraving on wedding rings

Usually they are engraved with words and inscriptions, but it is important that it is easy to read. But for this you need a suitable size of the product, because it will not be possible to apply such an inscription on a ring that is too narrow.

At the same time, engraving can be applied to any metal - gold, silver, platinum or titanium.

But we recommend using soft metal, as the letters will be easier to read on it.

Engraving can be applied to the front, inner side of the ring and its side edges.

Engraving in production

It is usually used in the manufacture of nameplates, plates, serial numbers, license plates and many other products.

Let's look at the example of nameplates and plates. For their production, as a rule, brass or aluminum is used. In the first case they have a golden tint, and in the second - silver. Both materials can be laser engraved.

But most importantly, do not forget that when producing industrial nameplates you must comply with the requirements established by law. Using markings, information about the product and manufacturer is applied to the nameplate. It includes technical characteristics of the device, manufacturer data, Rostest data, device serial number and a description of safety when working with the item.

The inscriptions are very thin and clear, so the nameplate itself is small. In addition, when applying inscriptions to a nameplate, their durability is important, so production uses exclusively laser marking methods. And thanks to the high speed of work, their production has no restrictions on circulation.

Engraving on a thermal mug

Metal thermal mugs are especially popular now. And they are used not only on hikes, but also, for example, in bars and restaurants. Engraving a thermal mug using a fiber optic marker is not at all difficult. One caveat - you will need a rotating device.

Separately, we should highlight the use of lasers in advertising.

The advertisement is engine of the trade. We often hear this expression, but let's figure out what exactly it means.

Let’s not go back to the times of mammoths and caves, when humanity fought for its place in the food chain, but consider the period of the dawn of science and culture, at a time when a person goes not to see a mammoth, but to a grocery store, lives not in a cave, but in a house , thinks not about how to survive, but how to live.

In the modern world, for a comfortable life you need only one thing - material well-being. If you have money, you have everything: food, housing, medicine, education, comfort and confidence in the future. And it turns out that a person only needs to hunt one animal for everything to be good, but this animal is cunning and dangerous, it cannot be killed, it must be tamed, only then will it become useful to you, and most importantly, faithful.

But what is all this philosophy for? And now we come to the most interesting part, how to catch this beast? There are many ways - talent, diligence, luck, intelligence or deception... An artist, musician, engineer, scientist - everyone follows their own path and each has their own methods. But everyone, without exception, needs bait, because without bait, tracking an animal is not easy, and perhaps even impossible. And this bait is nothing more than advertising. Advertising is needed to attract and lure, but then everything depends on the hunter and his skills.

Hundreds of firms and companies open every day, but just as many close every day. Business is cruel and merciless. Yes, sometimes, someone chooses the wrong time and the wrong place to provide their services, but often it’s not a matter of circumstances, but of skills. If in one place, at the same time, 2 companies with the same direction open, but a year later one is thinking about expanding, and the second is thinking about closing, then the time and place are right, but the problem is in the approach.

And competent advertising in our time is everything. Sometimes even the product itself can be outright hackwork, but the right presentation and motivation can displace a cheaper or higher quality product that does not have a good presentation.

Advertising surrounds us everywhere, absolutely everywhere! Radio, television, the Internet, newspapers, magazines, posters and signs, everyone around is trying to reach us and offer something. But in such an overabundance of advertising products, you begin to pay attention only to something unusual, non-standard, and everything else merges into a big bright spot.

Laser engraving, although no longer a new product or scientific breakthrough, can still be interesting for advertising in any field. The capabilities of laser equipment are enormous and make it possible to implement such original and large-scale projects that in the near future there is simply no one to displace them from the market. The laser cuts any materials, any thickness according to the most complex layouts with the highest accuracy and speed. Laser engraving is possible not only on the surface, but even inside, for example, three-dimensional models inside glass of the highest detail. And if you combine the capabilities of lasers with other technologies, for example, painting, UV printing or “direct” hands, you can create real masterpieces that will help you become the brightest and most memorable star in the advertising universe.