Our specialized service center provides maintenance and professional repair of electric generators (gasoline generators) and power plants of a large number src=»https://servys.ru/upload/medialibrary/banner_product/benzogeneratory.jpg» class=»aligncenter» width=»414″ height =»321″[/img] Power station (Electric generator or Gasoline generator or Diesel generator) is a device that provides and ensures autonomous power supply for a rural house, cottage, construction site, etc. This device is especially relevant if you have to spend quite a long time without a standard current source. Construction, various “field conditions”, emergency situations - in these and many other similar situations, a gas generator will be very useful, because otherwise there is simply no access to electricity in such places. They are gasoline, diesel, single-phase or three-phase, inverter and welding. The most popular are gasoline power plants, or, more simply, gasoline generators of various global and domestic brands. But any power plants, due to their long operation, require frequent maintenance, and repairs of power plants and electric generators (gasoline and diesel generators) are . You can do all this at our Servy service center in Moscow. We repair power plants, gas generators, diesel generators, power generators, welding generators, inverter generators, brands such as*:

Brands of electric generators (gasoline and diesel generators) and power plants accepted for repair

Briggs&Stratton Champion DPP DDE DENZEL Elitech ENDRESS EUROPOWER Fubag HERZ Honda Huter Hyundai Hyundai Kipor Patriot Robin-Subaru SDMO Vepr AL-KO Caiman Makita Ryobi Homelite Hammer Hitachi

All brands of electric generators (gasoline and diesel generators) and power plants

MasterYard RedVerg Snapper SunGarden

Our Servy service center repairs such gasoline, diesel, power, inverter, welding generators and power plants as: Aurora GARDENER, ALTECO, Aksa, AMG, Ayerbe, BauMaster, Best Weld, Big Master, BlueWeld, Bort, Brado, BRIMA, Carver, COLT, Chicago Pneumatic, CTG, CUMMINS, DeMARK, DENYO, DOMETIC, Edon, Eisemann, ELAND, Elemax, Eneral, EP Genset, Etaltech, Eurolux, FG Wilson, Firman, FIT, Fogo, FORWARD, FoxWeld, Geko, Generac, General Power, GenHolm, Genbox, GENMAC, GESAN, Gesht, Gigant, Grandvolt, Green Field, HILTT, inforec, KIRK, Kolner, Kubota, Kronwerk, Lega power, LIFAN, MASUTA, MAXCUT, Megavolt, Mikkeli, Mitsui Power, Moller, Mustang , MVAE, MOSA, Navigator, PIT, PIRAN, PowerLink, Pramac, RORAB, Profi, Redbo, RedVerg, RID, Rucelf, Russian Engineering Group, Simes Profi, SKAT, Skiper, Spec, Sturm!, Tsunami, Toyo, Unitedpower, Varteg , Wert, Wester, Workmaster, Yanmar, ZENIT, ZONGSHEN, Bison, Vepr, DIOLD, ZUBR, Interskol, Caliber, Kraton, Kuzmich, Lynx, Svarog, SOYUZ, TSS, Udarnik, Energo, Energomash, Energoprom

and others.

The gas generator works intermittently

A malfunction of the regulator is signaled by a situation when the revolutions of the gas generator fluctuate under load, and there are interruptions in starting a cold and hot engine. If measures are not taken, the situation will be aggravated by premature wear of internal components and failure of the device.

Adjusting the frequency of a gasoline generator can solve the problem, but it must be done correctly. The work will require a tester for measuring frequency and a long screwdriver with a Phillips head. Compliance with the given algorithm of actions will allow you to perform power plant maintenance quickly and safely:

- The first step is to disassemble the carburetor to gain access to the fuel jets. Then, using a compressor, carefully blow out the jets, channels and emulsion tube.

- The next task is to find the quantity screw and set the throttle valve so that the minimum gap value is 1.5 mm. Upon completion of the manipulation, the output parameters are checked. The value should not go beyond the range of 210-235 V. It is optimal to achieve a balance between the number of generated revolutions and voltage.

- Next, you need to work with the mixture quality screw to eliminate interruptions during idle. It is found in a special hole, screwed until it stops, and then loosened two or three turns. During the adjustment process, make sure that the device operates without problems during a cold engine start or at idle.

Violation of the given operating procedure will lead to a decrease in the effectiveness of the adjustment, and the master will not achieve his goal. If the algorithm is followed, there will be no further interruptions. A simple test will help ensure that the adjustment is correct. You need to put in a clean spark plug, turn on the gas generator for a couple of minutes and assess its condition. The presence of carbon deposits is a sign that adjustment needs to be continued by gradually loosening and tightening the bolts. If the spark plug is clean, the test is considered passed and the device is ready for further use.

Cost of repair of electric generators (gasoline and diesel generators) and power plants*

Service specialists can carry out inexpensive diagnostics of the device, and if irregularities in its operation are identified, they can carry out professional repairs of a gas generator or diesel generator or power plant, which will be performed at the highest level. Do not neglect preventive diagnostics and repair work. Do not forget that the correct and reliable operation of any tool is the key to your safety. The final cost (price) of the necessary repair of a gas generator or diesel generator or power plant largely depends on the manufacturer’s price list for spare parts and is agreed upon with the customer by telephone after a fault diagnosis has been carried out by a technician.

The cost of repairing electric generators (gasoline and diesel generators) and power plants starts from 500 rubles.

| Name of work on repair of electric generators (gasoline and diesel generators) and power plants | Cost of services, rub.* |

| Carburetor adjustment | 1900-2300 rub. |

| Starter replacement | 600 rub. |

| Starter repair | 900-1300 rub. |

| Rotor replacement | 1500 rub. |

| Stator replacement | 1300 rub. |

| Replacing the spark plug | 100 rub. |

| Replacing the carburetor | 900 rub. |

| Replacing the ignition coil | 500 rub. |

| Ignition adjustment | 1100 rub. |

| Replacing the throttle control cable | 1300 rub. |

| Replacing the air filter | 100 rub. |

| Comprehensive maintenance of electric generators (gasoline and diesel generators) and power plants (works) | from 1900 rub. (from model) |

Reasons for contacting the service center

If problems are noticed in the work, do not expect the situation to change. Consultation and diagnostics will allow you to do everything right. Contact us immediately if:

- the main performance indicators and any characteristics have been changed;

- increased vibrations;

- sound enhanced;

- the equipment overheats.

Repair from 60 minutes

Repair stages

- Call us or send a request

- Coordination of the date (urgent departure possible)

- Visit of a technician for repairs

Guarantee for repair of electric generators (gasoline and diesel generators) and power plants

Repair of generators and power plants in Moscow? No problem: contact “Servy”! Because gas generators and power plants work a lot and you need long-term, stable operation of the equipment after repair. Our service center Servy does its work efficiently and provides a guarantee on work performed for a period of 90 days . If your electric generator breaks down again, we will always fix the defects free of charge. All our craftsmen are constantly improving at special trainings conducted by leading companies producing electric and gas-powered tools, so each of the workers is familiar with the latest developments in the field of European technology standards. We closely monitor the level of qualifications of our employees, and annually improve them by sending them to special seminars from leading companies in the production of home and garden equipment. Many of them also undergo internships with well-known generator manufacturers in Europe - SDMO, Fubag, Endress, Honda and others.

Preventive measures

The device should be cleaned from time to time. We are talking about cleaning the fuel tank, as well as the elements of the cooling system from carbon deposits and dust. This will keep the device clean, and blockages will not cause it to overheat and subsequently fail.

In addition, it would not be superfluous to disassemble it from time to time and check the functionality of various mechanisms.

You will need to check the ATS and the functionality of the control unit especially carefully. If possible, it would be a good idea to also clean the internal elements from dirt and dust. Considering the design features of this device, there are no large-scale preventive measures for it.

To this you can also add monitoring the fuel and oil levels, checking the strength of fastening of various elements with bolts, as well as periodically cleaning the air filter from dirt and dust.

Types of electric generators (gasoline and diesel generators) and power plants accepted for repair

In our specialized service center in Moscow, you can repair any types of power plants, gas generators, diesel generators driven by an internal combustion engine, such as: gasoline - equipped with compact gasoline engines, diesel - powered by diesel fuel; portable and mobile; household, professional, welding; single-phase and three-phase; generators with transformer, rectifier and inverter models . Each of the listed types and types has its own advantages and disadvantages in operation and nuances in application. For example: gasoline generators are inexpensive, but have low power and are intended, as a rule, to operate under light loads (to illuminate a small country house); diesel generators - have increased power, productivity and endurance (suitable for work on construction sites), but at the same time have large overall dimensions and weight.

Gasoline Generator Diesel Generator Inverter Generator Welding Generator

But, unfortunately, both gasoline and diesel power plants can break down. Don’t be upset and run out to buy a new fancy model; we are ready to help you and repair any power station, gas generator or diesel generator in Moscow at a service center! We employ only professional engineers who will quickly identify and eliminate the malfunction of your equipment, in the shortest possible time, and for a reasonable fee, which will be several times less than the cost of a new unit. Of course, for long-term reliable operation, any power and construction equipment needs timely maintenance and repair, and generators are no exception.

How to start in winter?

Surely everyone will agree that it is very unpleasant to find yourself in a house without electricity in winter in cold weather. And if you have a properly connected gasoline generator, such problems do not arise. However, owners of such devices need to remember that there are several ways to start gasoline power plants in winter.

- Regardless of the method of connecting the device, you must treat the injectors with care. They should be held at a certain angle to prevent fuel fluid from getting onto the spark plugs.

- You can inject a special agent into the carburetor to quickly start a gasoline generator. You can purchase this substance at any electrical goods store.

- The easiest way to start a gasoline generator requires taking the device into a warm room, warming it up, and then returning it to its place. Most likely, the unit has been frozen and, like a car battery, requires heating the electrolyte. This method cannot be called fast, but it is “miraculous.”

To protect the generator system from various damages during cold weather, the owner must drain the fuel liquid from the tank and lubricate the movable components of the system, especially when the next start will be made after a long time. But the most important thing is that a poorly functioning generator must be kept in rooms where the air temperature does not fall below 0 degrees.

Typical breakdowns of electric generators (gasoline and diesel generators) and power plants

Why would an electric generator break down? But they, like many other equipment, have many causes of breakdowns, and most often this happens for the following reasons *

:

- A gasoline or diesel generator does not start, there is no spark formation reasons: faulty spark plug, faulty ignition coil (magneto), damage to parts of the manual starter, clogged fuel system, wear of the cylinder-piston group;

- A gasoline or diesel generator stalls, possible reasons: clogged fuel system (no fuel supply), wear of the cylinder-piston group, carburetor out of adjustment, clogged air filter;

- The gas generator does not produce the required voltage, the generator is not operating stable, the main reasons: the engine does not develop power, problems with the electronic boards.

The Servy service center has been repairing electric generators for several years, and therefore we can identify the main causes of the above breakdowns. Among them: improper operation (no maintenance), use of low-quality or not recommended fuels, untimely change of oil in the generator engine, many hours of uninterrupted operation of the generator, mechanical damage to the device units.

Emergency generator start

Sometimes it happens that the generator urgently needs to be started, but the manual starter fails at that very moment. If necessary, there are several methods for emergency starting.

The methods listed below

are not safe !

Remove the starter housing. Below it is a flywheel with a cooling impeller, pulled to the crankshaft by a nut. To set it in rotation, you can:

- Wrap a rope around the flywheel and use it in the same way as a recoil starter cable. Please note that if it gets caught on the fan blades, when the engine starts, this rope will turn into a whip whipping in all directions, so be careful. Stand so that the rope cannot hit your hands or head.

- Low-power engines can also be started manually: with the ignition off, turn the crankshaft several times, rotating the pulley by hand in the desired direction. In this case, the gas tap must be open and the starter flap must be closed. After this, turning on the ignition, bring the crankshaft to compression TDC (you will feel an increase in force on the flywheel), and then turn the pulley with a sharp jerk so that the spark energy is enough to ignite the mixture.

- A powerful cordless drill and a head with an extension from the tool kit are a good quick replacement for an electric starter. Clamp the extension in the chuck, put a socket of a suitable size on it and unscrew the crankshaft by the flywheel mounting nut. True, in this way it will only be possible to start a low-power generator - for a large-volume engine, the torque of the drill is not enough to turn it on the compression stroke.

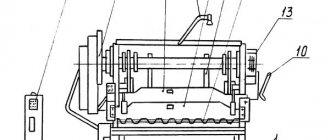

Welding unit design

The key components of a welding electric generator are a stator with magnetic poles placed on it, as well as an armature. This armature contains the turns of the transformer winding containing an electromotive force of alternating direction.

Any electric generator includes a magnetizing excitation winding. Its power comes from two sources:

- Independent.

In this case, the generator is called a unit with independent excitation. The demagnetizing winding is connected in series. The current strength is regulated by a rheostat. As the current in the welding network increases, the magnetic flux generated by the demagnetization winding increases. In this case, the magnetic flux, which is generated by the independent excitation winding, remains unchanged. As a result, the voltage at the generator terminals decreases and a falling external characteristic appears.

- From the generator.

Thus, we get a self-excited unit. The armature winding of the electric generator transmits direct current to the magnetizing winding. All generators can operate in both modes. To change the operating mode of the electric unit, it is enough to smoothly change the magnetizing current.

Circuit diagram of a welding generator with independent excitation and demagnetizing winding

Welding generators differ from each other and in their external characteristics:

- Generators with a falling external characteristic.

- Generators with a rigid external characteristic or a flat-sloping one.

- Universal generators.