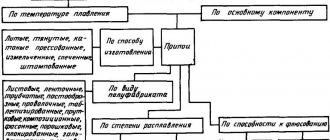

1.BRANDS

1.1 Depending on the chemical composition, tin-lead solders are manufactured in the following grades:

antimony-free – POS 90, POS 63, POS 61, POS 40, POS 30, POS 10, POS 61M, POSK 50-18, POSK 2-18;

low antimony - POSSU 61-0.5, POSSU 50-0.5, POSSU 40-0.5, POSSU 30-2, POSSU 25-2, POSSU 18-2, POSSU 15-2, POSSU 10-2, POSSU 8 -3, POSSU 5-1, POSSU 4-6, POSSU 4-4.

Examples of symbols:

Solder in ingots brand POS 40:

Solder Ch POS 40 GOST 21930-76

The same, brand POSSu 18-0.5:

Solder Ch POSSu 18-0.5 GOST 21930-76

| Mass fraction, % | ||||||

| Solder grade | OKP code | Main components | ||||

| Tin | Antimony | Cadmium | Copper | Lead | ||

| Antimony-free | ||||||

| POS 90 | 17 2311 1100 04 | 89-91 | — | — | — | Rest |

| POS 63 | 17 2312 0100 | 62,5-63,5 | — | — | — | |

| POS 61 | 17 2312 1100 10 | 59-61 | — | — | — | Same |

| POS 40 | 17 2314 1100 00 | 39-41 | — | — | — | “ |

| POS 30 | 17 2321 1100 09 | 29-31 | — | — | — | “ |

| POS 10 | 17 2326 1100 06 | 9-10 | — | — | — | “ |

| POS 61M | 17 2312 1200 07 | 59-61 | — | — | 1,2-2,0 | “ |

| POSK 50-18 | 17 2313 1200 02 | 49-51 | — | 17-19 | — | “ |

| POSK 2-18 | 17 2343 1100 09 | 1,8-2,3 | — | 17,5-18,5 | — | “ |

| Low antimony | ||||||

| POSSu 61-0.5 | 17 2312 1400 01 | 59-61 | 0,05-0,5 | — | — | Rest |

| POSSu 50-0.5 | 17 2313 1100 05 | 49-51 | — | — | Same | |

| POSSu 40-0.5 | 17 2314 1200 08 | 39-41 | — | — | “ | |

| POSSu 35-0.5 | 17 2315 1200 03 | 34-36 | — | — | “ | |

| POSSU 30-0.5 | 17 2321 1200 06 | 29-31 | — | — | “ | |

| POSSu 25-0.5 | 17 2322 1200 01 | 24-26 | — | — | “ | |

| POSSu 18-0.5 | 17 2323 1100 10 | 17-18 | — | — | “ | |

| Antimony | ||||||

| POS 95-5 | 17 2311 1200 01 | Rest | 4,0-5,0 | — | — | — |

| POSSu 40-2 | 17 2314 1300 05 | 39-41 | 1,5-2,0 | — | — | Rest |

| POSSu 35-2 | 17 2315 1300 00 | 34-36 | 1,5-2,0 | — | — | Same |

| POSSu 30-2 | 17 2321 1300 03 | 29-31 | 1,5-2,0 | — | — | “ |

| POSSu 25-2 | 17 2322 1300 09 | 24-26 | 1,5-2,0 | — | — | “ |

| POSSu 18-2 | 17 2323 1200 07 | 17-18 | 1,5-2,0 | — | — | “ |

| POSSu 15-2 | 17 2324 1100 05 | 14-15 | 1,5-2,0 | — | — | “ |

| POSSu 10-2 | 17 2326 1200 03 | 9-10 | 1,5-2,0 | — | — | “ |

| POSSu 8-3 | 17 2326 1300 00 | 7-8 | 2,0-3,0 | — | — | “ |

| POSSu 5-1 | 17 2327 1100 0 | 4-5 | 0,5-1,0 | — | — | “ |

| POSSU 4-6 | 17 2327 1200 09 | 3-4 | 5,0-6,0 | — | — | “ |

| POSSU 4-4 | 17 2327 1300 06 | 3-4 | 3,0-4,0 | — | — | “ |

| Impurities, nothing more. % | |||||||||||||||

| Solder grade | |||||||||||||||

| Antimony | Copper | Bismuth | Arsenic | Iron | Nickel | Sulfur | Zinc | Aluminum | Lead | ||||||

| Antimony-free | |||||||||||||||

| POS 90 | 0,10 | 0,05 | 0,1 | 0,01 | 0,02 | 0,02 | 0,02 | 0,002 | 0,002 | — | |||||

| POS 63 | 0,05 | 0,05 | 0,02 | ||||||||||||

| POS 61 | 0,10 | 0,05 | 0,20 | 0,02 | |||||||||||

| POS 40 | 0,10 | 0,05 | 0,02 | ||||||||||||

| POS 30 | 0,10 | 0,05 | 0,02 | ||||||||||||

| POS 10 | 0,10 | 0,05 | 0,02 | ||||||||||||

| POS 61M | 0,20 | — | 0,01 | ||||||||||||

| POSK 50-18 | 0,20 | 0,08 | 0,03 | ||||||||||||

| POSK 2-18 | 0,05 | 0,05 | 0,01 | ||||||||||||

| Low antimony | |||||||||||||||

| POSSu 61-0.5 | — | 0,05 | 0,20 | 0,02 | 0,02 | 0,02 | 0,02 | 0,02 | 0,02 | — | |||||

| POSSu 50-0.5 | 0,05 | 0,10 | 0,02 | ||||||||||||

| POSSu 40-0.5 | 0,05 | 0,20 | 0,02 | ||||||||||||

| POSSu 35-0.5 | 0,05 | 0,02 | |||||||||||||

| POSSU 30-0.5 | 0,05 | 0,02 | |||||||||||||

| POSSu 25-0.5 | 0,05 | 0,02 | |||||||||||||

| POSSu 18-0.5 | 0,05 | 0,02 | |||||||||||||

| Antimony | |||||||||||||||

| POS 95-5 | — | 0,05 | 0,1 | 0,04 | 0,02 | 0,02 | 0,02 | 0,002 | 0,002 | 0,07 | |||||

| POSSu 40-2 | 0,08 | 0,2 | 0,02 | 0,08 | — | ||||||||||

| POSSu 35-2 | 0,08 | 0,02 | |||||||||||||

| POSSu 30-2 | 0,08 | 0,02 | |||||||||||||

| POSSu 25-2 | 0,08 | 0,02 | |||||||||||||

| POSSu 18-2 | 0,08 | 0,02 | |||||||||||||

| POSSu 15-2 | 0,08 | 0,02 | |||||||||||||

| POSSu 10-2 | 0,08 | 0,02 | |||||||||||||

| POSSu 8-3 | 0,1 | 0,05 | |||||||||||||

| POSSu 5-1 | 0,08 | 0,02 | |||||||||||||

| POSSU 4-6 | 0,1 | 0,05 | |||||||||||||

| POSSU 4-4 | 0,1 | 0,05 | |||||||||||||

Marking POSK

Greater weld strength at a low melting point (145°C) can be provided by solders marked POSC.

This alloy contains cadmium. Typically, POSK is used when working with metallized and ceramic products.

Personalized solders

Among the tin-lead solders you can find compositions named after the scientists who developed them. Thus, Rose's eutectic alloy consists of 50% bismuth and equal parts of tin and lead and melts at 94°C. This solder is used for soldering copper parts and in the manufacture of products with a constant operating temperature.

Wood's solder has a melting point of 68.5 degrees Celsius. Half of its composition is bismuth, a quarter is lead, the rest is equal parts tin and cadmium. Wood's solder is used in the manufacture of precision (high-precision) instruments and sensitive sensors.

For soldering low-melting metals, the D'Arce alloy is used, which melts at 79 degrees and contains only 1 part of tin, the remaining 9 consist of equal amounts of lead and bismuth.

TECHNICAL REQUIREMENTS

2.1 Tin-lead solders in ingots are manufactured in accordance with the requirements of this standard according to technological instructions approved in the prescribed manner.

The chemical composition of solders must comply with the requirements of the table.

2.2 The shape of solder ingots of all grades is given in Appendix 3. The dimensions of the ingots specified in Appendix 3 are given for the design and manufacture of molds.

Permissible deviations in mold dimensions must correspond to accuracy class 13 according to GOST 26645-85.

2.3 The surface of the pigs should be free of slag and other foreign inclusions. The presence of shells and cracks is allowed.

2.4 The physical and mechanical properties of solders are given in reference Appendix 1.

2.5. Areas of primary use of solders are given in the recommended appendix

Tin-lead solders POS

Tin-lead solders in products, GOST 21931-76

Solders are filler metals (alloys) that, in the molten state, are capable of filling the gap between the products being soldered and, as a result of solidification, forming a permanent, strong connection.

Available in round wire, strip, triangular, round rods, flux-filled round tubes and powder

Some types of solders:

- POS - 90 - for tinning and soldering internal seams of food utensils and medical equipment;

- POSSU 4-4 - for tinning and soldering in the automotive industry.

Tin-lead solders in ingots, GOST 21930-79

This standard applies to tin-lead solders (PLS) in ingots and in products used mainly for tinning and soldering parts. The indicators of this standard correspond to the highest quality category.

| Brand | Content, % | Application area | ||

| Sn | Pb | Other Main Components | ||

| POS 90 | 89-91 | Rest | — | Food utensils, medical equipment |

| POS 61 | 59-61 | Rest | — | Electronic equipment, printed circuit boards, precision instruments |

| POS 40 | 39-41 | Rest | — | Electrical equipment, galvanized iron parts |

| POS 30 | 29-31 | Rest | — | Mechanical engineering products |

| POS 10 | 9-10 | Rest | — | Contact surfaces of electrical devices, instruments, relays |

Low antimony

| Brand | Content, % | Application area | ||

| Sn | Sb | Pb | ||

| POSSu 61-0.5 | 59-61 | 0,05-0,5 | Rest | Soldering parts sensitive to overheating |

| POSSu 50-0.5 | 49-51 | 0,05-0,5 | Rest | Aviation radiators |

| POSSu 40-0.5 | 39-41 | 0,05-0,5 | Rest | Galvanized parts of refrigerators, radiator tubes, windings of electrical machines |

| POSSu 35-0.5 | 34-36 | 0,05-0,5 | Rest | Cable sheaths for electrical products, thin-sheet packaging |

| POSSU 30-0.5 | 29-31 | 0,05-0,5 | Rest | Radiators |

| POSSu 25-0.5 | 24-26 | 0,05-0,5 | Rest | Radiators |

| POSSu 18-0.5 | 17-18 | 0,05-0,5 | Rest | Heat exchanger tubes, electric lamps |

Antimony

| Brand | Content, % | Application area | ||

| Sn | Sb | Pb | ||

| POSSu 95-5 | Rest | 4.0-5.0 | No more | Pipelines operating at elevated temperatures, electrical products |

| POSSu 40-2 | 39-41 | 1.5-2.0 | Rest | Refrigeration devices, thin sheet packaging |

| POSSu 30-2 | 29-31 | 1.5-2.0 | Rest | Refrigerators, light bulb production, abrasive packaging |

| POSSu 25-2 | 24-26 | 1.5-2.0 | Rest | Automotive products |

| POSSu 18-2 | 17-18 | 1.5-2.0 | Rest | |

| POSSu 15-2 | 14-15 | 1.5-2.0 | Rest | |

| POSSu 10-2 | 9-10 | 1.5-2.0 | Rest | |

| POSSu 8-3 | 7-8 | 2-3 | Rest | Electric lamp production |

| POSSu 5-1 | 4-5 | 0.5-1.0 | Rest | Tubular radiators, parts operating at elevated temperatures |

| POSSU 4-6 | 3-4 | 5-6 | Rest | Car body putty, tinplate soldering |

| POSSU 4-4 | 3-4 | 3-4 | Rest | Automotive products |

One of the main elements of electrical and radio installation work is soldering. The quality of installation is largely determined by the correct choice of the necessary solders and fluxes used when soldering wires, resistances, capacitors, etc.

To facilitate this choice, below is brief information about hard and light solders and fluxes, their use and their manufacture.

Soldering is the joining of hard metals using molten solder, which has a melting point lower than the melting point of the base metal.

The solder should dissolve the base metal well, spread easily over its surface, and well wet the entire soldering surface, which is ensured only if the wetted surface of the base metal is completely clean.

To remove oxides and contaminants from the surface of the metal being soldered, to protect it from oxidation and to provide better wetting with solder, chemicals called fluxes are used.

The melting point of fluxes is lower than the melting point of solder. There are two groups of fluxes: 1) chemically active, dissolving oxide films, and often the metal itself (hydrochloric acid, borax, ammonium chloride, zinc chloride) and 2) chemically passive, protecting only the surfaces to be soldered from oxidation (rosin, wax, stearin and etc.). .

Depending on the chemical composition and melting temperature of the solders, soldering is distinguished between hard and soft solders. Hard solders include solders with a melting point above 400°C, while light solders include solders with a melting point up to 400°C.

Basic materials used for soldering.

Tin is a soft, malleable metal with a silvery-white color. Specific gravity at a temperature of 20°C - 7.31. Melting point 231.9°C. It dissolves well in concentrated hydrochloric or sulfuric acid. Hydrogen sulfide has almost no effect on it. A valuable property of tin is its stability in many organic acids. At room temperature it is difficult to oxidize, but when exposed to temperatures below 18°C it can transform into a gray modification (“tin plague”). In places where gray tin particles appear, the metal is destroyed. The transition of white tin to gray accelerates sharply when the temperature drops to -50°C. For soldering it can be used both in pure form and in the form of alloys with other metals.

Lead is a bluish-gray metal, soft, easy to process, and can be cut with a knife. Specific gravity at a temperature of 20°C is 11.34. Melting point 327qC. In air it oxidizes only from the surface. It dissolves easily in alkalis, as well as in nitric and organic acids. Resistant to the effects of sulfuric acid and sulfuric acid compounds. Used for the manufacture of solders.

Cadmium is a silver-white metal, soft, ductile, and mechanically fragile. Specific gravity 8.6. Melting point 321°C. It is used both for anti-corrosion coatings and in alloys with lead, tin, bismuth for low-melting solders.

Antimony is a brittle, silvery-white metal. Specific gravity 6.68. Melting point 630.5°C. Does not oxidize in air. It is used in alloys with lead, tin, bismuth, cadmium for low-melting solders.

Bismuth is a brittle silver-gray metal. Specific gravity 9.82. Melting point 271°C. Dissolves in nitric and hot sulfuric acids. It is used in alloys with tin, lead, and cadmium to produce low-melting solders.

Zinc is a bluish-gray metal. When cold it is fragile. Specific gravity 7.1. Melting point 419°C. In dry air it oxidizes, in humid air it becomes covered with a film of oxide, which protects it from destruction. When combined with copper, it produces a number of durable alloys. Easily dissolves in weak acids. Used for the manufacture of hard solders and acid fluxes.

Copper is a reddish metal, malleable and soft. Specific gravity 8.6 - 8.9. Melting point 1083 C. Dissolves in sulfuric and nitric acids and ammonia. In dry air it is almost impossible to oxidize; in damp air it becomes covered with green oxide. Used for the manufacture of refractory solders and alloys.

Rosin is a product of processing the resin of coniferous trees. Lighter varieties of rosin (more thoroughly purified) are considered the best. The softening temperature of rosin is from 55 to 83°C. Used as a flux for soft soldering.

Tin-lead solder in products and ingots GOST 21930-76, this standard applies to tin-lead solders used for tinning and soldering parts. Depending on the chemical composition, tin-lead solders are manufactured in the following grades:

Antimony-free - POS-90, POS-63, POS-61, POS-50, POS-40, POS-30, POS-10;

Low antimony - POSSU 61-05, POSSU 50-05, POSSU 40-05, POSSU 35-05, POSSU 30-05, POSSU 25-05, POSSU 18-05;

Antimony - POSSu 40-2, POSSu 30-2, POSSu 25-2, POSSu 18-2.

Tin-lead solders are manufactured in accordance with the requirements of this standard according to technological instructions approved in the prescribed manner. The chemical composition of solders must comply with the requirements of Table 1, the mass fraction of impurities is indicated in Table 2.

Chemical composition of tin-lead solders GOST 21931-76

Table 1

| chemical composition, % | application area | |||||

| solder brand | main components | |||||

| tin | antimony | cadmium | copper | lead | ||

| antimony-free | ||||||

| POS-90 | 89-91 | — | — | — | rest | food utensils, medical equipment |

| POS-63 | 62.5-63.5 | — | — | — | rest | electronic equipment, printed circuit boards, precision instruments |

| POS-61 | 59-61 | — | — | — | rest | |

| POS-50 | 49-51 | — | — | — | rest | |

| POS-40 | 39-41 | — | — | — | rest | electrical equipment, galvanized iron parts |

| POS-30 | 29-31 | — | — | — | rest | mechanical engineering products |

| POS-10 | 9-10 | — | — | — | rest | contact surfaces of electrical devices, instruments, relays |

| low antimony | ||||||

| POSSu 61-05 | 0.05-0.5 | — | — | — | rest | soldering of parts sensitive to overheating |

| POSSu 50-05 | 0.05-0.5 | — | — | — | rest | aviation radiators |

| POSSu 40-05 | 0.05-0.5 | — | — | — | rest | galvanized parts of refrigerators, radiator tubes, windings of electrical machines |

| POSSu 35-05 | 0.05-0.5 | — | — | — | rest | cable sheaths for electrical products, thin-sheet packaging |

| POSSu 30-05 | 0.05-0.5 | — | — | — | rest | radiators |

| POSSu 25-05 | 0.05-0.5 | — | — | — | rest | |

| POSSu 18-05 | 0.05-0.5 | — | — | — | rest | heat exchanger tubes, electric lamps |

| antimony | ||||||

| POSSu 40-2 | 1.5-2.0 | — | — | — | rest | refrigeration devices, thin sheet packaging |

| POSSu 30-2 | 1.5-2.0 | — | — | — | rest | refrigerators, light bulb production, abrasive packaging |

| POSSu 25-2 | 1.5-2.0 | — | — | — | rest | automotive products |

| POSSu 18-2 | 1.5-2.0 | — | — | — | rest | |

Impurity composition of tin-lead solders GOST 21931-76

table 2

| mass fraction, % | ||||||||||

| solder brand | impurities, no more | |||||||||

| antimony | copper | bismuth | arsenic | iron | nickel | sulfur | zinc | aluminum | lead | |

| antimony-free | ||||||||||

| POS-90 | 0.10 | 0.05 | 0.1 | 0.01 | 0.02 | 0.02 | 0.02 | 0.002 | 0.002 | rest |

| POS-63 | 0.05 | 0.05 | 0.1 | 0.02 | 0.02 | 0.02 | 0.02 | 0.002 | 0.002 | rest |

| POS-61 | 0.10 | 0.05 | 0.2 | 0.02 | 0.02 | 0.02 | 0.02 | 0.002 | 0.002 | rest |

| POS-40 | 0.10 | 0.05 | 0.2 | 0.02 | 0.02 | 0.02 | 0.02 | 0.002 | 0.002 | rest |

| POS-30 | 0.10 | 0.05 | 0.2 | 0.02 | 0.02 | 0.02 | 0.02 | 0.002 | 0.002 | rest |

| POS-10 | 0.10 | 0.05 | 0.2 | 0.02 | 0.02 | 0.02 | 0.02 | 0.002 | 0.002 | rest |

| low antimony | ||||||||||

| POSSu 61-05 | — | 0.05 | 0.2 | 0.02 | 0.02 | 0.02 | 0.02 | 0.002 | 0.002 | rest |

| POSSu 50-05 | — | 0.05 | 0.1 | 0.02 | 0.02 | 0.02 | 0.02 | 0.002 | 0.002 | rest |

| POSSu 40-05 | — | 0.05 | 0.2 | 0.02 | 0.02 | 0.02 | 0.02 | 0.002 | 0.002 | rest |

| POSSu 35-05 | — | 0.05 | 0.2 | 0.02 | 0.02 | 0.02 | 0.02 | 0.002 | 0.002 | rest |

| POSSu 30-05 | — | 0.05 | 0.2 | 0.02 | 0.02 | 0.02 | 0.02 | 0.002 | 0.002 | rest |

| POSSu 25-05 | — | 0.05 | 0.2 | 0.02 | 0.02 | 0.02 | 0.02 | 0.002 | 0.002 | rest |

| POSSu 18-05 | — | 0.05 | 0.2 | 0.02 | 0.02 | 0.02 | 0.02 | 0.002 | 0.002 | rest |

| antimony | ||||||||||

| POSSu 40-2 | — | 0.08 | 0.2 | 0.02 | 0.02 | 0.08 | 0.08 | 0.002 | 0.002 | rest |

| POSSu 30-2 | — | 0.08 | 0.2 | 0.02 | 0.02 | 0.08 | 0.08 | 0.002 | 0.002 | rest |

| POSSu 25-2 | — | 0.08 | 0.2 | 0.02 | 0.02 | 0.08 | 0.08 | 0.002 | 0.002 | rest |

| POSSu 18-2 | — | 0.08 | 0.2 | 0.02 | 0.02 | 0.08 | 0.08 | 0.002 | 0.002 | rest |

Soft solders.

Soldering with soft solders has become widespread, especially during installation work. The most commonly used soft solders contain significant amounts of tin. In table Table 1 shows the compositions of some lead-tin solders.

Table 1

| Brand | Chemical composition in% | Temperature oC | ||||||

| tin | lead | antimony | no more impurities | |||||

| copper | bismuth | arsenic | Start | end | ||||

| POS-90 | 90 | 9,62 | 0,15 | 0,08 | 0.1 | 0,05 | 183 | 222 |

| POS-40 | 40 | 57,75 | 2,0 | 0,1 | 0,1 | 0,05 | 183 | 230 |

| POS-30 | 30 | 67,7 | 2,0 | 0,15 | 0,1 | 0,05 | 183 | 250 |

| POS-18 | 18 | 79,2 | 2,5 | 0,15 | 0,1 | 0,05 | 183 | 270 |

When choosing the type of solder, it is necessary to take into account its characteristics and use it depending on the purpose of the parts being soldered. When soldering parts that do not allow overheating, solders with a low melting point are used.

The most commonly used solder is POS-40 grade solder. It is used for soldering connecting wires, resistances, and capacitors. POS-30 solder is used for soldering shielding coatings, brass plates and other parts. Along with the use of standard grades, POS-60 solder (60% tin and 40% lead) is also used.

Soft solders are manufactured in the form of rods, ingots, wire (up to 3 mm in diameter) and tubes filled with flux. The technology of these solders without special impurities is simple and quite feasible in a workshop: lead is melted in a graphite or metal crucible and tin is added in small parts, the content of which is determined depending on the brand of solder. The liquid alloy is mixed, carbon deposits are removed from the surface and the molten solder is poured into wooden or steel molds. The addition of bismuth, cadmium and other additives is not necessary.

For soldering various parts that do not allow significant overheating, especially low-melting solders are used, which are obtained by adding bismuth and cadmium or one of these metals to lead-tin solders. In table Table 2 shows the compositions of some low-melting solders.

table 2

| Chemical composition in% | Melting point in °C | |||

| tin | lead | bismuth | cadmium | |

| 45 | 45 | 10 | _ | 1fi0 |

| 43 | 43 | 14 | __ | 155 |

| 40 | 40 | 21) | __ | 145 |

| 33 | 33 | 34 | __ | 124 |

| 15 | 32 | 53 | __ | 96 |

| 13 | 27 | 50 | 10 | 70 |

| 12,5 | 25 | 50 | 12,5 | 66 |

When using bismuth and cadmium solders, it should be taken into account that they are very brittle and create a less strong junction than lead-tin solders.

Hard solders.

Hard solders create high weld strength. In electrical and radio installation work they are used much less frequently than soft solders. In table Table 3 shows the compositions of some copper-zinc solders.

Table 3

| Brand | Chemical composition in% | Melting point in °C | |||||

| copper | zinc | no more impurities | |||||

| antimony | lead | tin | iron | ||||

| PMC-42 | 40-45 | rest | 0,1 | 0,5 | 1,6 | 0,5 | 830 |

| G1MTs-47 | 45-49 | 0,1 | 0,5 | 1,5 | 0,5 | 850 | |

| PMC-53 | 49-53 | 0,1 | 0,5 | 1,5 | 0,5 | 870 | |

The color of the solder changes depending on the zinc content. These solders are used for soldering bronze, brass, steel and other metals with a high melting point. PMC-42 solder is used when soldering brass containing 60-68% copper. PMC-52 solder is used for soldering copper and bronze. Copper-zinc solders are made by alloying copper and zinc in electric furnaces in a graphite crucible. As the copper melts, zinc is added to the crucible; after the zinc has melted, about 0.05% phosphorus copper is added. Molten solder is poured into molds. The melting temperature of the solder must be less than the melting temperature of the metal being soldered. In addition to the above-mentioned copper-zinc solders, silver solders are also used. The compositions of the latter are given in table. 4.

Table 4

| Brand | Chemical composition in% | Melting point in °C | ||||

| silver | copper | zinc | impurities no more | |||

| lead | Total | |||||

| PSR-10 | 9,7-10,3 | 52-54 | REST | 0,5 | 1,0 | 830 |

| PSR-12 | 11,7-12,3 | 35-37 | 0,5 | 1,0 | 785 | |

| PSR-25 | 24,7-25,3 | 39-41 | 0,5 | 1,0 | 765 | |

| PSR-45 | 44,5-45,5 | 20,5 —30,5 | 0,3 | 0,5 | 720 | |

| PSR-65 | 64,5-65,5 | 19,5 —20,5 | 0,3 | 0,5 | 740 | |

| PSR-70 | 69,5-70,5 | 25,5- 26,5 | 0,3 | 0,5 | 780 | |

Silver solders have great strength; the seams soldered by them bend well and are easy to process. PSR-10 and PSR-12 solders are used for soldering brass containing at least 58% copper, PSR-25 and PSR-45 solders are used for soldering copper, bronze and brass, PSR-70 solder with the highest silver content is for soldering waveguides , volumetric contours, etc.

In addition to standard silver solders, others are used, the compositions of which are given in table. 5.

Table 5

| Chemical composition in% | Temperature melting in oC | ||||

| silver | copper | zinc | cadmium | phosphorus | |

| 20 | 45 | 30 | 5 | 780 | |

| 72 | 18 | __ | __ | __ | 780 |

| 15 | 80 | __ | __ | 5 | 640 |

| 50 | 15,5 | 16,5 | 18 | — | 630 |

The first of them is used for soldering copper, steel, nickel, the second, which has high conductivity, is used for soldering wires; the third can be used for soldering copper, but is not suitable for ferrous metals; The fourth solder has a special fusibility and is universal for soldering copper, its alloys, nickel, and steel.

In some cases, commercially pure copper with a melting point of 1083°C is used as solder.

Solders for soldering aluminum.

Soldering aluminum is very difficult due to its ability to easily oxidize in air. Recently, aluminum soldering using ultrasonic soldering irons has found application. In table Table 6 shows the compositions of some solders for soldering aluminum.

Table 6

| Chemical composition in% | Note | |||||

| tin | zinc | cadmium | aluminum | silicon | copper | |

| 55 | 25 | 20 | — | — | — | Soft solders |

| 40 | 25 | 20 | 15 | — | — | |

| 63 | 36 | — | 1 | — | — | |

| 45 | 50 | — | 5 | — | — | |

| 78-69 | 20-25 | 2-6 | — | — | ||

| 69,8-64,5 | 5,2-6,5 | 25-29 | Brazing alloys with a melting point of 525°C | |||

When soldering aluminum, organic substances are used as fluxes: rosin, stearin, etc.

The last solder (hard) is used with a complex flux, which includes: lithium chloride (25-30%), potassium fluoride (8-12%), zinc chloride (8-15%), potassium chloride (59-43%) . The melting point of the flux is about 450°C.

Fluxes.

Good wetting of solder joints and the formation of strong seams largely depends on the quality of the flux. At the soldering temperature, the flux should melt and spread in an even layer, and at the moment of soldering it should float to the outer surface of the solder. The melting point of the flux should be somewhat lower than the melting temperature of the solder used.

Chemically active fluxes (acid) are fluxes that in most cases contain free hydrochloric acid. A significant disadvantage of acid fluxes is the intense formation of corrosion of solder seams.

Chemically active fluxes primarily include hydrochloric acid, which is used for soldering steel parts with soft solders. The acid remaining on the surface of the metal after soldering dissolves it and causes corrosion. After soldering, the products must be rinsed with hot running water. The use of hydrochloric acid when soldering radio equipment is prohibited, since during operation it is possible to break the electrical contacts at the soldering points. Please note that hydrochloric acid causes burns if it comes into contact with the body.

Zinc chloride (etching acid), depending on the soldering conditions, is used in the form of a powder or solution. Used for soldering brass, copper and steel. To prepare the flux, it is necessary to dissolve one part by weight of zinc in five parts by weight of 50% hydrochloric acid in a lead or glass container. A sign of the formation of zinc chloride is the cessation of the release of hydrogen bubbles. Due to the fact that there is always a small amount of free acid in the solution, corrosion occurs at the soldering joints, so after soldering the joint must be thoroughly washed in running hot water. Soldering with zinc chloride should not be carried out in the room where the radio equipment is located. It is also prohibited to use zinc chloride for soldering electrical and radio equipment. Zinc chloride should be stored in a glass container with a tightly closed glass stopper.

Borax (aqueous sodium salt of pyroboric acid) is used as a flux when soldering with brass and silver solders. Easily dissolves in water. When heated, it turns into a glassy mass. Melting point 741°C. Salts formed during brown soldering must be removed by mechanical cleaning. Borax powder should be stored in hermetically sealed glass jars.

Ammonia (ammonium chloride) is used in powder form to clean the working surface of a soldering iron before tinning.

Chemically passive fluxes (acid-free).

Acid-free fluxes include various organic substances: rosin, fats, oils and glycerin. Rosin (in dry form or a solution in alcohol) is most widely used in electrical and radio installation work. The most valuable property of rosin as a flux is that its residues after soldering do not cause corrosion of metals. Rosin has neither reducing nor dissolving properties. It serves solely to protect the soldering area from oxidation. To prepare alcohol-rosin flux, take one part by weight of crushed rosin, which is dissolved in six parts by weight of alcohol. After the rosin has completely dissolved, the flux is considered ready. When using rosin, soldering areas must be thoroughly cleaned of oxides. Often, for soldering with rosin, parts must be pre-tinned.

Stearin is non-corrosive. Used for soldering lead sheaths of cables, couplings, etc. with especially soft solders. Melting point is about 50°C.

Recently, the LTI group of fluxes used for soldering metals with soft solders has become widely used. In terms of their anti-corrosion properties, LTI fluxes are not inferior to acid-free ones, but at the same time, they can be used to solder metals that previously could not be soldered, for example, parts with galvanic coatings. LTI fluxes can also be used for soldering iron and its alloys (including stainless steel), copper and its alloys and metals with high resistivity (see Table 7).

Table 7

| Name | In weight proportions | ||

| LTI-1 | LTI-115 | LTI-120 | |

| Raw alcohol or rectified alcohol | 67-73 | 63-74 | 63-74 |

| Rosin | 20-25 | 20-25 | 20-25 |

| Aniline hydrochloride | 3-7 | — | — |

| Metaphenylenediamine | — | 3-5 | — |

| Diethylamine hydrochloride | — | — | 3-5 |

| Triethanolamine | 1-2 | 1-2 | 1-2 |

When soldering with LTI flux, it is enough to clean the soldering areas only from oils, rust and other contaminants. When soldering galvanized parts, you should not remove zinc from the soldering area. Before soldering parts with scale, the latter must be removed by etching in acids. Pre-etching of brass is not required. Flux is applied to the joint using a brush, which can be done in advance. Flux should be stored in glass or ceramic containers. When soldering parts with complex profiles, you can use solder paste with the addition of LTI-120 flux. It consists of 70-80 g of petroleum jelly, 20-25 g of rosin and 50-70 ml of LTI-120 flux.

But fluxes LTI-1 and LTI-115 have one big drawback: after soldering, dark spots remain, and intensive ventilation is required when working with them. Flux LTI-120 does not leave dark spots after soldering and does not require intensive ventilation, so its use is much wider. Usually, flux residues after soldering do not need to be removed. But if the product will be used in severe corrosive conditions, then after soldering, flux residues are removed using ends moistened with alcohol or acetone. The production of flux is technologically simple: alcohol is poured into a clean wooden or glass container, crushed rosin is poured until a homogeneous solution is obtained, then triethanolamine is added, and then active additives. After loading all the components, the mixture is stirred for 20-25 minutes. The prepared flux must be checked for a neutral reaction with litmus or methyl orange. The shelf life of the flux is no more than 6 months.

PHYSICAL AND MECHANICAL PROPERTIES OF SOLDER

| Solder grade | Melting point, oC | Density, g/cm3 | Electrical resistivity Ohm*mm2/m | Thermal conductivity, kcal/cm*s*deg | Temporary resistance rupture kgf/mm2 | Relative extension, % | Percussion viscosity, kgf/cm2 | Hardness according to Brinell, NV | |

| Soli-douc | Liquid- dus | ||||||||

| POS 90 | 183 | 220 | 7,6 | 0,120 | 0,130 | 4,9 | 40 | 4,2 | 15,4 |

| POS 61 | 183 | 190 | 8,5 | 0,139 | 0,120 | 4,3 | 46 | 3,9 | 14,0 |

| POS 40 | 183 | 238 | 9,3 | 0,159 | 0,100 | 3,8 | 52 | 4,0 | 12,5 |

| POS 10 | 268 | 299 | 10,8 | 0,200 | 0,084 | 3,2 | 44 | 3,2 | 12,5 |

| POS 61M | 183 | 192 | 8,5 | 0,143 | 0,117 | 4,5 | 40 | 1,1 | 14,9 |

| POSK 50-18 | 142 | 145 | 8,8 | 0,133 | 0,130 | 4,0 | 40 | 4,9 | 14,0 |

| POSSu 61-0.5 | 183 | 189 | 8,5 | 0,140 | 0,120 | 4,5 | 35 | 3,7 | 13,5 |

| POSSu 50-0.5 | 183 | 216 | 8,9 | 0,149 | 0,112 | 3,8 | 62 | 4,4 | 13,2 |

| POSSu 40-0.5 | 183 | 235 | 9,3 | 0,169 | 0,100 | 4,0 | 50 | 4,0 | 13,0 |

| POSSu 35-0.5 | 183 | 245 | 9,5 | 0,172 | 0,100 | 3,8 | 47 | 3,9 | 13,3 |

| POSSU 30-0.5 | 183 | 255 | 8,7 | 0,179 | 0,090 | 3,6 | 45 | 3,9 | 13,2 |

| POSSu 25-0.5 | 183 | 266 | 10,0 | 0,182 | 0,090 | 3,6 | 45 | 3,9 | 13,6 |

| POSSu 18-0.5 | 183 | 277 | 10,2 | 0,198 | 0,084 | 3,6 | 50 | 3,6 | — |

| POS 95-5 | 234 | 240 | 7,3 | 0,145 | 0,110 | 4,0 | 46 | 5,5 | 18,0 |

| POSSu 40-2 | 185 | 229 | 9,2 | 0,172 | 0,100 | 4,3 | 48 | 2,8 | 14,2 |

| POSSu 35-2 | 185 | 243 | 9,4 | 0,179 | 0,090 | 4,0 | 40 | 2,6 | — |

| POSSu 30-2 | 185 | 250 | 9,6 | 0,182 | 0,090 | 4,0 | 40 | 2,5 | — |

| POSSu 25-2 | 185 | 260 | 9,8 | 0,185 | 0,090 | 3,8 | 35 | 2,4 | — |

| POSSu 18-2 | 186 | 270 | 10,1 | 0,206 | 0,081 | 3,6 | 35 | 1,9 | 11,7 |

| POSSu 15-2 | 184 | 275 | 10,3 | 0,208 | 0,080 | 3,6 | 35 | 1,9 | 12,0 |

| POSSu 10-2 | 268 | 285 | 10,7 | 0,208 | 0,080 | 3,5 | 30 | 1,9 | 10,8 |

| POSSu 8-3 | 240 | 290 | 10,5 | 0,207 | 0,081 | 4,0 | 43 | 1,7 | 12,8 |

| POSSu 5-1 | 275 | 308 | 11,2 | 0,200 | 0,084 | 3,3 | 40 | 2,8 | 10,7 |

| POSSU 4-6 | 244 | 270 | 10,7 | 0,208 | 0,080 | 6,5 | 15 | 0,8 | 17,3 |

LOW FUSE SOLDER

| Solder | CHEMICAL COMPOSITION | Pace. pl., C | Tensile strength, kgf/mm2 | Tensile elongation, % | Brinell hardness, kgf/mm2 | ||||

| Sn | Bi | Pb | Cd | other | |||||

| Guthrie alloy | 21,1 | 50 | 20,5 | 14,3 | — | 45 | — | — | — |

| — | 8,3 | 44,7 | 22,6 | 5,3 | indium 19.1 | 47 | 3,8 | 1,5 | 12 |

| — | 12 | 49 | 18 | — | indium 21 | 58 | 4,5 | 50 | 14 |

| Wood alloy1 | 12,5 | 50 | 25 | 12,5 | — | 68 | 4,5 | 7 | 10,5 |

| — | 20 | 35,5 | 35 | 9,5 | — | 67…90 | 4 | 15 | 18 |

| Lipowitz alloy1 | 12,9 | 49,4 | 27,7 | 10 | — | 70 | 4,3 | 50 | 9 |

| — | 11 | 42,5 | 37,7 | 85 | — | 70…90 | 3,6 | 31 | 10 |

| D'Arsenval alloy1 | 9,6 | 45,3 | 45,1 | — | — | 79 | — | — | — |

| Alloy Rose1 | 25 | 50 | 25 | — | — | 93,7 | — | — | — |

| Newton's alloy | 18,75 | 50 | 31,25 | — | — | 96 | 4,9 | — | 8,6 |

| POSV-32-15-531 | 32 | 53 | 15 | — | — | 96 | — | — | — |

| — | 22 | 50 | 28 | — | — | 100 | 4,5 | 6 | 13,6 |

| -2 | 50 | — | — | — | indium 50 | 117 | 1,2 | 83 | 5 |

| — | 33,3 | 20 | 33,3 | 13,4 | — | 120 | 5 | 3,8 | 12,5 |

| POSV-333 | 33,4 | 33,3 | 33,3 | — | — | 130 | — | — | — |

| — | 42 | 58 | — | — | — | 139 | 5,6 | 200 | 22 |

| POSK-50 | 49,8 | — | 32 | 18,2 | — | 145 | 6,7 | — | 15,3 |

| — | 70 | — | 18 | — | indium 12 | 150…174 | 3,7 | 135 | 12 |

| -4 | 34 | — | 63 | — | zinc 3 | 170…256 | — | — | — |

| POS-605.6 | 59…61 | — | rest | — | antimony 0…0.8 | 182…185 | — | — | — |

| — | 42 | 58 | — | — | — | 139 | 5,6 | 200 | 22 |

| — | 49,5…50 | 0,25 | rest | — | antimony 0.2…0.5 | 182…216 | 4,4 | 3,8 | 14 |

| POS-506 | 49…50 | — | rest | — | antimony 0…0.8 | 183…209 | — | — | — |

| POS-907 | 88…90 | — | rest | — | copper 0…0.8 nickel 0…0.8 | 183…222 | — | — | — |

| POS-406.8 | 39…40 | — | rest | — | antimony 1.5…2 | 183…235 | — | — | — |

| POS-309 | 29…30 | — | rest | — | antimony 1.5…2 | 183…256 | — | — | — |

| POS-1810 | 7…18 | — | rest | — | antimony 2…2.5 | 183…277 | — | — | — |

| -11 | 50 | — | 47 | — | antimony 3 | 185…204 | 5,9 | 29 | 16 |

| — | 91,1 | — | — | 8,9 | — | 199 | 7,5 | — | 14 |

| Avia-14 | 55 | — | — | 20 | zinc 25 | 200 | — | — | — |

| -12 | — | — | 50 | — | indium 50 | 215 | 3,3 | 55 | 2,6 |

| -4 | 34 | — | 63 | — | zinc 3 | 170…256 | — | — | — |

| PSr-213 | 30 | — | 63 | 5 | silver 2 | 225…235 | — | — | — |

| -14 | — | — | — | — | indium 90 silver 10 | 231 | 1,1 | 61 | 2,7 |

| PS-780l-15 Su-7 | 15 | — | 78 | — | antimony 7 | 231 | — | — | — |

| -15 | 94 | — | — | — | antimony 4…6 | 232…240 | 4 | 38 | 13 |

| PS-99TS1 | — | — | 98,9 | — | sodium 0.1 zinc 1 | 234 | — | — | — |

| PK600-4004 | 40 | — | — | 60 | — | 235 | — | — | — |

| PKTs-40-6016 | — | — | — | 40 | zinc 60 | 240 | — | — | — |

| PS-830l-7Su-10 | 7 | — | 83 | — | antimony 10 | 242 | — | — | — |

| Pol-70TS304 | 70 | — | — | — | zinc 30 | 243 | — | — | — |

| — | — | — | rest | — | antimony 11…13 | 247…248 | 5 | — | 30 |

| Avia-24 | 40 | — | — | 20 | aluminum 15 zinc 25 | 250 | — | — | — |

| PSr-1.513 | 15 | — | 83,5 | — | silver 1.5 | 265…270 | — | — | — |

| POSSr-1.517 | 15 | 0,75 | 83 | — | silver 1.25 | 276 | — | — | — |

| PSr-2.513 | 5,5 | — | 92 | — | silver 2.5 | 235…305 | — | — | — |

| — | 0,75…1,25 | 0,25 | rest | — | antimony 0…0.4 silver 1.3…1.7 | 309 | 3,1 | 23 | 9,5 |

| PK60TS-4017 | — | — | — | 60 | zinc 40 | 310 | — | — | — |

| — | — | — | 95 | — | indium 5 | 315 | 3,5 | 52 | 6 |

| B | — | — | — | — | aluminum 12 copper 8 zinc 80 | 400 | — | — | — |

1 For soldering of metals with a melting point of 200AC and above 2 For soldering to glass 3 Soldering of signal fuses 4 For soldering of aluminum and its alloys 5 For soldering of mounting wires with PVC insulation, winding wires, sealed seams, products made of hardened steel 6 For soldering of current-carrying parts made of brass, silver, tin-plated nickel 7 For soldering parts and assemblies for electroplating, silver, gold-plated (solder with high corrosion resistance) 8 For tinning and soldering of cable products 9 For tinning and soldering of current-carrying parts made of copper, zinc and their alloys, for soldering parts of devices and radio equipment, for tinning before soldering with lower-melting solders 10 Cheap solder for various jobs 11 Solder with increased creep resistance 12 Solder with high resistance to alkali corrosion 13 For soldering molybdenum and tungsten 14 For soldering silver, glass and ceramics 15 For soldering food utensils, containers for medicines and water (POS-90 solder is suitable for these purposes) 16 For soldering magnesium and its alloys 17 For soldering parts made of galvanized steel, zinc, copper alloys, for soldering external parts of devices

ACCEPTANCE RULES

3.1 Solders are accepted in batches. Each batch should consist of pigs of the same brand and one heat. The mass of the party is not limited.

Each batch of ingots is accompanied by a quality document containing:

trademark or name and trademark of the manufacturer;

solder symbol;

chemical analysis results or confirmation of solder quality compliance

the requirements of this standard;

batch number;

net weight in kilograms;

date of manufacture.

3.2 Each pig of the batch is subjected to external inspection.

3.3 To control the chemical composition of the solder, every fiftieth pig is selected from the batch, but not less than five pigs at the beginning, middle and end of the casting of the melt.

At the manufacturing plant, it is allowed to check the chemical composition on a sample taken from the molten metal.

The manufacturer monitors the content of iron, sulfur, nickel, zinc and aluminum impurities in solders of all brands during the manufacturing process.

3.4 If unsatisfactory results of checking the chemical composition are obtained, a repeat check is carried out on a double sample taken from the same batch.

The results of repeated tests apply to the entire batch.

TEST METHODS

4.1 Inspection of the surface of pigs is carried out by visual inspection.

4.2. Sampling - according to GOST 24231-80. The shavings selected from all the ingots are crushed to a particle size of no more than 5 mm without control sieving, thoroughly mixed and reduced by quartering to a laboratory sample weighing 200 g.

The laboratory sample is melted in a crucible and ground on a belting to a particle size of no more than 2 mm, mixed and treated with a magnet. The laboratory sample is divided into two parts: one part is sent for chemical analysis, the other is saved in case of disagreement in assessing the quality of the batch.

Samples of liquid metal are taken in the form of splashes and rods with a diameter of 8 mm and a length of 75 mm.

4.3 Solder shavings containing more than 2.5% antimony are sifted through mesh No. 08 according to GOST 6613-86 to determine the fine fraction. The calculated data of the analysis results of both fractions are taken as the result of the analysis.

4.4 The chemical composition of solders is determined according to GOST 1429.0-77 - GOST 1429.15-77 or other methods that provide the required determination accuracy.

In case of disagreement in assessing the chemical composition of solder, its determination is carried out according to GOST 1429.0-77 - GOST 1429.11-77.

LABELING, PACKAGING, TRANSPORTATION AND STORAGE

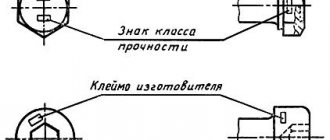

5.1 On each piece of solder the following is stamped:

a) trademark of the manufacturer;

b) brand of solder;

c) heat number;

5.1a Solder ingots are transported without packaging in transport bags or in containers in accordance with GOST 18477-79. Packages of pigs must be tied with steel packaging tape measuring at least 0.8x30 mm in accordance with GOST 3560-73, fastened with a lock. It is allowed to use fastening means that ensure the safety of the package in accordance with GOST 21650-76. The weight of the package is no more than 1250 kg. It is allowed to increase the package up to 1500 kg, provided that loading and unloading is carried out on the access roads of the consignor and consignee, while the floor of the car along the path of the loader must be lined with metal sheets 3-4 mm thick.

Schemes for laying and fastening solder ingots into bags are given in Appendix 4. When transporting by air, the ingots are packed in thick board boxes of type II-1 in accordance with GOST 2991-85, dimensions in accordance with GOST 21140-88, lined on the inside with plastic film in accordance with GOST 10354-82. The gross weight of the boxes is no more than 60 kg.

5.1b The designation of the solder brand is applied on the front surface of the pig on the left side with numbers corresponding to the percentage of the main components without indicating the letter designation POS, POSS, POS, POSK. The heat number is stamped on the right side of the front surface of the pig.

Examples of solder markings:

Solder grade POS 90:90.

Solder grade POS 61M: 61M.

5.2 Transport marking - according to GOST 14192-77.

5.3 Solder ingots are transported by all types of transport in covered vehicles in accordance with the transportation rules in force for transport of this type and the conditions of loading and fastening approved by the Ministry of Railways of the USSR.

5.4 Solder should be stored indoors. If the specified storage conditions are observed, the consumer properties of tin-lead solders do not change during storage.

Annex 1

Information

Compound

As noted above, lead solder usually contains Sn and Pb. The percentage amount of the first element is indicated by the numbers behind the letters. For example, POS-40 contains forty percent of stanum, and POS-60 contains sixty. It is worth noting that POS-60 and 61 have the same composition, but are labeled differently.

Many people often do not pay due attention to the composition of the alloy when soldering. Nevertheless, this point is very important, because it determines the installation characteristics and the quality of the work performed.