GOST 1759.0-87Group G31

INTERSTATE STANDARD BOLTS, SCREWS, STUDS AND NUTS Specifications Bolts, screws, studs and nuts.Specifications

MKS 21.060.10OKP 12 8200, 12 8300, 12 8400

Date of introduction 1989-01-01

INFORMATION DATA

1. DEVELOPED AND INTRODUCED by the USSR Ministry of Ferrous Metallurgy

2. APPROVED AND ENTERED INTO EFFECT by Resolution of the USSR State Committee for Standards dated December 30, 1987 N 5111

3. The standard fully complies with ST SEV 4203-83

4. INSTEAD GOST 1759-70 (regarding technical requirements and marking of fasteners)

5. REFERENCE REGULATIVE AND TECHNICAL DOCUMENTS

| Designation of the referenced technical document | Number of section, paragraph, application |

| GOST 9.301-86 | 2.3.3 |

| GOST 9.302-88 | 4.8 |

| GOST 9.303-84 | 2.3.1; 2.3.2 |

| GOST 9.306-85 | 2.3.1, Appendix 1 |

| GOST 1759.1-82 | 1.2; 4.4 |

| GOST 1759.2-82 | 2.1.2; 4.2 |

| GOST 1759.3-83 | 2.1.3; 4.3 |

| GOST 1759.4-87 | 2.2.1; 3.2; 4.9; 4.10 |

| GOST 1759.5-87 | 2.2.3; 3.2; 4.11; 4.12 |

| GOST 4784-97 | Annex 1 |

| GOST 5632-72 | 2.2.5 |

| GOST 5916-70 | 2.2.4 |

| GOST 9378-93 | 4.6 |

| GOST 12920-67 | 2.2.5 |

| GOST 15527-2004 | 2.2.5 |

| GOST 16030-70 | 4.5 |

| GOST 16093-2004 | 1.2 |

| GOST 17473-80 | Annex 1 |

| GOST 17769-83 | 3.1 |

| GOST 18160-72 | 5 |

| GOST 18175-78 | 2.2.5 |

| GOST 20072-74 | 2.2.4 |

| GOST 24705-2004 | Introductory part |

| GOST 25556-82 | 2.2.2 |

6. The validity period was lifted according to Protocol No. 3-93 of the Interstate Council for Standardization, Metrology and Certification (IUS 5-6-93)

7. EDITION with Amendment No. 1, approved in October 1989 (IUS 2-90)

This standard applies to bolts, screws, studs and nuts with metric threads in accordance with GOST 24705-2004 with a diameter from 1 to 48 mm.

MAIN PARAMETERS AND DIMENSIONS

1.1. The design, dimensions and surface roughness of bolts, screws, studs and nuts are established in product standards.

1.2. Tolerances for the dimensions, shape and location of the surfaces of bolts, screws, studs and nuts are in accordance with GOST 1759.1-82. The main thread deviations should be assigned according to GOST 16093 depending on the required coating thickness. Thread tolerance fields are indicated for uncoated products. After coating, the thread requirements are in accordance with GOST 16093.

(Changed edition, Amendment No. 1).

1.3. At the request of the consumer, it is allowed to produce bolts, screws and studs with an increased or decreased length of the threaded part.

1.4. By agreement between the manufacturer and the consumer, it is allowed to produce: bolts, studs and nuts with left-hand threads; bolts with one locking hole in the head.

1.5. Permissible deviations of shape from those established in the standards for the design of bolts, screws, studs and nuts of all accuracy classes must correspond to those specified in Appendix 5.

Fastener coatings

In accordance with GOST 1759.4-87, coatings and oxide films are provided for fasteners (see Table 2). The choice of coating type for a particular material is carried out in accordance with GOST. The thickness of the coatings δ (set by agreement) is selected depending on the thread pitch within the following limits:

- at fastener thread pitch P

- with an average fastener thread pitch P = 0.4 ... 0.8 mm, the thickness of its coating is δ = 6 ... 9 μm;

- with a large thread pitch of fasteners P > 0.8 mm, the coating thickness should be δ = 9 ... 12 µm.

Coatings of GOST fasteners must correspond to those specified in Table 2.

Table 2. Types of fastener coatings according to GOST

| Designation | Coating | Operating temperature, t °C, no more |

| 00 | Uncoated fasteners | |

| 01 | Chromated zinc plated fasteners | 300 |

| 02 | Cadmium plated with chromated fasteners | 200 |

| 03 | Multi-layer copper-nickel coating of fasteners | 600 |

| 04 | Multilayer copper-nickel-chrome | 600 |

| 05 | Oxide coating of fasteners | 200 |

| 06 | Phosphate oil-coated coating of fasteners | 200 |

| 07 | Tin plated fasteners | 150 |

| 08 | Copper plating fasteners | 600 |

| 09 | Zinc coating of fasteners (galvanized fasteners) | 200 |

| 10 | Oxide anodizing coating of fasteners with chromate plating | 200 |

| 11 | Oxide coating of fasteners made from acidic solutions | 200 |

| 12 | Silver plated fasteners | 600 |

| 13 | Nickel plated fasteners | 900 |

TECHNICAL REQUIREMENTS

2 1. Appearance

2.1.1. The surface of bolts, screws, studs and nuts must be clean, without traces of corrosion or mechanical damage.

2.1.2. Allowable surface defects of bolts, screws and studs are in accordance with GOST 1759.2.

2.1.3. Allowable surface defects of nuts are in accordance with GOST 1759.3.

2.2. Mechanical properties and materials

2.2.1. Mechanical properties of bolts, screws (except for mounting screws) and studs made of carbon unalloyed and alloyed steels are in accordance with GOST 1759.4.

2.2.2. Mechanical properties of set screws and similar non-tensile fasteners made of carbon unalloyed and alloyed steels - in accordance with GOST 25556.

2.2.3. Mechanical properties of nuts made of carbon unalloyed and alloyed steels are in accordance with GOST 1759.5-87.

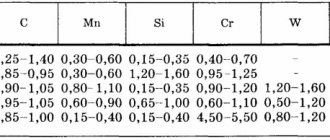

2.2.4. Mechanical properties of bolts, screws, studs and nuts made of corrosion-resistant, heat-resistant, heat-resistant and heat-resistant steels, as well as recommended steel grades - according to Tables 1 and 2.

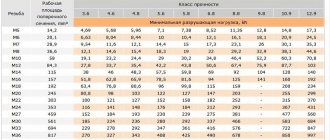

Table 1

Mechanical properties of bolts, screws and studs made of corrosion-resistant, heat-resistant, heat-resistant and heat-resistant steels at normal temperature

| Group symbol | Tensile strength σв, N/mm² | Yield strength σв (σ0.2), N/mm² | Relative elongation δ5, % | Impact strength KCU, J/cm² | Test load voltage σп, N/mm² | Steel | |

| No less | Brand | Standard designation | |||||

| 21 | 510 | 195 | 35 | Not regulated | 175 | 12Х18Н10Т | GOST 5632-72 |

| 12Х18Н9Т | |||||||

| 10X17H13M2T | |||||||

| 10Х17Н13МЗТ | |||||||

| 06ХН28МДТ | |||||||

| 22 | 590 | 345 | 20 | 60 | 310 | 12Х13 | |

| 08Х21Н6М2Т | |||||||

| 23 | 690 | 540 | 12 | 60 | 485 | 20Х13 | |

| 14Х17Н2 | |||||||

| 24 | 880 | 540 | 8 | 30 | 485 | 10Х11Н23ТЗМР | |

| 25 | 735 | 10 | 30 | 660 | 13Х11Н2В2МФ | ||

| 25Х1МФ; | GOST 20072 | ||||||

| 25Х2М1Ф | |||||||

| 20Х1М1Ф1ТР | |||||||

| 26 | 1080 | 835 | 10 | 50 | 750 | 07Х16Н6 | GOST 5632-72 |

table 2

Mechanical properties of nuts made of corrosion-resistant, heat-resistant, heat-resistant and heat-resistant steels at normal temperature

| Group symbol | Test load voltage σF, N/mm², not less | Steel | |

| Brand | Standard designation | ||

| 21 | 510 | 12Х18Н10Т, 12X18H9T | GOST 5632-72 |

| 10Х17Н13М2Т | |||

| 10Х17Н13М3Т | |||

| 06ХН28МДТ | |||

| 22 | 590 | 12Х13 | |

| 08Х21Н6М2Т | |||

| 23 | 690 | 20Х13 | |

| 14Х17Н2 | |||

| 24 | 880 | 10Х11Н23Т3МР | |

| 25 | 13Х11Н2В2МФ | ||

| 25Х1МФ, 25Х2М1Ф | GOST 20072 | ||

| 20Х1М1Ф1ТР | |||

| 26 | 1080 | 07Х16Н6 | GOST 5632-72 |

2.2.5. Mechanical properties of bolts, screws, studs and nuts made of non-ferrous alloys, as well as recommended grades of alloys - Tables 3 and 4.

Table 3

Mechanical properties of bolts, screws, studs of non-ferrous alloys at normal temperature

| Group symbol | Tensile strength σв, N/mm² | Yield strength σв, (σ0.2), N/mm² | Relative elongation δ5, % | Brinell hardness HB | Grade of material or alloy | Standard designation |

| No less | ||||||

| 31 | 260 | 120 | 15 | Not regulated | AMg5P | GOST 4784-97 |

| AMg5 | ||||||

| 32 | 310 | Not regulated | 12 | 75 | Brass L6Z, | GOST 15527-2004 |

| Brass LS59-1 | GOST 12920-67 | |||||

| 33 | Brass LS59-1 antimagnetic | |||||

| Brass L63 antimagnetic | ||||||

| 34 | 490 | Not regulated | Bronze Br. AMts9-2 | GOST 18175 | ||

| 35 | 370 | 195 | 10 | D1, D1P, D16, D16P | GOST 4784-97 | |

Table 4

Mechanical properties of nuts made of non-ferrous alloys at normal temperature

| Group symbol | Test load voltage σF, N/mm², not less | Grade of material or alloy | Standard designation |

| 31 | 260 | AMg5P, AMg5 | GOST 4784-97 |

| 32 | 310 | Brass LS59-1,L63 | GOST 15527-2004, GOST 12920-67 |

| 33 | Brass L63 antimagnetic | ||

| Brass LS59-1 antimagnetic | |||

| 34 | 490 | Bronze Br. AMts 9-2 | GOST 18175 |

| 35 | 370 | D1, D1P, D16, D16P | GOST 4784-97 |

2.2.6. It is allowed to manufacture bolts, screws, studs and nuts from materials and alloys not specified in Tables 1-4. Moreover, their mechanical properties must not be lower than those specified for the corresponding groups.

2.2.7. At the request of the consumer, brass fasteners made by cold heading must be subjected to heat treatment to relieve internal stresses.

2.3. Coatings

2.3.1. Bolts, screws, studs and nuts must be manufactured with one of the types of coatings according to Table 5 or without coatings.

Table 5

| Type of coverage | Coverage designation | |

| according to GOST 9.306-85 | digital | |

| Zinc, chromated | C. hr | 01 |

| Cadmium, chromated | Kd. xp | 02 |

| Multilayer: copper-nickel | M. N | 03 |

| Multilayer: copper-nickel-chrome | M. N. X. b | 04 |

| Oxidized, oil-impregnated | Chem. Oks. prm | 05 |

| Phosphate, oil impregnated | Chem. Phos. prm | 06 |

| Tin | ABOUT | 07 |

| Copper | M | 08 |

| Zinc | C | 09 |

| Oxidic, filled with chromates | An. Ok. NHR | 10 |

| Oxidic from acidic solutions | Chem. Pass | 11 |

| Silver | Wed | 12 |

| Nickel | N | 13 |

It is allowed to use other types of coatings - in accordance with GOST 9.303-84.

2.3.2. The choice of coating thickness is in accordance with GOST 9.303-84.

2.3.3. Technical requirements for coatings are in accordance with GOST 9.301.

2.4. Marking

2.4.1.General labeling rules

2.4.1.1. Bolts with a hexagonal head, screws with a cylindrical head and a hexagonal socket, studs and hexagonal nuts should be marked with the sign of the strength class (or material group) and the mark (trademark) of the manufacturer, and products with left-hand threads must additionally be marked with the sign of the left-hand thread.

The following are subject to mandatory marking:

- hex head bolts of strength classes 4.6, 5.6, 6.6, 8.8, 9.8, 10.9, 12.9;

- cylindrical head screws with hexagonal socket and studs of strength classes 8.8, 9.8, 10.9, 12.9;

- nuts of strength classes 05, 8, 9, 10, 12.

(Changed edition, Amendment No. 1).

2.4.1.2. Products not specified in clause 2.4.1.1 and of unspecified strength classes, as well as products made by cutting, are marked by agreement between the manufacturer and the consumer.

2.4.1.3. Marking marks can be convex or recessed.

2.4.1.4. When marking strength classes, it is allowed not to put a dot separating the first and second numbers of the strength class sign.

When low-carbon martensitic steels are used for products of strength class 10.9, the strength class sign must be underlined: 10.9 or 109.

(Changed edition, Amendment No. 1).

2.4.1.5. The dimensions of the marking signs are set by the manufacturer.

2.4.2. Marking of hex bolts and socket head cap screws

2.4.2.1. Bolts and screws with thread diameter d ≥ 6 mm are subject to marking.

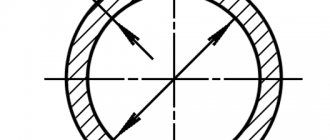

2.4.2.2. Marking marks are applied to the end or side surface of the head of a bolt or screw (Fig. 1). The marks on the side surface of the head should be recessed.

Damn.1

2.4.2.3. When marking with convex marks, it is allowed to increase the maximum maximum height of the head of a bolt or screw by:

- 0.1 mm - for products with thread diameter d ≤ 8 mm;

- 0.2 mm - for products with a thread diameter of 8 mm d ≤ 12 mm;

- 0.3 mm - for products with thread diameter d > 12 mm.

2.4.3. Stud markings

2.4.3.1. Studs with thread diameter d ≥ 12 mm are subject to marking. It is allowed to mark studs with a thread diameter d ≥ 8 mm using substitute marks:

○ — for strength class 8.8;

+ - for strength class 9.8;

□ — for strength class 10.9;

△ - for strength class 12.9.

2.4.3.2. Marking marks are applied to the end of the nut end of the stud.

2.4.4. Hex nut markings

2.4.4.1. Nuts with thread diameter d ≥ 6 mm must be marked.

2.4.4.2. Marking marks are applied on one of the end surfaces. In technically justified cases, it is allowed to apply markings on the side surfaces of the nuts (Fig. 2). Signs must be in-depth.

Damn.2

2.4.4.3. It is allowed to use dial markings for nuts (Fig. 3). In this case, the marking is applied on the chamfers with convex or recessed marks or on the end surface with recessed marks.

| Strength class | 8 | 9 | 10 | 12 |

| Nut dial markings |

Damn.3

2.4.5. Marking of bolts, studs and nuts with left-hand threads

2.4.5.1. The sign of a left-hand thread is an arrow indicating the direction of screwing in the bolts, studs and screwing in the nut.

2.4.5.2. The left-hand thread mark is applied on the end surface of the bolt head, on one of the end surfaces of the nut (Fig. 4a), and on the end of the nut end of the stud. In technically justified cases, it is allowed to apply a left-hand thread mark on the side surfaces of the nut and bolt heads (Fig. 4b). In this case, the signs must be in-depth.

2.4.5.3. The left-hand thread sign for bolts and nuts can be replaced by cuts on the edges of the hexagons (Fig. 4c).

Damn.4

Marking of bolts and nuts - complete explanation of all symbols

Home » News

Published: 09/02/2018

A bolt as a fastening product is a cylindrical rod with a thread and a head. It comes in different shapes - square, hexagonal and more complex configurations. But the principle of marking bolts is general. How to decipher it and apply it in practice is what we’ll talk about in this article.

Marking of fasteners is carried out in accordance with GOST No. 1759.0 from 1987, 18126 from 1994. However, letters on certain types of bolts are also applied according to other standards. For example, for foundation samples, GOST No. 24379.1 of 1980 is used.

Golf V key light on the instrument panel. insp.

Full

Explanations

There are 3 accuracy classes of fasteners. For bolts and nuts, this parameter is not indicated (position 2), since all of them, according to the standard, belong to category B. There are 4 design options. If the bolt is the first, then the number “1” is not indicated. Existing types of thread: Tr - trapezoidal, K - conical, M - metric. Its diameter and pitch are in “mm”. If it is traditional (right-wing), then this is implied. For left-hand threads, the symbol LH is indicated (position 6). The coating thickness (at position 12) is expressed in “µm”. With abbreviated labeling, only the most essential parameters are indicated. When simplified, the main characteristics are indicated - as a rule, length and cross-section. For example, 16 x 25.

What goes on the bolt head?

Arrow. If the thread is left-handed. For the right, traditional, marking is not provided. Strength class of metal (alloy). Options for the location of signs are shown in the table.

By type of steel

Carbon, for example - 8.8.

1 – shows the maximum load of the connection point (t/cm2). 2 (through a dot) – ratio of limits (yield/strength) x 10. Martensitic (with minimal carbon content). Likewise. To distinguish them from carbon ones, the designation is underlined. For example, 8.8. On some samples there may not be a dot between the numbers.

"Galvanization"

A2 – alloy grade. 70 – tensile strength.

Manufacturer's logo

The mark can be recessed or convex, and the size of the symbols is determined by the product manufacturer.

brat-msk.com

ACCEPTANCE

3.1. Rules for acceptance of bolts, screws, studs and nuts - according to GOST 17769.

3.2. Each batch of fasteners must be accompanied by a quality document indicating:

- name or trademark of the manufacturer;

- symbol of the product;

- list and results of tests performed;

- net mass of the batch;

- means of temporary anti-corrosion protection and protection period.

Notes: 1. It is allowed to place a document on the quality of products in a container or container, and its safety during transportation must be ensured.

2. Before 01/01/92, the mandatory tests were:

- according to GOST 1759.4 for strength classes 8.8-12.9, determination of tensile strength and determination of impact strength; for strength classes 4.8; 5.8; 6.8 test for the strength of the connection between the head and the rod;

- according to GOST 1759.5-87 for strength classes 8-12 test load test.

Other tests are carried out at the request of the consumer.

(Changed edition, Amendment No. 1).

CONTROL METHODS

4.1. Inspection of the appearance of bolts, screws, studs and nuts should be carried out without the use of magnifying devices. In controversial cases, it is allowed to use a magnifying glass with a magnification of 2.5-3x.

4.2. Inspection of surface defects of bolts, screws and studs - in accordance with GOST 1759.2.

4.3. Control of surface defects of nuts - according to GOST 1759.3.

4.4. Control of the sizes of bolts, screws, studs and nuts - according to GOST 1759.1-82.

4.5. The bluntness of the corners of the square head should be checked in a control matrix with a square hole made according to the 1st row of GOST 16030. A flat washer with a hole with a diameter larger than the diameter of the circumscribed circle of the head and a thickness of 0.5 of the height of the head should be installed under the head of the bolt. Rotating the preparation in the hole of the control bushing or template is not allowed.

4.6. The surface roughness of bolts, screws, studs and nuts should be checked by comparison with roughness samples in accordance with GOST 9378-93. It is allowed to control surface roughness using measuring instruments. The surface roughness of products made by cold stamping and the roughness of the end of the rods, except for the set screws, are not controlled.

4.7. The roughness of the threads of bolts, screws and studs should be checked on the side surfaces of the profile. The roughness of threads obtained by knurling and the roughness of threads of nuts is not controlled and must be ensured by manufacturing technology and tools.

4.8. Methods for checking the quality and thickness of coatings are in accordance with GOST 9.302.

4.9. Test methods and testing programs for bolts, screws and studs made of carbon unalloyed and alloyed steels - in accordance with GOST 1759.4.

4.10. Testing of bolts, screws and studs made of corrosion-resistant, heat-resistant, heat-resistant and heat-resistant steels, as well as non-ferrous alloys, must be carried out at the request of the consumer in accordance with Table 6 according to the GOST 1759.4 method.

Table 6

| Mechanical characteristics | Type of test | Material groups | ||||

| 21 | 22, 23, 24, 25, 26 | 31, 35 | 34 | 32, 33 | ||

| Temporary resistance | Tensile test | x | x | x | x | x |

| 0 | 0 | 0 | 0 | 0 | ||

| Yield strength | Tensile test | x | x | x | — | — |

| Relative extension | Tensile test | x | x | x | x | x |

| Brinell hardness | Hardness measurement | x | ||||

| 0 | ||||||

| Impact strength | Impact test | x | ||||

0 - for bolts, screws and studs with thread d ≤ M5 and length > 3d;

x - for bolts, screws and studs with thread d > M5 and length ≥ 3d.

Breaking loads are given in Appendix 2, test loads - in Appendix 4.

Other tests on bolts, screws and studs are carried out by agreement between the manufacturer and the user.

(Changed edition, Amendment No. 1).

4.11. Test methods for nuts made of carbon unalloyed and alloyed steels - according to GOST 1759.5-87.

4.12. Testing of nuts made of corrosion-resistant, heat-resistant, heat-resistant and heat-resistant steels, as well as nuts made of non-ferrous alloys with a test load should be carried out at the request of the consumer according to the GOST 1759.5-87 method. Test loads are given in Appendix 3.

4.13. When manufacturing bolts, screws and studs by cutting, without subsequent heat treatment, it is allowed to test the mechanical properties on the original metal or samples made from it.

Description: Nuts GOST, OST, DIN

A nut is a threaded fastener with a hole designed to work in conjunction with a bolt, stud and screw. Characterized by the following main parameters:

- diameter and thread pitch;

- accuracy class;

- height;

- turnkey shape and size;

- strength class;

- the presence or absence of locking elements;

- coating.

Although there are exclusive (original) nuts, the vast majority of them are produced according to GOSTs, OSTs, TUs or German DIN inherited from Soviet times, which are valid throughout the Eurozone.

Thread diameter and pitch

These are the main parameters of the nut. They determine its compatibility with the mating part. In fasteners, as a rule, metric threads are used, the profile of which has a triangular shape with an apex angle of 60°. The thread diameter is designated by the letter d, the thread pitch is P. Nuts with the same diameter can have different pitches. The largest of them is considered the main one.

According to GOST 8724-2002, the diameters of metric threads range from 0.25 to 600 mm, pitches from 0.075 to 8 mm. It is customary to distinguish between fasteners with a diameter from 1.6 to 48 mm and over 48 mm.

The symbol for a nut with a metric thread includes the letter M and two numbers separated by an “x” (which may or may not be present). The first indicates the thread diameter (d), the second indicates the pitch (P). If the second number is missing, it means the nut has a large pitch. For example, the designation “Nut M8x1” means that we have a product with a metric thread, 8 mm in diameter and 1 mm in pitch. If a product is marked “Nut M8”, this indicates that it has a large pitch (1.5 mm).

Threads can be right-handed or left-handed. In the latter case, the letters “LH” are added to the designation. For example, M8x0.75 – LH.

Class (degree) of accuracy

Determines the size of the gap that exists between the nut and the bolt, regulated by GOST 16093-81. The degree of accuracy of threaded parts is determined by two components.

- Diameter tolerance, indicated by the numbers 4, 5, 6, 7 and 8. The larger the number, the smaller the tolerance and the higher the accuracy.

- The position of the tolerance fields, which is designated by the letters E, F, G and H.

In the nut marking, the value of the position of the tolerance field follows the designation of the diameter tolerance. For example, M12-6N - indicates that this is a product with a diameter of 12 mm with a large pitch and an accuracy class of 6H.

Strength class

The strength of a nut (mainly its thread) depends not only on the material from which it is made, but also on the production technology, in particular heat treatment (usually hardening or normalizing). The load-bearing capacity of a threaded connection is also affected by the height of the nut (the number of working thread turns) and the pitch (the height of the thread profile).

The strength parameters of nuts are determined by GOST R 52628-2006. According to it, for products with normal or increased height (≥0.8d) and large pitch there are seven strength classes (4, 5, 6, 8, 9, 10, 12). For nuts with fine threads - five classes (5, 6, 8, 10, 12). For nuts with a height of 0.5d...0.8d. – 2 classes (04, 05).

The numbers indicating the class are the minimum value of the tensile strength of the bolt associated with the nut, divided by 100. That is. a nut with a strength class of 10 can reliably work in tandem with a bolt whose tensile strength is 1000 N/mm2.

GOST R 52628-2006 does not put forward requirements for the use of specific steel grades; it is limited only to indicating their mechanical properties and the content of certain (Mn, C, P, S) elements.

The most commonly used steel grades for nuts of a certain strength class:

- class 4 – St3kp, St3sp;

- class 5 – 10, 10kp, 20;

- class 6 – St5, 15kp, 15, 35;

- class 8 – 20kp, 20, 35, 45;

- class 9 – 35Х, 40х, 39ХА;

- class 10 – 40Х, 14Х17Н2, 16ХСН, 40ХГСА, 09Г2С;

- class 12 – ZOKHGSA, 12Х18Н10Т, 20Х13, 40ХН2МА, ZOKHGSA.

The strength class is marked on the nut with the corresponding number or code symbol (mark), printed in a certain place along the dial system.

Height

Along with strength, it determines the load-bearing capacity of a threaded connection. Thread collapse, which occurs as a result of exceeding the permissible load or too frequent screwing-unscrewing operations, is the most common cause of failure of a threaded connection.

A normal height is considered to be 0.8d. The smaller it is, the fewer thread turns, the higher the load per thread. However, low nuts also have their advantages, the main one being compactness. Their release is regulated by special GOSTs - 5916-70, 10607-94, etc.

Nut shape

It determines the methods of wrapping, the type of tool, and sometimes the method of locking.

The vast majority of nuts are hexagonal in shape - for an open-end or socket wrench. The turnkey size for nuts of the same diameter can be standard or reduced. The production of hex nuts is regulated by a large number of GOSTs - 10607-94, 10605-94, 10608-72, 5915-70, 15522-70, 2524-70, 2528-73, etc.

Round nuts have holes or slots on the end or sides for special keys and/or locking elements. Produced in accordance with GOST 10657-80 (with splines on the end), GOST 11871-88 (with splines on the cylindrical surface), GOST 6393-73 (with holes on the end), etc.

The square shape is used less frequently. For screwing, regular open-end wrenches are used. Square nuts are regulated by DIN standards - 557, 562, etc.

Wing nuts (GOST 3032-76) have special ears for tightening by hand.

Cap nuts (GOST 11860-85) are closed on one side with a spherical surface. This is usually done for design reasons.

Locking elements

Spontaneous loosening of nuts is one of the main problems of threaded connections. There are many ways to combat it - using locknuts, applying polymer to the threads, using special washers and studs. The latter sometimes require special elements on the nut. For example, slots on the cylindrical surface of round nuts (GOST 11871-88, etc.), into which the antennae of the lock washers are bent. Or slots on the end surface - the so-called. castle nuts (GOST 5918-73, 5919-73, 5932-73, 5933-73). Locking pins pass through them and are threaded into the hole of the bolt or axle.

APPENDIX 1 (recommended). Symbol diagram for bolts, screws, studs and nuts

The symbol for bolts, screws, studs and nuts should be written according to the following scheme:

Examples of symbols for fasteners. Screw - according to GOST 17473, accuracy class A, version 2, thread diameter d=12 mm with fine thread pitch, with thread tolerance 6e, length l=60, strength class 5.8, made of mild steel with zinc coating 9 microns thick, chromated

Screw A2M12 x 1.25-6e x 60.58.S.019GOST 17473-80

Nut - according to GOST 5916-70 version 2, thread diameter d=12 mm, with fine thread pitch, left-hand thread, with a tolerance range of 6H, strength class 05, made of steel grade 40X, with a zinc coating 6 microns thick, chromated

Nut 2М12×1.25LH-6Н.05.40Х.016 GOST 5916-70

Notes:

1. The symbol does not indicate:

- version 1, large thread pitch, right-hand thread, lack of coating, as well as parameters clearly defined by product standards;

- accuracy class B, if the standard for a specific fastener provides for 2 accuracy classes (A and B).

2. If a coating not provided for by this standard is used, its designation is indicated in accordance with GOST 9.306-85.

Bolt GOST 7798-70 high-strength with hex head: bolt m6, m8, m10, m12, m16, m20, m24

| Catalog / high-strength bolt GOST 7798-70: bolts m8, m10, m12, m16, m20, m24, m27, m30 |

Bolt GOST 7798-70 with a hexagonal head of accuracy class B with a thread diameter from 6 to 48 is most often used in mechanical engineering, industry and construction as connection parts.

The high-strength bolt GOST 7798-70 works reliably in aggressive environments, under high-temperature loads and at low temperatures. May have a thread with a fine or large pitch.

BSR bolts are used to secure parts of building structures, pipelines, and equipment to concrete, reinforced concrete and brick structures of buildings and structures.

The most widely used bolts are M6, M8, M10, M12, M16, M20, type 1. Types 2 and 3 are made to order.

The material for the manufacture of bolts in accordance with GOST 7798-70 using the cold heading method on machines with thread rolling uses steel wire with increased manufacturing precision. Requirements for wire diameter depend on the model of the press machine and the design of the bolt.

Hole bolts having a tensile strength of 800MPa and above are called high-strength. They perceive high static and dynamic stresses. The material for this fastener is 40X steel. It is used in metallurgy, in the chemical, pharmaceutical industries, for work in the Far North and in all cases where it is necessary to ensure high joint strength.

Bolt size range: bolt M6, M8, M10, M12, M16, M20, M24, M27, M30, M36, M42, M48, M52.

Bolt GOST 7798-70 is a foreign analogue of GOST 7805-70 or DIN 931, ISO 4014.

DIN 933 - full thread.

Bolt drawing GOST 7798 70:

Steel grade and main bolt dimensions. Bolt GOST 7798-70 m6, m8, m10, m12, m16, m20, m24 with hex head.

| NTD | GOST 7798-70 |

| Size range | bolt M6 - M48 |

| Accuracy class | IN |

| Thread tolerance field | 6g |

| Strength class | 3.6 4.6 4.8 5.6 5.8 6.6 8.8 10.9 |

| steel grade | 10kp 20kp 10,20,35 20G2R |

Hex bolt GOST 7798-70. Buy a construction bolt.

| d | M8 bolt | M10 bolt | M12 bolt | M16 bolt | M20 bolt | bolt M22 | bolt M24 | M27 bolt | bolt M30 |

| Thread pitch | 1,25 | 1,5 | 1,75 | 2 | 2,5 | 2,5 | 3 | 3 | 3,5 |

| k | 5,3 | 6,4 | 7,5 | 10 | 12,5 | 14 | 15 | 17 | 18,7 |

| b* | 22 | 26 | 30 | 38 | 46/52 | 50/56 | 54/60 | 60/66 | 66/72 |

| S | 13 | 17 | 19 | 24 | 30 | 32 | 36 | 41 | 46 |

| e, min | 14,2 | 18,7 | 20,9 | 26,2 | 30 | 35 | 39,6 | 45,2 | 50,9 |

| L | 20-70 | 25-90 | 25-90 | 30-120 | 50-150 | 60-150 | 60-150 | 80-200 | 80-200 |

Hex bolt GOST 7798-70. Bolt weight GOST 7798 70. Theoretical weight of 1000 pieces of bolts (in kg).

| Length, mm | Theoretical weight 1000 pcs. bolts kg with nominal thread diameter d , mm | ||||||||||||||

| M6 | M8 | M10 | M12 | M14 | M16 | M18 | M20 | M22 | M24 | M27 | M30 | M36 | M42 | M48 | |

| 8 | 4,306 | 8,668 | — | — | — | — | — | — | — | — | — | — | — | — | — |

| 10 | 4,712 | 9,394 | 16,68 | — | — | — | — | — | — | — | — | — | — | — | — |

| 12 | 5,118 | 10,120 | 17,82 | — | — | — | — | — | — | — | — | — | — | — | — |

| 14 | 5,524 | 10,850 | 18,96 | 27,89 | — | — | — | — | — | — | — | — | — | — | — |

| 16 | 5,930 | 11,570 | 20,10 | 29,48 | 43,98 | — | — | — | — | — | — | — | — | — | — |

| 18 | 6,336 | 12,300 | 21,23 | 31,12 | 46,21 | 65,54 | — | — | — | — | — | — | — | — | — |

| 20 | 6,742 | 13,020 | 22,37 | 32,76 | 48,45 | 68,49 | 95,81 | — | — | — | — | — | — | — | — |

| 22 | 7,204 | 13,520 | 23,51 | 34,40 | 50,69 | 71,44 | 99,52 | — | — | — | — | — | — | — | — |

| 25 | 7,871 | 14,840 | 25,22 | 36,86 | 54,05 | 75,87 | 105,10 | 133,3 | — | — | — | — | — | — | — |

| 28 | 8,537 | 16,330 | 26,92 | 39,32 | 57,40 | 80,29 | 110,60 | 140,2 | — | — | — | — | — | — | — |

| 30 | 8,981 | 17,120 | 28,52 | 40,96 | 59,64 | 83,24 | 114,30 | 144,8 | 193,0 | — | — | — | — | — | — |

| 32 | 9,426 | 17,910 | 29,43 | 42,59 | 61,87 | 86,19 | 118,00 | 149,4 | 198,6 | 237,0 | — | — | — | — | — |

| 35 | 10,090 | 19,090 | 31,28 | 45,34 | 65,24 | 90,62 | 123,60 | 156,3 | 207,0 | 246,9 | 340,6 | — | — | — | — |

| 38 | 10,760 | 20,280 | 33,18 | 48,00 | 68,59 | 95,04 | 129,20 | 163,2 | 215,4 | 256,9 | 353,3 | — | — | — | — |

| 40 | 11,200 | 21,070 | 34,36 | 49,78 | 71,25 | 97,99 | 132,90 | 167,8 | 221,0 | 263,5 | 361,8 | 474,8 | — | — | — |

| 45 | 12,310 | 23,040 | 37,45 | 54,22 | 77,30 | 105,70 | 142,10 | 179,4 | 235,0 | 280,1 | 373,0 | 500,9 | — | — | — |

| 50 | 13,420 | 25,020 | 40,53 | 58,67 | 83,35 | 113,60 | 152,40 | 190,9 | 249,0 | 296,7 | 404,1 | 526,9 | 834,5 | — | — |

| 55 | 14,530 | 26,990 | 43,62 | 63,11 | 89,39 | 121,50 | 162,40 | 203,7 | 263,1 | 313,3 | 425,3 | 553,0 | 872,1 | 1304 | — |

| 60 | 15,640 | 28,970 | 46,70 | 67,55 | 95,44 | 129,40 | 172,40 | 216,0 | 278,9 | 329,9 | 446,5 | 579,0 | 909,8 | 1356 | — |

| 65 | 16,760 | 30,940 | 49,79 | 71,99 | 101,50 | 137,30 | 182,40 | 228,4 | 293,8 | 348,8 | 467,7 | 605,1 | 947,4 | 1407 | 2009 |

| 70 | 17,870 | 32,910 | 52,87 | 76,44 | 107,50 | 145,20 | 192,40 | 240,7 | 308,8 | 366,5 | 491,1 | 631,1 | 985,0 | 1458 | 2076 |

| 75 | 18,980 | 34,890 | 55,96 | 80,88 | 113,60 | 153,10 | 202,40 | 253,0 | 323,7 | 384,3 | 513,6 | 659,7 | 1023,0 | 1509 | 2143 |

| 80 | 20,090 | 36,860 | 59,04 | 85,33 | 119,60 | 161,00 | 212,40 | 265,0 | 338,6 | 402,1 | 536,1 | 687,5 | 1061,0 | 1561 | 2211 |

| 85 | 21,200 | 38,840 | 62,13 | 89,77 | 125,70 | 168,90 | 222,40 | 277,7 | 353,6 | 419,8 | 558,6 | 715,2 | 1098,0 | 1612 | 2278 |

| 90 | 22,310 | 40,810 | 65,21 | 94,20 | 131,70 | 176,80 | 232,40 | 290,1 | 368,5 | 437,6 | 581,0 | 743,0 | 1141,0 | 1663 | 2345 |

| 95 | — | 42,790 | 68,30 | 98,64 | 137,80 | 184,70 | 242,40 | 302,4 | 383,4 | 455,4 | 603,5 | 770,8 | 1181,0 | 1715 | 2412 |

| 100 | — | 44,760 | 71,38 | 103,10 | 143,80 | 192,60 | 252,40 | 314,7 | 398,3 | 473,2 | 626,0 | 798,5 | 1221,0 | 1766 | 2479 |

| 105 | — | — | 74,47 | 107,50 | 149,90 | 200,50 | 262,40 | 327,1 | 413,3 | 490,9 | 648,5 | 826,3 | 1261,0 | 1826 | 2546 |

| 110 | — | — | 77,55 | 112,00 | 155,90 | 208,40 | 272,30 | 339,4 | 428,2 | 508,7 | 671,0 | 854,1 | 1301,0 | 1880 | 2614 |

| 115 | — | — | 80,63 | 116,40 | 162,00 | 216,30 | 282,30 | 351,8 | 443,1 | 526,5 | 693,5 | 881,8 | 1341,0 | 1934 | 2690 |

| 120 | — | — | 83,72 | 120,90 | 168,00 | 224,20 | 292,30 | 364,1 | 458,1 | 544,2 | 716,0 | 909,6 | 1381,0 | 1989 | 2760 |

| 125 | — | — | 86,80 | 125,30 | 174,00 | 232,10 | 302,30 | 376,4 | 473,0 | 562,0 | 738,5 | 937,4 | 1421,0 | 2043 | 2831 |

| 130 | — | — | 89,89 | 129,70 | 180,10 | 240,00 | 312,30 | 388,8 | 487,9 | 579,8 | 761,0 | 965,2 | 1461,0 | 2098 | 2903 |

| 140 | — | — | 96,06 | 138,60 | 192,20 | 255,80 | 332,30 | 413,5 | 517,8 | 615,3 | 806,0 | 1021,0 | 1541,0 | 2207 | 3045 |

| 150 | — | — | 102,18 | 147,50 | 204,30 | 271,60 | 352,30 | 438,1 | 547,6 | 650,8 | 850,1 | 1076,0 | 1621,0 | 2315 | 3187 |

| 160 | — | — | 108,38 | 156,40 | 216,40 | 287,40 | 372,30 | 462,8 | 577,5 | 686,4 | 895,9 | 1132,0 | 1701,0 | 2424 | 3329 |

| 170 | — | — | 114,58 | 165,30 | 228,50 | 303,20 | 392,30 | 487,5 | 607,4 | 721,9 | 940,9 | 1188,0 | 1780,0 | 2533 | 3471 |

| 180 | — | — | 120,68 | 174,20 | 240,60 | 319,00 | 412,30 | 512,2 | 637,2 | 757,5 | 985,9 | 1243,0 | 1860,0 | 2642 | 3614 |

| 190 | — | — | 126,88 | 183,10 | 252,70 | 333,80 | 432,30 | 536,9 | 667,1 | 793,0 | 1031,0 | 1299,0 | 1940,0 | 2751 | 3756 |

| 200 | — | — | 133,08 | 191,90 | 264,70 | 350,60 | 452,20 | 561,5 | 697,0 | 828,6 | 1076,0 | 1354,0 | 2020,0 | 2860 | 3898 |

| 220 | — | — | — | 209,70 | 228,90 | 382,20 | 492,20 | 610,9 | 756,7 | 899,6 | 1166,0 | 1465,0 | 2180,0 | 3077 | 4182 |

| 240 | — | — | — | 227,50 | 313,10 | 413,80 | 532,20 | 660,3 | 816,4 | 970,8 | 1256,0 | 1576,0 | 2340,0 | 3295 | 4466 |

| 260 | — | — | — | 245,20 | 337,60 | 445,40 | 572,20 | 709,6 | 876,1 | 1042,0 | 1346,0 | 1687,0 | 2500,0 | 3513 | 4751 |

| 280 | — | — | — | — | 361,50 | 476,90 | 612,20 | 759,0 | 935,9 | 1113,0 | 1436,0 | 1798,0 | 2660,0 | 3730 | 5035 |

| 300 | — | — | — | — | 385,70 | 508,50 | 652,20 | 808,3 | 995,6 | 1184,0 | 1526,0 | 1910,0 | 2820,0 | 3948 | 5319 |

The thread length indicated in the denominator is for bolts with a length greater than 120.

It is possible to supply high-strength bolts in accordance with GOST 7798-70 in sizes from M6 to M24, strength classes 8.8, 10.9, made of steel 20G2R.

Example of a symbol:

Bolt GOST 7798-70 version 1 with thread diameter d

=8 mm, with a turnkey size

S

=13 mm, length

l

=60 mm, with a large thread pitch with a tolerance range of

6g

, strength class 5.8, uncoated:

Bolt M8 - 6gx60.58 (S13) GOST 7798-70

Bolt 7798-70 version 2 with thread diameter d

=10 mm, with a turnkey size

S

=16 mm, with a fine thread pitch with a tolerance range of

6g

, strength class 10.9, made of steel grade 40X, with coating 01 6 microns thick:

Bolt 2М10х1.25 - 6gх60.109.40Х.016 GOST 7798-70

Bolt GOST 7798-70 version 3 with thread diameter d

=12 mm, with a turnkey size

S

=18 mm, length

l

=60 mm, with a large thread pitch with a tolerance range of

6g

, strength class 5.8, uncoated:

Bolt 3M12 - 6gx60.58 (S18) GOST 7798-70

Bolt 7798 version 1 with thread diameter d

=16 mm, with turnkey size

S

=24 mm, with fine thread pitch with a tolerance range of

6g

, strength class 10.9, made of steel grade 40X, with coating 01 6 microns thick:

Bolt M16x1.25 - 6gx60.109.40X.016 GOST 7798-70

Bolt GOST 7798 version 2 with thread diameter d

=20 mm, with a turnkey size

S

=30 mm, length

l

=60 mm, with a large thread pitch with a tolerance range of

6g

, strength class 5.8, uncoated

Bolt 2M20 - 6gx60.58 (S30) GOST 7798-70

Sale of bolts: M6, M8, M10, M12, M16, M20, M24, M27, M30, M36, M42, M48, M52 of various lengths from 0.05 tons.

How to buy bolts GOST 7798-70: bolts m8, m10, m12, m16, m20, m24 at low prices:

- fill out the simple “Place an order” form at the top of the page;

- call on the phone +7;

- send your application by email;

Delivery of GOST 7798-70 bolts throughout the Russian Federation: Moscow, St. Petersburg, Arkhangelsk, Astrakhan, Barnaul, Belgorod, Bryansk, Vladimir, Volgograd, Vologda, Voronezh, Yekaterinburg, Ivanovo, Izhevsk, Yoshkar-Ola, Kazan, Kaluga, Kirov, Kostroma , Krasnodar, Kurgan, Kursk, Lipetsk, Omsk, Orenburg, Penza, Perm, Pskov, Rostov-on-Don, Ryazan, Samara, Saransk, Saratov, Sevastopol, Simferopol, Smolensk, Stavropol, Tambov, Tver, Tomsk, Tula, Tyumen , Ulyanovsk, Ufa, Chelyabinsk, Yaroslavl, etc.

The information presented on this website contains a catalog of reference information on more than 3,000 types of metal products, is for informational purposes only, and can be used in various areas of enterprise activity.

| Steel wire Welding electrodes Steel rope Fasteners | Metal mesh Hex bolts Nut GOST, DIN Steel rivets | Adjustable cotter pins GOST, DIN washers Threaded rods Calibrated rolled products | Slings, rigging Construction nails Steel cable Screws GOST, DIN |

APPENDIX 2 (mandatory)

Table 7

Minimum breaking loads for coarse pitch bolts, screws and studs

| Nominal thread diameter d, mm | Thread pitch P, mm | Nominal cross-sectional areaAs, mm² | Minimum breaking load, H, for group symbols | ||||||||

| 21 | 22 | 23 | 24; 25 | 26 | 31 | 32; 33 | 34 | 35 | |||

| 4 | 0,7 | 8,78 | 4470 | 5170 | 6050 | 7720 | 9470 | 2280 | 2720 | 4290 | 3240 |

| 5 | 0,8 | 14,2 | 7240 | 8380 | 9800 | 12500 | 15300 | 3690 | 4400 | 6960 | 5250 |

| 6 | 1 | 20,1 | 10300 | 11900 | 13900 | 17700 | 21700 | 5230 | 6230 | 9850 | 7440 |

| 7 | 1 | 28,9 | 14700 | 17000 | 19900 | 25300 | 31100 | 7500 | 8900 | 14100 | 10660 |

| 8 | 1,25 | 36,6 | 18700 | 21600 | 25300 | 32200 | 39500 | 9520 | 11300 | 17900 | 13500 |

| 10 | 1,5 | 58,0 | 30100 | 34800 | 40700 | 51900 | 63700 | 15100 | 18000 | 28400 | 21500 |

| 12 | 1,75 | 84,3 | 42900 | 49700 | 58100 | 74100 | 90900 | 21900 | 26100 | 41300 | 31200 |

| 14 | 2 | 115 | 58700 | 67900 | 79400 | 101000 | 124000 | 29900 | 35700 | 56400 | 42600 |

| 16 | 2 | 157 | 80100 | 92600 | 108000 | 138000 | 170000 | 40800 | 48700 | 76900 | 58100 |

| 18 | 2,5 | 192 | 97900 | 113000 | 132000 | 169000 | 207000 | 49900 | 52500 | 94100 | 71000 |

| 20 | 2,5 | 245 | 125000 | 145000 | 169000 | 216000 | 265000 | 63700 | 76000 | 120000 | 90700 |

| 22 | 2,5 | Z0Z | 155000 | 179000 | 209000 | 267000 | 327000 | 78800 | 93900 | 148000 | 112000 |

| 24 | 3 | 353 | 176000 | 208000 | 243000 | 310000 | 380000 | 91500 | 109000 | 172000 | 130000 |

| 27 | 3 | 459 | 234000 | 271000 | 317000 | 404000 | 496000 | 119000 | 142000 | 225000 | 170000 |

| 30 | 3,5 | 561 | 286000 | 330000 | 386000 | 493000 | 605000 | 146000 | 174000 | 274000 | 207000 |

| 33 | 3,5 | 694 | 353000 | 410000 | 478000 | 610000 | 748000 | 180000 | 215000 | 340000 | 256000 |

| 36 | 4 | 817 | 416000 | 480000 | 563000 | 718000 | 881000 | 212000 | 253000 | 400000 | 302000 |

| 39 | 4 | 976 | 497000 | 575000 | 673000 | 860000 | 1053000 | 253500 | 302000 | 478000 | 361000 |

| 42 | 4,5 | 1120 | 571000 | 661000 | 773000 | 986000 | 1210000 | 291000 | 347000 | 549000 | 414000 |

| 45 | 4,5 | 1306 | 666000 | 770000 | 901000 | 1150000 | 1410000 | 339600 | 405000 | 640000 | 483000 |

| 48 | 5 | 1472 | 751000 | 868000 | 1020000 | 1300000 | 1590000 | 383000 | 456000 | 721000 | 545000 |

Table 8

Minimum breaking loads for fine pitch bolts, screws and studs

| Nominal thread diameter d, mm | Thread pitch P, mm | Nominal cross-sectional area As, mm² | Minimum breaking load, H, for group symbols | ||||||||

| 21 | 22 | 23 | 24; 25 | 26 | 32; 33 | 34 | 35 | ||||

| 8 | 1 | 39,2 | 19900 | 23100 | 27000 | 34400 | 42200 | 10200 | 12100 | 19200 | 14500 |

| 10 | 1,25 | 61,2 | 31200 | 36100 | 42200 | 53900 | 66100 | 15900 | 19000 | 30000 | 22600 |

| 12 | 1,25 | 92,1 | 46900 | 54300 | 63500 | 81000 | 99400 | 23900 | 28500 | 45100 | 34000 |

| 14 | 1,5 | 125 | 63200 | 73200 | 85600 | 109000 | 134000 | 32200 | 38400 | 60800 | 45900 |

| 16 | 1,5 | 167 | 85200 | 98500 | 115000 | 147000 | 180000 | 43400 | 51800 | 81800 | 61800 |

| 18 | 1,5 | 216 | 110000 | 127000 | 149000 | 190000 | 233000 | 56200 | 67000 | 106000 | 79900 |

| 20 | 1,5 | 272 | 138000 | 160000 | 187000 | 238000 | 293000 | 70500 | 84000 | 133000 | 100000 |

| 22 | 1,5 | 333 | 170000 | 196000 | 230000 | 293000 | 360000 | 86600 | 103000 | 163000 | 123000 |

| 24 | 2 | 384 | 196000 | 227000 | 265000 | 338000 | 415000 | 998000 | 119000 | 188000 | 142000 |

| 27 | 2 | 496 | 252000 | 292000 | 342000 | 436000 | 535000 | 129000 | 153000 | 243000 | 183000 |

| 30 | 2 | 621 | 317000 | 366000 | 428000 | 546000 | 671000 | 161000 | 193000 | 304000 | 230000 |

| 33 | 2 | 761 | 388000 | 449000 | 525000 | 670000 | 822000 | 198000 | 236000 | 373000 | 282000 |

| 36 | 3 | 865 | 441000 | 510000 | 596000 | 760000 | 933000 | 225000 | 268000 | 423000 | 320000 |

| 39 | 3 | 1030 | 525000 | 608000 | 711000 | 906000 | 1112000 | 268000 | 319000 | 505000 | 381000 |

| 42 | 3 | 1205 | 615000 | 711000 | 830000 | 1060000 | 1300000 | 313000 | 374000 | 590000 | 446000 |

| 45 | 3 | 1400 | 714000 | 826000 | 966000 | 1232000 | 1512000 | 364000 | 434000 | 686000 | 518000 |

| 48 | 3 | 1603 | 818000 | 946000 | 111000* | 1411000 | 1731000 | 417000 | 497000 | 785000 | 593000 |

* Corresponds to the original.

APPENDIX 3 (mandatory)

Table 9

Proof load for nuts with height m ≥ 0.8d and coarse thread pitch

| Nominal thread diameter d, mm | Thread pitch P, mm | Cross-sectional area of the mandrelAs, mm² | Test load, H, for group symbols | ||||||||

| 22 | 23 | 24; 25 | 26 | 31 | 32; 33 | 34 | 35 | ||||

| 1,6 | 0,35 | 1,27 | 650 | 750 | 880 | 1120 | 1370 | 330 | 390 | 620 | 470 |

| 2 | 0,4 | 2,07 | 1060 | 1220 | 1430 | 1820 | 2240 | 540 | 640 | 1010 | 770 |

| 2,5 | 0,45 | 3,39 | 1730 | 2000 | 2340 | 2980 | 3660 | 880 | 1050 | 1660 | 1250 |

| 3 | 0,5 | 5,03 | 2570 | 2970 | 3470 | 4430 | 5430 | 1310 | 1560 | 2460 | 1860 |

| 3,5 | 0,6 | 6,78 | 3450 | 3990 | 4670 | 5960 | 7310 | 1760 | 2100 | 3320 | 2500 |

| 4 | 0,7 | 8,78 | 4470 | 5170 | 6050 | 7720 | 9470 | 2280 | 2720 | 4300 | 3240 |

| 5 | 0,8 | 14,2 | 7240 | 8380 | 9800 | 12500 | 15300 | 3690 | 4400 | 6960 | 5250 |

| 6 | 1 | 20,1 | 10300 | 11900 | 13900 | 17700 | 21700 | 5230 | 6230 | 9850 | 7440 |

| 7 | 1 | 28,9 | 14700 | 17000 | 19900 | 25300 | 31100 | 7490 | 8930 | 14100 | 10700 |

| 8 | 1,25 | 36,6 | 18700 | 21600 | 25300 | 32200 | 39500 | 9520 | 11300 | 17900 | 13500 |

| 10 | 1,5 | 58,0 | 29600 | 34200 | 40000 | 51000 | 62600 | 15100 | 18000 | 28400 | 21500 |

| 12 | 1,75 | 84,3 | 49200 | 49700 | 58100 | 74100 | 90900 | 21900 | 26100 | 41300 | 31200 |

| 14 | 2 | 115 | 587000 | 67900 | 79400 | 101000 | 124000 | 29900 | 35700 | 56400 | 42600 |

| 16 | 2 | 157 | 80100 | 92600 | 108000 | 138000 | 170000 | 40800 | 48700 | 76900 | 58100 |

| 18 | 2,5 | 192 | 97900 | 113000 | 132000 | 169000 | 207000 | 49900 | 59500 | 94100 | 71000 |

| 20 | 2,5 | 245 | 125000 | 145000 | 169000 | 216000 | 265000 | 63700 | 76000 | 120000 | 90700 |

| 22 | 2,5 | 303 | 155000 | 179000 | 209000 | 267000 | 327000 | 78800 | 93900 | 148000 | 112000 |

| 24 | 3 | 353 | 180000 | 208000 | 243000 | 310000 | 380000 | 91500 | 109000 | 172000 | 130000 |

| 27 | 3 | 459 | 234000 | 271000 | 317000 | 404000 | 496000 | 119000 | 142000 | 225000 | 170000 |

| 30 | 3,5 | 561 | 286000 | 330000 | 386000 | 493000 | 605000 | 146000 | 174000 | 274000 | 207000 |

| 33 | 3,5 | 694 | 353000 | 409000 | 478000 | 610000 | 748000 | 180000 | 215000 | 340000 | 256000 |

| 36 | 4 | 817 | 416000 | 480000 | 563000 | 718000 | 881000 | 212000 | 253000 | 400000 | 302000 |

| 39 | 4 | 976 | 497000 | 575000 | 673000 | 858000 | 1053000 | 254000 | 302000 | 478000 | 361000 |

| 42 | 4,5 | 1120 | 571000 | 661000 | 773000 | 986000 | 1210000 | 291000 | 347000 | 549000 | 414000 |

| 45 | 4,5 | 1305 | 666000 | 770000 | 900000 | 1148000 | 1409000 | 339000 | 405000 | 640000 | 483000 |

| 48 | 5 | 1472 | 751000 | 868000 | 1016000 | 1296000 | 1590000 | 383000 | 456000 | 721000 | 545000 |

Table 10

Test loads for nuts height m ≥ 0.8d with fine thread pitch

| Nominal thread diameter d, mm | Thread pitch P, mm | Cross-sectional area of the mandrelAs, mm² | Test load, H, for group symbols | ||||||||

| 21 | 22 | 23 | 24; 25 | 26 | 31 | 32; 33 | 34 | 35 | |||

| 8 | 1 | 39,2 | 19900 | 23100 | 27000 | 34400 | 42200 | 10200 | 12100 | 19200 | 14500 |

| 10 | 1 | 64,5 | 32900 | 38100 | 44500 | 56800 | 69700 | 16800 | 20000 | 31600 | 23900 |

| 10 | 1,25 | 61,2 | 31200 | 36100 | 42200 | 53900 | 66100 | 15900 | 19000 | 30000 | 22600 |

| 12 | 1,25 | 92,1 | 46900 | 54300 | 63500 | 81000 | 99400 | 23900 | 28500 | 45100 | 34000 |

| 12 | 1,5 | 88,1 | 44900 | 52000 | 60800 | 77500 | 95100 | 22900 | 27300 | 43200 | 32600 |

| 14 | 1,5 | 125 | 63200 | 73200 | 85600 | 109000 | 134000 | 32200 | 38400 | 60800 | 45900 |

| 16 | 1,5 | 167 | 85200 | 98500 | 115000 | 147000 | 180000 | 43400 | 51800 | 81800 | 61800 |

| 18 | 1,5 | 216 | 110000 | 127000 | 149000 | 190000 | 233000 | 56200 | 67000 | 106000 | 79900 |

| 18 | 2 | 204 | 104000 | 120000 | 141000 | 180000 | 220000 | 53000 | 63200 | 100000 | 75500 |

| 20 | 1,5 | 272 | 138000 | 100000 | 187000 | 238000 | 293000 | 70500 | 84000 | 133000 | 100000 |

| 20 | 2 | 258 | 132000 | 152000 | 178000 | 227000 | 279000 | 67100 | 80000 | 126000 | 95500 |

| 22 | 1,5 | 333 | 170000 | 196000 | 230000 | 293000 | 360000 | 86600 | 103000 | 163000 | 123000 |

| 22 | 2 | 318 | 162000 | 188000 | 219000 | 280000 | 343000 | 82700 | 98600 | 156000 | 118000 |

| 24 | 1,5 | 401 | 205000 | 237000 | 277000 | 353000 | 433000 | 104000 | 124000 | 196000 | 148000 |

| 24 | 2 | 384 | 196000 | 327000 | 265000 | 338000 | 415000 | 99800 | 119000 | 188000 | 142000 |

| 27 | 2 | 496 | 252000 | 292000 | 342000 | 436000 | 535000 | 129000 | 153000 | 243000 | 183000 |

| 30 | 2 | 621 | 317000 | 366000 | 428000 | 546000 | 671000 | 161000 | 193000 | 304000 | 230000 |

| 33 | 2 | 761 | 388000 | 448000 | 524000 | 669000 | 821000 | 198000 | 236000 | 372000 | 281000 |

| 36 | 3 | 865 | 441000 | 510000 | 596000 | 760000 | 933000 | 225000 | 268000 | 423000 | 320000 |

| 39 | 3 | 1030 | 524000 | 607000 | 709000 | 905000 | 1105000 | 266000 | 317000 | 501000 | 379000 |

| 42 | 3 | 1205 | 615000 | 711000 | 831000 | 1060000 | 1301000 | 313000 | 374000 | 590000 | 446000 |

| 45 | 3 | 1397 | 712000 | 824000 | 964000 | 1229000 | 1509000 | 363000 | 433000 | 685000 | 517000 |

| 48 | 3 | 1603 | 818000 | 946000 | 1122000 | 1411000 | 1731000 | 417000 | 497000 | 785000 | 593000 |

APPENDIX 4 (mandatory)

Table 11

Test loads for coarse thread bolts, screws and studs

| Nominal thread diameter d, mm | Thread pitch P, mm | Nominal cross-sectional areaAs, mm² | Test load, H, for group symbols | ||||

| 21 | 22 | 23; 24 | 25 | 26 | |||

| 4 | 0,70 | 8,78 | 1540 | 2720 | 4260 | 5790 | 6590 |

| 5 | 0,80 | 14,20 | 2490 | 4400 | 6890 | 9370 | 10700 |

| 6 | 1,00 | 20,10 | 3520 | 6230 | 9760 | 13300 | 15100 |

| 7 | 1,00 | 28,90 | 5068 | 8960 | 14000 | 19100 | 21700 |

| 8 | 1,25 | 36,60 | 6410 | 11300 | 17800 | 24200 | 27500 |

| 10 | 1,50 | 58,00 | 10200 | 18000 | 28100 | 38300 | 43500 |

| 12 | 1,75 | 84,30 | 14800 | 26100 | 40900 | 55600 | 63200 |

| 14 | 2,00 | 115,00 | 20100 | 35700 | 55800 | 75900 | 86300 |

| 16 | 2,00 | 157,00 | 27500 | 48700 | 76100 | 104000 | 118000 |

| 18 | 2,50 | 192,00 | 33600 | 59500 | 93100 | 127000 | 144000 |

| 20 | 2,50 | 245,00 | 42900 | 76000 | 119000 | 162000 | 184000 |

| 22 | 2,50 | 303,00 | 53000 | 93900 | 147000 | 200000 | 227000 |

| 24 | 3,00 | 353,00 | 61800 | 109000 | 171000 | 233000 | 265000 |

| 27 | 3,00 | 459,00 | 80300 | 142000 | 223000 | 303000 | 344000 |

| 30 | 3,50 | 561,00 | 98000 | 174000 | 272000 | 370000 | 421000 |

| 33 | 3,50 | 694,00 | 121000 | 215000 | 337000 | 458000 | 521000 |

| 36 | 4,00 | 817,00 | 143000 | 253000 | 396000 | 539000 | 613000 |

| 39 | 4,00 | 976,00 | 171000 | 303000 | 473000 | 644000 | 732000 |

| 42 | 4,50 | 1120,00 | 196000 | 347000 | 540000 | 739000 | 840000 |

| 45 | 4,50 | 1306,00 | 229000 | 405000 | 633000 | 862000 | 980000 |

| 48 | 5,00 | 1472,00 | 258000 | 456000 | 714000 | 972000 | 1104000 |

Table 12

Test loads for bolts, screws and studs with fine threads

| Nominal thread diameter d, mm | Thread pitch P, mm | Nominal cross-sectional areaAs, mm² | Test load, H, for group symbols | ||||

| 21 | 22 | 23; 24 | 25 | 26 | |||

| 8 | 1,00 | 39,2 | 6840 | 12200 | 19000 | 25800 | 29400 |

| 10 | 1,25 | 61,2 | 10700 | 19000 | 29700 | 40400 | 45900 |

| 12 | 1,25 | 92,1 | 16100 | 28600 | 44700 | 60800 | 69000 |

| 14 | 1,50 | 125,0 | 21900 | 38800 | 60600 | 82500 | 93800 |

| 16 | 1,50 | 167,0 | 29200 | 51800 | 81000 | 110000 | 125000 |

| 18 | 1,50 | 216,0 | 37800 | 67000 | 105000 | 143000 | 162000 |

| 20 | 1,50 | 272,0 | 47600 | 84000 | 132000 | 179000 | 204000 |

| 22 | 1,50 | 333,0 | 58300 | 103000 | 162000 | 220000 | 250000 |

| 24 | 2,00 | 384,0 | 67200 | 119000 | 186000 | 253000 | 288000 |

| 27 | 2,00 | 496,0 | 86800 | 154000 | 241000 | 327000 | 372000 |

| 30 | 2,00 | 621,0 | 109000 | 193000 | 301000 | 410000 | 466000 |

| 33 | 2,00 | 761,0 | 133000 | 236000 | 369000 | 502000 | 571000 |

| 36 | 3,00 | 865,0 | 151000 | 268000 | 419000 | 571000 | 649000 |

| 39 | 3,00 | 1030,0 | 180000 | 319000 | 500000 | 680000 | 773000 |

| 42 | 3,00 | 1205,0 | 211000 | 374000 | 584000 | 795000 | 904000 |

| 45 | 3,00 | 1400,0 | 245000 | 434000 | 679000 | 924000 | 1050000 |

| 48 | 3,00 | 1603,0 | 281000 | 497000 | 777000 | 1058000 | 1202000 |