In technology, pressing is one of the methods of processing metals by pressure. It is a process in which a workpiece heated to a high temperature, placed in a closed mold, is extruded through a hole that has a smaller cross-section than that of the original workpiece. Pressing makes it possible to produce products of various cross-sections and complex profiles. The starting material for this technological process is most often rolled steel billets or ingots of non-ferrous metals and their alloys.

Among the advantages of those products for the production of which pressing , it should be noted the high accuracy of geometric dimensions. In this respect, they are much superior to products produced by rolling.

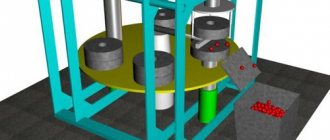

Pressing in molds

Pressing in molds is the most common due to the fact that it produces parts that are practically not subject to mechanical processing.

Pressing in molds can be one-sided or two-sided. Single-sided pressing is used in the manufacture of products of simple configuration, in which the ratio of length or height to diameter or thickness does not exceed 3.

The dimensions of the pressed product in the direction perpendicular to the direction of pressing are determined by the dimensions of the mold cavity and are stable for a given mold. The size in the pressing direction (height) can change with each subsequent pressing.

Obtaining a product of a given height can be ensured either by pressing using height limiters (the so-called pressing to the stop), when the stroke of the press plunger is limited by special limiters, or by monitoring the pressing pressure using an indicator or pressure gauge. Pressing to the stop ensures high productivity and the production of products with dimensions that depend on fluctuations in the characteristics of the powder due to the influence of the latter on the elastic aftereffect. The pressure pressing method is based on the existence of an exact correspondence between the applied pressure and the density of the compressed briquette for each type of powder.

The pressing operation, due to its specific features, imposes restrictions on the shape and size of the pressed products. For example, it is impossible to obtain products with side depressions, which have to be produced by additional machining. Holes perpendicular to the direction of pressing must be drilled after pressing and sintering operations.

The most common types of defects in pressed briquettes are delamination cracks (delamination) and shedding of edges. The causes of delamination are incorrect pressing mode (high pressing pressure when using non-plastic powders with a large elastic aftereffect), incorrect design of the mold and poorly processed walls, uneven filling of the charge into the matrix cavity and other factors.

When hot pressing, graphite molds or molds made of heat-resistant steel are used. In this case, the pressing process is usually combined with sintering, since the hot pressing temperatures used are 0.5 - 0.8 of Tmelt. main component of the mixture.

Metal pressing technology

Pressure processing is based on the process of plastic deformation using a mold without changing mass. When calculating the size and shape of a body, the law of constancy of volume is used: the volume of the body before and after plastic deformation is assumed to be unchanged. In the form of a formula, it can be represented as follows: V1 = V2 = const (V1 and V2 are the volumes of the body before and after deformation). The shape of the body changes along three main axes, all points move in the direction of least resistance - this principle is called the law of least resistance.

In other words, when the shape of a body freely changes in different directions, the greatest deformation occurs in the direction in which the majority of moving points have minimal resistance.

During pressing, the metal is squeezed out of a closed cavity through a hole, thus producing a rod or pipe with a profile equal to the cross-section of the hole. The starting material is ingots or individual blanks.

Two methods are used for pressing: direct and reverse. In the first case, the press punch moves in the same direction in which the metal flows through the die hole. Whereas with the reverse method, the workpiece is in a blind container, and it remains motionless, and the outflow of material from the hole of the matrix, fixed at the end of the hollow punch, occurs in the opposite direction relative to the movement of the punch with the matrix.

The laws of constant volume and least resistance apply to all methods of metal forming. The law of constant volume is used to determine the dimensions of workpieces, and the law of least resistance is used to understand what dimensions and cross-sectional shape a workpiece with a certain cross-section will receive. Important characteristics of such processing are the presence of a focus and a deformation coefficient.

Recommended reading

- Cutting copper with a laser: advantages and disadvantages of technology

- Types of metal cutting: industrial applications

- Metalworking according to drawings: convenient and profitable

Reverse pressing, when compared with direct pressing, requires less effort and leaves less press residue. But this method also has its drawback - the structure of the cast metal can be traced on the finished rod due to less deformation during the production process. The main advantage of pressed products is the accuracy of their dimensions. It is also important that by pressing metals it is possible to obtain a wide range of products, even with very complex profiles.

Technological process of metal pressing

consists of operations such as:

- preparing the workpiece for processing, that is, cutting, turning on a machine, since the quality and accuracy of the profile depends on the quality of the workpiece surface;

- heating the workpiece and removing scale;

- placing the workpiece in a container;

- pressing;

- finishing of the product, which involves separating the press residue and cutting.

For such processing, hydraulic presses with a vertical or horizontal plunger are used; their capacity is up to 10,000 tons. This process is divided into varieties based on the presence or absence of translational movement of the workpiece relative to the walls of the receiver. Only small areas near the matrix, which are called dead zones, are not taken into account; metal does not move there.

The most common method is, of course, direct flow pressing, which produces solid and hollow products. However, today the reverse (reversed) method, as well as other metal flow schemes, is actively gaining popularity. Each of these methods has its own advantages. Let us assume that the lateral outflow ensures convenient acceptance of the press product and a minimal difference in the mechanical properties of the product in the transverse and longitudinal directions.

Isostatic pressing

Isostatic is called pressing in an elastic shell under the action of all-round compression. If the compressive force is created by a liquid, the pressing is called hydrostatic, and if it is a gas, it is called gasostatic.

During hydrostatic pressing, the powder is poured into a rubber shell, it is placed in the working chamber of a hydrostat, in which the required pressure is created with a liquid using a high-pressure pump.

The liquid can be oil, water, glycerin. With this type of pressing, there is almost no friction of the powder particles against the walls of the shell, since those that are adjacent to the shell move with it. The equality and uniformity of compressive forces in all directions leads to the fact that the lateral pressure is equal to unity. The density of different sections of the resulting compact is almost the same.

The powder in the shell is subjected to vibration before pressure is applied to it to ensure uniform filling density and degassing, since the air present in the pores of the filling will prevent compaction.

Cylinders, pipes, balls and other products are produced by hydrostatic pressing. The disadvantages of hydrostatic pressing include the difficulty of obtaining briquettes with sizes close to the specified ones and the need to use mechanical processing in the manufacture of products of precise shapes and sizes, as well as the low productivity of the process.

Gas-static pressing has not yet become widespread due to the complexity of the designs of pressing devices. It can be carried out at room temperature or at elevated temperatures. Pressing at high temperatures is combined with the sintering process and makes it possible to obtain products of almost any material with a relative density close to theoretical.

Types and methods of metal pressing

Several types of metal pressing are used in production:

1. Cold pressing of metal.

This method is also called impact or cold extrusion; it is the formation of a hollow part by displacing the workpiece material with a punch into the open cavities of the die. This type of processing can be direct, reverse or combined - it all depends on whether the direction of metal flow coincides with the movement of the punch, is opposite to it, or occurs simultaneously in different directions. In addition, there is radial pressing, where the direction of metal flow is perpendicular to the direction of the deforming force.

Cold pressing allows you to produce parts of different shapes. It is considered economically feasible to produce parts with accuracy within 9–11 grades, while the level of surface roughness should be within Ra 2.5–0.63.

As output, rod or profiled blanks or those made from sheets can be used. Extrusion technology is suitable for the manufacture of parts from steel, non-ferrous metals, and their alloys such as cups, sleeves, cartridges, tubes, rollers, bolts, nuts, flywheels, flanges, etc. It is worth noting that steel began to be used for cold pressing of metal relatively recently , since it is much more difficult to extrude than other metals.

2. Direct metal pressing.

This technology involves the coincidence of the directions of extrusion of the press product from the matrix channel and the movement of the press stamp. Direct extrusion is the most commonly used part, allowing the production of solid and hollow parts in a wide range of cross-sections close to the cross-sectional dimensions of the container.

The main feature here is the mandatory movement of metal relative to a stationary container - this can happen without lubrication or with its use. In the first case, a workpiece in the form of an ingot is placed between the container and a press stamp with a press washer, pushed into the container and deposited there, extruded through the matrix channel before the formation of the press sink begins. Next, the almost finished product is removed and the press residue is removed.

Friction forces provide high shear deformations on the surface of the workpiece, which contributes to the renewal of the layers that form the peripheral zones of the profile. As a result, it is possible to produce parts with a high-quality surface, since a large elastic zone of metal is formed in the volume of the workpiece adjacent to the matrix. It virtually eliminates the appearance of defects on the surface of the product from the contact area of the workpiece with the container.

But the direct pressing method is far from ideal; it has disadvantages:

- additional efforts are required to overcome the friction force of the workpiece surface against the walls of the container;

- the uneven structure and mechanical properties of press products are specified, which leads to anisotropy of properties;

- a large volume of press residue is obtained, since it is necessary to remove the weakly formed part of the output end of the press product;

- friction between the deformed workpiece and the parts of the pressing tool leads to rapid wear of the latter.

3. Reverse pressing of metal.

In this case, the directions of metal flow into the matrix and the movement of the press stamp are opposite. The blank is placed between the container and the hollow die, after which it is pushed into the container, upset and extruded through the die channel. Next, the resulting press product is removed, the press residue is separated, the matrix is removed, and the press stamp is returned to its original position.

The ingot does not move relative to the container, so there is practically no friction between them, except for the corner cavity near the matrix - active friction is observed there. Overall, the overall pressing force is reduced because no energy is required to overcome frictional forces.

Compared with direct pressing, the reverse method has the following advantages:

- reduction and constancy of pressing force, since this indicator does not increase due to friction of the surface of the workpiece against the walls of the container;

- higher productivity of the press plant, which is achieved by increasing the flow rate of alloys due to a decrease in deformation unevenness;

- increased yield of a suitable product due to an increase in the length of the workpiece and a reduction in the thickness of the press residue;

- longer service life of the container, since it is not subject to friction with the workpiece;

- increased uniformity of mechanical properties and structure in the longitudinal section of the press product.

The disadvantages of this technology include:

- reduction in the maximum transverse size of the press product and the number of profiles produced in parallel, which is caused by a decrease in the through hole in the matrix block;

- the need for preliminary preparation of the surface of the workpieces by turning or scalping - in this way it is possible to obtain press products with a high-quality surface;

- reduction in the range of manufactured press products, as the cost of the tool set increases and the strength of the matrix unit deteriorates;

- greater consumption of auxiliary cycle time;

- increased complexity of the matrix assembly design;

- reduction in the permissible force on the press stamp, which is associated with its weakening due to the central hole.

4. Hot pressing of metal.

Hot pressing or pressure sintering involves the simultaneous application of pressure and temperature to the carbide mixture. It is worth noting that this technology has been used for quite a long time. It is most successfully used in the production of dies, drawing dies, grinding balls, rolls and projectile cores, since in this way it is possible to produce very hard and wear-resistant products with minimal porosity.

A special carbide mixture of metal powders for pressing is loaded into graphite molds and subjected to a pressure of 70–150 kg/cm2 at +1300...+1600 °C. The matrix is heated by direct passage of current or conductive punches. It is considered most appropriate to use hydraulic pressure for large production volumes and pneumatic pressure for small batches.

During heating of carbide dies, the punches enter the matrix at cobalt sintering temperatures, and final compaction occurs when the liquid phase appears. If sintering temperatures and pressing pressures are too high, part of the liquid phase is squeezed out through the gaps of the mold.

Specialists accurately determine the degree of sintering by monitoring temperature, sintering time and compaction (measuring the movement of the punch). Shaking or pre-pressing makes it possible to avoid excessively high matrices - this way it is possible to load the mold more densely. This treatment uses a ratio of compaction density to sintered product density of 2.5:1 to 2:1.

5. Semi-continuous metal pressing.

The length of the workpiece is selected in accordance with the strength level of the press stamp and the size of the working stroke of the press, which means that pressing can only be done with workpieces of a limited length. It is important to note that each blank is pressed with press residue. This limitation leads to a decrease in the yield of a suitable product and a decrease in press productivity. Let us explain that the yield of suitable products is considered an indicator of efficiency, which corresponds to the ratio of the finished product to the mass of the workpiece.

This drawback can be partially eliminated by giving preference to semi-continuous pressing technology or “blank-by-blank” pressing. This process can take place without lubrication or with lubrication - it all depends on the alloy used and the purpose of the future product.

The peculiarity of semi-continuous technology without lubrication is that each subsequent workpiece is loaded into a container when the previous one is extruded to three-quarters of its length. When using this technique, the workpieces are welded at the ends. The length of the workpiece left in the container is limited, since continued pressing can cause the formation of a press sinker. Loading the next workpiece into the container eliminates the risk of forming a sink cavity, which makes it possible to produce high-quality press products. Theoretically, it is possible to obtain a press product of unlimited length, which depends only on the number of blanks used. Sometimes, when pressing, the product is wound into a coil.

The disadvantage of this method is the low welding strength of elements obtained from individual workpieces. Usually this drawback is associated with the ingress of various contaminants into the press residue. In addition, the welding site can be greatly stretched due to the nature of the metal flow.

6. Continuous metal pressing.

Experts consider the cyclical nature of the process to be a disadvantage of pressing technology, so recently there has been active work on such methods of continuous pressing as “conform”, “extrolling”, “linex”.

At the moment, the most commonly used method in industry is the “conform” method. The peculiarity of the installation used in this case is that in its design the container is formed by the groove surfaces of the movable drive wheel and the protrusion of the fixed insert. The latter is pressed against the wheel by a hydraulic or mechanical device. As a result, the cross section of the container is a closed gauge. Thanks to frictional forces, the workpiece is drawn into the container and fills it. As soon as the stop is reached, the pressure in the workpiece increases to the value necessary to extrude the material through the die channel in the form of a pressed semi-finished product.

The role of the workpiece in continuous pressing technology is played by a rod or ordinary wire, and all operations go on without stopping, namely: deformation processes, that is, drawing into the pressing chamber as the wheel turns, preliminary profiling, filling the groove in the wheel, creating a working force, extrusion.

Powder rolling

Rolling of metal powders involves forming in a rolling mill. The essence of the rolling method is to feed powder into the gap between two rollers rotating towards each other.

By forces of external friction, the powder is drawn into the gap and compacted into a product of sufficient strength to ensure its transportation for sintering. The flow of powder into the rolls can be free, when it enters the deformation zone under the influence of its own mass, and under pressure, when the powder is forced into the rolls using special devices. For example, feeding powder into rolls using a screw device, when the back pressure of the powder in the deformation zone is created due to the difference in the productivity of the screw and the throughput of the rolls.

The thickness and density of the workpiece depend on the chemical and granulometric composition of the powder, the shape of its particles, the pressure of the powder on the rolls, the condition of the surface of the rolls and other factors. When rolling, each particle, depending on the pressing force and the shape of the particles, will have a different degree of deformation and a different density. Spherical particles will deform less than dendritic or needle-shaped particles, and the workpiece made from these particles will have a lower density. In addition, a workpiece made of particles with a highly developed surface has an increased density.

The process of rolling powder from the beginning of its entry into the rolls until it exits the rolls is divided into three periods. In the first period, which is called the initial unsteady period , the workpiece has variable thickness and density, since the density of the powder filling the deformation zone varies in height. When the rolls rotate, deformable powder particles are drawn into the gap between them, which cause a wedging effect, and new portions of powder enter the deformation zone. When the process of entraining and pressing the powder is balanced by the resistance of the mill to elastic deformation, a second period begins, called the steady rolling period, in which the billet emerging from the rolls has a constant density. In the third period, called non-stationary , reverse phenomena occur due to the unloading of the mill rolls.

In the initial and final periods, in parallel with the change in density, the pressure of the powder on the rolls changes and, as a result of elastic deformation of the mill, the thickness of the workpiece changes. In this regard, when rolling powders, they strive to minimize the duration of these periods, and the end sections of the workpieces are subject to trimming, since they are usually non-uniform in density.

The powder can be rolled cold or hot. Rolling at room temperature is the simplest, but less effective than rolling heated powder.

Billets after rolling are usually sintered in continuous furnaces in a protective atmosphere. In some cases, after sintering, one or more repeated compacting rolling and sintering are used to ensure the production of a workpiece with the specified properties. By simultaneously rolling several powders that differ in the properties of metals, or powder and sheet metal, multilayer rolled products are obtained.

Rolling of metal powders is used to produce blanks for structural, electrical, friction and antifriction products (tape, sheets, wire, etc.), as well as in the production of filters and other porous products for cleaning various media.

Mouthpiece pressing

Mouth pressing is the molding of blanks by pressing a mixture of powder and plasticizer through a hole in the matrix.

With mouthpiece pressing, either a mixture of powder and binder or a pre-compressed workpiece, which is heated before pressing, can be pressed through a mouthpiece.

Paraffin, polyvinyl alcohol, starch, and bakelite are used as plasticizers. Mold pressing is effective in the production of rods, pipes, angles and other long-length products from poorly pressed materials, including refractory metals and compounds, hard alloys and others.

Profile pressing of polymer composite materials

The press material is forced through a profile die with open inlet and outlet holes or a special head. During the extrusion process, this profile is formed and obtained, and in the case of thermosets, they are cured. A process with a periodically repeating cycle that ensures continuous production of profiles due to the fact that not the entire portion of the polymer composite material is extruded in one cycle, but the remaining heated PCM is welded with the newly received portion. The method occupies an intermediate position between pressing and extrusion.

Parameters of the PCM profile pressing process: pressing pressure 250-400 MPa for thermoset plastics and 40-50 MPa for thermoplastics.

Equipment for profile pressing of PCM: special horizontal presses, the piston of which slowly makes a working stroke and quickly returns to its original position, a mold with a replaceable matrix.

Profile pressing is used (along with extrusion) to produce pipes, rods and other profile products of long length.

Return to article Obtaining composite materials

Slip molding

Slip molding is a method of manufacturing products by pouring slip, which is a homogeneous concentrated suspension of powder in a liquid, into a porous form, followed by drying. In this case, the molding process is carried out without the application of external pressure. This molding process is sometimes called slip casting.

To prepare slip, very fine powders are used, the suspension of which in liquid (solutions based on water and alcohol) is homogeneous and stable for a long time. The slip contains a certain amount of additives (acids, alkalis, various salts) that prevent the accumulation of particles and improve the wetting of powder particles and mold walls with liquid.

The mold for slip molding is made of gypsum, porous ceramics, stainless steel and other similar materials.

The blank is obtained by pouring the slip into a moisture-absorbing mold, the liquid from which is removed through the pores. The molding mechanism consists in the directed deposition of solid particles on the walls of the mold under the influence of directed liquid flows. Flows arise as a result of the absorption of liquid into the pores of the mold under the influence of vacuum or under the influence of centrifugal forces during centrifugal slip molding.

The rate of growth of the solid layer depends on the rate of liquid removal, particle size, the ratio between the solid and liquid phases in the slip, temperature, and the amount of additives. The connection between particles is mainly due to mechanical entanglement.

The resulting workpiece is removed from the mold and subjected to drying and sintering. To make it easier to remove the workpiece, the inner surface of the mold is coated with a thin layer of a special substance (soap, graphite, paper, talc) that prevents it from setting with the material being formed.

Products obtained by slip molding, due to the high initial porosity, which can reach 60%, exhibit significant shrinkage during sintering. However, the density of the products after sintering is quite large and uniform in volume.

The slip molding method is used to produce products of complex shapes (pipes, crucibles, turbine blades, etc.), which are difficult to obtain using traditional pressing methods, especially in the case of compacting fragile powdery materials.

Dynamic molding

Dynamic molding is a pressing process using impulse loads or vibration. A distinctive feature of this forming is the high speed of application of load to the compacted powder. In this regard, it is often called high-speed.

The energy source used is the explosion energy of an explosive charge, a high-intensity shock wave that occurs during the discharge of accumulated electrical energy and affects the material through liquid, compressed gas energy, and vibration.

In explosive molding, the energy of the explosion imparts a certain velocity to the device striking the pressing punch, either transmitted to the pressed powder through a liquid, or acts on the pressed powder enclosed in an elastic shell or thin-walled metal container. This high-speed type of pressing leads to the release of heat and heating of the contact areas between particles, which facilitates the deformation process. As a result, the density of the workpieces reaches a higher value than with conventional pressing methods with low-speed loads.

A variation of dynamic molding is dynamic hot pressing (DHP method). The method is based on the preliminary cold molding of a porous workpiece from a powder mixture of a given composition, its subsequent short-term heating and additional pressing under dynamic loads. This method makes it possible to obtain practically non-porous products of precise dimensions and with high surface cleanliness.

Vibration molding uses the beneficial effect of vibration on the compaction process, which is associated with the destruction of interparticle bonds and improved inter-mobility of particles. As a result, dense packing of particles is achieved at lower pressing pressures and a high uniformity of density distribution throughout the volume of the workpiece is ensured.

Vibration energy is spent on overcoming the inertia and elastic resistance of the vibrating system and on overcoming the inertia, friction and adhesion forces of the compacted powder. In the case of compaction of a small powder, the main role is played by the inertia and elastic properties of the system. Therefore, to ensure the most advantageous compaction mode, the vibration frequency should be selected closer to the natural frequency of the system. When compacting large masses of powder, the main role will be played by the natural frequency of vibrations of the particle layer and the bonding forces between them. Therefore, the vibration frequency is chosen closer to the resonant one either in relation to the vibrating system, or in relation to the compacted mass of powder. With the correct choice of frequency, acceleration and vibration amplitude, the density and strength of compacts is higher than with static pressing.

In all cases requiring high pressures during static pressing, the use of vibration will be beneficial. The most effective use of vibration is when pressing powders of non-plastic and brittle metals, to which high static pressures cannot be applied due to the destruction of briquettes that occurs.