Press shears for metal are universal equipment for metal work of any complexity. They can be combined - such products have a punching press for creating holes in aluminum, steel and titanium.

Modern devices speed up work, reducing metal losses. They are used in press shops, construction metal depots, and enterprises processing recycled metal. They are used for cutting grooves, processing materials, cutting metal sheets, and creating holes in metal products.

Scrap Scissors

Press shears for scrap

This type of industrial equipment is used in metal depots, metallurgical plants, and loading terminals. The scrap metal shear press is the most powerful type of metal cutting machine. The force on the blades can reach 3,000 tons. They are designed for grinding all types of metal waste, including fittings, rails, channels, I-beams.

In addition to the blades themselves, the installation is equipped with a hopper, where the cut metal is pressed under considerable force into compact briquettes. Metal preparing for processing is poured into containers and fed into the work area automatically. The capacity of containers can reach tens and hundreds of tons.

Press shears for scrap are produced in two types - horizontal and vertical. Horizontal ones are smaller in size and are intended for medium-capacity sites, vertical ones for large factories and warehouses.

You can often find container-type hydraulic press shears. They are designed for processing all types of scrap, including car bodies, directly at the receiving sites. The output is crushed scrap of category 3A or 12A. The shears are mounted in a standard-sized container, which can be transported on a truck equipped with a multi-lift and installed on any site where there is hard soil, asphalt or concrete pavement. No special foundation is required.

Container shears are equipped with an electric or diesel drive. The second option is very convenient at temporary reception sites and when dismantling residential and industrial buildings. An example of such an installation is the CNS 400 scissors. The dimensions of the loading chamber are 1.6 x 2.25 x 2.48 m. The force on the cutting knife is more than 400 tons, and the force on the clamping device is 1.2 MN.

The scissors are capable of cutting round metal with a diameter of 110 mm, a profile pipe with a rectangular cross-section - up to 9x9 cm, a sheet 40 mm thick with a side of 1500 mm. The knife makes 2-3 cuts per minute, while the press productivity is up to 9 tons per hour. This is a medium-sized container press; more powerful ones can process 12-15 tons of scrap.

Marking

To designate the model of metal press shears, special markings are used:

- N - press shears;

- A letter or letter combination after the main “H” indicates modifications to the base model.

- The letters are followed by numbers: the first indicates the type of shear drive, the second indicates the technical features of the equipment. The last two digits correspond to the nominal force in tf.

The basic line of the instrument is based on the preferred series of numbers. Technical characteristics are determined using a table.

| The last two digits in the name of the scissors model | Nominal force, tf |

| 22 | 25 |

| 24 | 31,5 |

| 26 | 40 |

| 27 | 50 |

| 28 | 63 |

| 29 | 80 |

| 30 | 100 |

| 31 | 125 |

| 32 | 160 |

| 34 | 250 |

| 36 | 400 |

| 38 | 630 |

| 40 | 1000 |

| 46 | 4000 |

Shear presses used in scrap processing

Types of guillotine shears

A significant limitation in the functionality of alligator shears is the presence of lateral shear force during cutting, as a result of which the quality of the cut deteriorates and the safety requirements for operating personnel increase. This drawback is eliminated by using combined shear presses.

Hydraulic shear press for scrap metal

The principle of operation of such scissors is as follows. The movement from the electric motor through the flywheel and gear transmission is transmitted to the main actuator of the crank-wedge type. At the same time, in the shear slide there is a set of movable knives, which includes a tool for cutting long and profile steel, as well as wide-band scrap. Fixed knives are fixed to the frame and/or table. As a result, a reciprocating movement of the slider is realized in adjustable guides, in which shear forces are practically absent. A separate drive punches holes in the scrap, which can be used as transport holes.

The disadvantage of combined shear presses is the need to replace the set of knives when the overall dimensions of the scrap being cut change.

Scrap separation equipment operating from an electric drive is stationary and can only function directly at scrap metal reception centers. But often there is a need to quickly cut up large steel fragments of scrap metal directly at its location. In such situations, you cannot do without hydraulic shears, for the drive of which any hydraulic equipment can be used.

User manual

Before you start using the product, you must follow the following recommendations.

- Each tool comes complete with accompanying documentation, which must be reviewed first.

- Newer models usually have a protective lubricant that must be removed from the surface of the blades.

- The cylinder must be checked for oil level, and the entire pneumatic structure must be correctly combined into a single system. If there is no oil in the pump, it should be topped up using only suitable technical grades. Recommendations for choosing a lubricant are contained in the manufacturer's technical documentation.

When using the product, you must adhere to the following rules:

- the standard characteristics of the tool must correspond to the thickness of the material being processed or be greater;

- lubricants in the pump should be replaced at least once a year;

- in the event of an emergency, cutting must be stopped immediately;

- Most hydraulic tools are subject to repair, after which they can be reused.

It is also important to know general safety rules. When using the tool, it is important to consider:

- correct position of the tool, especially its working part;

- features of treatment with anti-corrosion compounds during long-term storage;

- mandatory cleaning of moving parts before starting work.

For an overview of the model of hydraulic metal shears, see below.

Selection principles

Types of gas cutting of metal

When choosing combination shear presses, you need to pay attention to a number of parameters:

- drive power;

- press force;

- required current strength, ability to connect to the network;

- dimensions of cutting parts;

- machine dimensions;

- availability of additional functions;

- the ability to change the position of the blades for cutting at different angles.

For mass production, it is advisable to choose CNC models. For the home workshop, manual installations are used.

Advantages and disadvantages

Press shears for metal have a number of strengths and weaknesses that you need to familiarize yourself with before purchasing. Advantages:

- High power.

- Possibility of carrying out different technological operations due to the replacement of equipment.

- CNC models do not require any effort from the operator during operation.

- High cutting precision.

- Maximum thickness of cut sheets.

- Hydraulic models allow you to work with parts of large thickness.

The disadvantage of the devices is that it is necessary to change the equipment when processing parts of different thicknesses and shapes. Models with high power take up a lot of space in the room. Another drawback is that it is impossible to make curved cuts.

Manufacturers and cost

There are different types of narrow-profile and combined press scissors. Manufacturers:

- Stalex;

- Metalmaster;

- Proma;

- JET;

- Rems;

- Kingsland.

The cost depends on the power of the equipment, dimensions, additional functions, and technological operations performed. The average price for manual models is 30,000 rubles, for industrial equipment - 400,000 rubles.

Operating rules

To extend the service life of the tool, it is important to follow the basic operating rules:

- the tool and cutting part must be kept clean;

- oil changes are carried out at least once every six months;

- Before storage, scissors should be cleaned and lubricated with an anti-corrosion compound;

- during operation, the thickness of the metal being cut should not exceed the standards stated by the manufacturer.

Possible faults

The main malfunctions of hydraulic tools for metal are:

- the rod does not return to the neutral position - the return spring must be replaced;

- no or insufficient oil pressure - requires changing the oil, closing the lever to relieve excess pressure or cleaning the hydraulic drive;

- There are oil smudges on the outside - the seals need to be replaced.

To avoid various breakdowns, you must follow the operating rules of the tool described in the technical data sheet. Before use, the tool must be checked for defects.

Hydraulic shears series NG, NGR, NGO

Manual equipment

Main types of metal cutting

Manual shear presses are adapted for primary use in small and private businesses associated with the production of piece parts of small diameter or cross-section. They are equipped with a multifunctional working area (for example, model H9818 scissors have four working positions), which does not require adjustments during operation. The force is transmitted from a pair of handles. It is possible to cut strips, sectional profiles, as well as punch holes and cut narrow grooves. Such combined press shears are distinguished by their compact dimensions, do not require pouring a foundation, and can be easily reinstalled to a new place of application. The drive of hand scissors is lever type, with an eccentric clamping of the metal being cut.

Combined hydraulic press shears Geka HYDRACROP 110/180

Technological capabilities of scissors

The range of application of the equipment under consideration can be expanded by installing a non-drive modular roller conveyor type MRP. In particular, it is possible to cut rods of round or square cross-section with a length of up to 3...6 m. The supplied basic set of tools and accessories includes:

- Knives for cutting straight and triangular grooves, flat plate knives made of steel grades U8A or 9ХС (specified in the passport when the product is delivered to the consumer);

- Hole punch centering mechanism, which ensures increased accuracy of hole punching;

- Spring balancer guaranteeing safe working conditions for the operator.

- Types of operations performed

The combined lubrication system used provides for the operation of the shears both inside and outside the production premises, and there is no need to supply compressed air to the installation site of the shears. The passport contains the necessary information about installing the scissors on a permanent basis, and the conditions for their shelter from adverse atmospheric influences.

Hand shears for metal

Design of manual shears

Manual press shears

The working part of the machine is two blades (knives) about 10 cm long. One of them is fixedly attached to the bed, the second can move in a vertical plane under the action of a lever mechanism. The lever is driven by the operator's muscular force and, through a mechanical transmission system, acts on the knife.

Using manual lever machines, you can cut sheet metal (steel) up to 8 mm thick and non-ferrous alloys up to 10 mm, reinforcement and rods with a diameter of up to 1.8 cm. Lever-type manual scissors are made from tool steel and alloys of grades P18, U8, U9 or their analogues.

Scope of application of scissors

Today, almost no renovation of apartments, private houses, or industrial buildings can be done without cutting metal. The process of finishing with metal siding, in general, is not possible without cutting the metal; fastening the metal frame for finishing with plasterboard cannot be done without it. Hand-held metal cutting shears are used for cutting tin shapes and for processing roofing materials such as metal tiles and corrugated sheet metal.

Any metal sheets up to 2.5 mm thick can be processed using scissors.

Their advantageous characteristics:

Metal cutting scissors

- maneuverability - using a grinder, jigsaw or saw, you can only make horizontal cutting;

- convenience - the scissors are lightweight, fit in your hand, and do not slide off the sheet when working, as is possible when using a grinder or saw;

- economical - no electricity or additional attachments are required, unlike an angle grinder;

- safety - with an angle grinder that works at high speed, there is a high probability of injury, especially if you lack experience, which is practically impossible when using scissors.

The design of scissors for cutting metal is simple - two handles and two cutting elements connected to each other. Even the most primitive models have the necessary characteristics. To ensure minimization of effort, a certain sharpening angle is used - 70 - 80o, and the blades are attached to each other at an angle of 12o. To facilitate the work of left-handers, they can be with a right-sided or left-sided cut.

Why is it profitable to purchase from us?

By contacting us, you are already saving. Yes, yes, exactly you!!!. Save time and effort spent searching for the equipment you need. Here you will find a large range of equipment at the best price for you. Our company will help you purchase hydraulic press shears of reliable quality, high productivity with minimal time spent on searches and logistics. This is due not only to the wide range of supplied equipment, both new and used, but also to the impeccable quality of work of our employees with an individual approach to each client, which guarantees maximum satisfaction of all your requests. Currently, the world market offers a large selection of hydraulic press shears from different countries of manufacture, such as China, Germany, Spain. But “All that glitters is not gold.”

So, what should you consider when choosing hydraulic shear balers for scrap metal?

Strength and reliability of the design.

Allows you to increase the longevity of equipment operation, thereby reducing

number of repairs and equipment downtime during working hours.

The dimensions of the loading chamber should be taken into account.

Depending on the size of the chamber, the performance of the equipment increases or decreases.

Loading chamber of shear press:

— Chamber length from 3000 to 9000 mm

— Width from 2000 to 4000 mm.

Technologically advanced electronic and hydraulic system Allows you to increase the speed of operations and reduce dynamic shocks in the hydraulic system

Cutting force for the required performance. We help you choose shear presses with optimal performance. Advantages of our equipment

The hydraulic press shears for scrap metal supplied by us have an EU international quality certificate. Exceptional quality, reliability, accuracy and durability - these are the qualities that allow us to confidently say that the offered equipment is the best choice! Press shears are available with cutting forces of 400, 450, 500, 600, 800, 1000 tons. Hydraulic press shears for cutting scrap offered on our website are modern top equipment that allows you to organize an effective metal processing process. Press shears for scrap metal can perform not only the function of cutting, but also pressing scrap into bags and also recycling them. Available in mobile and stationary versions. Italian press shears offer outstanding performance, automation of the entire technological process, high reliability and low maintenance costs. Press shears for processing small and medium volumes of metal, produced on the basis of the practical experience of Italian leaders.

Advantages of WSD series shear presses

Baling press shears are used: - for cold pressing and cutting scrap metal up to 3 mm thick. — cutting rectangular packages of the required length (including steel profiles up to 5 meters long) — for the production of packages for charge at metal smelting plants.

The user has the opportunity to select scissors depending on production requirements for such parameters as the size of the pressing chamber, bag and pressing mode.

This equipment is equipped with an electric or diesel engine, taking into account the required power or features of further operation.

For processing scrap metal, press shears are equipped with a hydraulic drive system; they can operate in manual or automatic mode with CNC.

The use of our equipment when processing scrap metal reduces the storage area of scrap metal, reduces the cost of its transportation, and therefore increases the profitability of the enterprise.

The profitability of your enterprise increases, since the cost of cut scrap metal is more expensive than pressed scrap and the output you get is “type 9”.

The main advantages for enterprises also include: a wide range of applications (various areas of the metallurgical industry), consumption of a relatively small amount of energy, ease of installation, reliability, overload protection, high level of safety and low noise level.

One of the additional options is assistance in installation, debugging of equipment and personnel training.

Design and principle of operation

The operating principle of the shear press for processing metal workpieces depends on the design of the equipment. Machine device:

- a frame for holding other parts, responsible for the stability of the unit;

- gear;

- drive - hydraulic or electric;

- eccentric shaft;

- mechanisms for clamping workpieces;

- parts supply system;

- back stop;

- slider with connecting rod;

- supports for cutting reinforcement and metal rods;

- control Panel.

CNC models are complemented by sensors for the movement of working parts, a display, and a cutting control system. Combination scissors contain several cutting parts.

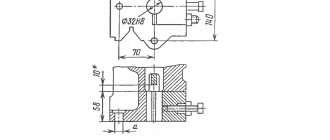

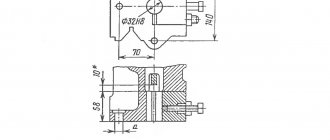

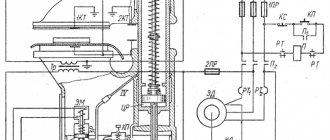

Operation of the HB5222 press

1 – gear shaft, 2 – flywheel, 3 – electric motor, 4 – gear wheel,

5 – connecting rod, 6 – shaft, 7 – balancer, 8 – press slide, 9 – electromagnet,

10 – slider of the strip section.

The shear press is driven from an electric motor (3) through a V-belt transmission, a flywheel (2) and a single-stage gear transmission (1, 4) to an eccentric shaft (6). The gear pair (1.4) is straight-toothed, cylindrical. The movement is transmitted to the slider (10) of the strip section through the connecting rod (5), to the slider (8) of the press for punching holes through the balancer (7) and the sinking stone. Switching on and off the actuators is carried out through a system of levers connected on one side with a connecting rod and a sinking stone, and on the other hand with electromagnets (9).

Place the switch in the position: “band strip section” or in the “hole-punching section” position.

- Hole punching:

Attach the punch and die in the corresponding slots. Then, turning the centering mechanism handle, lower the punch into the die and insert the die holder body so that a uniform gap is maintained between the die and the punch.

Attach the die holder body to the frame and check the gap again.

Depending on the thickness of the material being punched, align the puller body by loosening the nuts and locknuts, and by rotating the screws, insert the puller body with a gap of 1...2 mm from the plane of the sheet.

Tighten the nuts and locknuts. Installing the puller body skewed is not permissible.

To punch holes along the cores, use the centering mechanism. Lower the punch with the handle and align the core on the workpiece with the punch core.

- Variety strip section:

To cut shaped steel, install the appropriate tool in the socket of the slider and frame. Align the stop plate to the appropriate angle (90°, 45°) along the guide lines and secure it. Install replacement clamps. Insert the rolled piece into the tool socket and align it either according to the markings or against the cutting stop of the workpieces, the size of which you have previously set. Do not cut a strip that has oil stains on its surface.

When the scoring device is operating, the gap between the knives is set by spacers under the supporting surfaces and depends on the thickness of the material being cut. The knives of the scoring device must fit snugly to the supporting surfaces, must be well secured and dry.

Blow compressed air into the frame cavity under the strip slide to remove accumulated scale or remove it with a scraper.

For safety, the shear presses are equipped with guards for all rotating parts of the scoring device and the hole-punching area.

When working with scissors:

- do not cut or punch holes in profiles and materials larger than those indicated in the technical specifications at δв = 500 N/mm²;

- do not remove the barriers;

- do not work on the strip section without clamps;

- Do not adjust the shears while the electric motor is on.

Main technical purpose and operational parameters

The passport for the machine notes that this technique makes it possible to perform universal separation operations of plastic deformation with workpieces of various assortments - strips, profiled metal products (angle, both equilateral and unequal, circle, square). It is possible to punch holes and make shaped grooves in sheet and shaped rolled products. When installing additional devices and stamping tools (the specifications and nomenclature of which are given in the passport) on the combined scissors in question, it is also possible to perform sectional stamping of contours element by element, contour cutting and strip cutting, and even straightening. The machine passport includes a list of quick-change parts and tools, using which you can easily reconfigure the unit to work with various initial products.

Such a variety of cold stamping transitions allows for the effective use of combined shear presses in small-scale and individual production of products from various rolled steel profiles.

Shears model HB 5222 are easily integrated into specialized production lines for performing cutting and blank transitions for cold stamping of rolled products.

Combined press shears HB5222 after major overhaul

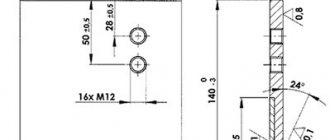

The main technical characteristics of scissors that comply with the standards TU 2-041-284-83 are:

- The maximum thickness of the material to be separated, mm, is 16 (based on the assumption that the strength of the metal or alloy is 450 MPa; for other values of mechanical parameters, the limit value of this parameter is established experimentally).

- The maximum dimensions of the strip to be cut (width×thickness), mm—190×18.

- The largest diameter of round rolled metal, mm (under the same conditions as point 1) – 50.

- Dimensions of an isosceles corner, the shelves of which are located perpendicular to each other, mm - 125 × 125 × 14.

- For the punching press assembly, the largest diameter of the hole to be punched, mm, is 32.

- Number of strokes of the main drive slider (adjustable), min -1 – 17…53.

- Electric motor power. kW – 4.8.

- Overall dimensions of the equipment (length×width×height), mm - 1780×1030×1865.

- Equipment weight, kg – no more than 2500.

Technical characteristics of HB5222

Composition of units and principle of their operation

Scissors model NG5222 include:

- AC drive motor;

- V-belt transmission;

- receiving shaft;

- flywheel;

- eccentric shaft;

- main slider drive connecting rod;

- balancer of the rolled section cutting section;

- punching press balancer;

- back stop;

- bed.

The unit is controlled using a system of levers that are kinematically connected to two control electromagnets. When the drive rods are switched into the corresponding slots, either the punch of the punching press moves or the balancer of the rolling cutting section swings. The scissors can operate in single and continuous stroke modes. It should be taken into account that, due to the absence of an engagement clutch, the stop of the slide occurs within a certain time.

The cutting tool is fastened in special grooves in the slide. Installation of the punching punch is carried out in the punch holder, while the matrix is installed on the punching table.

Electrical diagram

The scissors passport also includes a list of necessary tools and accessories, including handles for fixing the table and centering device, sets of punches and knives, a receiving tray and a number of others. A tool for cutting special rolled profiles is also available as an option.

This is how scissors work. The torque from the switched-on electric motor is transmitted by a V-belt transmission to the flywheel, which compensates for possible fluctuations in the shaft speed due to force overload of the shears. Next, using a spur gear, the movement is transmitted to the eccentric shaft, on which a connecting rod is mounted to drive the slider of the section cutting mechanism and the rod of the swinging balancer, which controls the movement of the punching press. If it is necessary to punch holes, the corresponding control electromagnet is turned on, which rotates the multi-link lever and produces a translational movement of the punch downwards, while a continuously swinging balancer is responsible for returning the punch to its uppermost position. To cut long or round rolled metal, a second electromagnet is turned on. He turns the double lever, which in turn pushes the connecting rod down. It imparts a rocking motion to the slider, and at the same time fixes the back stop, which is responsible for the accuracy of the cut, in a certain position. The shears are turned on/off using a pedal: after completing the technological operation, the operator releases the pedal and the drive stops in the required position. After this, it is possible to install the next workpiece to be processed into the working area of the scissors. There is also a push-button station for controlling the scissors when they perform the hole-punching operation.

Equipment working areas

Types and characteristics of separation scrap processing equipment

Scrap metal shear presses belong to one of the following groups:

Reinforcing shears designed for cutting long bars of reinforcing bars remaining after the destruction of worn-out reinforced concrete structures;

Alligator shears used when cutting oversized scrap, mainly in the idea of rods, channels and thick strips;

Combined press shears, which are the most universal type of equipment under consideration, because In addition to the above functions, alligator shears can also perform operations of punching holes in scrap metal.

Technical parameters and other requirements for scissors for cutting scrap metal are regulated by the current GOST 15032.

Separation equipment suitable for pre-processing of scrap metal must meet a number of specific requirements:

Allow convenient orientation and fixation of the crowbar in the working space of the scissors;

Be distinguished by a wide range of permissible scrap thickness;

Have the ability to autonomously connect to energy communications of scrap processing enterprises;

Characterized by the simplicity and reliability of the kinematic scheme.

Basically, the drive of press shears for scrap metal is mechanical, although standard sizes with a hydraulic drive are also known (they are more often used for cutting particularly large-sized scrap). For example, mounted hydraulic shears are used for cutting railway cars.

Design Features

Machines in this category are distinguished by exceptional durability and high technological characteristics. Each functional part of the mechanism is activated by a handle. Depending on the type of model, different mechanisms can be mounted in the frame of the shear press:

- metal scissors - designed for cutting profiles;

- hole-punching unit - allows you to make holes in metal workpieces;

- scissors for processing profiles and sheet metal;

- notching unit – used to make notches of any size.

The operating mechanisms are activated by pressing a button; pedal control is also provided. Thanks to the innovative lubrication system, wear of working elements is reduced and uninterrupted operation of the device is ensured throughout its entire service life.

Characteristics of baling presses

Among the characteristics that are standard for the entire Balta Press model range, we highlight: You need to choose a press for scrap procurement based on the planned volumes of the “tin”, the density of the resulting raw materials and productivity sufficient to organize a full-fledged production process. What stands out in choosing a press is its price. Equipment whose service life is expected to last for years, and sometimes even decades, cannot be cheap. The money saved at the purchase stage will inevitably lead to serious expenses within a couple of years - the equipment will fail before it has time to pay for itself.

- use of Hardox armor or its analogues;

- assembly using German technologies;

- reinforced stiffening ribs (up to 30-60 mm), guaranteeing the preservation of the shape of the frame during operation;

- hydraulic cylinders of our own production with German seals and Italian sleeves and rods;

- selection of add-ons (a hydraulic press can be additionally equipped with automation with a radio remote control, manipulator, etc.);

- possibility of easy replacement of parts.

Knives for shears for cutting long products. Technical requirements

Knives for press shears are manufactured in accordance with GOST 25454-82 Knives for shears for cutting long products. Technical requirements

- Knives should not have cracks, burrs, shells, sharp corners and edges (except for cutting ones);

- The surfaces forming the cutting edge should not have nicks or burns;

- The cutting edge should not be blunted, chipped, or have nicks;

- Knives must be made of steel grades: Kh12F1, KhBF in accordance with GOST 5990-73 for cold cutting of steel

- R6M5 according to GOST 19256-73, 4Х5В2ФС according to GOST 5990-73 for hot cutting of steel

- Surfaces forming the cutting edge (front, back) and supporting surfaces - 1.25 microns

Features of the operation of the grade section HB5222

Before working on the section section HB5222, check the fastening of the knives to the knife plates and the fastening of the L-shaped adjusting clamps. The gap between the knives of the section section is set depending on the thickness of the material being cut and must exceed 0.2…0.5 mm. When replacing blade plates, remove the L-shaped tool clamps and remove the blade plates

Attention! Press shears НВ5222 are designed for processing materials with a tensile strength δ ≤ 500 MPa (50 kgf/mm2). To cut shaped steel, install the appropriate tool in the socket of the slider and frame. Align the stop plate to the appropriate angle (900 and 450) along the guide lines and secure it

Install the stop and replaceable clamps. Insert the rental into the tool socket and align it according to the markings. Using the handle of the auto-clamping lock of the section section, release the clamping fist and turn it until the lever-clamp system comes into contact with the material being processed. When the hole on the cam is closest to the axis of the clamp, fix them. After that, start cutting. Do not cut a strip that has oil stains on its surface. Cutting material with the tops of knives is not allowed. Adjust the gap between the knives using spacers under the supporting surfaces. To avoid breakage, the knives should overlap each other by 3...5mm. The gap between the knives should not exceed 1/30 of the thickness of the material being cut

Varieties

There are several factors by which press shears are classified:

- Type of energy carrier. Can be hydraulic or mechanical.

- Functions. There are narrow-profile installations that can be used to cut only rods, reinforcement, profiles, and corners. There are also universal press shears that can be used to process various metal parts.

- Type of energy carrier. In production, machines that connect to the network are used; at home, manual models are relevant.

- Type of installation. Both large-sized models used for mass production and portable units that can be moved from place to place are sold. The second option is not suitable for cutting thick workpieces due to lack of power.

- Automation type. Control can be manual or automated. Expensive models are equipped with CNC, which allows technological processes to be carried out faster and reduces effort on the part of the operator.

Press shears are manufactured according to certain standards. These are GOST 15032, GOST 7355, GOST 8248.

Among the general diversity, there are three large groups of press scissors:

- Manual models. The design has two knives, one of which is fixed, the second is movable. They are activated by human effort.

- Disk. The principle of operation is that during the working process, the workpieces are separated by two disks, which rotate in the opposite direction from each other.

- Equipment for scrap. Powerful devices that are installed at large metallurgical plants. The cutting force reaches 3000 tons.

A separate group is container models. Installed on vehicles.

How to make an order?

By choosing to cooperate with our factory, you can be completely confident in the quality of such an offer, as well as in the fact that you are receiving original equipment directly from the manufacturer.

All items from the catalog are currently available in stock and can be sent at any time to the specified address in our state or the CIS countries. You can place an order using a convenient and understandable catalog, as well as by contacting our specialists using contact phone numbers. We will tell you more about each such offer, help you navigate the entire range and purchase the option that is best suited for you.

To clarify the price or order mechanical press shears NG, please contact us at the numbers listed at the top of the page.

Popular CPN models

A large number of varieties of combined industrial type shear presses are produced. In Russia, the following models are most widespread: SMZh625, NV5221, NV5222, NV5224. The most popular model remains the HB5221 installation. Below we will briefly look at the features of these models.

SMF625

It belongs to the category of simple, compact and cheap models, with which you can perform all basic metal work. Areas of application: cutting shaped or long rolled metal, working with metal sheets, punching holes, making triangular notches. The SMZH625 installation can be adapted for use in open areas. An additional application of SMZH625 is working with metal and rolled metal on construction sites with low or medium levels of pollution. The machine is used in temperate climates.

HB5221

This model belongs to the category of large massive machines that are designed to work with large batches of metal. HB5221 is suitable for working with all popular types of rolled metal (shaped, long, strip). This machine can be used for making holes, cutting out various notches and notches. The device has 4 active zones. This allows you to significantly increase labor productivity, which will be very useful in the case of large metallurgical industries (mechanical engineering, production of military equipment, construction of sea vessels, repair work). HB5221 machines have slight design differences due to the climate of primary use. A simple example: the UHL modification of the HB5221 machine is used to work in moderate or cold climates.

HB5222

This model is a modification of the previous HB5221 system. A major difference between this type of installation is that the 4 zones of the HB5222 press system operate in a completely autonomous mode. This allows the operator to efficiently organize work in production. Model HB5222 is designed to work with all types of rolled metal, for cutting sheet metal, for making holes, notches or recesses. This model of scissors is used in construction or engineering industries. Another area of application is small compact workshops, specializing in the dismantling of prefabricated metal structures (machines, equipment).

HB5224

This unit is an improved modification of the HB5221 model. The device is universal - it is suitable for processing sheets, rolled metal, various blanks and solid parts. Like the classic model, the HB5224 system is divided into 4 zones, which perform all basic operations with metal - cutting, making holes, pressing. The basic differences of the HB5224 are improved automation, the use of stronger metal alloys with anti-corrosion additives, the availability of equipment for notching operations, and the ability to cut angle metal.

Scope of use

CPNs are in demand in many areas of industry. They are widely used by both small metal processing companies and large manufacturing plants. And some of the models can be seen even in ordinary garage workshops. The equipment is quite in demand in the mechanical engineering industry, at metalworking bases, stamping lines, and in procurement shops. These mechanisms became so widespread thanks to:

- reliability of design;

- ability to customize for performing diverse tasks;

- compact size and relatively light weight;

- multifunctionality, thanks to which it is possible to customize the equipment to specific requirements;

- absence of strong vibration and noise during operation;

- the possibility of installing and integrating equipment into an automated production line;

- high quality of finished products.

Most installations can be easily integrated into an automated production line. They are not difficult to operate, are affordable, have a long service life, cut metal with high precision, and also perform many other equally important functions.

Recommendations for optimal use of the machine

Since combined shears are not high-precision separating equipment, when performing adjustment operations it is necessary to ensure that the depth of penetration of the movable and stationary knives into the cut rolled product does not exceed 25% of the original overall dimension of the metal section indicated in the passport

This condition is extremely important for cutting highly plastic metals and alloys (for example, aluminum). As a last resort, it is permissible to use heated cutting, when the original semi-finished product is heated to 150...200 °C

This condition is most often implemented for the separation of high-carbon (containing more than 0.5% C) or alloy steels.

When planning to use a hole-punching press, it is worth initially setting increased (compared to those recommended in the passport) gaps between the side guides of the puller and the workpiece, otherwise it may bend and bulge in the area of action of the hole-punching punch.

The passport for the machine also indicates the conditions for installing the scissors. Since this equipment is not characterized by the shock nature of its work, a special foundation is not required. The absence of an electro-pneumatic activation system allows the shears to be installed outdoors, supplying the moving parts with lubricant suitable for use in the appropriate temperature conditions. The equipment must be covered with a moisture-proof canopy.

Slider for section sheets, slider for punching holes in press shears HB5221

Slider for section sheets and slider for punching holes nb5221

Leaf creeper (Fig. 4). The slider 1, connected through a sinking connecting rod 2 with an eccentric shaft 4, swings on an axis 6 between guide bearings, adjustable with bolts. The slider returns to its original position and is held by spring 5 with rod 3. In the middle part of the slider there is a cutout in which a movable knife plate is attached, and in the lower right part there are sockets for attaching the knives of sheet shears and tools for punching grooves.

Press slide for punching holes (Fig. 5)

Press slide for punching holes (Fig. 5). The press slider 1 has a rectangular shape and performs a reciprocating motion. To obtain a normal gap between the guides and the slide, a cast iron strip and gasket are used. At the bottom of the slide there is a punch 2, on the press table there is a rack 4 in which the matrix 3 is installed. The press table is removable and secured with two bolts 5. When moving the table to a horizontal position, you can punch holes in box-shaped and shaped parts.

Centering mechanism

The centering mechanism allows the slider with the punch to be lowered to the intended location for punching the hole. The slider activation mechanism is controlled by a pedal or button.

Tool for cutting corners, circles, squares (Fig. 6, 7)

The tool for cutting a corner, circle, square (Fig. 6, 7) consists of movable and fixed 3, 4 plate knives. Knife-plate 3 is equipped with insert knives 1 and 2. The fixed knife-plate is attached to the socket of the frame, the movable knife-plate is attached to the socket of the section slider.

Channel and I-beam cutting tool

The channel and I-beam cutting tool consists of movable and fixed plates 4 (Fig. 8, 9), equipped with knives that vary depending on the number of the channel and I-beam. The fixed plate is equipped with knives 1, 2, 3, the movable plate is equipped with knives 1, 2, 3, 5.

Advantages of profile cutting with a guillotine

When cutting with guillotine shears, minimal deformation is observed with simultaneous quality and accuracy of the cut. After this process there is no need for additional mechanical processing.

The cutting is carried out both longitudinally and transversely. At the same time, it is possible to produce profiles with non-standard dimensions. It is possible to cut bent profiles made of difficult-to-cut materials. This depends directly on the equipment used. Also, with guillotine cutting, the amount of waste in the form of sawdust or shavings is minimal.

Of course, the advantages of cutting metal profiles using guillotine shears include the high speed and productivity of the process.

Automatic guillotine shears make it possible to use settings that are stored in computer memory to carry out complex work. Such equipment has a wide range of settings. And in each individual case, you can select certain cutting parameters. In addition, the undoubted advantage of automatic guillotine shears is the ability to batch cut profiled metal.

Nuances of the design of NG machines

NG machines have found wide application in various areas of production. This is due to the wide functionality and impressive technical characteristics of the machines. Therefore, you should get acquainted with their use and purpose in more detail. But to do this, you need to understand the design elements of the NG.

Combination press scissors ensure the performance of several different operations, avoiding preliminary changes to the device settings. This is possible thanks to four working zones. Work can be carried out in any sequence. There is no need to change tools. This is how fast, economical and productive processing of workpieces is achieved.

What should you know about the design of this machine?

- The bed consists of a pair of metal sheets - rear and front. They are connected to the base by welding.

- Four borings in the frame are used for mounting section drives and drive shafts on NG machines.

- The drives of the punching and sheet metal sections come from an electric motor through gear and V-belt transmissions to an eccentric shaft.

- The levers of the cutting devices of the machines are directly connected to the sliders of the sheet sections due to traction.

- The sliders of the punching sections are balanced due to special spring equalizers.

- The mechanism designed for cutting corners, squares, and metal circles consists of 2 plates. One is movable, the other is stationary. The movable plate is fixed in the slot of the slider of the sheet section. The fixed part is placed in the frame socket and fixed using L-shaped springs.

- Notching and sheet units include fixed and movable knives in the design - 3 and 2 units, respectively.

- The press shears provide three workstations that can be serviced by one operator.

- The electrical circuit has been modernized if we compare the NG5222 and the combined shear press N5222a. This electrical circuit allows the shear press to operate on single and continuous strokes.

- The control of the press scissors is pedal-based and push-button.

The combined design of the machine ensures its multitasking with maximum efficiency and economy. NG5222 has found its niche in the shear press market and confidently maintains its leading position.

Excellent technical characteristics, attractive price and high performance indicators make the NG5222 machine one of the most preferred devices. The price of press scissors starts from $1000. Quite reasonable cost for such machine parameters.

To get a consultation

Combined shear presses NG5222 with a nominal force of 40 tf with a mechanical drive are used for cutting strip, long and shaped rolled products and punching holes in sheet, strip and shaped rolled products. Having four working zones, the shear press allows you to perform multiple operations without changing tools or in any sequence.

Combined shear presses can find their application in engineering, repair and other factories, in commercial production and repair sites, and construction organizations.

Press shears NG5222 of our production have been supplied to the Central Federal District, Northwestern Federal District, Southern Federal District, North Caucasian Federal District, Volga Federal District, Ural Federal District, Siberian Federal District and CIS countries.