What is a gearbox for a walk-behind tractor?

The standard gearbox of a walk-behind tractor is a power unit that transmits torque from the engine and transmission directly to the working shaft on which cutters or wheels are mounted.

It bears a significant power (work) load. Modern walk-behind tractors use different technical solutions for this unit:

- gear transmissions;

- chain;

- worm;

- combined.

The gear housing (housing) is sealed. There is a gasket between the body and the cover. The seal is necessary to retain the oil. All rotating parts of the unit operate in an oil bath.

Located at the bottom of the walk-behind tractor in the center. On cheap models it may be non-separable and cannot be repaired.

Homemade design

You can make a gearbox for a walk-behind tractor with your own hands. Before starting work, it is necessary to take into account the engine speed and calculate the maximum load on the mechanism shafts.

Without determining these parameters, the assembled gearbox will not meet the specified power and will quickly fail . Here's what the build process looks like.

- We make the body. To do this, you can borrow a finished product from a motorcycle. If you don’t have a motorcycle at hand, you can weld the body yourself from sheet metal.

- Gears can be removed from the Friendship 4 chainsaw or you can also make them yourself. When making gears yourself, you need to take into account the diameter of the gearbox housing. Therefore, the size of the gears is determined using a caliper.

- To operate the mechanism you will need two gear shafts. These elements can be removed ready-made from the Ural motorcycle and installed in the walk-behind tractor gearbox after minor modifications. At the first shaft, you need to shorten the end cap and drill a hole in the housing. The second shaft is installed on the opposite side of the housing, where you first need to cut a hole of a suitable diameter. The hole must be supplemented with a flange, which is attached to the body using threaded connections. We install a steel washer and a ball bearing inside the flange.

- We connect the shafts to each other using a transmission mechanism.

- We supplement the output end of the shaft with a pulley, which will serve to install a belt drive.

After these manipulations, you will get an angle-type gearbox.

Classification of gearboxes used on walk-behind tractors and their characteristics

Below are the main types of such units that can be found on modern walk-behind tractors.

Angular

This type gets its name because it turns and transmits torque at an angle. Most often at a straight line, 90 degrees. This may be necessary when installing attachments - a rotary snow blower, a header, an active cutter, etc.

Angular gearboxes can be zero, which do not change the speed. And also increasing or decreasing. Overdrives increase the number of revolutions of the output shaft in comparison with the input, which results in a loss of power. Downshifts, on the contrary, reduce the output speed and increase force.

The picture shows an angular gearbox for mounting a snow blower:

The output speed is determined by the needs of the attachment. Where high speeds of the working body are required, booster units are installed. Where low speeds and power are needed, on the contrary, lowering ones are installed.

Downward

The operating principle of all reduction gearboxes is simple: a small gear rotates a larger one in diameter. A larger gear has a larger radial arm. The greater the leverage, the greater the force.

Most gearboxes have several gears that alternately transmit torque to each other. A reduction gear can be any type: worm, gear, chain or combined.

Some engines for walk-behind tractors are equipped from the factory with a reduction gearbox with a gear ratio of approximately 2:1. That is, at the output from the engine shaft, for example, 3600 rpm. At the output from the reduction gear shaft - 1800 rpm. But the rotation force is 2 times greater.

This is the engine in the picture. In the foreground is the cover and shaft of the reduction gearbox for a motor cultivator:

This is a complex mechanism equipped with an automatic (centrifugal) clutch.

But it cannot be considered as some kind of separate special device. This is an integral part of such a motor.

Motoblocks also use other reduction gears, most often homemade.

Gear

These are gearboxes in which rotation is transmitted using gears. Due to the dense and deep engagement of the gear teeth with each other, large power loads are transmitted. Knots of this type are used on the most powerful machines and mechanisms.

Gears are made of special durable steel that is resistant to breakage and abrasion. They rotate in oil, which extends their service life.

The image shows a repair kit, a set of gears for such a gearbox:

Disadvantage of this type: manufacturing high-quality gears with minimal tolerances is a high-tech, expensive process. High-quality gearboxes are expensive. If, in order to reduce the cost, the parts are made of poor quality, the unit does not last long.

Worm

A spiral helical worm gear rotates the gear. At the same time, the speed decreases many times and the force on the output shaft of the gear increases.

The advantages of this solution are simplicity, a minimum of parts, and a rigid grip.

The downside is that with constant rotation, the rubbing surfaces of the spiral and gear teeth wear out quite quickly. Especially if they are made of low-quality alloys and with large tolerances (low accuracy).

The photo shows an example of such a gearbox:

Gearboxes of this type are very suitable for opening gates, covers of industrial equipment, etc., that is, where the mechanism makes a minimum of revolutions. And the revs themselves are low. With constant loads and rotation of the working shaft of the walk-behind tractor, wear can be accelerated.

Kinds

Depending on the type of transmission used in the gearbox, converters are divided into several types. Different devices are used in mechanisms of different fields of activity.

Chain

The name is due to the design of the gearbox, which is based on a chain as a transmitting element. There may be more than one in one device. The movement is provided by sprockets, the small one is the leading one, the big one is the driven one. The principle is similar to the system on a bicycle. Productivity and reliability depend significantly on the quality of materials used to manufacture the main driving parts.

Among the negative aspects, the need for regular maintenance should be highlighted: chain tightening, lubrication. Unlike a belt drive, a chain drive does not allow slipping and lasts longer.

With reverse

The reversing mechanism provides the equipment with the ability to reverse. In this case, the reverse rotation clutch is installed between the bevel gears, which are located on the main shaft.

Belt

The simplest gearbox available on the market is of the belt type. As a rule, budget gearbox models use just such a device. The belt serves as a transmission element that is attached to the pulleys. Under heavy loads, the belt slips or breaks.

Belt converters reduce the aggressive effect on the power plant, reducing jerking. In addition, their design is simple and repairs are easy.

Among the minuses, unfortunately, there are more factors.

- At high temperatures the belt stretches. This is what reduces grip.

- Rapid wear and tear.

- Belt drive rupture due to kinks or twists.

- As the speed increases, the belt begins to slip.

- The pulleys must be in the same plane.

Gear

Gear reducers are most often used in engines of heavy equipment. The transmission consists of a gearbox, differentials and regulator, gears and belts. The design of the device is simple.

A gear transmission contains bevel or spur gears. Due to the fact that several of them can be placed on one shaft at once, the dimensions of the converter are reduced.

Among the advantages, one can also highlight the quietness of the engine on this type of gearbox.

Worm

The worm gear inverter features long service life and high reliability. The design is considered not very complex and requires qualified maintenance. The worm gear is already angular. In addition, it has a reverse, which allows the equipment to move not only forward, but also backward.

The gearbox got its name from the presence of a special worm gear in its composition, which moves along a screw having a trapezoidal four- or two-start thread. By varying the number of teeth, you can change the rotational speed. All components are made of anti-friction steel, which is characterized by increased strength.

The converter consists of only two main components. In addition, it is quiet and smooth.

Angular

One of the most efficient and reliable gearboxes. Therefore, it is used to equip production machines and equipment operating under heavy loads. This type of converter is also actively used in the automotive industry.

The angular gearbox ensures the connection of the engine with the transmission, which is designed for chain drive

Please note that the magnitude of the load will depend on the quality of lubricants and temperature conditions

Downward

The goal of a reduction gearbox is to reduce the number of revolutions while increasing power. This is achieved by using a gear system. As a rule, modern converters of this type are equipped with an air cooling system.

Design and principle of operation

The design and operating principle of the main types of gearboxes are described above. In addition to them, chain gearboxes are used on walk-behind tractors; this design is used on Cascade brand cultivators. They operate with gears, the rotation between which is transmitted using chains. They have reverse.

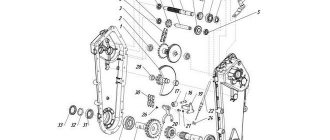

There are also combined mechanisms. The picture below is gear-chain type:

Criteria for selecting a walk-behind tractor by gearbox type

If the walk-behind tractor is low, it means it is equipped with a gear reducer. This type is compact, so the entire walk-behind tractor and its center of gravity are located noticeably lower than other options.

A low unit is easier to work with. There are no chains that tend to stretch over time, which leads to malfunction. The downside of this option is that it is noisier. And there are problems if the parts of the assembly are made of poor quality, from cheap alloys. In terms of complexity, such a unit is comparable to gearboxes of a car and other machines and units.

The most common type of gearbox on walk-behind tractors is the gear-chain gearbox, shown in the image above. It combines the advantages of a gear and chain gearbox, but has the same general disadvantages - chain stretching. The gearbox is tall, so units with it have a high center of gravity.

Types of mechanisms

According to the method of operation and action, all transforming mechanisms for walk-behind tractors are divided into several types:

- angular;

- downward;

- reverse with reverse speed (reverse gearbox);

To redirect rotational energy from a vertical drive to a horizontal plane, an angular gearbox using bevel gears (bevel gearbox) is used.

Reducing the number of revolutions and increasing the power of the drive mechanism is provided by reduction gearboxes, or creepers for the walk-behind tractor. They are considered the most reliable for operating a diesel or gasoline air-cooled walk-behind tractor. This allows them to be used for particularly difficult work - for example, plowing heavy soil or harvesting potatoes using a potato digger.

In a special article you can find drawings of a potato digger for a walk-behind tractor.

Making your own gearbox step by step

It is impossible to make a full-fledged gearbox with a crankcase, axles (shafts) on bearings and sets of gears or chain sprockets on your own. This is a complex assembly that requires a production line with many high-precision machines to produce. Sometimes owners adapt ready-made reduction or angular gearboxes from other machines and mechanisms for their units.

The simplest version of a reduction gear (more precisely, a reduction gear) is shown in the following video:

Chains and chain sprockets from a motorcycle were used here. It is impossible to describe step by step all the actions of such tuning. Main stages:

- In front of the factory gearbox, a homemade stand is placed under the working shaft, on bearings.

- Large gears from a motorcycle, a pair, are attached to the working shaft. One on each side of the rack.

- Small sprockets are mounted on the shaft located in the factory gearbox.

- Chains are stretched between the sprockets, like on a motorcycle.

The design must include a device for adjusting chain tension.

Application of gears

The scope of application of gearboxes is wide - from mini-drives in medical equipment to industrial power plants. They found a place in agriculture, metallurgy, the coal industry, mechanical engineering, shipping and automobiles. Gear reducers are used in different climatic conditions - indoors, outdoors, in heat, cold and even in arctic conditions.

The use of gear systems is due not only to the ability to change the direction of shaft movement. With the help of gears, the rotation speed increases and decreases, and the torque on the shaft changes (more often increases).

Model range of gearboxes for walk-behind tractors

All gearboxes of the above types are on sale. When choosing a new gearbox, you should first of all take into account compatibility - the unit must simply match the specific model in terms of dimensions, mountings, and gear ratio. At the same time, the specificity of modern walk-behind tractors is that the same model can have both different engines and gearboxes.

For example, let’s compare the well-known and popular Russian walk-behind tractor Neva MB2 with the traditional and new Multiagro gearbox.

Traditional gearbox:

- unlocking on one wheel . When rotating, one wheel is easy to turn in only one direction;

- gear shifting on the gearbox cover , which is inconvenient when traveling with a trolley. You have to stop, get off the cart and approach the walk-behind tractor to change gears;

- 2 forward speeds, 1 reverse speed . If you transfer the transmission belt to pulleys with a different gear ratio, the number of speeds doubles. As a result, 4 speeds forward, 2 reverse.

New Multiagro gearbox:

- two wheel unlocking . The left and right locking handles are located on the steering wheel. With their help it is easy to turn in both directions, and not in one;

- gear shifting using a cable is moved from the gearbox housing to the steering wheel, which is convenient;

- more gears: 3 forward, 2 reverse . When throwing the belt 6 forward 2 back.

It is still difficult to compare the reliability and service life of these different models. The new unit has been on sale relatively recently, approximately since 2022. But it was developed and tested for quite a long time. In terms of functionality and convenience, Multiagro has a clear superiority. This is a Russian production, St. Petersburg, .

Cross-section of the Multiagro gearbox:

A gearbox with gear switching on a walk-behind tractor essentially gives only advantages; it is a kind of analogue of a car’s gearbox. This is the responsible node. If performed well, it can have a fairly long service life. The main thing that depends on the owner to extend the service life of such units is the smooth activation of speeds, control over the quantity and quality of oil.

Motoblocks with gear transmission

A walk-behind tractor with a gear reducer is designed for plowing and cultivating small areas of land. Depending on the size of the plot, the power of a mechanical plow is selected, reaching 10-15 hp. With. The operation of a mechanism of such power is impossible on a belt or chain drive. After all, gears can withstand much greater loads.

A reduction gearbox installed on powerful walk-behind tractors can be made independently from spare parts of automobile differentials and gearboxes, or purchased in a store from a number of those produced for garden purposes.

or JSC "Red October - Neva", produce spur gear reducers for the transmission of Russian-assembled walk-behind tractors. These devices are produced as spare parts for cultivators, and therefore are not always interchangeable. This limits their installation on another walk-behind tractor model.

Walk-behind tractors with a gear reducer and a disc clutch have gained popularity due to gear shifting without stopping the pulley. But such designs are more complex and more expensive.

The most common are sealed gearboxes with an oil bath and an aluminum housing. Being lightweight and simple in design, such mechanisms require virtually no maintenance. There are non-separable models that, when they fail, are replaced and cannot be repaired.