Guillotine shears are a metal-cutting machine that uses the combined action of a sharp blade and high mechanical pressure in its work. Guillotine knives are driven by hydraulic cylinders or mechanical levers, depending on the type of shear.

Guillotines are used mainly for longitudinal and transverse cutting of sheet metal, the thickness of which can reach 60 mm. Many models of industrial metal shears can cut both foil and sheets 0.2 mm thick, as well as reinforcement and shaped steel. The industry produces more than 100 standard sizes of knives for various types of guillotine machines.

Guillotine knives.

| We supply knives for guillotine shears of domestic and foreign production. Knives are produced according to the Customer's drawings or according to GOST 25306-82. Knives are made of steel 6ХВ2С, 6ХС. Tolerances for geometric dimensions in accordance with GOST 25306-82 ensure complete interchangeability of guillotine knives without additional adjustment and grinding. |

Guillotine knives, models and sizes.

Model

| Model

|

If you don't find what you need? Call us at 8 (812) 424-18-16. Or send a request.

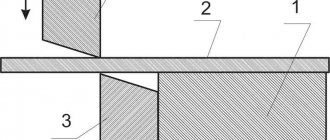

Guillotine shears are designed for cutting sheet material. Transverse cutting of a sheet, the thickness and width of which corresponds to the technical characteristics of the guillotine, is carried out in one stroke of the guillotine knife, longitudinal cutting - by a series of repeated cuts when moving the sheet along the cutting line. Cutting with sheet metal scissors can be done according to the markings, or without it - using the back stop. An important criterion for proper operation is adjusting the gap between the guillotine knives. The gap should be 1/15 - 1/30. It should be remembered that the accuracy and reliability of the scissors depends on the quality of sharpening and grinding of the guillotine knives.

Paper cutting steels

The knife is the main working tool of a paper cutting machine, determining the accuracy and quality of cutting. Even with the ideal technical condition of the machine, highly qualified operator and compliance with all other conditions, it is impossible to obtain high quality products without a high-quality and sharp knife.

Considering the special purpose of the knife and its important role, the following requirements are imposed on it:

the ideal condition of its surfaces, both cutting and fastening; no deformation of the body and cutting part; the flatness of its working edge - the maximum deviation of any point on its surface should not exceed ± 0.1 mm; the knife blade should not have nicks, cracks, burrs, notches, marks, burns and crumbled places, and the entire surface should not have delaminations, cracks and traces of corrosion; proper knife sharpness, i.e. the minimum conditional radius of curvature of the blade should be within 2...25 μm; maximum deviations of the cutting edge of the knife from straightness are ± 0.1 mm.

the knife should completely cut through the bottom sheets of the foot; the cut surface must be clean and smooth; The hardness of the cutting edge of the knife must be at least 57 HRC.

The following indicators are used to evaluate a knife:

- geometric parameters and cross-sectional shape, material,

- sharpening angle and shape,

- knife sharpness,

- cutting ability,

- resistance and durability,

- knife design.

Geometric parameters

The geometric parameters, or physical dimensions of the knife, are the length, thickness and height of the knife to be ground. They must provide it with the necessary rigidity and stability when cutting materials.>

Knife length

depends on the model of the paper cutting machine (determined by the format of the processed product) and is the sum of the maximum cutting length plus the amount of lateral shift of the knife during saber movement. Typically it is 1.2-1.3 times the maximum product format.

Knife thickness

is selected depending on the format of the machine on which it is installed, and, as a rule, is 9...14 mm.

Knife height

determines its service life, since it is grindable and decreases each time during the sharpening process. The top of the knife has one to three rows of threaded holes for attaching to a knife holder. When the knife is new, unsharpened, the bottom row of holes is used. After reducing the height of the knife, the upper row of holes is used to fasten the knife, and the end face of the knife is supported by eccentrics.

Knife material

Knives for paper cutting machines are made of high-strength steel (for example, DIN1.2379, DIN1.3343), and their surface is carefully polished, which guarantees a clean and precise cut.

DIN1.2379

It is used for manufacturing, incl. guillotine knives operating under conditions of increased wear. The steel has a good combination of strength and toughness, allowing it to perform well in most moderate-temperature cutting applications. When hardening, a hardness of no more than 62 HRC is achieved. Widely used in industry for the manufacture of cutting dies of complex shapes (matrices, punches, perforated dies) working with metals and other materials. It has excellent wear resistance when used in guillotine-type knives and allows cutting (chopping) materials, including metals.

DIN1.3343

It is used for manufacturing, incl. guillotine knives operating under conditions of increased wear and high temperatures. It copes well with cutting any materials, including metal, and retains its characteristics when heated to 500 degrees Celsius. When hardening, a hardness of no more than 63 HRC is achieved. Widely used for the manufacture of metal-cutting tools (drills, cutters, turning inserts). It has increased wear resistance when working under conditions of friction and heat. It is inferior in its characteristics only to hard alloy.

As a rule, the knife has a composite structure: the body is made of ordinary structural steel, and the cutting part is an insert made of a special material of increased hardness and wear resistance. Therefore, the material of a knife, as a rule, is understood as the material of its thin insert, which, when sharpened, provides the blade with high cutting qualities.

Knives for press shears.

| We produce knives for combined (varietal) press shears, shears for cutting scrap metal, flat knives for edge crushers, crushers, production lines for recycling rubber waste and tires . Knives are produced according to the Customer's drawings or manufacturer's specifications. Knives are made from forgings of steel 6ХВ2С (manufacturer's certificate is issued). |

Knives for combination scissors, models and sizes:

Scissors model

| Scissors model

|

If you don't find what you need? Call us at 8 (812) 424-18-16. Or send a request.

Knives for reinforcement machines.

| We produce knives for chopping and cutting reinforcement to the machines SMZH-172, SMZH-172A, SMZH-172BMA, SMZH-175, SMZH-172BA. We produce knives of different types and sizes - any shape, width according to the drawings and technical specifications of the Customer. The steel used in production is 6ХВ2С, 6ХС, with a hardness of 54…58 HRCе. | ||

Main dimensions:60x60x20, 110x40x18, 110x50x42.5, 110x110x24, 110x60x15, 110x40x24, 110x60x42, 110x110x13, 110x40x13, 160x50x42.5, etc. | Fitted with a bolt with M10, M12 thread, without thread with a 12 mm hole, countersunk under the head. | |

Pipe bending operation, what is it?!

By bending of pipe products we mean the processes of “cold” deformation, which occurs as a result of the influence of a clearly calculated load on the pipe, which leads to a change in the axis of the pipe’s inclination. Such deformations can be elastoplastic and [...]

read more

Production process technology

Knives for crushers.

| Knives for crushers rotary, hammer and agglomeration types of production for domestic and imported equipment are manufactured in accordance with GOST and meet all the requirements of technical regulations. We produce both standard and non-standard knives for crushers. | |||||||||||||||||

We offer the following types of standard knives:

| We produce knives according to the Customer's drawings: Crushing knives for PET rotary crushers (plastic shredders) and polymer recycling machines. Knives for crushers are used in the processing of non-metallic materials - for crushing cardboard, paper, wood, and plastics. Crushing knives for shredder. Shredder knives and crown knives are used for grinding and processing large waste thermoplastics: films, pipes. Crushing knives for agglomerator. Agglomeration knives are designed for crushing PET bottles, thin-walled polymer packaging, and for recycling film waste. | ||||||||||||||||

Disc knives.

| Disc knives and round knives are used for cutting metal, paper, polyethylene, fabric, and gauze. We supply all major standard products. Circular knives have an increased service life, thanks to the high-quality materials used in their manufacture. |

Main standard sizes of manufactured knives:

|

|

Service

Constant contact with hard materials, and especially metal, inevitably leads to the gradual dulling of knives during operation. Even knives made of high-hardness steel have limited service life. To restore the cutting properties of guillotine knives, they must be sharpened promptly and regularly. This work should be entrusted to professionals who have the necessary equipment and knowledge. Sharpening and grinding knives on special machines allows you to completely restore the performance characteristics of the tools, the main thing is not to violate the original sharpening angle provided by the manufacturer, because this can directly affect the efficiency of the cut and the service life of the product.