Introduction

In order for repairs, installation and other work to proceed quickly and efficiently, nothing should interfere, especially if it is a small screw that tends to fall off the screwdriver. For convenience, you can buy a special analogue with a magnetic tip.

But don’t throw your regular screwdrivers in the trash, because you can make these out of them too. To do this, most craftsmen use magnetizers, but there are also other ways to make such a miracle screwdriver. And for this you don’t need services, everything can be done easier and faster. Read on to learn how to magnetize a screwdriver at home.

How to make a magnet at home using improvised materials

For many people, a magnet is still a mystery, although in principle people became acquainted with this metal and phenomenon a very long time ago. Even then, a whole system for the production of various magnets was developed. Today this is far from uncommon, and even powerful magnets can be made at home.

Making a magnet using improvised materials

Of course, for many this will even seem like something supernatural and may even be a shock, but even now, sitting at home, most people can make a magnet with their own hands. Below are four methods that describe how to make a powerful magnet at home.

The first and probably therefore the simplest method: to implement it, you just need to take any object that can be magnetized (the object must be metal) and move it several times along a permanent magnet, and this should be done only in one direction. But, unfortunately, such a magnet will be short-lived and will very quickly lose its magnetic properties.

This magnetization method is performed using a 5 or 12 volt battery or accumulator. Most often it is used for magnetizing screwdrivers and is performed as follows:

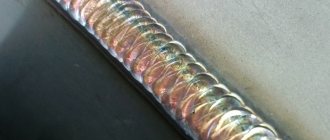

• A copper wire of a certain length is taken, which will be enough to wrap the screwdriver shaft 280 - 350 times. The wire from transformers, or the one intended for their production, is best suited. • The object is insulated; in this case, the entire shaft of the screwdriver is wrapped using electrical tape. • The winding itself is carried out and connected to the battery. One end is to the plus, the other to the minus. The winding should be carried out turn to turn, evenly. The insulation must also be tight.

As a result of these manipulations, it will be much more pleasant to work with a screwdriver. This operation can turn any old unnecessary screwdrivers into a truly convenient tool.

This option describes how to make a powerful magnet in a fairly simple way. In fact, it has already been fully described above, but this particular method involves a different material. In this case, ordinary metal will be used, or rather a small piece of it, preferably cubic in shape, and a more powerful coil. Now the number of turns needs to be increased 2-3 times for magnetization to be successful.

This method is very dangerous and is strictly prohibited for use by people who are not electrical professionals. It is carried out strictly in compliance with safety precautions, the main thing is to remember that only you and no one else bears responsibility for life and health.

He talks about how to make a strong magnet at home, while spending a small amount of money. In this case, an even more powerful coil, wound exclusively from copper, will be used, as well as a fuse for a 220-volt network.

The fuse is needed so that the coil can be turned off in time. Immediately after connecting to the network, it will burn out, but during this period of time it will have time to go through the magnetization process. The current strength in this case will be maximum for the network and the magnet will be quite powerful.

DIY powerful electromagnet

First, you need to figure out what it is. An electromagnet is a whole device that, when a certain current is supplied to it, works like a regular magnet. Immediately after cessation, it loses these properties. How to make a powerful magnet from an ordinary coil and iron was described above. So, if you use a magnetic circuit instead of iron, then you will get exactly the same electromagnet.

In order to figure out how to make a strong magnet at home that will work from the network, you just need to remember a little information from the school physics course and understand that as the coil, as well as the magnetic circuit, increases, the power of the magnet will also increase. But this will require more current to reveal the full potential of the magnet.

But neodymium remains the most powerful; they have all the most desirable properties and, despite their strength, are small in size and weight. How to make neodymium magnets with your own hands and whether it is even possible will be discussed further.

Making a neodymium magnet

Due to the complex composition and special production method, the question of how to make a neodymium magnet with your own hands at home disappears by itself. But many are still interested in how to make neodymium magnets, because it would seem that if you can make an ordinary magnet, then it is also quite possible to make a neodymium one.

Demagnetization of pipes before welding

» Articles » Demagnetization of pipes before welding

Welding pipes and steel structures using direct current is often accompanied by the effect of “magnetic blowing,” which is caused by residual magnetization. At the same time, the stability of the process deteriorates, metal spatters, defects such as pores, lack of fusion, lack of penetration, slag inclusions form in the weld, and sometimes welding becomes simply impossible due to arc failure and electrode sticking.

The main reason for the magnetization of pipelines is the use of magnetic flaw detectors to diagnose their technical condition, after which the magnitude of the residual magnetic field in the cutting of a welded joint can reach 100-150 mT (1000 - 1500 Gas) or more.

Additional factors contributing to the magnetization of pipelines are the Earth's magnetic field, elastic mechanical stresses, and technological magnetization of pipes during their manufacture and transportation.

Since the magnetization of pipes does not allow obtaining a good quality weld, demagnetizing them before welding is a necessary technological operation. It is almost impossible to achieve complete demagnetization, therefore welding is allowed with insignificant residual magnetization, which does not have a noticeable effect on the welding process.

For example, the STO Gazprom standard 2-2.2-136-2007 “Instructions on welding technologies for the construction and repair of field and main gas pipelines. Part 1" established that the residual magnetization of the ends of pipes and pipeline connecting parts should be no more than 2 mT (20 G).

When magnetization is more than 20 Gauss, demagnetization must be performed.

razmagnit.wordpress.com

11.3.3 Demagnetization by welding current sources | Ugra training center

11.3.3.1

Demagnetization of pipes using pulsed welding current sources is performed in the following sequence:

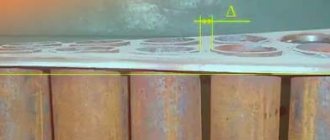

- wind the welding cable (from 18 to 20 turns) at a distance of 10 to 20 mm from the end of the pipe (Figure 11.13), while the ends of the two demagnetized pipes must be at a distance of at least 2500 mm;

— determine the initial value and direction of the magnetic field along the perimeter of the pipe at eight control points;

— set the minimum current on the welding current source (in the range from 30 to 70 A), close the contact to the plate;

— measure the magnitude of the magnetic field along the perimeter of the pipe at eight control points. If the magnitude of the magnetic field has not changed or increased, it is necessary to change the polarity of the current on the solenoid;

— set the maximum current on the welding current source (in the range from 240 to 300 A), close the contact to the plate, hold for 6-12 s, then open the contact and turn off the power source;

— dismantle the demagnetizing windings (solenoid).

1

- pipe; 2 - welding cable; 3 - DC welding power source; 4 - metal plate; 5 — detachable contact

Figure 11.13 — Installation diagram of equipment for demagnetizing pipes using the pulse method

11.3.3.2

Demagnetization of connections before welding with welding current sources using the compensation method is performed in the following sequence:

— determine the initial magnitude and direction of the magnetic field along the perimeter of the welded joint at eight control points;

— wind a welding cable with a cross-section of 35; 50 mm 2 on both ends of the pipes (Figure 11.14), while the winding should be in one direction, uniformly dense and single-row, the number of turns wound on the end of the pipe with a larger magnetic field is from 7 to 11, pipes with a smaller magnetic field fields - from 3 to 5 turns;

— connect the welding cable to a DC source;

- turn on the welding source and gradually increase the current value from the minimum value, while simultaneously monitoring the change in the magnetic field value;

— if the magnitude of the magnetic field in the welded joint increases, turn off the power source and change the polarity (change the ends of the welding cable on the power source);

— if the magnitude of the magnetic field in the pipe joint does not exceed 20 Gauss, proceed to welding the root layer of the seam, as the weld is completed, the current magnitude is reduced, while simultaneously controlling the magnitude of the magnetic field in the pipe gap;

How to demagnetize metal at home? — po4ki.ru — Garden, vegetable garden, dacha

Judging by numerous reviews, when starting to carry out any work, home craftsmen often encounter one problem - magnetization of tools.

According to experts, this property of the metal in some cases significantly helps in work, since the tools become better.

For example, using a magnetized screwdriver it is much easier to tighten screws in the most difficult to reach places.

But many are also interested in the other side of the issue. How to demagnetize magnetized metal? This interest is due to the fact that in some cases magnetization is undesirable.

It is unlikely that you will be able to make high-quality markings with a caliper with metal shavings stuck to it. It is also inconvenient to use a magnetized cutter. These tools, as a result of exposure to a magnet, noticeably reduce their performance properties.

You will find information on how to demagnetize metal at home in this article.

What is the cause of magnetization?

Before you become interested in how to demagnetize metal, you should understand the nature of this phenomenon. According to experts, magnetization is carried out by paramagnets, diamagnets and ferromagnets.

Products based on alloys of iron, nickel and cobalt have their own magnetic field, which is higher than the external one. Tools become magnetized if they are used near electric motors or other emitters.

As a result, they will take away some of the magnetic properties.

About a homemade device for demagnetization

Judging by numerous reviews, tunnel devices can be used for this purpose. The design of such a device includes a coil connected to the mains.

There is a hole inside the coil where the workpiece should be inserted. Demagnetization can be successfully performed using a homemade electromagnet.

It is not difficult to make it from some materials and available tools.

The operating principle is to control the current. Magnetization is carried out by constant voltage, and by alternating voltage - the opposite effect. The reels are made from old TVs.

It is enough to disassemble it and remove the demagnetization loop in the kinescope. Then it is folded at least twice. It all depends on what diameter the home craftsman needs.

It happens that one loop is not enough. In this case, it can be supplemented from another old TV. Further, the design is equipped with a fuse button, which will ensure uninterrupted operation.

A device designed for 220 Volts is suitable for permanent use, and 110 Volts are suitable for short-term connections. If the product is 12 V, then experts recommend using a transformer.

With such a homemade mechanism, you can successfully demagnetize even large parts.

About the use of magnetized tools

According to experts, some instruments are deliberately magnetized. These are mainly screwdrivers that are used when repairing mobile phones, computers and various household appliances. Such screwdrivers will become indispensable in situations where you need to tighten a screw, but there is no way to support it with your hands.

It is better not to subject watch instruments to the magnetization procedure, since this can stop their working mechanisms. It is not advisable to work with a magnetized drill or cutter, since small metal particles sticking to the working part of the tool will cause a lot of trouble for the master. Read on to learn how to demagnetize metal.

Vladimirs Vorohobovs

Many irresponsible residents take advantage of this. installing magnets near their meters and thus stealing water.. However, now there is an inexpensive seal that can be put on an already installed water or gas meter. Like a regular seal, it has its own unique number or letter code, which can be recorded in a journal and thereby verify that the seal has not been replaced. Installing such a seal on a meter does not require complex skills.

I didn’t find a single loss, I also found a court - a fine against them for tax evasion.

In general, to give more information against scammers:

1) We meet with them at the office to make a claim (in my case, I didn’t even find an office - at the specified address there is a nine-story residential building). There are no workers. The manager, a 24-year-old boy, refused to meet with me at a time convenient for him - he sent a written complaint about poor-quality measurements. I refused to pay the cost of measurements - 350 rubles for each meter (I have 4 of them and they all showed the same value, like other cases - very interesting, isn’t it? Do they have a scale with one value?) , because does not want to take repeated measurements in my presence and provide the documents required by law.

2) We look carefully at the measurement report - there are no signatures of the measurer (strange, the one who measured refused to sign the document...) and members of the commission. Only two negotiating bosses. Moreover, there was no commission - it stood on the site and did not enter the apartment. What then did the head of the HOA sign if she was not present during the measurements?

3) We read the laws and immediately forget about this piece of paper... We ask them for an accreditation certificate (costs 200 thousand, requires an office, equipment and at least two certified specialists) and a certified methodology (issued only by the Ulyanovsk Metrology Center)

4) We write to the manufacturer with a request for an independent examination and receive from them a colorful color letter with three seals and the signature of the deputy director that there are no norms, no standards, no GOSTs, and no internal specifications to refute or confirm the measurement result . No one has ever measured them and no one is going to do so. (Well, Ulyanovsk is ahead of the rest! And why is it that only we have come up with the idea of measuring something, but not Moscow?))

5) For insurance, we call the metrology center and present to the chairman of the HOA the specified certificates of verification of the certified (and ONLY

in Ulyanovsk an organization) that has the right to check water meters (it turns out that not everyone who gets there has the right to check them...)

You can stop the water meter with some tricky manipulations with a neodymium magnet. To do this, use a magnet in the immediate vicinity of the counter to find the point where it stops completely. This can be the front side, the side surface of the meter, and less often the back wall of the device. The reader performs all manipulations experimentally at his own risk. This information is taken from open sources on the Internet, is provided for informational purposes only, and does not oblige you or push you to anything.

Magnetizer for screwdrivers and more

The magnetic properties of the tool make life much easier. There is confidence that not a single screw, even the smallest one, will fall out or get lost. In any case, it will remain at the tip of the tool.

But there are also situations when this turns into a “disservice”. If you work with electronics, a magnetized tool can have a negative impact. This led to the invention of the so-called magnetizer.

The operating principle of this device is very simple, but nevertheless very effective. It allows you to quickly endow any screwdriver with the properties of a magnet, and, if necessary, get rid of this effect. The device, which is very simple in design and principle of operation, allows you to magnetize the tip:

- screwdriver;

- scissors;

- self-tapping screws;

- screws;

- screws

Essentially, any metal object can be given magnetic properties. Due to the fact that the device does not require the use of an electrical network or additional charging, it can be used in any conditions. The compact size also contributes to this to a large extent. In this case, you do not need to have any special knowledge or skills.

The body of the structure consists of polymer. Two magnets are placed inside. Two holes on the body allow you to impart magnetic properties or, conversely, demagnetize. In order not to confuse which one is intended for what, all holes have corresponding markings.

If you place a screwdriver or other metal object inside the corresponding hole, it will be magnetized. If these magnetic properties are no longer needed, the object is placed in another hole. If, apart from screwdriver bits, nothing else needs to be magnetized, then you need to purchase a device that has small slots. This is why the cost changes.

In addition, a small hole affects the proximity of the magnets, and, accordingly, the strength of their influence. The reverse is also true: a larger tool or fastener will require a device with larger holes.

In fact, the entire device is a small piece of plastic with two holes, and sometimes with one or two magnets. Small size, light weight - all this allows the device to be used not only in the workshop, but also to be easily transported. The cost of the product is low, usually no more than six hundred rubles, but some models cost much more.

Tips for choosing

In addition to their shape, the devices also differ in the strength of the radiation and the method of attaching the cable.

Experienced treasure hunters are advised to choose powerful double-sided magnets, since they are universal and easy to use, although they are more expensive.

Weight and ammunition

Any tool is most effective if it is selected in accordance with the task at hand. The choice of magnet is no exception. To begin with, you should decide what items it will be used to search for, and based on this, select the appropriate device.

In addition to the magnet itself, you will need a cable with which the search device can be lowered to the bottom of the reservoir. It is better to choose ammunition with a large margin of safety, exceeding the power of the magnet itself, in order to avoid ruptures and loss of the device. Finding him later is almost impossible.

Review of popular devices and their prices

The most well-known magnet manufacturers offer devices of varying power and cost:

How to make a demagnetizer by hand

In the video of the popular channel “Rinat Pak” it is planned to show and tell what a simple device for magnetizing and demagnetizing parts can be made from. The master worked a lot with metal, and after work a lot of shavings and sawdust remain, and it happens that carbon steel tools become magnetized, the shavings and sawdust stick and it becomes uncomfortable to work. They get in the way a lot. And there is a situation where you need to magnetize the screwdriver so that the bolts stick when tightened. The device was needed to be small, take up little space and be lightweight.

There is a magnetizing and demagnetizing device made from a transformer that weighs almost 2 kilograms, which is not convenient. Firstly, you can’t put it in your pocket, it’s heavy and takes up a lot of space. But you need a compact device.

I decided to make my own from a transformer from a washing machine pump. They throw away a lot, the pumps don't work. Often the working part remains - a coil with a magnetic core. I decided to use a regular pump. To disassemble it, you need to unclip two latches; this is done simply and the pump can be easily disassembled. We remove part, we will need the other to make a device for magnetizing and demagnetizing parts. They are all approximately the same, they operate on 220 volts, as far as I have seen. A ready-made device that will become a device for magnetization and demagnetization.

First of all, when we removed the coil with the magnetic core, what do we do? Let's call the coil itself. Two contacts for connecting wires, it is designed to work with 220 volts. We check it for rupture. If the coil is working and there is no short circuit, then we can safely make a device out of it.

Types of magnetic clips

There are many types of magnetic clips, let's look at the most common:

- Label. It is small in size, fixed directly to clothing, often in a place where the buyer does not look. If it is damaged in the store, the signal will immediately turn on. There is no splatter paint inside the label.

- RF tag. Triggers at the exit when trying to secretly remove an item. It can be easily removed at home without damaging clothes and does not contain paint inside.

- Magnetic-acoustic sensor. It looks like a plastic tag with a convex part, inside of which there is a bottle of paint. When you try to remove it without a special device, it closes even more tightly or splashes neon paint around itself.

Search Magnet Care

To use a search magnet for a long time, it is important to properly care for it. There are no special requirements for processing the coating, but you need to wipe it with a dry cloth and clean it of small adhering metal particles

The magnet is a fairly reliable tool; its service life depends on the characteristics of its use. Over a decade, it loses no more than 1% of power.

Do not hit or heat the device. When exposed to temperatures above 80 °C, it will lose its magnetic properties and turn into a useless piece of metal.

Important! The design negatively affects the operation of electronics; the damage radius depends on the power. When searching for artifacts, you should keep smartphones and laptops at a safe distance, and it is better to store search magnets in special bags (more details below)

Demagnetization of search magnets

Even the most powerful magnets lose their properties over time. Ferrite products will last for several decades, but neodymium products will last 200-300 years.

Causes of involuntary demagnetization:

- Heat. When heated above 80 ⁰C, the magnet will completely lose its attractive force. Only some models have increased resistance to temperature changes and can withstand up to 200 ⁰C.

- Strong blows. Mechanical impacts on a magnet (impact, falling from a height) deprive it of its value.

- Errors when cutting and drilling. Strong pressure when processing a magnet with a grinder can lead to loss of characteristics.

- Impact of external factors. When exposed to a magnetic field with an induction of about 3-4 Tesla, the magnet can be demagnetized.

It will be possible to restore the lost properties only in large-scale production using an industrial magnetization installation.

The main reasons for metal magnetization

Magnets are media that create their own magnetic field. Main groups of magnets:

- paramagnetic materials;

- ferromagnets;

- Diamagnets.

Steel products based on alloys of iron, cobalt or nickel refer to substances whose own magnetic field is higher than the external one, i.e. to ferromagnets. The magnetization of a substance is considered to be the sum of the magnetic properties of particles per unit volume.

At the moment the Curie temperature threshold is reached, spontaneous domains with magnetization are formed, which spread until they are completely filled. Under normal conditions, it is possible to obtain a magnetized tool when working close to electric motors, magnetrons and other elements. The metal takes away the properties of magnetism from a nearby emitter, thereby becoming magnetized.

Working with small parts with a magnetized tool can cause a lot of trouble. Sharpening metals with increased magnetism properties is impossible to ideal sizes, because... the material is covered with shavings.

About working with large batches of parts

There are times when it is necessary to remove magnetization from many metal products. This is possible through the desired temperature. How to demagnetize metal by heating? According to experts, this will require heating the products to a certain state, which is also called the Curie point. Iron is heated to a temperature of 768 degrees. A ferromagnet will require a higher range. Upon reaching the desired temperature threshold, spontaneous magnetized domains are formed.

The process goes as follows. First, one part is brought to the Curie point. Next you should cool it. It is important that it is not affected by external magnetic fields (the only exception is the Earth’s magnetic field). Next, using a sensitive induction meter, the maximum magnetization is assessed. Next, in the control zone at a distance of no more than 2 cm from the part, the range of different values obtained by the MF-23 or MF-23M indicator is measured. Magnetic induction should be +/- 2 mT.

Description of the experiment

So, in the experiment we observe how a permanent magnet moves inside a hollow copper pipe at a constant speed. Let's fix an arbitrary point in the body of the copper tube and mentally draw a cross section. A magnetic flux created by a permanent magnet passes through this section of the copper pipe. Due to the fact that the magnet moves along the pipe, an alternating current

magnetic flux, either increasing or decreasing depending on whether the magnet is approaching or moving away from the point where we mentally drew the section. An alternating magnetic flux, according to Maxwell's equations, generates a vortex electric field, generally speaking, throughout space. However, only where there is a conductor, this electric field sets in motion the free charges located in the conductor - a circular electric current arises, which creates its own magnetic field and interacts with the magnetic field of a moving permanent magnet. Simply put, a circular electric current creates a magnetic field of the same sign as a permanent magnet, and a certain dissipative force acts on the magnet, and more specifically, a frictional force. The reader may rightly ask the question: “Friction of what against what?” Friction occurs between the magnetic field of the dipole and the conductor. Yes, this friction is not mechanical. Or rather, the bodies do not touch. Well, let! There is still friction!

In general, in words everything looks more or less smooth, but can it be described in the language of mathematics? Let's get started...

Magnetization is illegal

Government Resolution No. 354, which caused a stir, allowed owners to be punished for damaging metering devices by billing them for water consumption based on the pipe’s capacity for six months. These are huge amounts of hundreds of thousands of rubles. Meanwhile, as it turned out, there is no legal basis for checking and measuring the so-called “magnetization”...

Who cares! Approximately this conclusion can be drawn after a round table on the topic “Theft of hot and cold water in apartment buildings by installing magnets on individual metering devices,” which was held on March 26 in the Legislative Assembly of the Ulyanovsk Region under the leadership of the head of the Housing and Communal Services Committee of the ZS Gennady ANTONTSEV.

How to demagnetize a screwdriver or a metal object using a magnet

To do this, you will need a spool of wire that can withstand 120-127 volts and a powerful step-down transformer. The structure is assembled according to the following scheme.

Wind the wire around the coil of the transformer and connect it to it. After this, a screwdriver is placed in the internal cavity of this coil and alternating voltage is applied.

If you have an old unnecessary TV, you can assemble a device with your own hands, which includes a kinescope demagnetization loop (it is located around it). Connect its ends together to form a circle and wrap it with electrical tape, leaving two wires outside.

Attach the resulting structure to a block of wood, which will serve as a handle. Using a button from any power tool, connect two wires to a 220 volt network.

Important! Be sure to insulate all wires and contacts to prevent electric shock!

The device is ready for use. Turn it on and place a screwdriver in the ring. Hold it for no longer than 5 seconds, then turn off the device, otherwise it may overheat.

There are a huge number of ways to demagnetize a screwdriver at home, so you can choose any one you want.

How to make a demagnetizer by hand

In the video of the popular channel “Rinat Pak” it is planned to show and tell what a simple device for magnetizing and demagnetizing parts can be made from.

The master worked a lot with metal, and after work a lot of shavings and sawdust remain, and it happens that carbon steel tools become magnetized, the shavings and sawdust stick and it becomes uncomfortable to work. They get in the way a lot.

And there is a situation where you need to magnetize the screwdriver so that the bolts stick when tightened. The device was needed to be small, take up little space and be lightweight.

There is a magnetizing and demagnetizing device made from a transformer that weighs almost 2 kilograms, which is not convenient. Firstly, you can’t put it in your pocket, it’s heavy and takes up a lot of space. But you need a compact device.

I decided to make my own from a transformer from a washing machine pump. They throw away a lot, the pumps don't work. Often the working part remains - a coil with a magnetic core. I decided to use a regular pump.

To disassemble it, you need to unclip two latches; this is done simply and the pump can be easily disassembled. We remove part, we will need the other to make a device for magnetizing and demagnetizing parts. They are all approximately the same, they operate on 220 volts, as far as I have seen.

First of all, when we removed the coil with the magnetic core, what do we do? Let's call the coil itself. Two contacts for connecting wires, it is designed to work with 220 volts. We check it for rupture. If the coil is working and there is no short circuit, then we can safely make a device out of it.

What other ways are there?

If you have a round magnet with a hole in the middle in your house, you can use it to demagnetize a screwdriver.

To do this, simply thread the screwdriver through the magnet, starting from the tip and ending with the bottom of the handle. This action is performed at a leisurely pace. As a rule, one time is enough to demagnetize, but you can repeat it if necessary.

If there is no hole or it is not wide enough, there is a second method. Position the screwdriver in relation to the magnet at the minimum distance at which it is not attracted to it.

After this it should demagnetize.

For the third method we will need a magnetometer. First, determine the level of magnetic field strength of the screwdriver. Then find a field with the same voltage on the magnet, but at a pole with the opposite sign. After that, all you have to do is press the screwdriver exactly to this part.

Using a magnet

Experienced craftsmen recommend that beginners use a regular magnet for demagnetization, but it must be large in size and round in shape. For example, consider a magnet from a speaker.

Before starting work, you need to run a strip under the surface of the magnet. To do this, you can take scissors, tweezers, a metal tool or a drill.

Bring the magnet to the instrument as close as possible for 10-20 seconds. This will be enough to completely demagnetize the product.

If a magnet sticks to a metal surface

Sometimes the powerful rare earth neodymium magnet will stick to various metal surfaces. This could be an entrance door, a sewer hatch, or a car body. If it is a powerful search magnet, then to disconnect it you will have to put in a lot of effort or use improvised tools. How to separate neodymium magnets at home or unstick a magnet from a metal surface? The following method is proposed.

If the surface is flat and smooth enough, then the easiest option is to move the magnet to the edge of the sheet of metal. If this method is not effective, then it will be safer and more reliable to use wooden wedges.

What it is

A neodymium magnet is a magnetic element that is composed of neodymium rare earth boron and iron material. It has a crystal structure, tetragonal shape and formula Nd2Fe14B.

It was first created by General Motors in 1982. It is the strongest permanent magnetic element, the power of which is several times greater than usual. Equipped with a large magnetic induction of 12,400 gauss.

Note! This is a brittle alloy with the formula NdFeB, as well as a hard nickel-plated protective layer and the corresponding class. It is very popular and comes in various forms.

DIY degausser

Craftsmen when working with various metals are faced with a problem - magnetization of tools.

In some jobs, magnetic properties help with actions, for example, with a magnetic screwdriver you can install a screw in a hard-to-reach place.

The build-up of metal shavings when using a caliper, file or drill can interfere with marking or a straight cut line.

How to demagnetize metal at home

The main reasons for metal magnetization

Magnets are media that create their own magnetic field. Main groups of magnets:

- paramagnetic materials;

- ferromagnets;

- Diamagnets.

Steel products based on alloys of iron, cobalt or nickel refer to substances whose own magnetic field is higher than the external one, i.e. to ferromagnets. The magnetization of a substance is considered to be the sum of the magnetic properties of particles per unit volume.

At the moment the Curie temperature threshold is reached, spontaneous domains with magnetization are formed, which spread until they are completely filled.

Under normal conditions, it is possible to obtain a magnetized tool when working close to electric motors, magnetrons and other elements.

Magnetized screwdriverMagnetized paper clip

Working with small parts with a magnetized tool can cause a lot of trouble. Sharpening metals with increased magnetism properties is impossible to ideal sizes, because... the material is covered with shavings.

Using a demagnetization device

The demagnetization device comes in three variations.

The basic elements can be selected at home, using simple methods that do not require much effort to manufacture.

There are special devices that can both demagnetize and magnetize an element.

Magnetometer

Magnetometers are used in the following sequence:

- The magnetic field strength of the instrument is an important parameter that needs to be determined, because it is possible to get a negative result;

- the same parameter must be found on a magnet of the opposite sign;

- touching the tool to the area of the device will demagnetize it.

The process takes place within 10 seconds; at home, no connection to the electrical network is required.

The functionality is checked as follows: the self-tapping screw is brought to the magnetized metal, and the level of magnetization is checked.

Afterwards the demagnetization process occurs and is checked again.

About the special device

Magnetometers are available especially for this purpose, through which a tool can be both given a magnetic charge and removed. For those who do not know how to demagnetize metal, experts recommend doing the following:

- First you need to determine what voltage the magnetic field is at. This is a very important aspect, since a mistake can lead to the opposite result.

- You also need to measure the voltage on the magnet. It must have the opposite sign.

After these steps, you should touch the magnetometer area to the instrument, as a result of which the latter will be demagnetized.