Welding electrodes OZS-12 are intended for connecting steel pipelines, boiler parts and other components of water supply systems.

Thanks to the special composition of the rod and coating, they ensure high-quality welding of T-joints with the formation of a concave seam. The electrodes are not demanding in terms of equipment and qualifications of the welder, and are also notable for their low price (on average 750 rubles per pack weighing 5 kg).

Electrode welding.

What does OZS-12 electrode marking mean?

The abbreviation OZS stands for the following:

- O – experienced;

- Z – plant;

- C – construction;

- 12 – brand number.

The electrodes were developed in the 70s at the Institute of Electric Welding, a division of the Academy of Sciences of the Ukrainian SSR. The goal of the specialists was to create products that were not inferior in their characteristics to rods with a basic type of coating, but at the same time superior to them in terms of environmental friendliness. The problem was successfully solved; after numerous tests, from the late 70s, electrodes began to be actively used in Soviet industry and in everyday life.

The principle of the electrode design for various types of welding machines

There is nothing fundamentally new. The electrode still consists of a rod made by using metal, coating and auxiliary components, such as rods. The selected metal determines the technical characteristics of the element.

You can often find components that consist of only one wire that does not have a coating and they are called accordingly - uncoated electrodes. One of the main representatives of such means is tungsten electrodes.

As has been said many times, a metal rod can be coated with one of the following coatings, or have several coatings at once:

- acid coating;

- main type of coating;

- cellulose coating;

- rutile coating;

- combined type processing;

- highly specialized coverage.

It is worth noting that the coating also has its own types. The coating can be protective and ionizing. The first has thick layers, and the second has a thin-layer structure.

Electrodes OZS-12 – description

Electrodes for welding OZS-12 are made from carbon wire Sv-08 and Sv-08A (of increased purity relative to sulfur and phosphorus). A thick layer of coating is applied to the rods, which contains 92–95% rutile, a natural mineral in the form of titanium dioxide (TiO2). It performs several important functions at once:

- ensures good ignition and stable arc burning;

- releases slags that protect the weld pool from exposure to the atmosphere;

- chemically binds metal oxides, preventing its oxidation in the weld area.

The same protective and alloying functions are performed by ferrites contained in the coating, such as ferromanganese. Carbonates (for example, CaCO3) contribute to the formation of a protective gas around the bath and, like rutile, stabilize the combustion of the electric arc.

Titanium dioxide has another property that is indispensable for welding. Due to the high chemical inertness of the material during the work, the release of gases harmful to health and the environment is minimized.

Purpose and application

“OZS” are used for manual welding of steels containing carbon. They are used for cutting structures and sheets, as well as for surfacing worn parts and mechanisms. These electrodes allow you to work in different positions, which makes it possible to work even with complex installations.

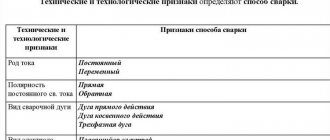

When working with “OZS” electrodes, use direct current of reverse polarity, or alternating current with a voltage of at least 50V.

The rods are supplied in different diameters from 2 to 6 mm.

The OZS brand is widely known and in demand. These electrodes are certified by NAKS and are manufactured in accordance with GOST. One of their features is the ability to weld on an oxidized surface.

The most common brands are “OZS-4”, “OZS-6”, “OZS-12”. All of them belong to the E-46 type. This means that they are suitable for work where high viscosity and resistance to external influences are required from the seam.

The rods are supplied in 5 kg packs. They are produced by several Russian manufacturers: Esab, SpetsElektrod, Bor and others.

You can cook in different positions, but not from top to bottom. You will need direct or alternating current, the source of which can produce at least 50 W at idle.

“OZS” electrodes have a rutile coating. The content of this mineral makes it possible to avoid the formation of pores and cracks during and after welding. You can cook even on poorly cleaned surfaces. The electrodes also provide a stable arc. This property is very useful if you are going to make the seam smooth, beautiful and durable. It will have high resistance to external loads.

Before you start working with the electrodes, they need to be properly calcined. For this, a special oven is used, where they should be sent for about 40 minutes at a temperature of about 150°C. Calcination is necessary so that the proportion of moisture in them does not exceed the prescribed 0.7%.

Welding Features

The permissible moisture content in the coating is no more than 0.7%. Exceeding the values can lead to hydrogenation of the weld metal and loss of the required toughness and ductility. Therefore, before welding, the rods are calcined for half an hour at a temperature of 150–180 °C.

- You can weld parts using both a medium and an extended arc, without fear of the formation of pores in the weld metal.

- The seam on a part can occupy any spatial position, including vertical on the descent.

- Welding with both a transformer (alternating current) and an inverter (constant reverse polarity) is acceptable.

OZS-12 electrodes are sensitive to high temperatures - when calcining, the values recommended above must be strictly observed so as not to damage the coating. The same applies to the welding mode: if the current exceeds the recommended one, pores may form in the metal of the joint.

general information

OZS-12 products can operate when supplied with direct or alternating voltage and are designed for current in the circuit up to 70 A. Thanks to this feature, the electrodes are used in domestic conditions.

Inverters or standard welding transformers with reduced power consumption and connection to a 220 V network are suitable for their use. For the welding arc, alternating or direct voltage with reverse polarity is used.

The electrodes belong to the E46 model, the seam has a tensile strength of at least 460 MPa. The rod is coated with a mineral rutile coating containing natural titanium dioxide.

The material reduces the risk of cracks in the joint metal and maintains stable combustion of the arc discharge (compared to acid-type coatings).

It is possible to use an ilmenite layer (a natural mixture of titanium dioxide and iron). The industry produces rods of the E series with a digital index from 42 to 60, which are distinguished by the strength of the weld.

Area of use

The electrodes are designed to create a permanent connection of parts made of carbon steel (up to 0.25% carbon). The rods allow welding in horizontal or vertical positions, as well as on the ceiling part of the joint.

The products are used by repair teams and private craftsmen to connect water pipes without drying the interior or metal structures for domestic use.

The resulting joint has high tensile strength. To protect the metal from corrosion, it is necessary to apply layers of primer and paint.

Electrodes are used in the manufacture of industrial structures for:

- mining industry;

- lifting mechanisms for technical purposes;

- chemical and petrochemical enterprises;

- gas industry;

- public utilities.

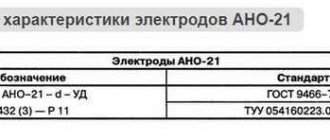

Classification according to GOST

Products are manufactured in accordance with GOST:

- 9466-75;

- 9467-75.

Markings with explanation

The basic designation of OZS-12 products is understood as:

- OZ is a pilot plant (the electrodes were created in the USSR in the laboratory of the E.O. Paton Institute of Electric Welding);

- C – intended for construction work;

- 12 – serial number of the model (several models of electrodes were developed at the same time, differing in the type of coating and chemical composition).

We recommend reading: Rules for selecting electrodes for welding cast iron

The marking is applied with waterproof paint to the coating closer to the metal base (for example, the products of the Losinoostrovsky plant are designated by the letters LEZ OZS-12).

Additional information about the strength of the weld metal, the diameter of the rod and the permissible welding directions is indicated on the packaging in the form of 2 groups of symbols, separated by a horizontal line.

Properties of OZS-12 electrodes.

Welding modes for OZS-12

When using OZS-12 electrodes, a power source is used that maintains the open circuit voltage within 45-55 V. The parameters are set manually depending on the cross-section of the rod, the position of the joint in space and the thickness of the workpieces being connected.

The main values are given in the table.

| Electrode cross-section, mm | Current strength in the circuit, A |

| 2 | 30-90 |

| 2,5 | 50-110 |

| 3 | 70-130 |

| 4 | 11-180 |

| 5 | 130-220 |

Advantages of OZS-12 electrodes

Thanks to several important advantages, welding electrodes OZS-12 are considered one of the most universal. Let's list the main advantages.

- Rutile coating ensures minimal release of toxic substances during work.

- Thanks to the coating (TiO2 is a good conductor), the first and second ignition is easy and the electric arc burns stably.

- Welding can be performed with any kind of current and in any spatial position, which makes it possible to install complex structures directly on the construction site.

- Even in the presence of scale or traces of oxidation at the joint site, pores do not form in the metal of the resulting weld.

- Parts can be welded with electrodes with a small diameter at low and extremely low currents - with a compact inverter or transformer from a household network.

- In addition to butt joints, the electrodes also work well with T-joints, allowing you to obtain a neat concave seam; They are also easy to install potholders.

The metal of the resulting joint demonstrates high resistance to fatigue under constant loads in the weld area. In this respect, the OZS-12 brand is superior to many electrodes with basic and acidic coatings for similar purposes.

Advantages and disadvantages

Advantages of OZS-12 brand electrodes:

- simplicity of primary ignition of the discharge;

- possibility of using direct and alternating current equipment;

- to restore the arc, contact between the tip and the surfaces being welded is not required;

- arc discharge stability, which is not affected by the distance between the electrode tip and the surfaces being welded;

- reduced porosity of the deposited metal, independent of the length of the welding arc;

- thanks to the rutile coating, the risk of hot cracks is reduced;

- a thin layer of slag that can be easily removed with a hammer and a wire brush;

- a small volume of sprayed melt from the weld pool;

- welding of parts is allowed without preliminary cleaning of traces of rust and paint residues;

- reduced content of harmful substances in the smoke generated during the combustion of the coating;

- welding is allowed in the vertical direction with the tool fed from top to bottom;

- the seam formed has smooth edges and a fine pattern.

We recommend reading Calculation of electrode consumption during welding

Disadvantages of rods:

- limited applicability;

- hygroscopicity of the coating (moisture reduces the characteristics of the material);

- large fragments of slag remain on the surface of the weld;

- the need for long-term calcination before use;

- unstable product quality (for example, buyers often criticize LEZ products, the characteristics of which depend on the batch).

Areas of use

OZS-12 electrodes are used for welding critical structures designed for high loads.

- Pipelines in the oil, petrochemical, gas and utilities industries.

- Gas tanks, tanks at oil storage facilities.

- Boiler equipment.

- Lifting and transport machines and devices (conveyors, cranes, elevators, winches, hoists, etc.).

Products of this brand are especially effective when installing building structures: they provide high-quality welding of T-joints.

Application of the most popular models

Let's get acquainted with the purpose of the most common “OZS” models:

- OZS 4 - designed for welding critical and ordinary structures and parts with carbon in the composition and strength up to 450 MPa.

- OZS 6 - used for welding products and materials in various positions. Developed by SpetsElectrode.

- OZS 12 - make it possible to easily weld, install tacks and connect pipe joints. The electrodes work even at low currents. This makes it possible to use equipment connected to a household electrical outlet. When making T-joints, you are guaranteed to get concave seams.

Famous manufacturers

The Russian market offers electrodes of both domestic and foreign production. OZS-12 is produced in accordance with GOST 9466-75, 9467-75.

For many years, electrodes of this brand have been produced by the Magnitogorsk Electrode Plant, founded in 1949. MEZ products are certified by the National Welding Control Agency, the Russian River Register, and are certified with approval for welding various groups of technical devices of hazardous production facilities.

Since 1999, they have been produced under the TIGARBO brand located in the city of Kamensk-Shakhtinsky (Rostov region). They are produced under the MONOLIT brand by the Svetlogorsk Welding Electrode Plant (SZSE, Republic of Belarus).

Also among the electrode manufacturers: the oldest Moscow specialized enterprise - Yaroslavl Electrode and Hardware Production LLC (YarEL brand), the Swedish concern ESAB, which today has several production sites in Russia, and other Russian and foreign companies.