The pipe design includes various flange connections, tees, bends and other products. To seal joints in such structures, steel gaskets are used, which contain a minimal amount of carbon.

Christmas tree fittings are designed to solve many problems. In particular, one of these tasks is the installation of piping of pipelines for various purposes. The use of this equipment allows you to control the movement of the working environment and ensure the execution of processes that control production. The devices are used to seal branches from main pipelines.

Purpose of fountain fittings

Devices of this class are responsible for solving the following engineering and technical problems:

- ensuring well sealing;

- diversion of products transported through the pipeline system;

- to adjust and maintain well flow;

- when providing access to the well bottom;

- to ensure sampling without stopping production processes.

Products of this class are used at high pressures arising under the influence of loads. Fittings are used when there is a possibility of exposure to aggressive environments inside the well. Quite often it is used if the liquid contains a large number of impurities of different origins and sizes.

When using such a system, it is necessary to take into account that this equipment must have a long service life and the necessary margin of safety. The main consumers of these products are enterprises engaged in the production and transportation of hydrocarbons, as well as the construction of pipeline transport systems.

Shut-off valves - main technical parameters

The technical characteristics of shut-off valves are important when used in industrial, municipal and household sectors. The main parameters are often indicated on the body of products when they are cast or stamped; usually the symbols have a protruding raised surface. GOST 24856-2014 gives the following definitions for the main characteristics of shut-off valves:

- Nominal parameters are numerical indicators of functional characteristics from a standardized range of values, given without tolerances for deviations.

- Nominal or conditional pressure PN (nominal pressure) - the maximum pressure indicator, expressed in kilograms per second, bars or atmospheres at a constant temperature of the transported medium of 20 ° C, at which the shut-off valves of pipelines operate during the service life prescribed by state standards.

- Nominal diameter DN (nominal diameter) is a dimensional parameter approximately equal to the internal cross-sectional size of devices. The DN indicator is measured in millimeters and is taken equal to one of the values of the standardized series. DN serves as the main dimensional indicator when choosing any type of fittings.

Rice. 21 Polymer taps

- Operating pressure (line pressure; operating pressure; service pressure; working pressure) - the highest excess pressure at which pipeline fittings fulfill their service life with selected materials and a given temperature.

- time is the time interval during which the locking element moves from the “open” to the “closed” position or vice versa.

- Flow area or passage (flow area) - a section at an angle of 90 degrees relative to the direction of flow at any point in the passage section of the fittings.

- Leak or leakage (leak; leakage) - penetration of the transported medium outside the dimensions of the housing, caused by the difference in pressure between the supplied flow and atmospheric air. It is measured in the volume of the working fluid coming out per unit time when the shutter mechanism is closed.

- Normal or standard conditions (normal conditions) - characteristics of the environment for measuring the volume of gases: correspond to a temperature of 20 ° C and an atmospheric pressure of 760 mm Hg. Art. at zero humidity.

- Design temperature - temperature parameters of the casing walls of the device, equal to the arithmetic average of the values measured on the inner and outer shell of the device when operating under normal operating conditions.

Rice. 22 How to correctly formulate the name of the valve, its symbol and an example of body marking

Shut-off valves for pipelines are widely used in all industries, utilities, and households to control the flow of media transported through pipelines. The shut-off valves chosen by the average consumer for heating and water supply must meet the requirements of compatibility with the physical and chemical characteristics of the supplied working medium, have the appropriate design, materials of manufacture, and basic technical parameters.

Types of fittings

GOST, which are in force in our country, define the following types of Christmas tree fittings:

- Tee (cross) - the scheme allows you to connect taps to prefabricated and metering installations using flow lines.

- Double-row (single-row) - it is equipped with valves or taps. The former are used to work in oil wells, the latter - in gas wells.

In addition to the classification described above, the following is also used:

- By pressure. Typical equipment operates at pressures from 7 to 105 MPa. Valves that are designed to operate at high pressure are used for working in deep wells. In addition, it is installed in wells in which the presence of dangerous formation pressure has been noted.

- According to the size of the barrel passage. This size ranges from 50 to 150 mm. Devices with working diameters from 100 to 150 mm are installed in oil and gas wells with high flow rates.

The designer, when selecting material for the production of reinforcement, must take into account the properties of the environment. By the way, to install products in an explosive environment, it is not advisable to install components and assemblies made of cast iron.

Typical fittings include different types of gate valves, valves, etc. Special piping includes pressure reducing valves, gates and valves for supplying catalysts and operating backup fittings.

Working environment

The main regulatory document that explains what pipeline fittings (PVA) are and describes all related terminology and definitions is GOST 24856-2014.

The standard states that pipeline valves are technical devices placed on pipeline lines, equipment and containers.

The purpose of shut-off valves (VA) is to control the flow of the medium by changing the cross-section of the pipe passage.

Control refers to the ability of devices to shut off, open, regulate, distribute, mix and separate flows.

The working fluid controlled by the valves is liquids, gases and their mixtures, pulps, vapors, plasmas, bulk and powder substances, suspensions. In the industrial sector, valves are most often used to regulate the flow of hot and cold water, steam, oil and its products, oil, and natural combustible gas.

Rice. 2 Operating principle and design of typical valves and taps

Pressure classification

GOST 24856-2014 establishes the following groups of fittings depending on the pressure of the medium in the pipes they control:

Low pressure - capable of withstanding a pressure of the medium in the pipeline of no more than 2.5 MPa (25 bar).

Medium-pressure - operates when the working fluid is supplied under pressure from 2.5 to 10 MPa (25 - 100 bar).

High pressure - operated when the pressure of the medium moving in the communications exceeds 10 MPa (100 bar).

Xmas tree design

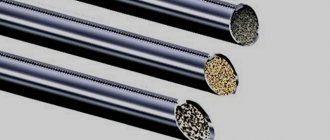

GOST 13846–84, implies the use of tee and cross type circuits. Typical fountain fittings include the following components:

- pipe head;

- fountain tree;

- manually controlled locking devices;

- chokes.

The pipe head is designed to hang tubing in several rows on it and ensure their tightness. In addition, it takes part in some technological processes associated with the development, operation and maintenance of the well.

This device, if necessary, replaces the side valves installed on it. For this purpose, blind plugs are used, installed in threads cut in the body.

The fountain tree is designed to solve the following problems:

- sending finished products to the line;

- taking part in the installation of additional devices;

- performing measurements of pipeline network operating parameters;

- ensuring the lowering of devices for cleaning well pipes.

Locking devices are represented by plug valves and gate valves with supplied lubricant. Their main task is to block the movement of the working environment.

Types of shut-off valves based on valve design

Pipeline fittings of different types differ in the design of their actuating units (gates), which ensure the closure of the pipeline passage channel. Also, the design of the locking mechanism in many cases determines the overall dimensions and area of use of the injection molding machine.

Valves

A valve is a type of injection molding machine whose shut-off or adjusting element moves at an angle of 90 degrees relative to the transported flow.

Blocking flow movement using valves is one of the most commonly used methods in the industrial and utility industries; they are usually used on pipelines with a diameter of 50 mm and above. GOST 24856-2014 regulates the following types of valves:

- Wedge gates are devices with a moving gate shaped like a wedge. When lowered, it rests on the surfaces of the seat rings, placed between each other at a similar angle. For example, a cast iron valve with a rubber-coated wedge 30h39r.

- Parallel gates - have saddle seals placed mutually parallel.

- With a retractable spindle, rod (gate valve with rising stem) - when opening or closing the passage channel, the rotating spindle or rod on which the lock is attached moves relative to the central axis of the connecting taps by the length of the working stroke.

- With a non-rising spindle (gate valve with non-rising stem) - when opening and closing the passage channel, the rotating spindle does not move in a forward direction relative to the central axis of the device, and its threaded section does not extend beyond the internal body area.

Rice. 12 Wedge-shaped valve - a structural device using the example of model 30s41nzh

- Gate or knife (slide gate, slab gate) - the gate element is a plate with a parallel arrangement of seat rings. (You can learn about gate valves in a separate article).

- wedge gate - the locking element is made of two inclined discs. In their placement, the ability to self-align relative to the body seat rings is structurally implemented.

- With an elastic wedge (flexible wedge gate) - has a wedge shape and consists of two inclined disks. Between the disks there are elastic or rigid moving parts, the movement or deformation of which allows the wedge to self-align relative to the body seat rings.

- parallel disc gate - has two parallel disks located relative to each other. When lowering the movable valve element, one of the parts of the assembly rests against the bottom of the passage channel, the disks diverge and are tightly pressed against the seat sealing rings.

- Rotatable gate - block the movement of the flow of the working medium by rotating the gate element placed in the passage channel around its axis.

- Hose gate (pinch gate) is a special type of valve that works to shut off a section of a pipeline whose passage channel in the gate is made of a plastic flexible hose. When operating in closing mode, the shutter element presses on the hose, thereby stopping the movement of the working fluid along it.

Rice. 13 Slider (knife) valve - structural device

Valves

Shut-off valves are a type of valve in which the passage channel is blocked by a specially made part in the form of a piston, called a spool. In the design of valve fittings, the channel passage in the body is designed in such a way that the valve can close it from above. The passage channel has a curved shape with a shutter perpendicular to the inlet and outlet pipes.

The spool is usually made in the form of a plate, cylindrical piston, sphere or needle. Its sealing surface in contact with the seat ring can be flat, conical or spherical.

GOST 24856-2014 regulates the following types of valves:

- Shut-off (on-off, stop) - designed to lock the passage channel, they have a valve-shaped design.

- Regulating (control) - control the supply volume of the transported working flow by moving the valve a certain distance.

- Safety valve - the valve performs protective functions in the pipeline or on equipment.

- Shut-off (isolation) - characterized by a fast response time, blocking the flow of the transported working fluid in the event of emergency or emergency situations.

Rice. 14 Hose seal

- Hermetic, hermetic valve (tight disc-type) - used in ventilation systems, structurally similar in design to a disc valve, moving in the final stage perpendicularly or parallel to the central axis of the pipeline.

- Normally closed (NC) (air-to-open, normally closed) - a valve directly controlled by an electric actuator or auxiliary mechanism that creates forces to move the shut-off or adjusting element. In the absence of electricity, they are set to the “closed” position.

- Normally open (NO) (air-to-close, normally open) - a device with a direct electric drive or an auxiliary mechanism that moves the spool to lock or adjust the size of the passage channel. In the absence of power supply, it spontaneously sets to the “open” position.

- An electromagnetic valve (solenoid) is a device with a drive in the form of an electromagnetic coil and its armature connected to a spool. The drive can be located either inside the housing or placed outside its surface.

Technical requirements for design

GOST 13846–89 determined that Christmas tree equipment is designed to seal wells, block the movement of the working medium and perform other technological procedures. In accordance with the standards regulated in GOST 15150–69, these devices can operate at temperatures from -60 to +40 degrees.

GOST 51365–2009 defines the technical conditions and requirements for the specified fittings. Designers involved in the design of equipment should be guided by the requirements of this document.

Types of shut-off valves and classification

The type of valve is its classification according to the direction of movement of the shut-off and control element relative to the flow of the medium and the determination of the distinctive design features.

GOST 24856-2014 regulates the following types of ZA:

- Gate is a device with a control element moving at right angles to the flow.

- A globe valve is a device with a shutter or adjusting element that moves parallel to the flow.

- Faucet, valve (ball, plug) - a device with a shutter-regulating element in the form of a rotating body or its fragment, turning around its axis. In this case, the shut-off unit can be located in an angular position relative to the direction of the medium flow.

- Butterfly valve is a type of shut-off valve in which the shutter or adjusting element is made in the shape of a disk. The disk rotates around an axis, which can be located perpendicular or angular to the flow.

Rice. 4 Shut-off valves on industrial pipelines

Marking of fittings

To mark this type of product, alphanumeric abbreviations are used, which are designated as follows: AFKh or AFKH, where AF indicates the type of fittings, in this case the fittings are fountain, the letter “K” indicates the method of hanging the pipeline. The letter X (from 1 to 6) indicates the diagram in accordance with GOST 13846–84. In addition, the product labeling may indicate numerical parameters showing the working diameter and pressure, climatic version and some others, in particular, the corrosion resistance class.

Types of fittings on pipelines

The term “valve type” refers to its functions, the main ones being:

- constipation,

- regulation,

- prevention,

- obstacle to reverse movement,

- stream separation.

Shut-off valves (on-off, shut-off, stop) are technical devices that perform the function of hermetically shutting off the flow of the transported working fluid.

In addition to the main locking type, in the technical industry there are the following types of combined or multifunctional (combined, multifunction), combining different functions of fittings:

Shut-off and control (on-off and control) - in addition to completely blocking the flow, shut-off control valves for heating, water supply and other needs are capable of changing the volume of a moving medium by partially blocking the channel passage.

Stop and check - in addition to blocking the channel passage, it prevents the passage of the medium in the opposite direction.

Non-return shut-off (stop non-return) - in addition to preventing flow movement in the opposite direction, it implements the function of forced closing or limiting the movement of the shutter element.

Rice. 3 Sectional design of shut-off valves

Installation and dismantling of fountain fittings

During the operation of an oil or gas well, the structure is installed. Column heads are used for connection. The holes located in the upper flange allow you to fix parts of different sizes. The equipment installation process is carried out in several steps.

A gasket made of low-carbon steel and having an oval shape is placed in the space between the flanges. Using an elevator, the pipe string is lowered to the installation site. After this, the pipes are assembled together using threaded connections. By the way, it makes sense to coat the threads with a protective lubricant before assembly. After completing assembly of the installation, it is necessary to carry out pressure testing.

Repair of this equipment must be performed only at special enterprises. Before sending it for repair, the unit must be disassembled. The tree must be washed and at this time the remaining components must be examined.

The Christmas tree fittings and their piping scheme are designed so that they can protect the environment from the influence of the working medium supplied in the pipeline system.