The weight of the reinforcement must be known in order to calculate the required amount of material for reinforcing reinforced concrete structures. Knowing the required footage, using a table of values for the mass of reinforcing bars, you can convert meters into kilograms and calculate the required number of rods for purchase.

What does the mass of reinforcement depend on?

The main indicator that influences how much 1 linear meter of steel reinforcement weighs is the diameter. The larger it is, the correspondingly greater the mass.

With a reinforcement diameter of 6 to 80 mm, the weight of 1 meter ranges from 222 to 3960 grams.

As you can see, the difference is huge. Therefore, knowledge of the specific gravity of the reinforcement will not be superfluous when calculating the pressure of a structure on the foundation - several unaccounted tons of load can have a detrimental effect on the reliability and durability of any building.

Technical characteristics of A1 fittings

Main physical characteristics:

- yield strength – 235 N/mm2;

- temporary tensile strength – 373 N/mm2;

- relative elongation – no less than 25%.

Performance properties of steel reinforcement A1 (A240):

- Good weldability due to low carbon steel construction.

- Environmental friendliness. These products have safety certificates indicating their compliance with regulatory requirements.

- Possibility of bending at the angle necessary to create a structure.

- Low resistance to corrosion. Increased by painting, galvanizing, aluminum zinc plating.

- Lower cost compared to periodic profile reinforcement.

Table of weight of reinforcement by diameter

All data indicated in this table of reinforcement weights corresponds to GOST 5781-82. The error can be a maximum of several percent for reinforcement classes A1 (A240), A3 (A400) and A500C.

| Diameter of fittings, mm | Weight of 1 meter, kg | Rod weight 11.7 m, kg | Linear meters per ton |

| 6 | 0,222 | 2,5974 | 4504,5 |

| 8 | 0,395 | 4,6215 | 2531,65 |

| 10 | 0,617 | 7,2189 | 1620,75 |

| 12 | 0,888 | 10,3896 | 1126,13 |

| 14 | 1,21 | 14,157 | 826,45 |

| 16 | 1,58 | 18,486 | 632,91 |

| 18 | 2 | 23,4 | 500 |

| 20 | 2,47 | 28,899 | 404,86 |

| 22 | 2,98 | 34,866 | 335,57 |

| 25 | 3,85 | 45,045 | 259,74 |

| 28 | 4,83 | 56,511 | 207,04 |

| 32 | 6,31 | 73,827 | 158,48 |

| 36 | 7,99 | 93,483 | 125,16 |

| 40 | 9,87 | 115,479 | 101,32 |

| 45 | 12,48 | 146,016 | 80,13 |

| 50 | 15,41 | 180,297 | 64,89 |

| 55 | 18,65 | 218,205 | 53,62 |

| 60 | 22,19 | 259,623 | 45,07 |

| 70 | 30,21 | 353,457 | 33,1 |

| 80 | 39,46 | 461,682 | 25,34 |

Having the table at hand, you can quickly find out the specific gravity of 1 meter of reinforcement according to GOST, for example, with a diameter of 32 mm. Find the corresponding size in the first column and to the right of it is its theoretical mass, it is 6.32 kg, and a ton includes 158.48 meters.

Two classes of metal products

The most common fittings are class A1 and A3. The classes differ in the nature of the surface of the rods. The surface of the rods A1 is smooth, while that of A3 is corrugated. Thanks to its corrugated surface, A3 is in high demand among builders as reinforced concrete reinforcement, as it guarantees the most durable connection with the cementitious material. This connection is ensured by ribs and transverse projections located longitudinally over the entire surface of the product. According to GOST 5781-82, these ribs and protrusions are located relative to each other strictly at the same angle.

Why do you need to know the weight of the reinforcement?

Professional builders often have a question: what is the mass of a linear meter of reinforcement. Why do they need this? The fact is that when purchasing rods for the construction of large structures, it is purchased not individually, but in kilograms, and in case of large volumes, in tons.

In order to calculate how long a certain amount of reinforcement will last, you need to know its total mass and specific gravity of 1 meter. If you have this data, you can make simple calculations in a matter of seconds, obtaining the total length of the metal rods. To do this, we take the entire mass of rods and divide by the weight of 1 linear meter.

Material calculation example

To reinforce a strip foundation, 2.5 tons of 25-diameter rods are required. We take the specific gravity of 1 meter from the table, equal to 3.85 kg. Next, we convert tons to kilograms, multiply by 1000, it will be 2500 kg, and divide by 3.85, we get 649 meters of material. The standard length of a metal rod is 11.7 m, to find out the required number of rods, divide 649 by 11.7, we get 55.5 pieces. In this way, you can count the number of rods with any cross-section. This will help, especially in private construction, to check that the correct amount of material has been delivered to you.

The opposite situation may also occur. The specialist knows how much material he needs, and also knows the optimal diameter. Having found out the theoretical weight of a meter of reinforcement according to GOST, he just needs to multiply this number by the total length of the required metal rods to determine how much material is needed for construction.

Assortment of fittings A1

According to regulatory documentation, products are produced in the diameter range of 6-40 mm. It goes on sale in coils - up to 10 mm in diameter - or rods 6-12 mm long.

Calculation of the mass of a batch of reinforcement - using a table from which the mass of 1 m is determined, and then this value is multiplied by the total footage of the batch.

Weight table for 1 m reinforcement A1

| Diameter, mm | Cross-sectional area, cm2 | Weight 1 m, kg | Number of meters per ton |

| 6 | 0,283 | 0,222 | 4505 |

| 8 | 0,503 | 0,395 | 2532 |

| 10 | 0,785 | 0,617 | 1620 |

| 12 | 1,131 | 0,888 | 1126 |

| 14 | 1,54 | 1,21 | 826 |

| 18 | 2,54 | 2,0 | 500 |

| 20 | 3,14 | 2,47 | 405 |

| 22 | 3,8 | 2,98 | 336 |

| 25 | 4,91 | 3,85 | 260 |

| 28 | 6,16 | 4,83 | 207 |

| 32 | 8,04 | 6,31 | 158 |

| 36 | 10,18 | 7,99 | 125 |

| 40 | 12,57 | 9,87 | 101 |

The fittings can be made from:

- carbon fiber

- fiberglass

- gland

- basalt plastic

- hardwood

Types and their dimensions:

Based on elasticity, GOST divides them into options:

- A 600 (A-IV). Size from 6-40 mm, steel – 80С, 20ХГ2Ц

- A-400 (A-III). Size from 6-40 mm, steel – 35 GS, 25 G2S, 32G2Rps

- A 800 (AV). Diameter from 6-40 mm, alloy – 23Х2Г2Т

- A-1000 (A-VI). Diameter from 6-40 mm, steel – 22Kh2G2AYu, 22Kh2G2R, 20Kh2G2SR

- A 300 (A-II). Size from 10-80 mm, alloy – St5sp, St5ps, 18G2S, 10 GT

- A-240 (AI). Size from 6-40 mm, alloy – St3kp, St3ps, St3sp.

There are also 2 interval hardened varieties:

- B500C. Size 6-12 mm, cold rolled steel

- A-500C. Size 6-40 mm, hot rolled steel

In accordance with the purpose:

- Working fittings. Mainly joined lengthwise to prevent changes in the size of the structure

- Anchor fittings. They are driven into the foundation of the structure for the purpose of further connection with the main frame

- Mounting fittings. Combines the details of the entire frame into a single structural mesh

- Operating fittings. Installed vertically or vertically, similar to clamps or welded rods. Accepts force along a vertical line, partly acting as mounting rods

- Shut-off valves . Separates the working environment from the sealed sphere.

By mood:

- Transverse - increasing the strengthening of the building from inclined cracks

- Longitudinal - prevents compression and stretching of the frame and prevents vertical cracks.

By use:

- Non-stressed - the least durable, used for structures where there are no large loads on the reinforcement.

- Stressed - subject to change in advance, and therefore is more susceptible to stress. Suitable for durable buildings

Five methods of using reinforcement.

Due to the manufacturability of installation and low cost, reinforcement is widely used in various parts of construction.

- Reinforced masonry walls of buildings. Welded (knitted) reinforcement, fine-diameter mesh is used, or single rods can be used, which are placed in the mortar between the rows of masonry.

- Base. To increase the strength of the foundation slab, longitudinal and transverse placement of rods in a couple of rows is used (if low, 1 row is allowed). On average, per 1 meter of longitudinal reinforcement reinforcement, 1 transverse clamp or rod is installed.

- Reinforced reinforcement frame. The rods are combined with welding seams, with the help of which a “framework” is erected, guaranteeing the rigidity, endurance and elasticity of the load-bearing supports.

- Knitted reinforcement mesh. It is used for not very large areas of reinforcement, in situations where it is not feasible to combine mesh nodes by electric welding, during urgent work, or when reinforcing with steel threads made of non-weldable metals or alloys.

- Hinges, clamps. They are used for the purpose of installing key links of a building structure in large frames to redistribute and weaken the load.

Weight of composite reinforcement

Nowadays, fiberglass reinforcement bars are increasingly being used instead of steel reinforcing bars. They have a lot of advantages, including light weight. In addition, fiberglass has better tensile strength than steel, which allows the use of products with a smaller diameter. For example, an 8 mm composite rod is equivalent in its physical and mechanical characteristics to a 12 mm steel rod. Accordingly, the load decreases even more noticeably.

Table for determining the equivalent diameters of steel and composite reinforcement Source luxkompozit.ru

Compare how much a meter of 12 mm steel alloy reinforcement weighs (890 g) and a meter of fiberglass rod with a diameter of 8 mm (110 g). The difference is 8 times.

Briefly about the main thing

When starting construction and ordering materials for it, it is important to be able to calculate them correctly and control delivery, without allowing suppliers to deceive you. To do this, you need to know how many kilograms of cement are in a bag, how many boards are in a cubic meter, how many kg are in 1 meter of reinforcement with a diameter of 12 mm. Such knowledge can be very helpful in calculating loads on building structures and in solving transportation issues. In the case of fittings, everything is simple - you just need to look at the table and find the necessary data in it.

Weight table

In accordance with the current standard, reinforcement of classes A240, A400 and A500C is used in construction. All weight values in 1 linear meter, in a rod 11.75 m long and in 1 ton of timber are summarized in the table. The error is acceptable, but insignificant, no more than a few percent.

Summary table for all diameters Source vezetnerud.ru

Why and how to determine the weight of reinforcement

Most private developers wondered how much 12 mm reinforcement weighs per meter - it is what is most often used for pouring foundations, monolithic basement walls, and armored belts. The answer to this helps solve at least two problems.

- Determination of the carrying capacity of the vehicle required to deliver materials to the construction site.

Not all developers use delivery services, and not all small sellers provide such a service. If you don’t need so many rods, it’s cheaper to pick them up yourself, but you need to know whether the load will be excessive for the car. Since the standard length of the reinforcement is 6 or 12 meters, many people cut it in half right on the spot and transport it on a trunk or in a trailer. Or they select short rods from unmeasured lots.

The number of short rods in unmeasured batches can reach 7% Source prom.st

See also: Catalog of companies that specialize in the design and installation of metal structures (canopies, greenhouses, etc.)

- Determination of reinforcement footage in ton.

Large volumes of rolled metal are sold using not meters or pieces as a unit of measurement for calculations, but a ton. If you know how many linear meters of reinforcing bars are contained in one ton, it will not be difficult to calculate the weight required for ordering and purchasing.

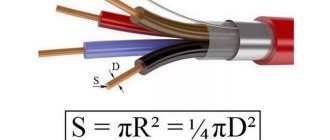

In theory, knowing the diameter of the required products and the density of the steel alloy from which they are made, you can independently calculate their weight. But in practice, such calculations will have a large error, since the reinforcement bars do not have a constant cross-section, but a periodic one, with longitudinal and transverse stiffeners. And they have two diameters - minimum and maximum.

Reinforcement cross-section - drawing Source ugmk.com

But there is no need to do this. A table compiled on the basis of GOST 5781-82 will help you find out how much the reinforcement weighs. This document regulates all parameters of these metal products. Their mass depends primarily on their diameter.

- The thinnest rods have a diameter of 6 mm and the weight of one linear meter is slightly more than 220 grams.

- The thickest 80 mm reinforcement is much heavier - more than 39 kg per linear meter.

The larger the diameter and denser the reinforcement pattern, the more important it is to know how much a meter of reinforcement weighs. The mass of the metal frame must be taken into account when calculating the load on the base, and an error can lead to unpredictable consequences.

Examples of calculations

To find out how much 1 meter of 12 mm reinforcement weighs, just find this diameter in the first column. The following gives the mass of 1 l.m. – 888 grams. And there are only 1126 meters in a ton, or, if you divide this value by the length of the rod, almost 96 pieces.

The design documentation may only indicate the diameter and weight of the reinforcement without indicating the footage. When purchasing individually, you will have to calculate how many pieces you need. For example, you need to buy 1.5 tons of 16 mm reinforcement to install a strip foundation.

- We find from the table how much 1 meter of reinforcement weighs - it is 1.58 kg.

- We convert 1.5 tons into kilograms, multiplying by 1000 - 1500 kg.

- Divide 1500 by 1.58 and we have 950 m.

- Or divide 1500 by 18.56 (the weight of one bar) and get 81 pieces.

These simple calculations will allow you not only to avoid making mistakes when purchasing, but also to check the amount of material delivered to the site.

When you need to find out how much a certain number of rods will weigh, do the opposite: multiply the weight of the rods of the required diameter by their number or footage. For example, you need to buy 30 rods, the thickness of the reinforcement is 20 mm. With a mass of one rod of 29 kg, the total weight will be 30 x 29 = 870 kg.