Increasing the cutting speed of steel is an issue that will always be relevant for production. At one time, people thought they had the answer by making quick cutters. But several decades passed, and the first carbide cutters were in the hands of engineers, superior in all respects to previous samples. The material of one such cutter was T5k10 alloy, some believe that it was steel.

Stalinite

This carbide alloy does not contain tungsten, which makes it low in cost. It was also invented in the Soviet years and is widely used in industry. As practice has shown, despite the fact that this hard alloy does not contain tungsten, it has high mechanical characteristics, which in most cases satisfy technical requirements. Stalinite has significant advantages over tungsten materials. First of all, it is a low (1300-1350 degrees) melting point. Tungsten materials undergo changes only starting at 2700 degrees. A melting temperature of 1300-1350 degrees greatly facilitates surfacing and increases its productivity. The basis of stalinite is a mixture of cheap powdered ferroalloys, ferromanganese and ferrochrome. The production of this material is similar to the process for producing tungsten compounds. Stalinite contains 16-20% chromium and 13-17% manganese.

Developments

Today, various studies are being carried out in the domestic industry, including an in-depth analysis of the possibility of increasing the characteristics of hard alloys. They mainly concern the granulometric and chemical composition of materials.

As a fairly successful example over the past few years, we can cite the compounds of the TSN group. Such alloys are specially designed for friction units operating in an aggressive acidic environment. This group continues to develop new compounds in the VN group proposed by the All-Russian Scientific Research Institute of Traumatology and Technology.

During the research, it was found that by reducing the grain size of the carbide phase, characteristics such as strength and hardness of the alloys significantly increase. The use of technologies for regulation and plasma restoration of particle size distribution today makes it possible to produce materials whose fraction size is less than a micron. TSN grade alloys are today widely used in the production of oil and gas and chemical pump components.

t5k10 - definition of steel, application, characteristics

Increasing the cutting speed of steel is an issue that will always be relevant for production. At one time, people thought they had the answer by making quick cutters. But several decades passed, and the first carbide cutters were in the hands of engineers, superior in all respects to previous samples. The material of one such cutter was T5k10 alloy, some believe that it was steel.

Decoding and composition of t5k10

T5k10 alloy belongs to the group of tungsten-titanium alloys. Its main feature is its high resistance to abrasive wear. In particular, sliding chips of the workpiece. In addition, T5k10 has an increased temperature at which the surface sets with steel, which increases the cutting speed, rigidity and durability of the tool.

The alloy is entirely a product of powder metallurgy. The alloy components are pre-crushed and placed in a certain ratio in a special mold. Further, under the influence of temperatures above 3000 ºC and pressure of about 300 MPa, the chemical elements are sintered, actually forming the T5k10 alloy.

T5k10 is a hard alloy with increased oxidation resistance. Its specific gravity is 13100 kg/m3. It does not have high values of both heat and electrical conductivity. It also does not stand out for its elastic characteristics. Limit plastic deformation – 0.4%.

The alloy is extremely resistant to mechanical loads. The ultimate bending strength is 1450 MPa. For comparison, the same parameter for steel of ordinary quality St.3 is only 38 MPa. High hardness, about 88 units on the Rockwell scale, makes T5k10 impervious to surface chipping.

All of the above features of the alloy became so due to the presence of certain chemical elements in its composition. T5k10 can be deciphered as follows:

- T5 – indicates a titanium carbide content of 5%. Their main purpose is to increase strength and resistance to impact loads. In addition, titanium reduces the influence of atmospheric gases on the properties of the alloy, in particular oxygen and hydrogen.

- K10 – indicates the presence of 10% cobalt. With an increase in its content, the strength characteristics increase, but at the same time the wear resistance of the cutter decreases.

- The rest - about 75% of the composition - is tungsten carbide. It is this component that determines the properties of t5k10. Carbides are responsible for hardness, and tungsten for refractoriness and heat resistance.

- Harmful impurities enter the alloy due to imperfect smelting technology and the purity of the starting metals. Also, during sintering, there is a high probability of gases such as oxygen, nitrogen and hydrogen entering the composition.

Application of t5k10

The main purpose is the production of cutters for processing steel and other materials. The following technological applications should be noted here:

Rough turning. In this case, cutting is carried out intermittently, and the cross-section of the steel cut is uneven; Shaped turning; Finish planing; Rough milling of alloy steels.

prompriem.ru

T5K10 Chelyabinsk

| Brand: | T5K10 |

| Classification: | Hard sintered alloys |

| Addition: | Titanium tungsten group |

| Application: | For processing materials by cutting: Rough turning with an uneven cut section and intermittent cutting, shaped turning, cutting with turning tools. finishing planing. rough milling of discontinuous surfaces and other types of processing of carbon and alloy steels, mainly in the form of forgings, stampings and castings on crust and scale. |

| Foreign analogues: | Known |

Chemical composition in % of material T5K10

GOST 3882-74

| Co | — |

| until 9 | Carbides: WC= 85%. TiC= 6% |

| Note: In the latest version of GOST 3882-74 (with amendments 1-6) chem. no composition |

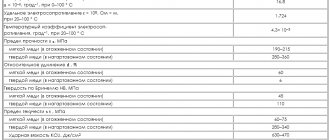

Properties of material T5K10

| Bending strength 1421 N/mm² Density 12.5-13.1 g/cm³ Hardness HRA no less than 88.5 |

Foreign analogues of material T5K10

Attention!

Both exact and closest analogues are indicated. MC131

| Germany | Sweden | Bulgaria | Hungary | Poland | Czech |

| DIN,WNr | SS | BDS | MSZ | PN | CSN |

HS345

| |||||

| S30S |

| S30 |

Designations:

| Mechanical properties : | |

| sв | -Short-term strength limit, [MPa] |

| sT | - Proportional limit (yield strength for permanent deformation), [MPa] |

| d5 | -Elongation at break, [%] |

| y | -Relative narrowing, [%] |

| KCU | -Impact strength, [kJ/m2] |

| HB | -Brinell hardness, [MPa] |

| Physical properties: | |

| T | -Temperature at which these properties were obtained, [Deg] |

| E | -Elastic modulus of the first kind, [MPa] |

| a | -Coefficient of thermal (linear) expansion (range 20o-T), [1/degree] |

| l | -Thermal conductivity coefficient (heat capacity of the material), [W/(m deg)] |

| r | -Material density, [kg/m3] |

| C | -Specific heat capacity of the material (range 20o-T), [J/(kg deg)] |

| R | -Specific electrical resistivity, [Ohm m] |

T5K10-Hard sintered alloys T5K10-chemical composition, mechanical, physical and technological properties, density, hardness, application

Affordable metal products

Carbide powder mixtures

Applications and products of hard alloys

The material is widely used in modern industry. The production technology of the alloys themselves is also developing, their quality is improving, the composition is changing, and new markings are appearing. But in addition to changing the material itself, the principles of working with it also change. New types of compounds applied to products are emerging, thanks to which they acquire new functions and roles in industry.

Today, hard alloys are used:

- In the production of cutting tools. Tools made from high-strength materials can improve the quality of production, speed it up and reduce the cost of scrap and the purchase of materials. High heat resistance and strength allow you to work at extreme speeds. Therefore, alloys are much more valuable in the production of tools than simple steel. In their production, diamond blanks are often used, which significantly improves the quality of the material and its properties. Examples of such tools include cutters, drills, etc.;

- In the manufacture of high-strength parts for mechanical products, industrial machines, automobiles and equipment, knives and blades for graders - in mechanisms that experience high overloads and forces;

- In the production of equipment intended for heavy loads. For example, mining equipment, drilling rigs. Alloys are used in supports of industrial scales and in other mechanisms designed for high forces and pressures;

- In the manufacture of small but key parts of various mechanisms. For example, bearings, terminals, various protective coatings, etc. are made from this material.

- In the production of various shapes and matrices, in the casting of steel products, both simple and complex in shape.

- For mechanical post-processing of complex materials (steel, cast iron, non-ferrous metals, heat-resistant materials, etc.).

- When stamping various products.

Before purchasing tools, parts, or simply raw materials that contain alloys, you must carefully study what class they belong to and what properties they have. This will help to understand the meaning of the markings, which indicate the composition of the product and, as a result, its ability to withstand certain loads. Each class of material is intended for use in a specific area of production and may be completely unsuitable for another, which should also be taken into account.

Rating: 0/5 — 0 votes

Grades of hard alloys: classification of materials

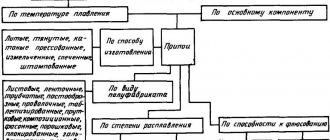

Hard alloys are classified according to two main criteria.

Method of obtaining

According to the method of production, hard alloys are divided into two types.

- Cast. They are made using casting technology. Alloys of this group include stellites, sormites, and hard alloys with a high nickel content. Typically, pressing and thermal post-processing (hardening, aging, annealing, etc.) are used in production. The result is high quality materials. Cast carbide alloys are intended for surfacing on metalworking tools.

- Sintered. Such hard alloys are also called metal-ceramic due to the fact that the manufacturing technologies are very similar. The materials are produced using powder metallurgy technology. It is supplemented by laser/ultrasound processing or acid etching. The resulting materials are of the highest quality.

Sintered carbide alloys are fixed to tools mechanically or using soldering technology.

Material VK8 Chelyabinsk

Not a single production can operate without steel, be it heavy engineering or the manufacture of household electrical appliances. There are many brands of this product, as well as a large number of dispensing forms. Our company sells VK8 material in large quantities and with a minimal margin. To clarify the properties and characteristics of a particular brand, you can contact the company’s managers.

Like all products, VK8 material is purchased from leading manufacturers. Therefore, we are ready to provide a quality guarantee with full responsibility. The minimum number of intermediaries determines the low cost. Coupled with fast delivery, this allows us to conduct stable and mutually beneficial cooperation.

In addition to tempering, in the form of one or another part (blank), our company carries out metal processing. All events undergo strict control for compliance with GOST and rules. The specialists of our company carry out such work as galvanizing, creating parts according to customer drawings, producing castings, manufacturing various profiles and much more.

Having the latest equipment and vast experience in our arsenal, we can offer product testing for a number of parameters, such as strength characteristics, chemical composition, alloy purity, and so on.

Each buyer is offered a huge range of products in various formats, as well as current services and works. To quickly understand and choose a product that meets your needs, you need to contact the company manager and receive detailed information on all issues of interest.

Read also: Replacing batteries in an interskol screwdriver

Decoding steel grades | uralspecmet.ru

Deciphering steel grades is not a very difficult matter if you know what letters are used to denote certain chemical elements that make up a grade or alloy. In Russia and the CIS, an alphanumeric system has been adopted, numbers indicate the content of steel elements, and letters indicate the name of the elements.

There are certain designation features for different groups of construction, structural, stainless steel, tool steel, etc.

The designations common to all are the letter designations of alloying elements: N - nickel, X - chromium, K - cobalt, M - molybdenum, B - tungsten, T - titanium, D - copper, G - manganese, C - silicon, F - vanadium, P - boron, A - nitrogen, B - niobium, E - selenium, C - zirconium, Yu - aluminum, H - indicates the presence of rare earth metals. High-speed tool steels are deciphered as follows - such grades have the letter P (the designation of steel begins with this), followed by a number indicating the average tungsten content (for example, P18; P9), then followed by letters and numbers determining the mass content of the elements. (for example, R6M5 steel) the number 5 shows the proportion of molybdenum in this grade. The chromium content is not indicated, since it is consistently about 4% in all high-speed steels and carbon, since the latter is always proportional to the vanadium content. It should be noted that if the vanadium content exceeds 2.5%, the letter F and a number are indicated (for example, R6M5F3 steel). Unalloyed tool steels are divided into high-quality ones, indicated by the letter U and a number indicating the average carbon content (for example, U7; U8; U10) and high-quality, designated by an additional letter A at the end of the name (for example, U8A; U10A; U12A) or an additional letter G, indicating an additional increase in manganese content (for example, U8GA).

Characteristics

Properties depend on several factors. No two brands are completely identical.

First, let's look at exactly what characteristic features are categorized.

Name and percentage of chemical elements

Everything is simple here. The alloy is characterized into groups of 4 different composition qualities - this is “VK”, that is, with tungsten carbide and cobalt; titanium tungsten; titanium-tantalum tungsten and with wear-resistant coatings. It’s already clear from the name which substance has the priority amount. This is how the characteristics are determined.

Physical and mechanical properties

Perhaps the most important. We will list them in more detail and analyze them below; now we will point out that all compounds, without exception, are manufactured according to a recipe approved by GOST. The domestic standard corresponds to international ones, so you can calculate all the technical qualities of each brand. After we list their average values, we present a short table.

Features of technological processes for obtaining

Depending on whether powder pressing or casting was taken as a basis, characteristic features are determined. For example, about sintered materials, every specialist knows that an important indicator is the size of the carbide grains. The smaller it is, the more monolithic the result will be. It also influences what metalworking methods can be used and where the material will then be used.

Physical and mechanical characteristics

Of course, it is quite difficult to say average values, because too many things influence what the result will be. Below we will provide more precise tabular data from the official document, but first we will imagine what properties are generally evaluated and why.

Allowable strength

This is the resistance of the metal to any mechanical influence from the outside. That is, there is no deformation left on the surface after a collision with other parts. And this is very accurately said about carbide materials.

Measurements are taken using bending. The pressure exerted on the workpiece varies from 1200 MPa for VK2 to 2150 MPa for VK25.

Hardness

This is the ratio of the load to the surface area that is deformed under the influence of an indenter - that is, a cone or ball that is pressed into the sample as an experiment. It is measured in HRA and reaches up to 91, which is very high compared to steel.

Realizable thermal conductivity

This is the ability to conduct and retain heat from a hotter part to a colder part. The process continues until an energy balance is established. The average is about 51 W/(m×C).

Density of hard alloys

This indicator means how much mass per unit volume. In simpler terms, this is how tightly particles of a substance are pressed against each other. And since metals are, in principle, very heavy and practically do not contain voids, their density is very high. The characteristic fluctuates in the range of 14.9 – 15.2 g/cm3.

Heat resistance

Any material is destroyed under the influence of significant temperatures, but the limit that the compositions can withstand is different for everyone.

In this case, the sample can withstand up to 1200 degrees.

Corrosion resistance

Rust resistance is mainly provided by alloying additives. Some brands have added chromium, just like stainless steel, which increases the indicator.

Now we present a summary table, note that the data is taken from the GOST document.

| Labeling (we take the most popular) | Bending strength, MPa | Thermal conductivity, W/(m °C) | Hardness, HRA | Density, g/cm3 |

| VK2 | 1200 | 51 | 91,5 | 15,1 |

| VK4 | 1500 | 50,3 | 89,5 | 14,9 |

| VK6 | 1550 | 62,8 | 88,5 | 15 |

| VK8 | 1700 | 50,2 | 87,5 | 14,8 |

| VK10 | 1800 | 67 | 87 | 14,6 |

| T5K10 | 1450 | 20,9 | 88,5 | 13,1 |

| TT7K12 | 1700 | –– | 87 | 13,3 |

| TT8K6 | 1350 | –– | 90,5 | 13,3 |

| TN-20 | 1000 | –– | 89,5 | 5,8 |

Chemical composition and preparation

The composition of the metal includes:

- W – 91.7%;

- Co – 7.4-8%;

- O – 0.4%;

- C – 0.6-0.66%;

- Fe – 0.3%.

Cobalt is used to bind tungsten carbide. This is a metal similar in appearance to ferrum, but its shade is darker. Its use in the composition makes the alloy more malleable and durable. Tungsten carbide is a chemical compound of tungsten and carbon.

The composition of the VK8 alloy includes small fractions of a carbide compound and cobalt, which allows us to consider the material a product of powder metallurgy. To obtain them you need to perform several actions:

- grind the mixture;

- divide it into factions;

- mix the fractions in the required proportions;

- form the workpiece using a press and adhesive;

- process at a load of 30 MPa and a temperature of 1400 degrees.

As a result, moisture is released from the cobalt, which wets the part, and when this element crystallizes, carbide particles combine. The structure is characterized by strength and wear resistance.

Chemical composition and method of preparation

Constantan alloy - properties and applications

According to GOST 3882-74, the VK8 hard alloy is a mixture of tungsten carbide and cobalt grains, acting as a connecting link. Cobalt (GOST 123-2008) is a metal similar in appearance to iron, but has a darker shade. Its main purpose in VK8 is to impart ductility and strength to the alloy. Tungsten carbide (GOST 28377-89) is a compound of carbon with the refractory metal tungsten. Hardness - over 80 Rockwell units.

VK8 is a product of powder metallurgy, since the above properties of the constituent elements do not allow mechanical processing by forging. The production of fine fractions of carbide and cobalt is carried out by reduction from oxides and includes the following operations:

- Crushing the mixture of structural components.

- Sifting through a sieve with a mesh size of 1-2 microns.

- Mixing fractions in proportions according to the required chemical composition of the VK8 hard alloy.

- Pre-shaping by pressing using organic glue.

- Treatment with pressure over 30 MPa and temperature of 1400 ºС.

As a result of these processes, the molten cobalt wets and, during subsequent crystallization, holds the carbide crystals together. As a result, a strong and wear-resistant connection is formed.

Physical properties

VK8, unlike high-speed steels, has greater hardness, which corresponds to 87.5 HRC units. As an example, P12 steel has only 60-70 HRC.

The heat resistance of the alloy, i.e. the temperature at which the material will work without losing rigidity, is 800-1000 ºС. Thanks to this and the high thermal conductivity value (50.2 W/m C), the VK8 cutter can operate at cutting speeds of up to 200 m/min, depending on the type of material being processed. Whereas under the same conditions, P12 steel allows one to achieve a value of only 50 m/min.

Tensile strength 1660 N/mm2, density 14.5 g/cm3, impact strength 35 kJ/m2 - these mechanical properties make it possible to use the alloy under conditions of dynamic and vibration loads.

Physical properties are determined not only by its chemical composition, but also by the grain size of tungsten carbide. The larger the grain, the higher the strength reading and the lower the wear resistance value. And vice versa, if the alloy has a fine-grained structure.

How to obtain hard alloys

Metal compounds are a mixture of powders that are pressed and baked. It contains carbides and cobalt. The powders are mixed in baking dishes and pressed under a pressure of 200 kgf/cm2. After pressure treatment, the molds are heated to a temperature of 1500 degrees. Ready-made compounds are used in the production of difficult-to-process materials.

Properties of hard alloys

To understand which metal or mixture is the strongest in the world, you need to know their properties. The main characteristics will help you understand certain types of materials and use them wisely in production. Properties of hard alloys:

- High mechanical and thermal shock strength.

- Wear resistance.

- Red fastness. This indicator appears at temperatures from 900 to 1000 degrees.

Properties of hard alloys such as impact resistance, ductility, compressive or bending strength and hardness directly depend on the amount of cobalt contained in the compounds. The grain size of the tungsten carbide is also important.

Characteristics of hard alloys

To determine the hardest alloy, you need to understand the characteristics. These include the chemical composition of the metal compound, its mechanical and physical properties, and the process of obtaining finished alloys.

Mechanical and physical characteristics:

- Heat resistance.

- Density (14.9g/cm3–15.2g/cm3).

- Hardness (89.5HRA-91 HRA).

- Thermal conductivity - 51 W.

- Permissible strength - 2150 MPa.

These characteristics also include the resistance of the compounds to the effects of corrosive processes. The hardest alloy has inflated physical and mechanical characteristics.

Heat-resistant metal

Stamps

According to state GOSTs, special markings are established that mark all compounds of hard metals. It consists of capital letters and numbers:

- VK6M - tungsten-cobalt mixture. The number 6 indicates the amount of cobalt in the composition. The letter “B” indicates tungsten, respectively, the letter “K” indicates cobalt. The letter “M” indicates the area in which this alloy is used. Tools for metal processing are made from it.

- VK2 - in this case the mixture contains 2% cobalt and 98% tungsten.

- BK8 - this mixture of cobalt contains up to 8%.

- T14K8 - such compounds contain a third element - titanium. It contains 14% of it. Cobalt 8%. Everything else is tungsten.

- T5K10 - similar to the previous mixture, in which 5% titanium, 10% cobalt and 85% tungsten.

- TT7K12 - tantalum is added to the above elements. Its percentage is the same as that of titanium.

Alloy grades are indicated on finished parts and blanks.

Areas of use

There are many applications for hard alloys. These include:

- Production of tools for metal processing.

- Manufacturing of parts for industrial equipment.

- Equipment for working with metal workpieces.

Often hard alloys are used as a coating on softer ones. The scope of application extends to the construction of large transport vehicles.

Classification

The variety of such materials requires a clear division according to their characteristic features. Classification of hard alloys is made according to the following criteria:

- composition of chemical elements (name, percentage);

- on production technology;

- Areas of use.

Based on the chemical elements present, they are divided into the following categories:

- tungsten-cobalt (marking VK);

- titanium-tungsten-cobalt (TC);

- titanium-tantalum-tungsten-cobalt (TTK).

According to the production technologies used, they are divided into: sintered, cast, and powdered. Sintered, composed of carbides. Divided into three groups:

- single-carbide (tungsten carbide);

- two-carbide (including carbides of two metals: titanium and tungsten);

- tricarbide (welded from three elements).

Based on the percentage content of each element, they are divided into the following groups.

The first includes materials consisting of tungsten carbide and cobalt. They are designated VK. This large group includes alloys: VK4, VK3M, VK6M. The hard alloy VK8 and VK3 is very popular. VK3 stands for the same as all tungsten alloys.

The second combines titanium-tungsten alloys. It has the abbreviation TK. These include: T5K10, T14K8.

The third includes all titanium tantalum tungsten alloys. Designated TTC. For example, TT7K12 and others.

The fourth combines materials that have a wear-resistant coating. They are designated by the abbreviation VP. It includes: VP3115, VP3325. Each of them is based on a well-known alloy. For example, VPZ115 has a base of VK6.

Tungsten-containing hard alloys

They are marked as follows - VK6, VKZM, VK6M, VK8. The main area of application is the production of cutting tools. Alloy VK8 is used for the manufacture of cutters.

Set of tips VK6

It allows you to process cast iron. Used for the production of tools capable of so-called chip-free processing of materials.

Titanium-tungsten-containing hard alloys

Tools for high-speed processing of various types of steel are made from grades T5K10, T14K8, T15K6. They are used to process metals and various compounds with increased hardness and heat resistance.

Prices for receiving VK TC, hard alloys

| Name | Description | Price | |

| VK - TK (Otpay) | Scrap of hard alloy VK - TK (Open) | 850 | |

| VK - TK (MIX) | Hard alloy scrap VK - TK | 1050 | |

| VK (Sorted) | VK hard alloy scrap (Sorted) | 1100 | |

| TK - TTK | Hard alloy scrap TK - TTK | 1000 | |

| TN - KNT | Hard alloy scrap TN - KNT | 100 | |

| VK (Sludge) | VK grinding waste scrap (Sludge) | 800 |

What are VK TK hard alloys?

The most important quality of a hard alloy is wear resistance. VK TC is a solid metal material that retains its original characteristics when exposed to high temperatures (900-1150 C). It is used in tools with these alloys to work under extreme conditions. In order to produce such metals, it is necessary to use highly hard, refractory materials, which include chromium, titanium and tungsten carbides. To connect such materials, a cobalt binder with different contents of nickel and cobalt is used.

Classification of hard alloys

Hard alloys have their own classification like all other metals. It helps to distinguish and selects material for specific purposes. Today, there are two ways to produce the alloy:

- cast;

- sintered.

Cast alloys - produced using casting technology:

- Stellites. Composition: chromium, carbon, tungsten, nickel. Cobalt is used for binding.

- Sormaites. Composition: carbon, chromium, nickel on iron. Nickel-based hard alloys.

When casting an alloy, press technology is most often used, during which high-strength products are obtained, which in turn require heat treatment.

Sintered alloys (metal-ceramic) - are manufactured using powder metallurgy technology. This is a high-precision production, the output of which is a very durable and high-quality material that does not require additional processing.

According to their chemical composition they are distinguished:

- VK – single-carbide, tungsten-cobalt;

- TK – two-carbide, titanium-tungsten-cobalt;

- TTK – tricarbide, titanium-tantalum-tungsten-cobalt;

- TN - tungsten-free.

Tungsten-cobalt alloys

The most common alloys are tungsten carbide alloys. This group includes VK6 and VK8. These alloys are also divided into two groups:

- Containing other metals in tungsten.

- Contains cobalt in the binder composition.

Example of VK marking

— composition of tungsten carbite and cobalt. The number indicates the cobalt content as a percentage. These are the following alloys: VK8, VK10, VK6

.

Titanium-tungsten-cobalt alloys

The TK alloy is manufactured for tools; such tools cut steel and produce draining chips. The TC includes:

- Wolfram carbide;

- titanium carbide;

- for cobalt binder.

Titanium reduces adhesion to steel; this alloy is very wear-resistant when processing steel. If you add more titanium carbides, the strength will decrease, but wear resistance and hardness will increase.

Example of TC marking

— composition of tungsten carbite, cobalt, titanium carbite. The number after the letter T is the titanium carbide content in percent. The number after the letter K is the percentage of cobalt content. These are the following alloys: T5K10, T14K8, T15K6, TZ0K4

.

Titanium-tantalum-tungsten-cobalt alloys

GOST 3882-74 distinguishes 5 brands. This alloy contains tantalum, which improves wear resistance when cutting.

Example of TTK marking

- composition titanium, tungsten and cobalt and tantalum. The number after TTK indicates the content of titanium and tantalum carbides. The number after K is the percentage of cobalt. These are the following alloy brands: TT7K12, TT20K9

.

Tungsten-free alloys

GOST 26530-85 distinguishes two types of tungsten-free alloys:

- TH20;

- KHT16.

Example of TN marking (tungsten-free)

— ТНМ20, ТНМ25, ТНМ30.

Production Features

The production of hard alloys using powder metallurgy technology is carried out in the following sequence:

- To obtain carbides and pure cobalt, technologies for their reduction from oxides are used;

- For production, the particle size should not exceed 1 - 2 microns. And it can only be obtained in ball mills followed by sifting.

- Mixing components in proportions that correspond to the chemical composition of the alloy.

- Cold pressing, for this, glue is added to the resulting mixture, which ensures the molding of the future product and its preservation to its final shape.

- The penultimate operation is sintering. This process occurs at a temperature of 1400 ºC. During heating, upon reaching a temperature of 800 - 850 ºC, the glue burns out. At maximum temperature, cobalt goes into a liquid state and wets the particles of carbide powders. As it cools, the cobalt begins to crystallize and the particles join together.

- The last operation is the mechanical processing of the workpieces. For this, a diamond-coated tool is used. Any other one is simply not suitable for this operation.

To improve the cutting properties of the product, special coatings can be applied to them, for example, titanium nitride.