Correctly calculated overlap of reinforcement during tying affects the final quality of the structure. The reliability of this method is difficult to challenge, however, there are certain nuances in the work process, if not observed, the result of the connection may turn out to be fragile and short-lived. This can also affect the rate at which the concrete hardens, causing the base to become very soft.

Why is it necessary to comply with reinforcement overlap standards when knitting?

When pouring the foundation of a house or when erecting any other concrete structure (column or monolithic block), the issue of strength and durability of the structure remains pressing. Subject to compliance with all building codes, an additional metal frame will greatly strengthen the structure and make it durable, and the base unaffected by natural conditions and time.

If the rules are not followed, the foundation of the house may soon collapse, which will lead not only to the loss of a large amount of materials, but also to human casualties. This is due to the fact that incorrectly calculated overlap of reinforcement leads to non-hardening of concrete in some places, which leads to weakening of the entire structure as a whole. To build a strong and reliable frame, several methods are used, including knitting, for which it is necessary to use an overlap.

Requirements of regulatory documents for reinforcement connections

When connecting rods using the knitting method, it is important to consider a number of factors:

- relative arrangement of reinforcement in the spatial frame;

- features of placement of areas with overlap relative to each other;

- the length of the overlap section, determined by the cross-section of the rod and the grade of concrete.

When locating a section with overlapping rods in the zone of maximum load, the amount of overlap should be increased to 90 times the diameter of the rods being connected. Building codes clearly indicate the dimensions of joint areas.

The length of the joint is affected not only by the cross-sectional diameter, but also by the following points:

- magnitude of the effective load;

- brand of concrete mixture used;

- class of steel reinforcement used;

- placement of butt joints in the spatial frame;

- purpose and scope of reinforced concrete products.

It should be noted that the amount of overlap decreases with increasing grade of concrete used.

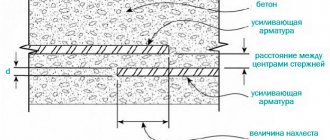

In cases where tying wire is used, the distance between the rods is often taken equal to zero, since in this situation it depends solely on the height of the profile protrusions

Let's consider the change in the amount of overlap that takes up compressive loads for class A400 reinforcement with a diameter of 25 mm:

- for concrete grade M250, the rods are fixed with a maximum overlap of 890 mm;

- concreting the reinforcing grid with M350 mortar makes it possible to reduce the overlap to 765 mm;

- as the grade of concrete used increases to M400, the overlap of the rods decreases to 695 mm;

- Filling the reinforcement frame with concrete mortar M450 allows you to reduce the overlap to 615 mm.

To reinforce the tension zone of the reinforcement cage, the overlap for the specified reinforcement is increased and amounts to:

- 1185 mm for M200 concrete;

- 1015 mm for concrete M350;

- 930 mm for M400 concrete;

- 820 mm for M450 concrete.

When carrying out activities related to reinforcement, it is important to correctly position the overlap areas and take into account the requirements of building codes and regulations.

- distribute connections evenly throughout the reinforcement frame;

- maintain a minimum distance between joints of at least 610 mm;

- take into account the brand of concrete mortar and the cross-section of reinforcing bars.

Compliance with the requirements of building codes guarantees the strength and reliability of concrete structures reinforced with a reinforcing frame. Having studied the recommendations of SNiP in detail, it is easy to independently select the required amount of reinforcement overlap, taking into account the design features of the reinforced concrete product. Recommendations from professional builders will help you avoid mistakes.

Yes, it is necessary to fix the rods, otherwise the concrete will displace them and there will be neither a protective layer nor a uniform distribution.

But it cannot be swept away if the clamps are 25-30 cm apart and it is pulled towards them. One rod would pull out the other if the ribs could fit into each other. It seems that on Japanese reinforcement in the topic of projects of earthquake-resistant houses, the ribs are perpendicular to the axis of the rod. But our twisted ribs + a pair of straight ribs will not hold each other by the ribs. IMHO.Thanks to myself for the wish, I think I’ll still tie it, + bend the legs 15 centimeters on all the rods.

Not all fiber has hooks at the ends, and not all is metal. F. N. Rabinovich in the book 2004 “Composites based on dispersed reinforced concrete” writes, “Research has shown that carbon fibers can be effectively used to improve the quality of concrete products. They are not exposed. corrosion in hydrating cement, significantly increase the tensile strength of the cement stone and its elastic modulus. However, the cost of carbon fibers significantly exceeds the cost of steel and glass fibers, so their use as reinforcement requires special justification. Of greatest practical interest is the consideration of the properties of steel and mineral (glass) fibers, as well as some types of fibers of organic origin. Steel fibers. Metal fibers used as reinforcement are produced in various ways: mechanical, electromechanical, and melt spinning. The most widely used mechanical methods include drawing, conventional drawing, broaching, and cutting of metal foil or sheet and other similar materials. The choice of metal fiber production technology depends significantly on the required diameter. Ultrafine fibers are usually produced by drawing through diamond filters. However, despite the high strength and efficiency of such fibers, their use due to their significant cost is possible only in small quantities in cases where it is economically justified. The greatest use for concrete reinforcement is made from wire-cut pieces of steel fibers with a diameter of 0.3-1.6 mm (Fig. 6). General purpose low-carbon steel wire GOST 3282-74 (as amended) is usually used. Of particular interest is the production of flat steel fibers with a cross section of 0.15-0.4 by 0.25-0.9 mm from metal foil, tapes, sheets, plates or flattened round wire. The volumes of industrial production of thin steel wire make up a relatively small part (about 24 but 2.5-3.0%) of the total production of reinforcing steel. Therefore, the issues of expanding the production of steel wire with the necessary parameters for the production of fiber reinforcement are quite relevant at present, which, in turn, can lead to a corresponding reduction in the consumption of traditional assortments of reinforcing steel. Also promising is the expansion of the production of flat fibers obtained from sheet materials (rolled thin sheets) or from massive steel billets. "

Thank you for your wish.

Reinforcement is an important part of the design of all monolithic structures, on which the long-lasting and reliable future of the structure depends. The process involves creating a frame from metal rods. It is placed in formwork and filled with concrete. To create this frame, they resort to knitting or welding. In this case, a correctly calculated overlap for the reinforcement plays an important role in knitting. If it is insufficient, the connection will not be strong enough, and this will affect performance. Therefore, it is important to figure out what kind of overlap to make when knitting.

There are two main methods of fastening reinforcement, according to building codes and regulations (SNiP), namely clause 8.3.26 SP 52-101-2003. It states that the connection of rods can be performed using the following types of joining:

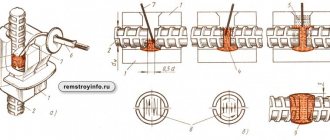

- Joining of reinforcement bars without welding, overlapping.

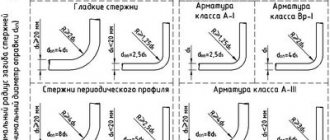

- overlapping using parts with bends at the ends (loops, legs, hooks); for smooth rods, only loops and hooks are used;

- overlap with straight ends of reinforcing bars of periodic profile;

- overlapped with straight ends of reinforcing bars with transverse type fixation.

- Mechanical and welded connection.

- when using a welding machine;

- using a professional mechanical unit.

SNiP requirements indicate that a concrete foundation requires the installation of at least two continuous reinforcement frames. They are made by fixing the rods overlapping. For private housing construction, this method is used most often. This is due to the fact that it is available and cheap. Even a beginner can start creating a frame, since you need the rods themselves and soft knitting wire. You don't need to be a welder or have expensive equipment. And in industrial production, the welding method is most often used.

Note! Clause 8.3.27 states that overlapping reinforcement connections without welding are used for rods whose working cross-section does not exceed 40 mm. Places with maximum load should not be overlapped by bonding or welding.

Overlapping of rods by welding is used exclusively with reinforcement grades A400C and. Only these grades are considered weldable. This also affects the cost of products, which is higher than usual. One common class is the . But merging products with them is unacceptable. As the material heats up, it becomes less durable and loses its resistance to corrosion.

In places where there is overlap of reinforcement, welding is prohibited, regardless of the class of the rods. Why? If you believe foreign sources, there is a high probability of the connection breaking if it is subjected to heavy loads. As for Russian rules, the opinion is as follows: using electric arc welding for joining is allowed if the diameter size does not exceed 25 mm.

Important! The length of the weld directly depends on the class of the reinforcing rod and its diameter. For work, electrodes with a cross section of 4 to 5 mm are used. The requirements regulated in GOSTs 14098 and 10922 state that overlaps can be made by welding with a length less than 10 diameters of the reinforcing bars used for the work.

The amount of overlap when connecting reinforcement according to SNIP

The Sanitary Standards and Rules of 2003 (abbreviated SNiP) describe all types of fittings connections that currently exist. Overlapping joints are created without the use of welding machines, in this they differ from mechanical (for which couplings and special equipment are used) and welded (for which a welding machine is respectively required). There are three types of overlap joints:

- Rods with hooks and claws (bends) at the ends.

- Rods with a straight end (with welding or installation at the intersection of reinforcement).

- Rods with straight ends (profile).

The Sanitary Standards and Rules of 2003 recommend overlapping reinforcement with a cross-section of up to 40 mm. In turn, the world analogue of building codes, namely ACI 318-05, states the maximum permissible value of the cross-section of the rods is 36 mm. This is due to the lack of evidence base for the reliability of connections of larger diameter, since no tests have been carried out. Also during knitting, it is worth leaving a certain free space around the overlap.

It must be taken into account that the minimum distance that must be left for reserve, both horizontally and vertically, is 25 mm. However, if the cross-section of the reinforcement itself is more than 25 mm, then the margin must be calculated according to the diameter step. The largest distance between elements is 8 sections of the rod. But when using wire in knitting, the distance is reduced to 4 sections.

It is not recommended to use tying in areas of greatest pressure, since the joint is not designed for such loads, but only for fastening the reinforcement and maintaining them as a single structure.

Types of connections between reinforcing elements

Wanting to understand the possible options for joining reinforcing bars, many craftsmen turn to the requirements of current regulatory documents. After all, a successfully executed connection provides the required margin of compressive and tensile strength. Some developers are trying to find an answer in accordance with SNiP 2 01. Others are studying building codes and regulations numbered 52-101-2003, which contain recommendations for the design of structures made of reinforced concrete reinforced with non-stressed steel reinforcement.

In accordance with the requirements of current regulatory documents, steel reinforcement is used to strengthen non-stressed elements, in contrast to stressed structures, where reinforcing ropes of classes K7 and higher are used for reinforcement. Let us dwell on the methods used for fixing reinforcing bars.

The current building codes and regulations (SNiP) describe in detail the fastening of reinforcement using all currently existing methods.

The following options are possible:

- overlapping connection of knitted rods without welding. Fixation is carried out using additional curved steel rods that repeat the configuration of the reinforcement connection. According to SNiP, it is allowed to overlap straight rods with transverse fastening of elements using tying wire or special clamps.

The overlap of the reinforcement when knitting depends on the diameter of the rods. Concrete-filled structures made of knitted rods are widely used in private housing construction. The developer is attracted by the simplicity of the technology, ease of connection and reasonable cost of building materials;

- fixing reinforcing bars using household electric welding equipment and professional units. The technology for connecting reinforcement using welding installations has certain limitations. After all, significant internal stresses arise in the welding zone, which negatively affect the strength characteristics of the reinforcement cages.

It is possible to overlap reinforcing bars using electric welding using reinforcement of certain brands, for example, A400C. The technology of welding steel reinforcement is mainly used in the field of industrial construction.

Building codes and regulations contain instructions on the need to strengthen the concrete mass with at least two solid reinforcement contours. To implement this requirement, steel rods are connected to the ceiling. SNiP allows the use of rods of various diameters. In this case, the maximum cross-sectional size of the rod should not exceed 4 cm. SNiP prohibits overlapping rods using tying wire and welding in places where there is a significant load located along or across the axis.

These include mechanical and welded butt-type joints, as well as overlap joints made without welding

Reinforcement overlap under different conditions

The joint locations of the reinforcement and the location of the lattice should be determined by the designer, not the builders. Since the overall picture of the project, as well as knowledge of the load in different places, is known only to him. Otherwise, the design may be damaged.

For example, when reinforcing a column, several fundamentally important steps should be followed:

- The outlet must be bent to a slightly longer length than the cross-section of the reinforcement (for a diameter of 16mm it is 20mm).

- It is necessary to bend the reinforcement without heating, but with the help of special means that can provide the required bending radius.

- The bend radius must be indicated in the project and emphasis should be placed on it, since builders are unlikely to do this without instructions.

Consumption rates for reinforcement for overlap

The required length of reinforcement bars varies according to several criteria:

- For compression reinforcement, the required length will be as follows. So, for fittings with a diameter of 6 mm - length 20-22cm; 8mm - length 20-29cm; 10mm - length 25-36cm; 12mm - length 30-43cm; 14mm - length 35-50cm.

- For tensile reinforcement, the required overlap length of the bars must be greater. For example, for a diameter of 6 mm - length 20-29cm; 8mm - length 27-38cm; 10mm - length 33-48cm; 12mm - length 40-57cm; 14mm - length 46-67cm.

The higher the strength class of concrete, the shorter the length of the overlap rods should be. The only exceptions are 20, 28 and 32 mm fittings. With concrete strength class B35, the length of the rods should be 655, 920 and 1050 mm, respectively.

Do you comply with the norms for overlap of reinforcement when tying?

Yes

No