Graphite electrodes are conductors containing carbon-graphite. Visually, they are distinguished by their shiny surface and gray color. The electrode has a flexible texture, so you can easily cut it to the required size. Conductors are relevant for welding non-ferrous alloys. Graphite electrodes are also used to join hard metals. According to experts, graphite ones are considered more practical compared to coal ones.

If we turn to the properties of graphite itself, the melting point is about 3500 degrees. There is no single technology for producing rods. They are made from the remains of electrodes from melting furnaces. To obtain the desired tip shape, the electrode is sharpened. In operation, graphite electrodes exhibit lower resistance. Compared to carbon, graphite is used for welding under high current.

Specifics of using graphite electrodes:

- a welding arc is formed due to the contact of the electrode and the metal base. The edge of the material melts, resulting in a weld pool. It forms the seam;

- To work with graphite electrodes, direct current is required. Only with straight polarity will the arc be stable. Indirect polarity occurs when cutting metal products;

- A special feature of graphite electrodes is the economy of rods, which practically do not crack. The minimal consumption of material attracts welders, who most often choose graphite consumables for this very reason.

Pros and cons of graphite electrode

If you have not worked with graphite electrodes before, it is important to evaluate the strengths and weaknesses of the material.

Advantages of a graphite electrode:

- they are made from leftover rods from smelting furnaces. This is why the electrode is easy to use;

- the ability of the electrode to withstand high current levels;

- act as excellent electrical conductors, which has a positive effect on the quality of welding;

- durability of the electrode due to resistance to aggressive factors, does not oxidize.

The disadvantages of graphite electrodes include:

- serious requirements for the shape and sharpening of electrode tips;

- during welding with electrodes there is a possibility of an increase in the amount of carbon;

- the minimum diameter is 6 mm, which narrows the range of applications for a graphite electrode.

Quality requirements

Carbon-graphite electrodes without visible or hidden defects will be sent for sale. Rejection signs include the presence of structural cracks with a length and depth of 4.8 mm, defects in cutting or thread rolling, deviation in the internal diameter of the sockets by more than 0.58 mm.

The presence of local depressions on the surface of products is not considered defective, provided that the thickness of the GE is not less than the minimum permissible diameter and is more than 3 mm.

Each batch of products undergoes acceptance control. To determine the quality of GE, a number of tests are carried out. Test results are documented and attached to the package of accompanying documentation.

Types of tests:

- determination of geometric parameters;

- measurement of electrical resistivity;

- checking resistance to bending loads;

- estimation of material density;

- determination of the coefficient of thermal expansion;

- measuring the weight of products;

- measurement of maximum deviations of the perpendicularity of the ends;

- identification of visible and hidden defects, chips, cracks;

- determination of deviations in the alignment of sockets and GE;

- identification of thread cutting defects.

Tests are carried out in accordance with the requirements of GOST 2Z776-79, GOST 2Z775, GOST 166, GOST P 5Z228, GOST P 5425Z.

Graphite electrode consumption

During the melting process, the graphite rod is consumed. Although the material is considered melt resistant, slow melting occurs. This process is significantly slower, unlike other types of consumables. If, when exposed to high temperatures, the diameter of the rod decreases and becomes smaller than normal, then extension is necessary. For this purpose, nipples are used, which are sometimes included in the kit from the manufacturer.

With standard furnace operation, consumption ranges from 4 to 8 kg per ton. To reduce the cost of consumables and make the process more economical, you need to control a number of parameters:

- quality of consumables used;

- features of the smelting furnace;

- heat treatment mode and set temperature;

- steel quality and burner type.

In general, graphite electrodes are practically not consumed. Loss of mass of consumables occurs due to the evaporation of the graphite itself.

Advantages of graphite, principle of wire welding

A feature of this type of electrodes is their ability to conduct current without melting, which is typical for other types of electrodes. Graphite electrodes can be produced with different tip shapes and different lengths. It can be regular or copper-plated (having a copper coating, up to 5% of the composition). Among the advantages of this type of electrodes are the following:

- low price, availability, slow consumption;

- the rod material does not stick to the elements being connected;

- graphite heats up to the melting temperature of the metal very quickly;

- A current of 5–10 A is sufficient to produce an arc.

In addition, if copper wires are welded with a graphite electrode, the resulting connection is corrosion-resistant and heat-resistant, and the electrodes themselves are not prone to cracking during operation.

In order to prevent melting of the wire insulation, a metal radiator (most often copper, since copper has high thermal conductivity) is attached to the point where the twist comes out of the insulation. Heat from twisting is removed due to the large contact area. Before welding copper wires, they must be prepared, cleaned of insulation and/or varnish. The twisting must be done tightly so that the turns are closely adjacent to each other, the length of the twist should be 5-6 cm. The ends of the wires must be cut off at the same distance so that none of them is outside the welding area.

At the place where the radiator is attached, the ground clamp of the device is connected to the wires, after which a graphite electrode is brought to the cut edges. Contact should be short-term, no more than 1 second. After the contact ceases, a spherical section of molten copper forms at the end of the twist.

Features of graphite electrode

The structure of the rod consists of two elements with an insulating gasket. Copper or aluminum oxides are used as an insulator. Graphite electrodes are made from compressed carbon. For this reason, the percentage of carbon in the metal may increase during the metal welding process.

The composition and technical features of the electrode depend on the manufacturer. To obtain comprehensive information on the electrode, decipher the product labeling. All consumables must be produced in accordance with GOST standards and other regulatory documents. The technical characteristics of a graphite electrode include the following indicators: density, ash impurities, resistance force, strength, elasticity.

Composition and technical characteristics

The main component of coal rods is coal coke. In addition to it, the composition contains metal powder, which gives the electrode strength and a resin that connects all components. The diameter of such electrodes can be different - from 1.5 mm to 300 mm.

In addition to size and cross-section, carbon electrodes have other parameters:

- The current strength that is supplied to the electrode. It depends on the material and equipment you are working with.

- Shapes and sizes of grooves . They depend on the end of the rod and its dimensions. The most popular are large electrodes, which can be used to work with massive parts.

- The thickness of the cut depends on the current power. But here you need to carefully ensure that the product withstands and does not melt.

Where is graphite electrode used?

Consumables are quite popular, so their scope is wide. Graphite electrodes are used to perform a number of tasks. Graphite rods are suitable for treating metal surfaces before welding and cleaning parts.

With the help of graphite electrodes, it is possible to reduce the risk of defects and avoid seam defects. Several main directions in the use of consumables are identified:

- welding of non-ferrous alloys;

- elimination of defects when creating a cast alloy;

- fusing hard alloys onto a metal base.

Application of rods and features of working with them

The graphite electrode has found application not only for making welded connections of wires: it is used in a much larger list of operations.

Graphite welding rods are necessary for pre-processing metal surfaces before welding work, as well as other types of processing, cutting metal workpieces, cleaning metal edges, etc. Not only metallurgy actively uses electrodes of this type, but also legal proceedings.

Carbon arc welding.

Electrodes for welding made of graphite allow you to quickly and with a high degree of efficiency cut rivets and pierce elements made of alloy and carbon steel.

They are also relevant when melting steel and cast iron, as well as some alloys in electrothermal furnaces. And thanks to the presence of nipples, such rods can be connected to each other, which allows for a continuous supply of consumables for welding in the furnace.

On a note! Practice shows that the use of graphite rods for welding copper wires and for arc cutting of metal can reduce the number of scraps and defects in welds. The main thing is that when working with graphite, it is important for a welder to follow technology and adhere to safety rules.

Graphite rods are also relevant for performing other operations:

- welding operations with products made of non-ferrous metals, elements made of thin metal;

- welding of defects that appeared due to violation of casting technology;

- surfacing of hard-alloy parts to a metal base.

Often, graphite electrodes are used for welding together with a filler that is supplied during the operation or placed in advance at the location of the seam.

It is worth recalling that working with graphite and a welding machine has its own characteristics, which should definitely be taken into account in order to obtain durable, extremely strong and reliable welded joints:

- To save welding rod consumption and maintain a stable arc during long-term welding, straight polarity should be used. That is, you need to apply minus directly to the electrode.

- It is important to carry out welding processes taking into account the influence of external factors on the stability of the arc, this will allow achieving a better result.

- When working with graphite electrodes, the efficiency value is lower than when working with consumable electrodes.

- Welded joints when welding with graphite are characterized by average ductility. The seams may also have voids, which affects their durability.

For these reasons, graphite welding should be performed by a qualified craftsman, and beginners in these matters should practice well beforehand.

Drawing of welding work using a carbon electrode.

There are two technological methods that are relevant for working with graphite rods:

- The material is fed directly into the arc flame. In this case, the welded wire is placed between the metal element and the electrode at an angle of 30 degrees and is fed slightly earlier than the electrode itself. The rod feed angle is 70 degrees, which significantly speeds up the work process.

- The master welds a bead of base metal using an electrode, after which an additive is fed into it. The main difference of this technology is that the rod is fed first and only after that the wire.

The danger of using this technological technique for an inexperienced welder is the high probability of burning through the metal, although the speed of work greatly increases. For this reason, it is more suitable for operations with metal parts that have thick walls.

On a note! Electrolysis using graphite is carried out exclusively at a stable current with direct connection.

When working with graphite electrodes, it is important to remember the following: the determining parameter when using them is the current density used. If the maximum value of this parameter is exceeded for any reason, the graphite may deteriorate.

To extend the service life of the products, special nipples can be screwed in on both sides to extend the electrode. This solution will improve the reliability of graphite electrodes and save money on the purchase of new rods.

Current regulation

The current for welding wires is adjusted within the range of 30-120 amperes, this is the range that is typical for most inverter welding units.

Gas shielded welding diagram.

The exact welding current in any embodiment has to be determined empirically by the welder due to the following factors:

- any inverter model is characterized by certain features, so it is extremely important to carefully read the instructions for a specific device;

- the network voltage of a particular building may not correspond to 220 Volts;

- the copper conductors of the wires contain components of different compositions if they are made by different manufacturers;

- The experience of the craftsman largely determines the results of a welding operation using graphite rods.

It is important to know the current values at which it is possible to effectively connect wire cores with different cross-sections when welding with a graphite electrode:

- when welding cores with a diameter of 1.5 mm2, the inverter is set to 70 amperes;

- three wires with the same cross-section should be welded at a current of 81-91 amperes;

- the current strength for connecting three cores with a diameter of 2.5 mm2 by welding should reach 81-101 amperes;

- four 3 mm2 wires are welded with a current strength in the range of 101-121 amperes.

Welding aluminum wires

A graphite electrode is used for spot welding of copper and aluminum wires. Operations are carried out under submerged arc. This is a special powder inside the welding wire that melts and produces shielding gas.

Scheme of argon-arc welding of aluminum.

The latter prevents welded edges from contact with oxygen and resulting oxidation.

The current current value is set using the regulator. The current is rectified by using a diode bridge and a ripple filter.

Although we note that experienced craftsmen can connect wires by welding even with alternating current and without adjustment by waiting for the required arc holding time. But performing welding work with alternating current gives a lower quality result.

How to make and weld twist correctly?

It is important to prevent the insulating material of the wire from melting, which will require attaching a metal radiator to the point where the twist exits the insulation. More often than others, the copper option is chosen, because this metal is characterized by high thermal conductivity.

The large contact area improves the heat transfer process and removes heat from the twist.

Before starting welding of wire cores, preparatory work should be carried out. Remove insulation and varnish if present. The twisting is done as tightly as possible so that the turns are in close contact with each other.

The optimal twist length is 5-6 cm. In this case, the ends of the wires are cut off at the same distance so that they fall within the welding zone.

In the place where the radiator is fixed, you will need to attach the unit ground clamp to the wires, and then bring the graphite electrode to the cut edges. Contact for welding should be as short as possible.

The optimal time is 1 second, after which a section of molten copper in the form of a ball will form at the end of the twist. In the same way, the remaining twists of wire strands can be welded using graphite electrodes.

Brands of graphite electrodes

To decide which consumable is suitable for a specific task, you need to consider the most popular brands of electrodes.

- EG or graphite products. The composition contains coke from petroleum and coal pitch. Models may differ in resistance from each other. Some manufacturers produce them together with nipples.

- EGS is produced on the basis of needle spit and stone pitch. Relevant for steelmaking.

- EGPs are used for cutting metal. Along with petroleum coke in the composition and coal pitch, the electrodes are additionally impregnated with pitch. They are used in industry in ferroalloy shops and in the metal foundry industry.

- EGSPs are used in electric arc welding. The rods are made of needle coke and coal tar pitch.

Properties and varieties

A carbon electrode is a solid rod consisting of coal (coke) and several additives. Resin is used here as a binding element.

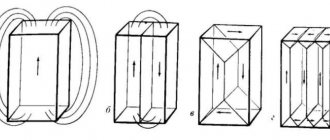

These rods can be used to weld all types and varieties of metals - from refractory and heavy to light and porous. The diameter of the carbon electrode can vary from 1.5 to 25 mm, and the length - from 25 to 300 mm (the longest are used when the parts to be connected are located in a hard-to-reach place). They can also have different shapes:

- round;

- semicircular;

- rectangular;

- hollow.

In most situations, round and semicircular electrodes are used for work - this is the best option for obtaining a standard weld.

Rectangular products are mainly used to seal defects on steel surfaces, while hollow ones are characterized by the fact that they are capable of creating a U-shaped groove at the joint.

It is also worth knowing that in addition to the usual ones, there are copper-plated carbon electrodes. They are coated with copper to increase strength, but all other performance properties remain approximately the same.

How is graphite electrode produced?

Coal is mainly used to make rods. It can be natural or artificial. Next, binder additives are included. Impurities may vary depending on the modification and characteristics of the product. Production includes several stages:

- extrusion or pressing of material under the influence of high temperatures;

- creating the desired shape or configuration;

- marking of threaded connections;

- treatment of the electrode with a copper layer to protect it from oxidation and give it durability.

Most popular brands

There are 2 main types of carbon electrodes on the market. These are SK and VDK. They are respectively designed for conventional and air-arc welding.

Arcair electrodes from Esab are most often found on the Russian market. They perform the following work:

- elimination of defects;

- repair of products and structures;

- removal of seams;

- preparatory work;

- removal of excess material;

- trimming excess reinforcement and product fragments.

Welding copper with graphite electrode

Copper wires can be welded using electrodes. This is a great alternative to other methods. Professional welders highlight a number of advantages of this technology:

- it is possible to achieve maximum reliability by creating a high-quality connection;

- the bases are soldered at the end, the main surface remains intact. Due to this, it is possible to avoid overheating of the structure. Therefore, it is possible to increase the loads;

- efficiency of the process. Heating takes a couple of seconds, which simplifies working with graphite electrodes.

Carbon gouging

Gouging is the removal of a narrow surface layer using carbon arc welding. The word itself originates from the verb “to plan,” since this process is somewhat similar to the processing of grooves on a planing machine. Gouging technology is based on heating the metal with an electric arc to boiling temperature, followed by blowing it out of the weld pool with a narrowly directed air flow. Gouging is carried out to depths of up to tens of millimeters, and its productivity, depending on the thickness of the carbon electrode and the current strength, is measured in grams of metal removed per centimeter of groove.

Safety precautions when using graphite electrodes

When working with welding and cutting metal, you must adhere to safety precautions. Graphite electrodes are used to work with low voltage, but without knowing the precautions, you can encounter negative health consequences.

There are several basic rules:

- It is mandatory to use protective equipment in the form of a welder’s mask, clothing and leggings.

- Prepare the work area. Remove flammable items. The minimum distance from the welding site is 5 meters.

- Before you begin, make sure the equipment you want to use is in working order.

- Disconnect the power to the wires that are going to be welded.

The requirements are quite simple, but their implementation will protect you from irreversible consequences. When choosing a graphite electrode, take into account the diameter of the workpieces for soldering and the features of the welding machine.

Welding mode

The carbon electrode for welding falls into the category of infusible electrodes, which distinguishes it from other metal rods. Thus, when carrying out welding work with such a product, you can use only direct current of direct polarity. This means that the minus is connected to the electrode, and the plus to the metal workpiece.

In certain situations, welding requires the use of a filler element. For example, when flanging thin metal workpieces. This procedure will be more profitable and simpler. There is a large selection of additives on the market that are used in this type of welding. For example, if you are working with copper, it is better to give preference to bronze filler material.

You should also pay attention to the parameters of the cross-section of the filler wire or plate. If it is larger, then there is a risk that the seam will not be welded through. If the cross-section is insufficient, on the contrary, you can burn it out.

Advice! When choosing copper-plated carbon electrodes for welding, select the filler material based on the thickness of the workpieces being joined.