Even novice welders know that during welding work various components are used, such as wire or electrodes. And if to operate a welding machine you only need access to electricity and can work endlessly, then components tend to run out. To ensure that materials do not run out at the most inopportune moment, their quantity can be pre-calculated. This is especially useful during repairs, since it is possible to calculate the cost of welding work and tell the customer the exact price.

In this article we will explain in detail how to calculate the wire, give an example of the calculation and tell you about all the features.

Wire Features

Before calculating the consumption of welding wire, familiarize yourself with all the features of the filler material used in the work. First of all, the wire may have a different deposition rate, which significantly affects the final figures in the calculation.

If you use wire for welding with automatic or semi-automatic welding equipment, then calculating the consumption of welding components is simply necessary. When using argon arc welding, this is not necessary, but it won’t be superfluous either. Since with these types of welding it is recommended not to interrupt the welding seam, and this can only be achieved after accurately calculating the amount of wire. It is better to know in advance the consumption of welding wire when welding with a semi-automatic machine than to correct mistakes later. There is such a thing as a material consumption rate. At the same time, the norm includes not only the amount of wire, but also its overuse in case of welder errors or unforeseen circumstances. When calculating, all stages of welding are taken into account: from preparatory to final. This can be compared to a construction estimate. Knowing the required amount of, say, brick, you know in advance how tall and thick the walls will be. Let's talk in more detail about the consumption standards for welding materials.

Wire specifics

To correctly determine the consumption of welding wire, you need to know all its operating characteristics, composition, and quality.

The filler material must be free of impurities, contain a minimum of gases and slags, and have different melting indices, which determines the calculation.

When welding automatically or semi-automatically, they work on creating a seam without interruption. Therefore, you need to accurately determine the length of wire that will be used.

Otherwise, a defect-free result will not be achieved. During argon arc welding, miscalculations are recommended, but not required.

Although real professionals do not start work until they calculate the amount of material required.

There are fixed limits for the use of consumables. When calculating the footage of filler wire, attention is also paid to such nuances as defects in the work.

Naturally, it needs to be corrected, and it does not matter whether it arose due to the fault of a specialist or under the influence of extraneous factors.

And this will require additional volume of working material. It is necessary to take into account test welding before starting the main process.

Both the employer and the contractor are required to have information about the required materials, and, accordingly, finances to complete the project. For this purpose, design and financial documentation is drawn up.

Consumption rates

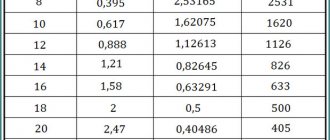

For gas or argon-arc welding, there are wire consumption standards that are prescribed in regulatory documents. They were not taken out of thin air, but were calculated based on the existing experience accumulated by professional welders. Each type of welding and type of wire has its own physical and chemical properties that must be taken into account when calculating, so it is impossible to give exact figures for material consumption for all welds at once. However, there are approximate general values, which you can see in the table below. The table is for informational purposes only, do not take these numbers seriously, carry out the calculations yourself.

Most often, the consumption of welding wire per 1 meter of seam is calculated. This is very convenient because you can easily and quickly make subsequent calculations to increase or decrease the amount of material for the seam. On the Internet you can easily find a calculator for the consumption of welding materials, which will simplify the calculations. But we recommend learning how to calculate the amount of wire yourself.

Wire consumption

Each type of welding work has its own specifics. In this or that welding, materials are used, each of which has its own physical and chemical properties.

To correctly draw up a table of their consumption, you need to take into account all factors, the type of welding machine, seam, filler material, and the qualifications of the craftsman.

That is, take an individual approach to each option. Of course, it is impossible to perfectly calculate the consumption of funds used in work.

But thanks to research in this industry, based on various indicators, average statistical data have been derived.

You can take them as a basis, but it is recommended to calculate all indicators yourself, based on a specific task.

The most convenient way to calculate wire consumption is its consumption per meter of seam. Knowing the filler wire consumption per 1 meter, even a beginner will be able to correctly estimate how much it will take for the entire seam.

And as we already mentioned, you need to include a slightly larger amount of materials in the estimate.

How to calculate consumption

The consumption of welding materials for argon-arc welding or the consumption of wire for semi-automatic welding per meter of seam is made according to the following formula:

N = G*K

Where “N” is the desired parameter or, in other words, the rate of wire consumption per 1 meter, which we need to calculate. “G” is the mass of deposit on the finished weld, again one meter long. And “K” is the correction factor, which depends on the mass of the deposited material to the metal consumption required for welding. To find out the value of G (weight of deposit on a welded joint), we need this formula:

G = F*y*L

The letter "F" indicates the cross-sectional area of the joint in square meters. The letter “y” is the density of the metal from which the wire is made.

Note! "y" value is extremely important because each brand of wire can vary significantly in weight due to the metal used to make it.

The value “L” is automatically replaced by the number 1, since we are calculating exactly 1 meter. If you need to calculate more or less than a meter, then use a different figure. Using these formulas, you can calculate the wire consumption during bottom welding. For other welding methods, you need to multiply “N” “K” , other than 1.

"K" value changes according to the position:

- In the lower position, “K” is equal to the number 1

- With semi-vertical - 1.05

- When vertical - 1.1

- With ceiling - 1.2

If you are welding metal using a semi-automatic machine, consider the shielding gas used in the work, the characteristics of your welding machine, the diameter of the wire and the features of the parts.

Thanks to these simple calculations, you can easily find out the amount of wire needed to weld parts when using argon arc welding or any other type of welding work. Take into account all the features of the type of welding and the wire used so that the calculations are accurate.

What is a calculator for?

The construction of various structures requires the calculation of certain parameters that determine this process. We are talking, first of all, about construction calculators, the specificity of which is the accurate calculation of actions for the material involved (painting calculations, comparison of pipe weights, total sealant consumption, etc.). Today, the Internet is replete with a huge number of sites where it is possible to resort to the help of construction calculators, and this is a very outstanding fact by its standards.

Calculation of the mass of knitting wire

In a few seconds, you can accurately determine all the quantities (mass, diameter, weight) for a particular material, being involved in construction.

As an example, a site that tells you how to build a sauna with your own hands, and at the same time measure the weight of the knitting wire, is suitable. On the resource page (if you follow the link) an online calculator appears where you can calculate the mass of the metal cord by indicating the appropriate items in the boxes provided. In fact, there is nothing complicated in all this, you just need to use the right standards. In addition, on the same site there is a tab - CONSTRUCTION CALCULATORS, by going to which you will find a whole list of these computing mechanisms - more than 30 of them. In addition to the already mentioned wire, here you can calculate the weight of the cable, channel, measure the area of the ceiling, etc. How to put this whole “tool” to use immediately later in the text.

Calculation example

To better understand the calculation principle, let's give an example. So, what will be the consumption of filler wire during semi-automatic welding if ordinary steel is used as the welded metal? Let's start by calculating the weight of the surfacing; the formula G = F*y*L .

G=0.0000055 (m2) * 7850 (kg/m3) * 1 (meter) = 0.043 kg

After this, you can begin to calculate the main value using the formula N=G*K

N = 0.043 * 1 = 0.043 kg

Please note that welding is performed in the down position. This means that the correction factor is equal to one, but the final value does not change.

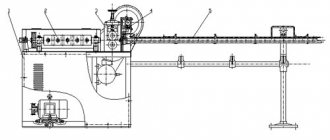

Calculator for the amount of wire for reinforcing a strip foundation

The construction of a strip foundation necessarily involves the installation of a reinforcing frame structure. The use of welding is not encouraged, and assembly is usually carried out using the technology of linking parts using steel wire.

Calculator for calculating the amount of binding wire for reinforcing a strip foundation

When planning such work, many calculations are made, including the amount of material required. This may seem like a trifle, but it still makes sense to get an idea of the number of knots to be tied and, therefore, the amount of wire required for this. A calculator for calculating the amount of binding wire for reinforcing a strip foundation will help with this.

The calculation is simple and understandable, but still requires some explanation. They will be given below.

Calculator for calculating the amount of binding wire for reinforcing a strip foundation

Go to calculations

A few explanations on the calculation

As is known, the reinforcing frame of a strip foundation consists of the required calculated number of longitudinal rods, which are assembled into a volumetric structure using vertical and horizontal jumpers. For these jumpers, it is more convenient to use ready-made rectangular clamps rather than individual pieces of reinforcement. However, this does not affect the number of anchor points.

This means that it is necessary to count the number of intersection points of the reinforcement bars - it is in these places that the wire binding is carried out. And to calculate you need to know:

- The number of rods of longitudinal reinforcement of the tape.

- The total length of the strip foundation, taking into account both the external sides and, if available, internal jumpers for capital partitions.

- The installation step of the clamps (it can be arbitrary, but not more than 0.75 of the total height of the tape).

- In addition, you can take into account that in the area of corners or junctions of the tape, reinforcement is performed - the installation step of the clamps is doubled. This is also taken into account by the calculation program.

The calculator will first calculate the approximate number of points to be connected with twisted wire. This, by the way, can also be useful in the case when ready-made wire loops packaged in reels or plastic tightening clamps are purchased to tie the frame together.

Based on the approximate length of a piece of wire per knot of 300 mm, a recalculation is carried out, which will give the minimum length of wire for tying the frame. And since it is often sold by weight, at the same time the result will be obtained in weight equivalent, and for different types of BP grade wire, with a diameter of 1.0 to 2.0 mm.

Wire prices

wire

If tying knots requires longer segments, then it is easy to increase the result proportionally - there will be no mistakes.

Let us emphasize one more point - this is a minimal amount of material obtained. Taking into account the fact that some nodes may break if tightened too tightly, and they will have to be redone, and the pieces of wire themselves can easily be dropped and lost in the turmoil of a construction site, it is advisable to also lay in a reserve, increasing the estimated amount by one and a half or even two times. Knitting wire is not an expensive material, and the remaining surplus can always be used during further construction.

How is the reinforcement of a strip foundation calculated?

the reinforcement of strip foundations , will help you correctly calculate the frame structure, with all the elements of its reinforcement . And another publication will take a closer look at the technology of knitting a reinforcing frame .

Basic information and brands of nichrome

Nichrome is an alloy of nickel and chromium with additions of manganese, silicon, iron, and aluminum. The parameters of this material depend on the specific ratio of substances in the alloy, but on average they lie within the limits:

- electrical resistivity - 1.05-1.4 Ohm*mm2/m (depending on the alloy grade);

- temperature coefficient of resistance - (0.1-0.25)·10−3 K−1;

- operating temperature - 1100 °C;

- melting point - 1400°C;

In tables, resistivity is often given in µOhm*m (or 10-6 Ohm*m) - the numerical values are the same, the difference is in dimension.

Currently, there are two most common brands of nichrome wire:

- Х20Н80. It consists of 74% nickel and 23% chromium, as well as 1% each of iron, silicon and manganese. Conductors of this brand can be used at temperatures up to 1250 ᵒС, melting point – 1400 ᵒС. It also has increased electrical resistance. The alloy is used for the manufacture of elements of heating devices. Specific resistance – 1.03-1.18 µOhm m;

- Х15Н60. Composition: 60% nickel, 25% iron, 15% chromium. Operating temperature no more than 1150 ᵒC. Melting point – 1390 ᵒС. Contains more iron, which increases the magnetic properties of the alloy and increases its anti-corrosion resistance.

You will learn more about the grades and properties of these alloys from GOST 10994-74, GOST 8803-89, GOST 12766.1-90 and others.

As already mentioned, nichrome wire is used everywhere where heating elements are needed. High resistivity and melting point make it possible to use nichrome as a base for various heating elements, from a kettle or hair dryer to a muffle furnace.