Which surface grinding machine is better to buy?

Grinding and fitting metal products manually requires a lot of labor. For more precise processing of parts of various sizes, surface grinding machines are used. The correct choice depends on a number of criteria.

One of them is the size and strength of the frame - this structural element must be massive and reliable. Effective vibration damping during operation is provided by cast iron frames.

It is worth paying attention to the work table and the type of workpiece fastening:

- For processing complex parts, magnetic fixation is the best choice.

- Budget models are equipped with tables with mechanical fastening elements. They may have a high level of reliability, but often only provide grinding on one side.

The accuracy of workpiece processing is influenced by the design of the table guides. There are hydraulic and mechanical methods of moving it. The first method is more effective. However, there is still a risk of the work surface jamming during operation.

To avoid this, the guides are regularly lubricated, so it is important to consider their accessibility for maintenance.

The productivity of the machine is largely determined by power. When planning to use it on an irregular basis or to work with small batches of workpieces, we recommend purchasing a model with a power of no more than 1000 W. Industrial enterprises install machines with motors over 1.5 kW.

It is important to determine the dimensions of the workpieces that will be processed on the machine. They affect a number of parameters of the worktable: dimensions, distance between it and the spindle, transverse and longitudinal stroke.

It is worth choosing a model whose working surface will noticeably exceed the size of the parts.

Recommendations: 12 Best Engravers

12 Best Sawing Machines

15 best angle grinders (angle grinders)

Operating principle and design features

Surface grinding machines offered by our company perform surface treatment with abrasive belts or discs. In the manufacture of consumable tools, artificial or natural abrasives are used in the form of electrocorundum, silicon carbide, or other materials fixed to the base using special glue or synthetic resin. The belts have different widths, grain sizes, and are available with a complete or partial application of abrasive material. Machines with a disk working body process the surface of both the peripheral and end parts of the circle.

The design of the unit includes a movable tabletop mounted on a durable welded steel base. Processing of the workpiece with a fixed magnetic plate or pressure pads is carried out by a drum with a fixed tape or a disk rotating in a vertical plane. The part is fed using stops and guide bars. When choosing a surface grinding device, the determining criteria are:

- accuracy class;

- power;

- performance;

- functional.

The operation of the machine involves automatic cleaning of wood dust and removal of waste using a special exhaust device installed directly in the work area and connected to dust extraction equipment or an aspiration system. Modern models are equipped with a centralized lubrication system and have separate motors for the operation of the working body, hood and table movement mechanisms.

The best surface grinding machines for a private workshop

Such models have low productivity and small dimensions. They are designed for processing small workpieces, are easy to maintain and have economical energy consumption.

Weiss Machinery MSG818A

4.9

★★★★★

editorial assessment

95%

buyers recommend this product

The features of the model include the ease of moving the workpiece along the working surface due to the presence of double V-shaped and ball guides.

The package includes a cooling system that allows the machine to function without stopping for a long time.

The maximum spindle speed is 2850 rpm, power is 1.5 kW. The manual oil pump ensures easy maintenance of the machine. Its use makes it possible to quickly lubricate moving and hard-to-reach elements, preventing their rapid wear.

Advantages:

- durability;

- high performance;

- halogen lamp;

- ease of maintenance;

- efficient cooling.

Flaws:

- complexity of installation.

Weiss Machinery MSG818A is designed for grinding metal surfaces of various parts. The maximum load on the table is 128 kg, which allows you to efficiently process large workpieces.

Proma PBP-170

4.9

★★★★★

editorial assessment

94%

buyers recommend this product

The ease of transportation of the machine is ensured by the presence of a ring for attaching a transport cable. Ergonomic handles help to securely hold the workpiece during operation. A special screen prevents small particles or sparks from entering the operator.

The grinding wheel speed is 2800 rpm, the work table size is 152x304 mm.

A special feature of the model is the ability to connect to a household electrical network, which allows you to install the equipment in a garage or use it in a private household. Fast rotation of the workpiece facilitates grinding and increases machine productivity.

Advantages:

- high speed of rotation of the circle;

- voltage - 230 V;

- reliable fixation of the part;

- small dimensions;

- operator safety.

Flaws:

- lack of autofeed function.

Proma PBP-170 will be an excellent purchase for sanding at home. It can be used during construction or renovation work.

READ ALSO

16 best electric planers

OSH-2030

4.8

★★★★★

editorial assessment

90%

buyers recommend this product

Convenience of processing parts at different angles is ensured by the presence of flywheels for adjusting the longitudinal, transverse and vertical position of the workpiece.

In addition, for continuous grinding, the operator has the ability to quickly move the table using a rack and pinion.

The power of the main drive is 1.1 kW, the dimensions of the working circle are 150x16x32 mm. Comfort of using the machine is guaranteed by the inclusion of a magnetic plate, a stationary lamp and a cabinet.

Advantages:

- high performance;

- adjusting the position of the part;

- ease of use;

- small dimensions;

- extended equipment.

Flaws:

- small table area.

OSH-2030 is used to perform grinding work on flat, cylindrical or inclined surfaces. It is worth purchasing for both single and small-scale production of products.

Machine repair and modernization

During operation and production of parts put into production, all mechanisms begin to wear out over time . Parts are replaced after the service life of each specific element has expired. This attitude towards equipment increases the accuracy of work and personnel safety. Machines are subject to major overhaul after twenty years of operation.

The manufacturer provides a service life warranty for each element of the machine, but depending on the workload of the equipment, replacement may be required earlier. Modernization of equipment makes it possible to increase the number of parts produced.

Best Industrial Surface Grinders

Models of this type are installed in specialized workshops and are characterized by high productivity. They are designed for long hours of work and have large dimensions for comfortable grinding of parts of various sizes.

JET JPSG-0618H

5

★★★★★

editorial assessment

100%

buyers recommend this product

Accurate processing of workpieces is ensured by the use of dual angular contact and single-row roller bearings, as well as a 1.5 kW motor.

The dual V-shaped and flat guides of the caliper and running surface are coated with anti-friction material and have automatic lubrication channels, which ensures wear resistance and ease of maintenance.

The diameter of the grinding wheel is 203 mm, the spindle speed is 2850 rpm. The increased size of the column and the cast iron frame guarantee high vibration resistance and stable operation under heavy loads. The lateral movement of the table automatically maintains precise feed pitch.

Advantages:

- automatic lubrication;

- electromagnetic table;

- robust design;

- high processing accuracy;

- long service life.

Flaws:

- high price.

JET JPSG-0618H is used for industrial processing of ferrous or non-ferrous metals, as well as polymer materials.

Visprom PBP-250

4.9

★★★★★

editorial assessment

94%

buyers recommend this product

Thanks to the presence of a special casing, most of the grinding disc is closed from external influences, which guarantees the safety of the operator during operation. The table position and spindle height are adjusted using flywheels - this allows you to achieve the most accurate positioning.

The size of the work table is 250x500 mm, the maximum load on it is 200 kg. The machine is equipped with a liquid cooling system that prevents overheating of the main elements.

A clamping plate with a permanent magnet makes it possible to secure the workpiece on one side for better grinding of surfaces.

Advantages:

- machine power 1500 W;

- high-precision processing;

- reliable fixation of the part;

- convenient setup.

Flaws:

- high energy consumption.

Visprom PBP-250 is recommended for purchase for working with complex structures at metalworking enterprises. A productive and economical solution for high-quality grinding on an industrial scale.

Grinding methods

Metal processing on surface grinding machines is carried out in two ways:

- the end of the circle;

- periphery.

In the first case, the high productivity of the surface grinding machine is noted. With this type of grinding, the arc of contact between the part and the apparatus is described by an insignificant value. As a result, a fairly high temperature is created in the grinding zone, which somehow reduces the accuracy of the operation (circular feed contributes to a significant decrease in accuracy). In addition, there are some difficulties with removing chips from the surface grinding machine.

Machining the workpiece with the end of the wheel

There are the following grinding techniques using a surface grinder.

Multi-pass processing

The element is fixed on the surface and moves at a speed of about 45 meters per minute. The product is repeatedly moved under the circle, which gradually moves deeper until the allowance is completely removed. The last moves take place without feed or with a small vertical feed.

Single pass circuit

This method is applicable for devices with round tables, when the surface grinding machine runs vertically to its full depth in one pass. Due to this, one revolution of the surface removes the entire allowance. If you need to remove a larger allowance with maximum grinding precision, it is better to take devices with three heads. They are suitable for use in large facilities where mass production is carried out.

Two-way method

The technique involves synchronous grinding of two ends of the part. It takes more than one pass to completely remove the allowance. With this method, the main feed occurs due to the circular or linear feed of the part, and cutting is carried out due to the rotation of the tool.

Regardless of which type of metal peripheral machining is chosen, it will differ from the previously described techniques in that it produces little heat and low cutting force. For this reason, products that are not too hard are processed with the periphery of the circle. It should be noted that the productivity of grinding with the end is always greater than with the periphery.

The following methods of grinding with the periphery of a wheel are distinguished.

Deep

With each stroke, a significant allowance is removed, and the longitudinal feed speed in this case is minimal. Due to the fact that the abrasives located at the end bear the brunt of removal, the circle wears out quite quickly.

With continuous feed

Grinding is carried out if the surface to be processed is limited by shoulders, and is also used to process elements whose height exceeds their width. There is no cross feed with this method, and the accuracy of the work is low. Wear occurs unevenly, so constant adjustment is required.

With transverse intermittent feed

With this technique, even large surfaces are processed efficiently. The height of the grinding tool must always be higher than the cross feed. Transverse reverse and feed of the circle deeper usually occur simultaneously. This technique is characterized by high precision; it is used on surface grinding machines with a round table and a horizontal spindle.

Benchtop Surface Grinder

How to make a grinding machine yourself

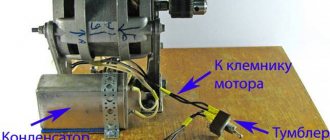

For home use, you can make the machine yourself if you have the available parts. The grinder is the most common model for home use. Its structure and assembly method are extremely simple. For assembly you will need the following parts:

- The frame is made of thick metal corners.

- Engine.

- Rollers in the amount of 4 pieces.

- Springs - 2 pieces.

- Sanding tape.

The inconvenience of using this device for permanent use is the constant stretching of the tape. To regulate the tension of the tape, install springs and use the handle to adjust their length. The handle also serves as a lifting bar for one roller.

Installing crossbars together with such a device allows you to replace the tape less frequently. If the rollers are made of titanium or durable steel, then they will not require replacement. The roller bushings are secured to the frame with strong bolts until they are stationary. The rotating part of the roller is made according to the bearing principle.

Such a machine in your home arsenal will allow you to process metal and wood products. When assembling the machine yourself, special attention should be paid to the engine power. The motor power from the washing machine is enough to process wood. This device can be used to sharpen and polish home tools. To process products that require high precision grinding, it is better to purchase a factory-made machine.