How to use a jack: general operating rules

Like any other technical device, the jack requires compliance with safety precautions during operation. Its use is not difficult, the main thing is to know where to put the jack and what to do with it next. This is far from a new device; most samples have been tested by time and personal experience.

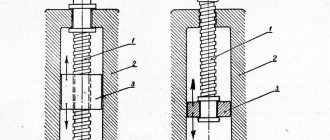

Classic rack and pinion jack

Driver's courses do not teach how to properly use and install this device. You need to study everything yourself. In addition, most people, not knowing clear rules, believe that with its help you can not only lift and lower a load, but also hold it for a long time. To avoid possible health risks, you need to learn how to install a jack correctly.

A specially developed list of rules can help with this:

- The vehicle must only be placed on a level surface. There should not be any slopes or other irregularities. The machine must be parked in such a way that there is no likelihood that it will move.

- All wheels must be locked very securely. Bricks, wooden wedges, stones or any other objects are suitable for this.

- The car should rise and fall very smoothly, without sudden movements or jerks.

- It is important to clearly know where to place the jack correctly. To lift the car on the bottom there are special mounts for the jack hook. Under no circumstances should you attach it to the front or rear bumper, or to any other parts of the car that are not intended for this purpose.

- It is necessary to engage reverse or forward gear, put the car on the handbrake and block the wheels on the opposite side from the side being lifted.

- It is necessary to use a support because the jack can only lift loads, but not hold them. A do-it-yourself jack stand is suitable, but it is important that it is made of wood, iron or any other material other than brick or other unreliable material.

- Before lowering yourself under the car, it is important to check the security of the machine and the device several times. To do this, you can simply rock the car in different directions.

- After completing the work, you need to know how to lower the jack along with the car. The same rules apply here - no sudden movements, smoothness.

Jacks exist in three types: mechanical, hydraulic and pneumatic (inflatable). Each of these types has its own specific operating rules.

Which jack is better? — ZR examination

You shouldn't go on long trips without a jack. Should you be content with a standard jack or choose a better one? We consider the advantages and disadvantages of the most common devices.

Pankrat sent a treatise from the tract to Kondrat: Pankrat couldn’t lift the tractor without Kondrat’s jack.

The best modern jack is a mobile phone: you call, complain about a flat tire, and you’re waiting for help. However, you shouldn’t rush to evict the good old jack from the trunk just yet. Even a European who had a punctured tire on Sunday on the way from Milan to Verona sometimes has to roll up his sleeves. But in Russia such an instrument cannot be superfluous by definition.

OUR ADVICE

How to select a jack height? After all, it may be needed when the tire is flat and the car sank “below the waterline.” The first step is to measure the distance from the ground to the threshold or the place where the jack should be located. When the tire is flat, it should be lower by the height of the tire profile. The upper height limit is determined by the vehicle type. For passenger cars, the downward travel of the suspension from the nominal position does not exceed 60–80 mm, while for SUVs it can be more than 150 mm.

Based on the type of drive, jacks are divided into manual (mechanical or hydraulic), electric and pneumatic (they are connected to the exhaust pipe). They can also be classified according to the design of the actuators: rhombic and rolling, bottle (screw and hydraulic) and rack and pinion, lever-screw and “cushion” type.

We have assessed the pros and cons of different types of inexpensive jacks - in our photo gallery they are arranged alphabetically.

approximate price

990 rub.

A diamond jack, much like the ones that come with many cars. The declared pick-up and lifting heights are 100 and 390 mm, respectively. We checked: it turned out to be 110 and 390 mm. It has a comfortable grip with a rubber element. The height lift capabilities are suitable for almost any passenger car, but they may not be enough for crossovers.

How to Use a Rack and Screw Jack

When using rack and screw jacks, the above rules and recommendations, plus some specific ones, apply.

Screw device

Rack and pinion devices, like screw devices, have become widespread due to their simplicity of design. They are mainly popular among off-road enthusiasts. The design of such devices allows you to lift a lot of weight, which plays a decisive role. They can be used in any conditions due to their unpretentiousness and small dimensions, which is an advantage compared to hydraulic lifts, which are massive and take up a lot of space in the trunk.

Safety precautions when working with rack and pinion devices:

- Install the lift at an angle so that it does not rest against the hood.

- Place the jack perpendicular to the surface of the support.

- Check fixation and tightness.

- Press the switch firmly with your whole hand, since it moves tightly.

Possible breakdowns and how to repair them yourself

Over time, any equipment begins to fail and require special maintenance. The first thing you need for a hydraulic jack is periodic inspection of the mechanism and topping up the oil. Also, after a certain interval it will be necessary to wash it and completely change the oil.

The most common cause of failure of such a device is failure of oil seals and gaskets. This leads to oil leakage from the working tank. The rod may also get stuck on the reverse stroke. It can be prevented if the problem is corrected the first time an oil leak is detected. To do this, you need to drain the oil, disassemble the mechanism and replace the seals with oil seals and refill with fresh oil. When everything is ready, liquid is pumped through the assembled device.

Sometimes the rod can simply jam due to accumulated dirt or corrosion, which is why disassembling and washing the device, as well as a special anti-corrosion treatment, helps.

Repair kit for jack

Other breakdowns occur if the device was operated incorrectly, then the following may occur:

- The piston moves jerkily or slowly. This indicates that air has entered the working compartment and you need to add oil and pump it.

- Reduced pressure on the piston. Most often, the problem lies in the intake valve, which may require repair or replacement.

- Stopping the lifting piston. This phenomenon with a rolling jack is associated with a clogged filter or the fact that the oil has run out.

- The piston stops rising completely. Often the problem is the lack of liquid in the reserve tank.

Most of the damage that occurs to the jack can be repaired after disassembly. However, if the problem arose due to mechanical damage to the piston or something happened to the outer casing, then replacing the device is recommended.

Important! If the jack breaks, you need to read the instructions, which must be included with each device. It contains a diagram, the necessary information about operation and maintenance periods. It is necessary to ensure that the device is not constantly in overload mode, that is, when selecting a jack for working with a machine, it is necessary to select one that has a load capacity of several tons.

If the jack is subjected to extreme loads and is not inspected from time to time for lack of oil, then a whole series of breakdowns will not be long in coming

It is necessary to ensure that the device is not constantly in overload mode, that is, when selecting a jack for working with a machine, it is necessary to select one that has a load capacity of several tons. If the jack is subjected to extreme loads and is not inspected from time to time for lack of oil, then a whole series of breakdowns will not be long in coming.

Advantages of rolling jacks for cars:

- Compared to other types of jacks, there are models with very high load capacities.

- As a rule, such devices are equipped with reliable fixation and there is no fear of failure.

- The design is very stable and comfortable.

- A person spends little effort.

However, it should be noted that such a device has two drawbacks: the need for a flat surface, which does not always happen when there is a breakdown on the road, and oil freezing when operating at low temperatures.

In all other respects, rolling jacks are very practical. They save the effort of drivers and craftsmen. In addition, a wide variety of models allows you to choose exactly the device that is most suitable for working with a particular car or for service in a service station.

How to use a hydraulic jack

Hydraulic devices have become widespread in auto repair shops. They can be rolled or bottled, have a lot of weight, but are easy to move. They can lift a car to a height of 40 centimeters. For the correct use of such devices, the following set of recommendations must also be observed:

- Before lifting it is necessary to check the fixation. The surface should be as level as possible and the wheels should be locked.

- When working with the front wheels, it is necessary to block the rear ones and vice versa. If you need to move the device to another location, you need to make sure that the strength is sufficient to hold the machine.

- Do not lift more weight than specified in the instructions.

- The hydraulic jack operates smoothly, but do not raise or lower the vehicle too quickly.

Hydraulic lift

Don't make dangerous mistakes!

Follow the rules, do not act at your own risk. Otherwise, you will have to resort to expensive repairs later. Under some types of jacks you need to put thick rubber as a gasket. Make sure that the area you are working on is level.

Don't forget, a jack is a tool that lifts a car, not keeps it raised. Don't make dangerous mistakes, otherwise the car may land on your foot.

Photos from Internet resources

How to use an inflatable jack

This type of lift is a pneumatic device. In this case, a special pillow is installed under the bottom of the machine, which is subsequently inflated with a special device. To work with such a device you need:

- Place the cushion under the car and spread it evenly.

- Place special mats on top and bottom that are included in the kit. They are designed to avoid pillow punctures.

- Close the lock connecting the valve and hose tightly. This is necessary to avoid air leakage from the pillow.

- Connect the end of the hose to a source of air or gas supply. Special compressors are used.

- The pillow is inflated with air or vehicle exhaust gases.

It is important to monitor the process of inflating the pillow. It should pass evenly in all directions. If any side lags, then it is necessary to check and correct the position of the pillow or lower it and start the process again.

How to make the right choice?

When choosing, you must take into account that rolling jacks come in different varieties and have different technical characteristics.

Types of rolling jacks

- Rolling hydraulic jack. The lifting mechanism in it is driven by the created oil pressure in the piston. It is used both for personal purposes and in car repair shops for lifting cars weighing up to 4 tons. A type of rolling hydraulic jack is a scissor jack: extended, double-plunger.

Hydraulic rolling jack MEGAPOWER M-83503. Load capacity 3.5 tons, lifting height 145-500 mm (price about 5 thousand rubles)

Hydraulic rolling jack device

The main difference between a rolling jack and the others is its horizontal location. Wheels mounted on the body make it easy to transport the device across the surface without lifting it. On one side there is a drive lever, on the other there is a lifting platform combined with a hydraulic cylinder. The pressure in the hydraulic cylinder is created by pumping up a pump located in the housing, which begins pumping up after pressing the drive lever. When the support platform is raised, its position changes and it approaches the lever.

REMAX rolling jack with raised platform. Load capacity 3 tons, pick-up height 133 mm, lifting height 465 mm (price about 5 thousand rubles)

To ensure reliable support when lifting, you need to roll the jack under the car at the same time as pumping it up.

Specifications and model overview

- Load capacity . A 2-ton rolling jack and a 3-ton rolling jack can respectively lift weights up to 2 and 3 tons, there are also 5-ton ones: common use is service stations, dealership car centers and car repair shops. The lifting capacity of pneumohydraulic models ranges from 5 tons to 10 tons, respectively. Used for maintenance and repair of buses, special equipment and trucks. Some models of pneumohydraulic jacks can lift loads of more than 20 tons, for example TORIN SJQ0100 - lifting capacity 22 tons.

- Pickup height . The smaller this parameter, the more universal the use of the jack. To service a sports car, a lifting height of no more than 65 mm is required. Sports cars have the lowest ground clearance (ground clearance), the Niva (VAZ-2121) has 220 mm, the Volkswagen Touareg II has 300 mm, and the Hummer H1 has 410 mm.

- Lifting height . To lift the car when removing wheels, a jack model with a lifting height of 300-350 mm is sufficient. To service and repair cars in auto repair shops, we need models of rolling jacks for cars with a lift height of more than 400 mm.

Jacks from brands such as MATRIX, WINNTEC and Ombra are popular among car enthusiasts who love reliability.

Comparative characteristics and prices of rolling jacks of the MATRIX, WINNTEC, Ombra brands

Characteristics of MATRIX jacks, brand - Germany, manufacturer China

Characteristics, additional devices

Characteristics of WINNTEC brand jacks, TURBO LIFTER system, manufacturer: Netherlands

Characteristics, additional Devices

Roll-away garage jack Ombra, brand Russia, manufacturer China/Taiwan

Characteristics, additional Devices

It is more convenient to use a jack with a rotary handle - we can recommend the MATRIX jack 510345 :

- Load capacity - 3 tons;

- Pickup height - 130 mm;

- Lifting height - 410 mm;

- The handle is rotary;

- Price from 3500-4000 rub.

It should be noted that jacks with a rotary handle are needed mainly for professional repairmen. In many cases, a rotary knob is not necessary.

Powerzone 380044 jack :

- Load capacity - 3 tons;

- Pickup height - 100 mm;

- Lifting height - 463 mm;

- The handle is fixed;

- Price from 5000-6000 rub.

Podkatroy three-ton jack Powerzone 380044

Important! A rolling hydraulic jack is designed to lift a load, but is not intended to hold it. When buying a jack, buy safety stands.

Set of safety stands “Zubr” 285-420 mm (price about 1200 rubles)

Also, do not forget that you will need wheel chocks (shoes), which are placed under the wheels of the car so that it does not fly off the jack or from the stands.

Factory-made wheel chocks (shoes)

How to properly jack a jeep

Have you ever had to change the spare tire on a jeep? Many will think that this is a rather stupid question, what could be so difficult about replacing a spare tire? Except, perhaps, the opportunity to get dirty from head to toe?

However, we didn’t just start covering this topic. There is a very significant nuance in this, to the naked eye, primitive matter, and not every young jeep driver knows it. Because the need for a spare tire in our city life arises very rarely. Jeeps have large wheels, deep tread, plus the prevalence of tire centers and the presence of compressors - and the chances of a city jeep driver to get a jack rapidly drop to almost zero.

But there are rare cases when you go out into nature and suddenly...

We focus our lives on the experience of past years. And for a young SUV driver, this is usually experience in using a passenger car or, in extreme cases, an SUV. A kind of sub-jeep.

And this very experience tells us what needs to be done. And you need to do a fairly simple thing - unscrew the nuts from a flat tire, jack up the vehicle, install a spare tire, lower the car and, desperately getting dirty, continue on your way.

Experienced comrades already know what we will talk about now and, I think, they cannot contain their smile.

Let’s follow our “passenger” algorithm carefully, as applied to a jeep.

How to use a hydraulic trolley jack

Before starting work:

- Screw in the bypass valve;

- Place the jack under the car so that the lifting platform fits under the desired lifting point;

- Press the lever until the platform is fully raised, using the full stroke of the lever to increase the lifting speed;

- Roll the jack under the car at the same time as lifting the plunger to create reliable support;

- Install a safety stand;

- Remove the jack.

Upon completion of work:

- Roll the jack under the installation site;

- Raise the hydraulic cylinder with the support platform;

- Remove the safety stand;

- Open the shut-off valve to lower the load.

Basic safety requirements when working with a jack

- The jack can only be placed on a flat, hard surface: concrete floor or hard asphalt. For tire fitting work outside the garage or workshop, you need a concrete area. Only in this case is there a guarantee that the jack will not move and the car will not fall off.

- The permissible lifting capacity of the jack must be observed and always compared with the weight of the vehicle. The 2 ton trolley jack can lift passenger cars, while the 5 ton lifting capacity can lift SUVs and minibuses. If the vehicle's weight is higher than the jack's lifting capacity, damage will occur not only to the jack, but also to the vehicle body.

- It is imperative to secure the wheels standing on the ground with locking shoes so that the body does not move.

- Do not carry out repairs or other maintenance work on the vehicle while it is standing on the jack support platform. After raising the car to a height, you need to support the car with safety stands and remove the rolling jack from under the car. The developed jack designs cannot serve as long-term support for the car.

The selection and operation of a rolling jack is described in the video clip.

This video will tell you how to jack up your car correctly and safely.

Before we begin with the advice from the foreign video, let’s remember what types of jacks exist in nature.

Screw jack

The classic model of jacks, widespread both here and abroad in the 70s and 80s. The screw jack is designed for lifting passenger cars weighing up to 1 ton. Although I remember that the 124 Mercedes of 1989 also had a native “Mercedes” jack of this type, despite the fact that the curb weight of the diesel car was 1.4 tons.

Lever and screw jack

Maximum load up to 800 kg.

Diamond jacks

A common type of car jacks, which, due to their ease of use, compact design when folded and high load capacity from 0.7 to 2 tons, can be called a universal type of car lift.

In addition to the main types of devices designed for lifting cars and SUVs, there are a number of devices with a similar operating principle: rack and pinion jacks, rack-and-screw devices, hydraulic, rolling and other types of devices.

The video uses two types of jacks as an example: diamond-shaped and rolling jacks.

1. What you MUST do before jacking up the car: choose a flat asphalt, concrete or any other area with a hard surface.

2. DO NOT jack up a loaded vehicle!

3. Put the car in gear (first or reverse) and apply the handbrake

4. Place wheel chocks under the wheels. Depending on which wheels will be lifted into the air, place “shoes” under those wheels that will remain on the ground, rear or front.

To install a diamond-shaped jack, determine the location of its installation on the car (highlighted by a special stamping), shown in the video at 1.45 minutes, front and rear. Pay attention to the stampings on the jack; they should coincide with the place marked on the threshold of the car when the jack comes into contact with the threshold.

We turn the handle. Once the desired car wheel is in the air, we replace it. You should not use a diamond jack to work under a car. It may not be safe. Just change the tire and put the car on the ground. As insurance, it is best to use a new or removed wheel; simply place it between the threshold of the car and the asphalt, even if the car falls off the jack, it will receive minimal damage.

Rolling jack (working with the front of the car). The video below explains where to place the rolling jack. Its installation locations may vary. Auto video recommends using towing eyes, the car's anti-roll bar or body power points to lift the front wheels (2.30 to 4.25 minutes of video).

At the same time, he warns that it is necessary to avoid contact of the jack with the engine crankcase, elements of the exhaust system and gearbox.

After lifting the car, to work under it, if you do not just want to change a wheel, you need to install stops. The stops are placed in the reinforced parts of the thresholds intended for this purpose, 1.45 minute video.

Let's jack up the rear of the car. Just like in the front, you can roll the jack under any reinforced parts of the body: suspension elements, towing eye.

The video also says that you should absolutely not lift the car by jacking it up through the suspension arms, non-reinforced body elements (an example is shown at 6.53 minutes), the muffler and the exhaust system as a whole, if you do not want to cause damage to your car.

Thus, this video explains the main points of installing two types of jacks on a passenger car.

Next, the author gives several important explanations when lifting a heavy frame SUV. Everything is simpler here. But do not forget about the four-point precautions that we described above in our material.

We avoid getting the jack on the fuel tank and elements like the transfer case. Good places to install a jack are shown in the following video fragments:

In the third example of installing a jack, the author advises placing the jack pad on the frame closer to the rear of the SUV, this way the car will be better secured, the video says.

The car was lifted through the rear axle - 9.03 minutes. Be careful! If the bridge is made of aluminum or other soft metals, this may cause damage to the vehicle's structural components!

The front of the SUV can be jacked up where the towing eye is attached. But the best place to install the jack is shown at 9.52 minutes of the video. The location where the lower arm is attached to the frame.

And one more important tip. If you doubt the correct installation of the jack, you can ask for help from more experienced garage colleagues who will demonstrate the operation of the jack in practice. If there are no competent car enthusiasts nearby and you can get to the nearest car service center, go there. They will definitely jack you up correctly there. REMEMBER THAT IMPROPER INSTALLATION OF THE JACK CAN NOT ONLY CAUSE PROPERTY DAMAGE, BUT ALSO CAUSE SERIOUS HARM TO HEALTH IF THE CAR SLIDES OFF THE JACK!

Advantages of rolling jacks

Large working stroke limits - the design of rolling jacks combines a low level of pick-up with a high lifting height. With a mechanical jack it is impossible to achieve such parameters. Rolling hydraulic jacks allow you to service vehicles with a ground clearance of 65 mm (sports cars) and raise the body to a height of up to 500 mm, which is absolutely optimal for servicing.

Mobility of movement - with a jack weighing up to several tens of kilograms (some models weigh more than 100 kg), it is easy to move it around the work area by grasping the long lever.

High productivity - lifting a load with a jack with a hydraulic drive or a pneumatic-hydraulic drive requires less effort than with a mechanical jack of the same lifting capacity. The ascent itself takes much less time. The lowering of the load occurs with the opening of the exhaust valve: the car smoothly lowers as the oil pressure in the hydraulic cylinder drops. Reducing time losses is the main advantage of rolling jacks. When working in auto repair shops, this is an important indicator of work performance, increasing the number of cars serviced.

Maintenance of rolling hydraulic jacks

Proper use and proper care will extend the trouble-free operation of the jack - the lifting device should not fail at the most important moment.

If the stroke of the rod is not smooth, the car does not rise smoothly, jerkily, the lifting speed is reduced, you need to make a lot of effort when you press the lever - these signs indicate that urgent measures are needed and prevention alone will not do.

In order not to take forced urgent measures, you need to constantly maintain the jack. Caring for a load-lifting device is not complicated and does not require much time, so that not only the service life is increased, but also the safety guarantee.

Adding oil is the main condition for trouble-free operation of the device. Oil leaks out in small quantities through the seals during operation. To add oil, place the jack on a flat surface, lower the lifting mechanism and unscrew the cap in the oil filler hole. After this, add the required amount of oil. When the mechanism is used intensively, dirty oil must be changed periodically. When adding and replacing, you need to use only high-quality oils:

- industrial oil – I-20;

- hydraulic – Total LHM+;

- for automatic transmissions;

- for shock absorber struts – MGP-10.

Important! When carrying out work, do not mix different mixtures and allow foreign liquid to enter the hydraulic cylinder!

Removing excess air from the hydraulic cylinder is a condition for high performance of the jack. Air bubbles in the hydraulic cylinder are formed at the slightest oil leakage through the seals or due to untimely topping up. To release air, unscrew the cap on the oil filler hole and, with the bypass valve open, quickly press the lever. Air is forced out of the oil when pumped by the built-in pump.

Regular lubrication of rubbing metal parts is the main condition for reducing jack wear.

Constant monitoring of oil leaks, inspection of wheels, checking the reliability of their fastening is the key to trouble-free operation of the jack.

Store the jack in a dry place : corrosion due to contact with moisture is the enemy of the metal parts of the jack.

The need to lift loads to a small height without moving them has always arisen. Previously, several people with different devices were involved for these purposes. But with the invention of the jack, lifting became possible for one person. Hydraulic jacks are widely used. They are used both at home and in production. They differ in load capacity, design, lifting height and dimensions. The principle of operation is the same for everyone.

The main purpose of a hydraulic jack is:

- lifting a load;

- fixation at a given height;

- movement.

Recommendations for use

After finishing use, the jack must be freed from loads. The device should be stored in a warm and dry place. Due to excess moisture, the mechanism may rust, and cold will negatively affect the quality of the oil. It is recommended not to work with a jack in severe frost.

Loads on the device should not exceed those for which it is designed.

With constant use, pumping (oil change) should be carried out every 2-3 months. For rare use - once every six months.

Thus, in the event of a hydraulic jack failure, it is necessary to check 3 components:

- Quality and quantity of liquid.

- Presence of air bubbles in the system.

- Contamination, loose valve fit.

In most situations, to solve all problems with the device, it is enough to clean it and change the oil.

Man has invented many devices for lifting weights. To briefly describe the principle of their operation - the transformation of the distance traveled into effort.

Let's look at examples of such transformations:

- Lever arm. On the long side, the distance traveled is greater and the effort is less. On the short side it's the opposite;

- Block system. The cable, passing through a certain number of blocks, loses distance with each loop, proportionally acquiring additional traction force;

- Gears with different gear ratios. The small gear rotates quickly and with less force. Big – on the contrary;

- Chain (belt) pair. A smaller diameter pulley rotates effortlessly and faster. A larger diameter pulley develops high torque on the shaft at a lower rotation speed;

- Communicating vessels. Two piston pairs connected to each other operate on the principle of a lever. A piston of a smaller diameter moves with a small force with a large swing. While its larger “brother” moves a short distance with proportionally increased effort.

A hydraulic jack operates on the principle of communicating vessels.

Relatively compact dimensions (compared to the force that the tool can develop) make it indispensable when working with large weights. Portable bottle jacks (this is their second name) develop a force from 1 to 20 tons. Larger specimens can weigh up to 200 tons.

At the same time, hydraulics are among the safest devices for lifting heavy objects.

Principle of operation

The operating principle of hydraulic jacks is based on two physical laws. The first law is the flow of liquid in communicating vessels . The second law is an increase in power due to a change in the area of the applied force . This method is used in presses. This device is called a multiplier.

With the help of a multiplier, the fluid pressure created by the pump increases several times. This is enough to lift a load that weighs no more than a ton. The applied load is several kilograms .

Pumping of the working fluid is carried out by a hand pump . The plunger is moved by a lever. The check valve, made of a screw, prevents the reverse movement of liquid. When turned counterclockwise, it stops working.

Design Features

Each subtype of hydraulic jacks has its own design features, and even devices of the same category may have some differences. The only and unchanged element of all such devices is the rod lifting mechanism itself. To a person with minimal knowledge of mechanics who does not understand the terminology, the device may seem complicated, but in fact, its principle is quite simple. To understand how a hydraulic jack works, it is enough to know what parts it consists of and how they interact with each other.

1.Lever arm

.

Plays a major role in pumping liquid inside the device, from one reservoir to another. 2. Plunger

.

Moves with the handle. When moving up, it picks up liquid from one reservoir, and when lowering, it pushes it into another, creating pressure under the rod. 3. Piston

.

The base of the rod, tightly adjacent to the walls of the cylinder. It rises due to the liquid entering underneath it, causing an increase in pressure in the tank. 4. Stock

.

It goes along with the piston and is the final element of the entire structure, resting against the required load. 5, 6. Check valves

.

Allow liquid to move in only one direction, from one reservoir to another, without flowing back. For example, valve 5 opens when suction (vacuum) is created in the compartment with the piston, and closes when pressure is generated. The 6th valve acts in reverse, closing when liquid is sucked in, and opening when feeding. 7. Bypass valve

. An important design element necessary to normalize pressure by opening the valve between two tanks. Lowers the rod if there is a load on the latter.

Perhaps the most basic hydraulic jack is the bottle jack, since it does not use any additional elements that are lifted by a rod and rest against a load. Next in simplicity comes the rolling one, where the rod is already connected to the load-bearing platform. The most unique in terms of implementation include rhombic ones, which lift a load using 4 interconnected levers.

Classification of hydraulic lifts

There are many types of lifts on the modern market, but the following stand out among them:

Bottle Type Hydraulic Jack

It has the simplest design and is widely used. They can lift loads from 2 tons to 100 tons. Car enthusiasts usually purchase models with a carrying capacity of 5 tons. Bottle models are available in a vertical design.

They are equipped with a support platform with a large area and have a compact appearance. To increase the lifting height, the structure is made of two rods. The two-rod jack has two modifications.

In the first case, the second rod has a threaded connection, due to which it is unscrewed. After this, the first one is raised hydraulically. In the second case, the rod is telescopic. The second element begins to move after the first one finishes moving.

Rolling jacks

This is a bottle model that is positioned horizontally and placed on a wheeled cart. A wheeled trolley is placed under the object. The lever pumps up the pressure, the rod comes out and activates the pick-up with the lifting lever. Lowering is accomplished by unscrewing the check valve. The only difference is that it is not the screw that needs to be turned, but the lever that was used to lift it. Rolling jacks can be found in every tire shop.

Hitch jacks

They are used in places where the location of a stationary model is impossible. They can hook and lift a load if there is a distance of 15 mm underneath it. Hook models also have step adjustment.

Diamond jacks

They are named so because of their lifting structure. Four frame elements connected by hinges form a diamond shape. Such models, only screw ones, were used by car enthusiasts in the USSR. Lifting is carried out by changing the angles between the frame elements.

Hybrid models

They combine parts of rolling and bottle jacks in their design. Structurally, they are made on two levels. They are used by car repair shops because cars from different manufacturers come for service. Hybrids have two lifting platforms.

The first rises above the floor to a height of 375 mm, and the second to 690 mm. A lever or foot pedal is used as a drive. To facilitate operation, hybrid models are equipped with an electromechanical drive.

Features of using a diamond jack

This is a type of screw jack, but due to a fundamentally different structural design, it can be placed in a separate category. If the simplest screw models use an elementary cylindrical base with a thread along which the rod rises and falls, then rhombic models are formed by four rigid ribs secured by a hinge system. Their connection in the center is ensured by clamps, due to which the angle between the lower and upper ribs changes and the mechanism is lifted. The force is transmitted from the hook. This is a metal rod that is usually supplied in the kit. How to use a jack with a hook? Typically, the corners of the clamps are provided with lugs or rings connected to a screw mechanism. The owner only needs to thread the hook into the hole and make circular turns, while simultaneously lifting the upper segments of the device.

Jack device

The supporting structure of a hydraulic jack is the body. It is made of cast iron or durable steel. It is affected by the weight of the load being lifted, and in addition, the body is a reservoir for oil and a guide for the rod.

The filled oil is the working fluid. It presses on the piston, causing it to rise. The initial force is created by a plunger, manual pump. The plunger is activated by a lever. The valve is designed in such a way that it holds the piston and rod in the operating position.

This design is used in all hydraulic jacks. Therefore, the design diagram of a bottle-type hydraulic jack can be found in any textbook or manual related to hydraulics and hydraulic drive.

Jack Maintenance Tips

The instrument requires regular cleaning to remove dirt. Sand with solid particles is especially dangerous for rack and pinion mechanisms. The rubbing elements are periodically lubricated with machine oil, which restores the smoothness and ease of movement of functional organs. If you are planning a long trip, then you should check the design in advance for the integrity of the body, the quality of bolted connections and the operation of movable parts. Hydraulic models also need to be checked for leaks to ensure that the working fluid remains at the proper level.

Advantages and disadvantages

Among the advantages , it should be noted that the hydraulic drive, due to the incompressibility of the working medium, achieves greater power. The efficiency reaches 80%. Thanks to the liquid working medium, lifting and lowering occurs smoothly.

The disadvantages include the fact that the design has large overall height dimensions. Therefore, unlike mechanical models, the distance to the lifted load is greater. The liquid medium does not allow you to accurately set the lowering height.

If stored horizontally, the oil inside may leak out through the seals. And to put it into working condition, you need to fill in a new portion of oil and pump it to remove air.

Hydraulic devices break down quite often, and their repair is an expensive part of the cost. Therefore, constant maintenance is recommended for them.