Brand Resanta over the years has become famous and recognizable in the field electrical equipment on the Russian market. Resanta — trademark the largest Latvian manufacturer of electrical equipment SIA "RESANTA".

The RESANTA company began its activities with the production of the first stabilizers in 1993 in Riga. In the period 1993-2008. The volume of RESANTA products increased 10 times, which were sold not only in the CIS countries, but also in non-CIS countries. This made it possible to expand production areas, as well as improve the quality of manufactured electrical equipment.

Today, the range of the Resanta brand is dynamically expanding, new models are being developed, the quality is being improved and the functionality of the equipment is improving. Resanta product line includes the following categories:

- Surge Protectors;

- welders;

- thermal equipment;

- uninterruptible power supply devices;

- multimeters;

- compressors;

- testers;

- other electrical equipment .

At the moment, there are more than 40 Resanta service centers throughout Russia, which offer customers high-quality electrical equipment.

Resanta voltage stabilizers find their application in residential buildings and various institutions where there are problems with microvoltage, for example, constant power surges in the network.

Resanta products are certified, which confirms their high quality. All electrical equipment is provided with warranty service.

The products have repeatedly received the highest ratings at various international exhibitions. For example, the Resanta enterprise won an award for the voltage stabilizer ASN-500/1-C at the 18th international exhibition of electrical equipment "Electro - 2009".

Information about the Resanta brand is taken from open sources.

Source: www.elec.ru

All the pros and cons of the Resanta brand inverter

The Resanta inverter, like a number of similar equipment, produces high current, which is a decisive factor in comparison with the classic AC transformer used for welding before the advent of more advanced equipment. In order to be able to take advantage of the benefits of welding connections of elements in a domestic environment, it is necessary to have a device such as a Resanta inverter or another analogue, since the standard parameters of the electrical network (voltage 220 V and frequency 50 Hz) are not enough to implement such tasks.

Application area

In fact, the Resanta inverter is one of the modern versions of welding machines. Until the user became acquainted with such units, transformers and rectifiers for welding were in use. In comparison with them, an inverter for a home is much lighter, and therefore easier to operate. Under these conditions, equipment productivity increases significantly.

All these factors make it possible to use units such as the Resanta inverter for both domestic and industrial purposes. At home, it is necessary to convert the standard network parameters to provide a sharp jump for electric welding. Having an inverter available, you can do this without difficulty, taking into account the convenience of the design and the availability of elements for transportation.

Detailed information about the manufacturer

During its existence, this brand has significantly strengthened its position in the Russian market. Today it is one of the largest manufacturers of various types of electrical equipment. Among the product range there is a Resanta inverter. The high degree of popularity of the proposed technology is due to the attractive ratio of high quality and reasonable cost in current conditions.

But the company does not stop there, but constantly improves the equipment it produces. Among others, in addition to products such as the Resanta brand inverter, a number of the following devices are offered:

- Compact Series;

- Prof series products;

- Devices operating at reduced voltage values;

- Semi-automatic inverter;

- Units with argon arc welding function;

- Protective equipment for work, in particular, masks for electric welding.

As you can see, the company strives to cover almost all areas where the use of such equipment is allowed. An inverter manufactured by Resanta may differ from similar models with other design features from the range not only in appearance, but also in the range of permissible voltage values.

Design features and model range

Inverters are presented in a wide range. Each model differs from the other primarily in the value of the maximum operating current. There are separate lines of such equipment: SAI, SAI COMPACT, SAI PROF, SAI PN. A lightweight inverter of the Resanta brand can be selected from the Compact series. At the same time, the main parameters practically do not differ from those in analogues of standard AIS devices; the only difference is more compact dimensions and less weight.

Watch the video and product review:

The SAI series inverter from Resant is equipped with a number of additional and extremely important functions for operation. The design provides protection against overheating, the so-called “anti-sticking”, “hot start” and “arc force”. The inverter of the PROF line from Resant differs from other devices in the ability to set the required value of the welding current using a digital panel. Another difference is a wider operating voltage range (up to 260 V).

The Resanta welding inverter can be used with different values of electrical parameters. The designation of each model indicates the maximum permissible operating current. Also, in the technical characteristics of such a device as a Resanta brand welder, there is a limitation on the level of current consumption. Additionally, the degree of protection of the device, the diameter of the electrode, the welding arc voltage and no-load voltage are indicated.

The welding inverter from the manufacturer Resanta is also characterized by such a parameter as the duration of the load, which allows you to estimate the duration of operation of the device at maximum load values.

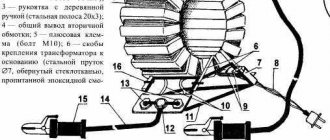

The operation of this equipment is based on the principle of converting alternating mains voltage of a standard frequency value into a direct voltage of 400 V, after which the Resanta inverter welding machine converts this value into high-frequency alternating voltage.

Pros and cons of the device

If we compare Resanta brand equipment with analogues that were used before the advent of a fundamentally new type of equipment, we can highlight a number of positive qualities:

- Compact dimensions, and even the most productive Resanta inverter electric welding machine will have several times less weight and overall body dimensions;

- Easy control - due to the fact that the design provides a digital panel, thanks to which the inverter electric welding machine from the manufacturer Resanta can be controlled as simply as possible;

- Overheat protection prevents equipment failure;

- The high level of performance that distinguishes the Resanta brand inverter electric welding machine determines the rapid performance of the work, while the efficiency of the equipment can reach 95%;

- Lightness allows the unit to be transported to the required distances, thanks to which the SAI welder becomes a mobile device.

Among the positive qualities that are determined by the design features of such equipment, one can highlight the security of the units. This means that the Resanta SAI welding inverter and analogs from other lines of this manufacturer are made in a completely closed housing, which significantly reduces the likelihood of a large amount of contaminants getting inside the mechanism. Some models of equipment such as the Resanta SAI welding inverter are equipped with a special case where the device is placed. This simplifies the task of transporting it to the welding site.

Let's watch the video, the advantages and disadvantages of welders:

However, the Resanta SAI welding inverter also has its drawbacks, for example, the relatively high price of the units themselves, as well as their maintenance. Thus, these models of maximum performance (with an operating current above 300 A) will cost approximately 35,000 rubles.

Customer ratings

As for the working side of the issue, the electric welding inverter from the manufacturer Resanta of the SAI line is in good standing with users. Electrical equipment of this brand has been offered on the Russian market for more than three years. And during this time, there have been practically no complaints about the quality of operation of such equipment as the electric welding inverter of the Resanta company, model SAI; on the contrary, with unstable voltage and surges in electrical networks, it is quite possible to use electrodes with a diameter of 3 mm.

However, there are some nuances that become clear during operation. The point is that the welding electric inverter of the Resanta brand of the SAI series is almost never serviced under warranty, since it is extremely difficult to find a service center. And at the end of the allotted service life, the cost of repairs, if necessary, is quite high.

Thus, the welding electric inverter of the Resanta company of the SAI line has all the qualities to carry out the relevant work. The wide range of products of this brand allows you to select the most suitable device in terms of compliance of the electrical parameters with the assigned tasks.

How to choose a model

Not everyone knows which Resanta welding machine is best for the home. If we calculate the time of direct welding from the total time the equipment is turned on, then this figure will be 70%, which is quite good for such units.

For home use, experts advise choosing a model from the SAI series, as well as SAI PN. According to the data specified in the device’s passport, the welder can operate at a voltage of 154-242 V. However, in fact, already at a value of 190, the Resanta welding machine exhibits some inconsistencies - for example, the electrode begins to stick. But there is a way out - just take smaller electrodes.

Power surges are often observed in rural areas. Then experts recommend paying attention to the AIS PN series. For such devices, 140 V will be sufficient.

What is the best portable welding machine for 220? If you need to choose small-sized equipment, you should prefer the “Compact” series, which is one and a half times lighter than similar units with standard parameters.

So, we have decided on the category, now we need to select the appropriate model. You should immediately pay attention to the welding current indicator, which can be easily determined by its name. Next to the abbreviation SAI there will be an index. For example, the Resanta SAI-160 welding machine can operate at a maximum current value of 160 A.

The power of the unit depends entirely on the intended type of work. You should pay attention to the thickness of the metal and the diameter of the electrodes. For example, the Resanta 160 welding machine requires only electrodes of a certain diameter. You can, of course, purchase a model with a power reserve, but this will cost more, which is not always appropriate.

In any case, before purchasing, you should pay attention to such parameters as the type of welding, network type, maximum power and current, as well as additional functions.

Reviews and price of the welding machine Resanta SAI 190

The manufacturer of the Resanta SAI 190 welding machine is Latvia, although on different websites you can find both Russia and China in the “Country of Manufacturer” column. The Resanta brand appeared back in 1993, and since then it has expanded its area of activity not only in the nearest countries, but also abroad.

Having started with voltage stabilizers, Resanta now produces various electrical equipment: uninterruptible power supply devices, compressors, heating equipment, etc. Reviews of the Resanta welding machine model SAI 190 on the network are mostly positive . Both the price and quality of the device are satisfactory. But, before we start analyzing reviews about this device, let’s get acquainted with its technical characteristics.

History of the company

is the only representative of arc welding machines in its price class. Of course, such equipment has analogues, but they are usually an order of magnitude more expensive, which is not acceptable for everyone. Unfortunately, domestic consumers are accustomed to thinking that low cost is an indicator of poor quality of the instrument. However, in this case this is not at all the case.

The company entered the construction equipment market in 1993. All production facilities were initially concentrated in Riga - at that time the company produced voltage stabilizers. However, with the rapid growth in demand, the company began to expand not only the range of its products, but also the geography of supplies.

The company appeared on the Russian market only in 2003 and immediately established itself as a consumer-oriented and responsible supplier. Welding machines and other equipment of this brand meet modern quality standards. Developers do not stand still, but are constantly working to introduce new technologies. This is the only way a company can be competitive.

The entire production process is accompanied by multi-level quality control. Consumers especially note the uninterrupted feedback from the support team. In addition, a whole network of representative offices has been opened in our country that provide repairs and maintenance of equipment.

As for the Resanta inverter welding machine, the voltage conversion in it occurs in two time periods. In the first, alternating current turns into direct current, and in the second, alternating current appears again, but the frequency increases. Welding in MMA mode requires electrodes with a special coating. It is very difficult to figure out which Resanta welding machine is best for the home, because all models are compact, so they can be easily moved and used to carry out any type of welding work.

All devices produced by the company are intended for manual arc welding using a coated stick electrode. It is worth noting that the equipment is fully adapted to the climatic conditions in which Russians live. It can function smoothly at temperatures from minus 10 to plus 40 degrees. Welders have an electrical protection class of IP21, so they can work in rooms that are not heated. However, they should be used under a canopy, since they are not protected from water, although they prevent the formation of condensation.

Next we will look at this equipment in more detail, and also find out which Resanta welding machine is best for the home.

To ensure that it lasts as long as possible and does not damage other electrical devices in the house, you should study the electromagnetic compatibility card, which can be found on page 3 of the inverter passport.

What is this welding machine?

Main technical characteristics

- Dimensions of the device are 310x180x130 mm, weight - 4.7 kg.

- Welding type – manual arc (MMA).

- The device can produce direct welding current ranging from 10 to 190 A.

- There is one power phase, and the input voltage is from 140 to 260 V.

- The maximum applicable electrode diameter is up to 5 mm.

- The device can operate in a temperature range from -10°C to +40°C.

The power cable is 1.5 m, and the length of the cable on which the electrode holder is located is 2 m. Regarding this point, small dissatisfaction often arises among reviews. Users would recommend lengthening them.

I bought it back in 2013. True, he started working for him only seven months later. Since then I have only been happy. I myself am a blacksmith of artistic forging, I have to do a lot of forging and cooking. This machine cooks everything from thin leaves to centimeter-long channels. The arc catches just perfectly . The ignition is fine. I'm glad there is an anti-stick function - it helps at the right time. The voltage regulator is very sensitive but precise.

The only thing is that the wires are a bit short - only 1 meter. But they are thick and can withstand -35. The body, although metal, weighs quite a bit. Over the entire period of operation, this welding has never failed. It cooks effortlessly and very predictably. Just take note that inverter welders are very afraid of dust from grinders. When working with an angle grinder, it is better to protect the welder by covering it with something. In my case, I used an old thick work jacket. The price at the time of purchase was 5.2 thousand rubles. I cooked for up to six hours a day, everything was fine with refrigeration. A very decent device.

Additional features and features

The case is equipped with a bright indication of power and overheating. The protection system consists of three functions:

- automatic shutdown;

- overheat protection;

- forced air cooling system.

“Anti stik” also takes place here - the anti-stick function, which was already mentioned earlier. The degree of protection of the device is IP21. Possibility of hot start and arc forcing.

The advantages of the Resanta Sai 190 model in the reviews included the build quality. Varnished boards, no non-separable power modules, and no SMD surface mounting. It was also considered an indisputable advantage that the transformer is attached to the board using screws.

Power cables are admired by many due to their heat resistance: in frosty weather they do not harden, and if they come into contact with a hot surface, they are not particularly deformed.

Main technical characteristics

The company’s wide range of equipment suggests significant differences between different models, but it is worth highlighting the key parameters that apply to all Rosanta welding machines.

For all units, a common characteristic is the input voltage. For example, the SAI series is designed to operate in a fairly large range - from 140 to 240 volts. Models of the PROF series are capable of operating even at 100 volts.

The electrodes have a thickness of 1-6 millimeters, which allows you to work with metal of different thicknesses. For low-power, simplest devices, the electrode diameter does not exceed 4 mm, and for equipment with a three-phase connection and a powerful two-phase connection, this figure can reach 6 mm. Also, the speed and quality of work with thick and refractory products is affected by the welding current.

Reviews about quality

For the most part, the Resanta Sai 190 welding machine is stable in almost all respects. It is lightweight, mobile, understandable and easy for beginners to use.

I've never done welding before. I bought Resanta Sai 190 and mastered it instantly. Liked. Very light, both in weight and in handling. I digested everything I could at my summer cottage, including things I didn’t even intend to. I didn't have any problems during the work. It welds from thin metal (I haven’t tried less than one millimeter) to thick metals one centimeter - the basis for a ladder of such thickness, it was welded with a bang. Never overheated, never bothered me in any way. I recommend .

Professionals also leave positive reviews. What is most pleasing is that the Resanta Sai 190 series PN works perfectly at low voltage. This is good for rural areas, as well as for home work - in a garage or shed, for example.

I bought this device for my father-in-law in the village, since they have low voltage in the area. I have two welder friends who specifically bought this model. Based on their recommendation, I already took it, and as a result I am very pleased. My father-in-law is far from a pro in welding, but he got along with this machine right away. I have my own foxweld 160, and it doesn’t cook, it doesn’t have enough voltage. And this one cooks, that’s how. And it cooks so well, evenly, beautifully, pleasantly. I can’t say anything about quality yet, time will tell.

Model categories

Equipment for welding work is divided into groups. The number of modifications of units is so large that they are divided into special categories. Each of them contains models with the same basic technical parameters.

1. Characteristics of the welding machine "Resanta" SAI PA. The main indicator of such devices is that they all operate in semi-automatic mode. That is, they have a mechanism for pulling the wire and a control valve that changes the gas flow rate. Management occurs from one panel.

2. SAI PO inverters are the first welders that the company began to produce. They operate in MMA mode using piece electrodes.

3. AIS PN models operate at reduced voltage. Such devices are called simplified because they were designed for domestic use, and they are relatively cheap. The minimum power threshold is 140 V.

4. SAI AD units are designed for argon arc welding.

5. SAI PROF welding machines are already professional because they allow you to adjust the welding arc. The equipment is adapted to reduced voltage and is used in overloaded networks.

5. SAI K equipment are compact welders with a high degree of mobility. They are suitable for working at heights and in confined spaces.

The cost of the welding machine Resanta sai 190

Among the latest reviews, the disadvantages include the price, although this had not been noticed before. Of course, in 2013 the cost of the device was around five thousand rubles , and now on various sites there are price tags with double the amount.

For example, the “220 Volt” website offers the Resanta SAI 190 device (with the indicated manufacturer Latvia) at a price of 8,310 rubles. It is noteworthy that the length of the electrode cable is specified as 2 meters, and the cable with the grounding terminal is 1.5 m.

On other sites you can find a lower price, about 8100 rubles, but in this case take into account the costs of delivery and the level of trust in the online store. You may not be able to save money.

But the same Resanta Sai 190, only with the prefix “PN” on the Yulmart website, has three-meter cables with electrodes, and a power cable 1.9 m long . But for some reason China is indicated as the country of origin, and the price is already 11,490 rubles. Most likely, it is in China that assembly takes place using technologies from Latvia, from the brand itself. This happens all the time now, although often the word “Chinese” is associated with not very good quality. To the surprise of many, this is not the case. And the assembly of Resanta SAI 190 can serve as proof of this.

Most reviews are positive. But there are also negative comments. For example, user “Andrey Shirokov” indicated that the fan freezes in the cold. And that's it, no clarifications. It is likely that the frost was -30 °C, when the device expects a range of -10 °C to +40 °C. The problem, most likely, is not in the device itself, but in improper operation and inattentive study of the instructions, which, by the way, are included as standard. Therefore, before you write a review yourself, or read ready-made ones from other users, make sure that it is correct by clarifying all the points.

Source: stanok.guru

Rules for choosing Resanta welding machines

If you are choosing a welding machine to carry out work at home or in the country, then it is better to pay attention to the Resanta SAI model or its modification, specially designed for operation at low voltage (SAI PN). Although the manufacturer indicates that the equipment can operate with deviations of the standard supply voltage from –30% (154 V) to +10% (242 V), such inverters operate effectively provided that the voltage does not fall below 190 V. If Since the voltage in the electrical network will be even lower, welding can only be performed with small-diameter electrodes.

Welding inverter Resanta SAI-190PN for operation from reduced mains voltage

It is no secret that the voltage in our electrical networks (especially in rural areas) rarely corresponds to the standard value of 220 V. There are situations when the network does not produce even 190 V voltage. If you live in an area where voltage drops in the network are a common occurrence, it is better to purchase an inverter specially designed for such cases - AIS PN. The technical capabilities of the Resanta devices of this series allow them to work effectively even with voltage drops to 140–160 V.

If the important parameters of a welding inverter for you are its dimensions and weight, then you should pay attention to the devices of the “Compact” series. Inverters of this series are distinguished by their reduced dimensions, and their weight is 1–1.5 kg less than that of equipment from other model lines.

Comparison of Resanta welding inverters by size and weight

Resanta inverters belonging to other categories are more suitable for semi-professional and professional use. They are distinguished not only by increased power, but also by expanded functionality, which is often not in demand by home craftsmen. There is no point in purchasing such devices for your workshop, since you will have to pay for unnecessary functionality.

A specific inverter model, if the category of this equipment has already been determined, is selected depending on how much welding current you need to perform the work. It is quite easy to determine what maximum current a particular device can generate: the value of this parameter is indicated in the designation of each model.

The main differences between the SAI-PN and SAI-PROF lines from other models

You should choose a device based on the maximum welding current depending on the thickness of the part you are going to weld and what diameter of the electrodes will be used for this. Thus, for working with electrodes with a diameter of 4 mm, Resanta inverters are suitable, which are capable of generating a welding current of at least 190 A. Naturally, to work on such devices, you can use any electrodes of a smaller diameter.

Electrodes with a diameter of 3 mm can be used for welding using those inverters that generate a welding current of 140 A. More powerful (and, accordingly, more expensive) devices that are capable of delivering a welding current of 220 and 250 A are used to work with electrodes with a diameter of 5 and 6 mm. When making a choice, always answer the question whether you will need such a powerful device at the moment or in the future.

Summary table of technical characteristics of Resanta welding inverters

Classification by place of application

offers equipment for both amateurs and professionals:

1. Household welders, as a rule, are used in the garage or at the dacha - that is, to perform a small amount of work. Below we will look at which portable welding machine is best. 220 volts is the voltage of a regular outlet, so household units can be used even in confined spaces. This type of equipment is great for beginners who are just learning to weld. The current range varies from 120 to 200 amperes. Some devices have smooth arc adjustment.

2. Professional equipment produces better quality seams. Such devices are suitable for housing and communal services employees and small car repair shops. With the help of these welders you can work even in harsh conditions, and they can function continuously for much longer than household appliances. Welding current ranges from 200 to 300 amperes.

3. Industrial welding machines are used for welding large structures, which can be made of different materials. The seam here is as precise as possible, and the power of the Resanta welding machine is 250-500 amperes. It is allowed to use welding wire with a diameter of 0.5-0.8 millimeters on a reel.

It is worth noting that it also develops and produces stabilizers that can ensure stable operation of the unit, as well as measuring equipment and thermal equipment.

In 2014 and 2015, it was recognized as the best domestic manufacturer of stabilization and welding equipment.

How is power supplied to the equipment?

One of the reasons for the high popularity of Resanta brand inverters as equipment for the home workshop is that they successfully operate from a conventional electrical network with a voltage of 220 V. Some models, which is especially convenient for performing work in places where there is no centralized power supply, can operate from autonomous sources of electric current - gasoline or diesel generators.

It is very important that the electrical outlet to which the Resanta inverters are connected is grounded, since they comply with protection class IP 21.

So that when the inverter is operating, the machine installed in the electrical panel does not turn off the power supply, it must withstand a current of at least 16 A (when welding at a current of 190 A).

To connect the welding inverter, you need to make a dedicated power line

Features of operation of Resanta inverters

Before connecting the inverter to the electrical network, it is necessary to connect the power cable and ground cable to its connectors, and also check that its switch is in the off state. Before pressing the power button, it is necessary to set the minimum value of the welding current on the equipment.

The power switch for Resanta inverters is located on the rear panel

The electrical cable that connects the inverter to the power supply must be completely unwinded from the reel so that it does not create an inductor that could negatively affect the welding process. In addition, in order for the Resanta brand inverter to serve you for a long time and allow you to effectively perform welding operations, you must adhere to a number of recommendations.

- It is not recommended to work in the immediate vicinity of the inverter with an angle grinder or other tools, which are a source of metal dust that can damage welding equipment.

- There should be enough free space around the inverter, and its body should not be covered with cloth or other objects. This rule must be followed in order to ensure effective ventilation of the equipment.

- Inverters react very critically to high humidity, so they can be used and stored in dry rooms. It is also necessary to protect them from direct exposure to precipitation.

- If you brought the device into a warm room from the cold, you can start using it only after the condensation on the internal elements has completely dried (about 2 hours).

- The inside of the inverter should be regularly cleaned of accumulated dust, this will extend its life and minimize the risk of sudden failure.

Operation and repair

The inverter often fails for the following reasons:

- moisture getting inside the housing;

- accumulation of dust inside the unit, which prevents it from cooling in a timely manner;

- failure to comply with the operating mode specified in the instructions.

To identify faults, the housing is removed and the electronic components are checked. If there are cracks, dark spots, carbon deposits and swollen capacitors, these elements need to be replaced. If everything is visually in order, but the device does not work, it is recommended to look for the problem using measuring instruments, periodically checking the electrical circuit.

If it is not possible to repair the device yourself, you should contact the service specialists.

The best Resanta welding machines for domestic needs

To weld a canopy on a gate, repair a gate, or create a greenhouse in the yard, you need a simple welding machine, which every owner can afford to buy. The equipment must have sufficient power reserve and the ability to be used from a household outlet. The devices below have these properties.

Resanta SAI 160 - for all beginners

This is an inverter model, where the transformer and rectifying unit take up very little space. Thanks to this, the device has dimensions of 34x14x26 cm, but is capable of cooking with direct current.

The device has reliable sockets for connecting cables that do not become loose over time due to frequent use. The maximum current reaches 160 A, which is suitable for a metal thickness of 4-5 mm, while the power does not exceed 4.9 kW.

Pros:

- an intuitive current adjustment scale that tells you the correct electrode diameter as the ampere increases;

- productivity at a current of 160 A is 70%;

- power of 4.9 kW does not overload the household network;

- able to cook normally when the current drops to 140 V;

- weight is only 3.8 kg (convenient to carry around the yard, you can hang it on your shoulder and work at height);

- the current strength is reduced to 10 A, so thin metal is welded without installing additional resistance;

- The set includes a power plug, cable, and belt;

- the electrode ignites quickly thanks to the 80 V idle speed;

- functions that make it easier for beginners (anti-stick).

Minuses:

- wide ventilation openings pull a lot of dust inside;

- mass cable is only 1.5 m;

- no case;

- does not support operation with electrodes with a diameter of 5 mm;

- The current regulator protrudes outward, making it easy to knock down the indicator with an accidental touch;

- clothespin mass made of thin iron (weak);

- fan made of flimsy plastic.

Resanta SAI 190K - for any work in the yard

This budget model features a more thoughtful build with secure control buttons recessed on the front panel. Two indicators inform you that the device is connected to the network and that there is overheating.

The device has a maximum power rating of 190 A and a power of up to 7.15 kW. Able to work 4-6 hours every day with short breaks. The weight of 4.3 kg allows welding to be carried out by hanging it on the shoulder.

Pros:

- the arc ignites without long scratches on the surface;

- stable operation at low current, when other devices cannot cook;

- there is no spontaneous arc extinction;

- cooks even with an electrode with a diameter of 5 mm;

- no deviations in operation at low temperatures (-10 degrees);

- more beautiful streamlined design than its analogues;

- enabling automatic increase in current when stuck;

- tolerates voltage drops well;

- supports longer cables with a cross-section of 50 mm2.

Minuses:

- short cables included lead to frequent overturning of the device when welding large products;

- a short network cable requires an extension cord;

- metal plates in the holder are made of low-quality alloy, so they can become deformed over time;

- there is no afterburner adjustment (the amount of current increase cannot be set, the value is provided by default by the manufacturer).

Which is the best welding machine to choose?

The choice of a suitable device depends on the purpose of use, parameters and technical nuances. If the important point is the weight, as well as the dimensions of the device, you should choose a compact model (SAI K). The weight and size of such devices are significantly smaller than other samples. For domestic use (garage, cottage), an inverter-type device (AI) is suitable.

When the network voltage is low, which occurs in rural areas, it is better to choose a device under the abbreviation “SAI PN”. Such equipment is capable of fully operating in the range from 140 to 160 volts. The remaining categories of equipment belong to the semi-professional and professional types. Such devices have increased power and additional options.

The best Resanta welding machines for professional activities

To carry out welding work every day, professional models are needed that can withstand prolonged loads and have a sufficient set of functions. Here are the most popular devices of this class.

Resanta SAI 190 PN - for containers and frames

This productive model is well suited for installation activities and the creation of metal structures. The device operates in a temperature range from -10 to +40 degrees.

IGBT transistors produce a stable voltage that does not “sag” even when the mains power drops to 140 V. In addition to the current strength, the value of V can be adjusted on the front panel, which makes it possible to control the seam leg. All controls are protected by a transparent cover.

Pros:

- the current strength of 190 A allows you to work freely with a 5 mm electrode, which is optimal for powerful metal structures;

- digital display helps you set the most accurate settings;

- The device has a well-thought-out four-way ventilation system for improved cooling;

- In addition to belt clips, there is a rigid handle for short, on-site transfer;

- rotating carabiners for shoulder carrying included;

- the welder himself chooses the degree of fusion of the filler metal;

- PV 70% is optimal for most installation work, where welding and preparation for joining alternate;

- acceptable weight 6.4 kg;

- the degree of arc forcing is adjusted (you can set how many specific amperes to supply when sticking);

- A 16 A automatic machine can handle operation from a socket;

- reducing the current to 10 A for the purpose of welding thin containers.

Minuses:

- weak fastening on the pliers (you may have to twist it yourself);

- it takes time to get used to the sensitive current regulator;

- the terminal block fixing nuts are unscrewed from vibration;

- The welding cable is not copper, but copper-plated (with aluminum cores inside).

Resanta SAI 250 PN - for construction

This is a more “advanced” model of the “PN” series with adjustable arc afterburner. The current reaches 250 A, which makes it possible to cook with 6 mm electrodes.

This allows you to assemble large metal structures from channels, angles and thick reinforcement (connections of frames of poured supports in monolithic buildings). The power of the device is 7.7 kW, and the dimensions are 42x16x30 cm.

Pros:

- withstands temperatures down to -25 degrees;

- melts metal 10-12 mm thick;

- overheating protection is triggered very rarely, which indicates good cooling;

- works consistently for 8-10 hours every day;

- instant excitation of the welding arc from touch;

- capable of cutting metal at a maximum current of 6 mm thickness;

- soft arc burning.

Minuses:

- a weight of 7.23 kg requires placing the device on the floor and only short-term work with the shoulder mount, which is not very practical at height;

- for construction use, you will have to purchase an additional ground cable and holder, since the existing one is 2 m long;

- cost about 12,000 rubles;

- large dimensions, inconvenient for limited space;

- high power requires carrying with a thick wire section;

- The holder cables and ground may periodically fall out of their sockets during active rotation.

Resanta SAI 315 - for a full-fledged welding shop

This device is powered by a three-phase network and produces a constant voltage with a maximum current of 315 A. The power of the model reaches 16.5 kW. It is well suited for everyday production of metal structures (containers, frames, agricultural products, frames). Cooks with electrodes from 3 to 6 mm.

Pros:

- thanks to the no-load voltage of 85 V, it instantly ignites the arc;

- melts metal 20 mm thick;

- wide adjustment along the seam leg;

- rigid handle for transportation;

- large display with clear numbers;

- eight-lane perforation for ventilation;

- quiet operation, despite high power;

- high-quality case with no plastic elements.

Minuses:

- there is a large load on the network, so the connection must be made only to wiring with a large cross-section;

- needs a stabilizer (if line sags are frequent), since it is sensitive to voltage drops of more than 10%;

- the large body is inconvenient for transportation;