- - classification, GOST of ropes and cables,

- - metal ropes and cables of different diameters,

- — prices and characteristics.

Steel rope GOST 2688 80 Steel rope GOST 7668 80 Steel rope GOST 7669 80 Steel rope GOST 3077-80 Steel rope din 3055 Steel rope din 3060 Steel rope din 3066

PA KANPRO LLC offers to buy galvanized steel rope by choosing a product that suits its characteristics. Sales are carried out in wholesale quantities, the price of the products is objective and quite loyal. Delivery costs are calculated separately.

Prices and characteristics of steel rope

Steel cargo rope

| ø, mm | GOST / Lubrication | Weight 1000m, kg | Price m, ₽ (per drum) | Price m, ₽ (unwinding) | |

| 4,1 | Steel rope 2688-80/A1 | 64 | 31.10 | 35,77 | Buy |

| 5,1 | Steel rope 2688-80/A1 | 96 | 35,36 | 38,19 | Buy |

| 6,2 | Steel rope 2688-80/A1 | 142 | 43,83 | 47,34 | Buy |

| 7,6 | Steel rope 2688-80/A1 | 211 | 54,80 | 59,18 | Buy |

| 8,3 | Steel rope 2688-80/A1 | 256 | 62,55 | 70,68 | Buy |

| 9,1 | Steel rope 2688-80/A1 | 305 | 70,30 | 75,92 | Buy |

| 9,6 | Steel rope 2688-80/A1 | 359 | 75,62 | 81,67 | Buy |

| 11 | Steel rope 2688-80/A1 | 462 | 92,63 | 100,04 | Buy |

| 12 | Steel rope 2688-80/A1 | 527 | 104,78 | 113,16 | Buy |

| 13 | Steel rope 2688-80/A1 | 597 | 113,70 | 122,80 | Buy |

| 14 | Steel rope 2688-80/A1 | 728 | 134,41 | 145,16 | Buy |

| 15 | Steel rope 2688-80/A1 | 844 | 150,08 | 162,09 | Buy |

| 15 | Steel rope 2688-80/A2 | 844 | 150,08 | 162,09 | Buy |

| 16,5 | Steel rope 2688-80/A2 | 1025 | 177,51 | 191,71 | Buy |

| 16,5 | Steel rope 7668-80/A1 | 1045 | 193,52 | 209,00 | Buy |

| 18 | Steel rope 7668-80/A1 | 1245 | 227,11 | 245,28 | Buy |

| 19,5 | Steel rope 2688-80/A1 | 1405 | 237,84 | 256,87 | Buy |

| 20 | Steel rope 7668-80/A1 | 1520 | 266,62 | 287,95 | Buy |

| 20 | Steel rope 7668-80/A2 | 1520 | 266,62 | 287,95 | Buy |

| 22 | Steel rope 7668-80/A1 | 1830 | 301,59 | 325,72 | Buy |

| 23,5 | Steel rope 7668-80/A1 | 2130 | 349,33 | 377,28 | Buy |

| 24 | Steel rope 2688-80/A2 | 2130 | 345,21 | 372,83 | Buy |

| 25 | Steel rope 3079-80/A1 | 2245 | 391,69 | 423,03 | Buy |

| 27 | Steel rope 3079-80/A1 | 2650 | 460,04 | 496,84 | Buy |

| 30,5 | Steel rope 3079-80/A1 | 3405 | 584,14 | 630,87 | Buy |

| 33 | Steel rope 3079-80/A1 | 3920 | 666,00 | 719,28 | Buy |

| 35 | Steel rope 3079-81/A1 | 4435 | 747,23 | 807,01 | Buy |

| 39 | Steel rope 3079-82/A1 | 5395 | 906,18 | 978,67 | Buy |

Galvanized steel rope

| Length | Price m, ₽ | ||||

| from 1 meter | To order | Buy | |||

- Types of steel ropes (cables)

- STEEL ROPES GOST 3063-80

- STEEL ROPES GOST 3077-80

- Aviation steel ropes GOST 2172-80

- STEEL ROPES GOST 3079-80

- Steel ropes GOST 14954-80

- Steel ropes GOST 3062-80

- Steel ropes GOST 3071-88

- Steel ropes DIN 3061

- Steel ropes DIN 3062

- Steel ropes DIN 3071

Steel rope GOST 7668-80 (6x36+OS), double lay, type LK-RO with organic core

| Rope diameter | Weight of lubricated rope | Marking groups, N/mm2 (kgf/mm2) | Price including VAT rub. / meter | ||

| 1770 (180) | |||||

| mm | kg. / 1000m | Breaking force of the rope as a whole, kN, not less | Breaking force of the rope as a whole, KG, not less | Black in grease | |

| steel rope 11.5 | 513 | 75,1 | 7663 | 195,16 | |

| steel cable 13.5 | 696 | 101 | 10306 | 230,30 | |

| steel rope 15 | 812 | 116 | 11837 | 247,62 | |

| steel cable 16.5 | 1 045 | 150 | 15306 | 296,01 | |

| steel rope 18 | 1 245 | 175 | 17857 | 347,42 | |

| steel cable 20 | 1 520 | 215 | 21939 | 407,84 | |

| steel rope 22 | 1 830 | 258 | 26327 | 461,34 | |

| steel cable 23.5 | 2 130 | 304 | 31020 | 534,36 | |

| steel rope 27 | 2 800 | 396 | 40408 | 687,58 | |

| steel cable 31 | 3 655 | 517 | 52755 | 882,57 | |

| steel rope 33 | 4 155 | 588 | 60000 | 1002,26 | |

| steel cable 36.5 | 4 965 | 703 | 71735 | 1188,03 | |

| Check the availability of our products with managers, contact numbers: (495) 221-76-96, (495) 255-24-68 | |||||

Types of steel ropes (cables)

Although steel wire is used as the basis for the production of ropes, its characteristics vary. Various laying options can also be used. All this leads to a variety of cable designs.

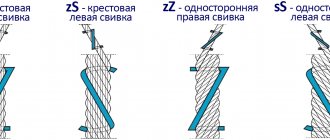

Depending on the laying method, they are:

- single;

- double;

- triple;

- stitched.

Based on the characteristics of the strand profile, ropes with flat, triangular and straight oval strands are distinguished. In the direction of weaving, products can be straight or reverse. Another classification is based on the material of the core. It can be steel, synthetic, natural hemp or jute.

Recommendations for the use of various rope designs

Each rope design has advantages and disadvantages that must be properly taken into account when selecting ropes for specific operating conditions. When choosing, you should maintain the necessary relationships between the diameters of the winding elements and the diameters of the ropes and their outer wires, as well as the necessary safety margin to ensure trouble-free operation.

Single lay ropes made of round wires - ordinary spiral ones (GOST 3062-80; 3063-80; 3064-80) have increased rigidity, so they are recommended for use where tensile loads on the rope predominate (lightning protection cables of high-voltage power lines, fences, guy wires and etc.)

Double lay ropes with linear touching of the wires in the strands, while being easy to manufacture, have relatively high performance and have a sufficient number of different designs. The latter allows you to select ropes for work under large end loads, with significant abrasive wear, in various aggressive environments, with the minimum permissible ratios of the diameter of the winding element and rope diameter.

Ropes of the LK-R type (GOST 2688-80, 14954-80) should be used when, during operation, the ropes are exposed to aggressive environments, intense alternating bending and work in the open air. The great structural strength of these ropes allows them to be used in many very stressful operating conditions of crane mechanisms.

LK-O type ropes (GOST 3077-80, 3081-80; 3066-80; 3069-80; 3083-80) work stably under conditions of severe abrasion due to the presence of increased diameter wires in the upper layer. These ropes are widely used, but their normal operation requires a slightly increased diameter of blocks and drums.

Ropes of type LK-Z (GOST 7665-80, 7667-80) are used when flexibility is required, provided that the rope is not exposed to an aggressive environment. It is not recommended to use these ropes in aggressive environments due to the thin filling wires in the strands, which are easily corroded.

Ropes of the LK-RO type (GOST 7668-80, 7669-80, 16853-80) are distinguished by a relatively large number of wires in the strands and therefore have increased flexibility. The presence of relatively thick wires in the outer layer of these ropes allows them to be successfully used in conditions of abrasive wear and aggressive environments. Due to this combination of properties, the LK-RO type construction rope is universal.

Double lay ropes with point-linear contact of wires in strands of type TLK - O (GOST 3079-80) should be used when the use of ropes with linear contact of wires in strands is impossible due to violation of the minimum permissible installation ratios between the diameters of the winding organs and the diameters of the wires of the rope or if it is impossible to ensure the recommended safety factor.

Double lay ropes with point contact of wires in TK type strands (GOST 3067-88; 3068-88; 3070-88; 3071-88) are not recommended for critical and intensively operating installations. These ropes can only be used for non-stressful operating conditions, where alternating bends and pulsating loads are insignificant or absent (slings, bracing ropes, temporary timber fastenings, support and brake ropes, etc.)

Multi-strand double lay ropes (GOST 3088-80; 7681-80) , depending on the accepted directions of laying of the strands in individual layers, are made ordinary and non-twisting. The latter ensure reliable and stable operation on mechanisms with free suspension of the load, and the large supporting surface and lower specific pressures on the external wires make it possible to achieve a relatively high performance of the rope. The disadvantages of multi-strand ropes are the complexity of manufacturing (especially pre-deformation), the tendency to delamination, and the difficulty of monitoring the condition of the internal layers of the strands.

Triple lay ropes (GOST 3089-80) are used when the main operational requirements are maximum flexibility and elasticity of the rope, and its strength and supporting surface are not of decisive importance. Organic cores in strands are appropriate when the rope is intended for towing and mooring, where increased elastic properties of the rope are required. Due to the use of wires of small diameters compared to the wires of double lay ropes, triple lay ropes require pulleys of significantly smaller diameters for normal operation.

Triangular strand ropes (GOST 3085-80) are characterized by increased structural stability, a very high fill factor and a large supporting surface. The use of these ropes is especially suitable for high end loads and severe abrasive wear. It is recommended to use these ropes both in installations with friction pulleys and in multi-layer winding on drums. The disadvantages of triangular strand ropes are sharp bends of the wires on the edges of the strands, increased rigidity of the rope, and the complexity of manufacturing the strands.

Flat ropes (GOST 3091-80; 3092-80) are used as balancing ropes in mine hoisting installations. The advantages of these ropes include their non-twisting properties. However, the manual operations involved in sewing ropes and the relatively rapid destruction of the collar during operation limit the extent to which these ropes can be used in industry.

Steel rope

Steel rope or cable has a wide range of applications. Products are an important element:

- many lifting systems and equipment;

- tower, gantry and truck cranes;

- winches, hoists;

- pipe-laying, shaft and elevator installations;

- hoists, mounting and traction mechanisms.

Our association also sells steel cables with various characteristics of breaking force and flexibility. To give the products the required properties, high-quality carbon steel is used; upon agreement with the client, the cargo rope is coated with a layer of zinc in accordance with the requirements of class “C” and “F”.

Characteristics of manufactured ropes

| Coating | Galvanizing group | Purpose | Register | Conversion factor |

| Without cover | — | Cargo | No case | 1,000 |

| Without cover | — | Cargo | Maritime Register | 1,050 |

| Without cover | — | Cargo-human | No case | 1,150 |

| Without cover | — | Cargo-human | Maritime Register | 1,219 |

| Hot galvanizing | AND | Cargo | No case | 1,000 |

| Hot galvanizing | AND | Cargo | Maritime Register | 1,050 |

| Hot galvanizing | AND | Cargo-human | No case | 1,150 |

| Hot galvanizing | AND | Cargo-human | Maritime Register | 1,219 |

| Hot galvanizing | coolant | Cargo | No case | 1,200 |

| Hot galvanizing | coolant | Cargo | Maritime Register | 1,260 |

| Hot galvanizing | coolant | Cargo-human | No case | 1,380 |

| Hot galvanizing | coolant | Cargo-human | Maritime Register | 1,449 |

| Hot galvanizing | WITH | Cargo | No case | 0,926 |

| Hot galvanizing | WITH | Cargo | Maritime Register | 0,972 |

| Hot galvanizing | WITH | Cargo-human | No case | 1,065 |

| Hot galvanizing | WITH | Cargo-human | Maritime Register | 1,129 |

One of the most important and complex wire products is steel ropes. Steel cables come in various designs and types and differ from each other in the cross-sectional shape of both the rope elements and the rope itself as a whole, as well as in the physical and mechanical characteristics of the cores and wires.

invites you to buy steel rope in Moscow from the manufacturer, offering the most reasonable prices for products and favorable delivery conditions throughout the country.

Load rope - prices and characteristics

A steel cargo rope is based on a core, around which a rope strand consisting of wire of different sections is wound. Elements made of hemp, metal or inorganic compounds can be used as a core. This information is placed in the product passport and is reflected in the markings, which are applied directly to the cable tag. To protect the cargo rope from moisture and other unfavorable factors, even during production, the products are coated with a thin layer of zinc and a special lubricant.

At the final stage, the product is wound onto a drum or folded into a coil. You can buy steel cable from us with a winding length of 500 or 1000 m. At the client’s request, it is possible to cut products to the required length with an accuracy of one meter.

Products are shipped from a warehouse where the availability of the most popular product options (diameter from 4.1 to 39 mm) is constantly maintained. Prices for cargo ropes are based on the diameter of the products. The cross-sectional circumference can range from 4.1 to 39 mm. We recommend checking current prices for cargo ropes with managers; they will also advise on all issues of ordering and delivery, and calculate the cost and timing of transportation.

Galvanized steel rope (cable), DIN 3055 (6×7+FC), DIN 3060 (6×19+FC), DIN 3066 (6×37+FC)

Diameter designation:

the first number is the diameter of the cable, the second number includes the braid

Rope construction:

the first number is the number of strands of the cable, the second is the number of wires in the strand

Core:

organic

Rope material:

steel

Coating:

galvanized

This rope is recommended for use in various fields. Steel cable is used mainly for guy wires, suspensions, and fences. They have different flexibility and elasticity.

| Rope diameter, mm | Structure / Lay of rope | Rope breaking force, kN, not less | Manufactured to standard | meters in bay | Approximate weight, kg/100m | Price including VAT rub./meter |

| Steel rope 2 | 6×7+FC | 1,95 | DIN 3055 | 200 | 1,4 | On request |

| Steel cable 2.5 | 6×7+FC | 3,2 | DIN 3055 | 200 | 2,5 | On request |

| Steel rope 3 | 6×7+FC | 4,39 | DIN 3055 | 200 | 3,2 | On request |

| Steel cable 4 | 6×7+FC | 7,8 | DIN 3055 | 200 | 5,6 | On request |

| Steel rope 5 | 6×7+FC | 12,2 | DIN 3055 | 100 | 8,8 | On request |

| Steel cable 6 | 6×7+FC | 17,5 | DIN 3055 | 100 | 12,6 | On request |

| Steel rope 8 | 6×19+FC | 31,2 | DIN 3060 | 100 | 22,1 | On request |

| Steel cable 10 | 6×19+FC | 48,8 | DIN 3060 | 100 | 34,6 | On request |

| Steel rope 12 | 6×19+FC | 65 | DIN 3060 | 100 | 49,8 | On request |

| Steel cable 14 | 6×37+FC | 85 | Din 3066 | 100 | 67,8 | On request |

| Steel rope 16 | 6×37+FC | 117 | Din 3066 | 100 | 88,6 | On request |

| Check the availability of our products with managers, contact numbers: (495) 221-76-96, (495) 255-24-68 | ||||||

Characteristics of cable DIN 3055

The description of metal cable DIN 3055 is highlighted additionally, since it is the most popular: price and quality contribute to high sales.

| Wire diameter, mm | 1 | 1,5 | 2 | 2,5 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 |

| Working load, kN | 0,20 | 0,34 | 0,47 | 0,74 | 1,05 | 1,88 | 2,94 | 4,20 | 7,50 | 11,75 | 16,90 | 22,00 | 30,00 |

| Breaking load, kN | 0,80 | 1,20 | 2,25 | 3,40 | 4,98 | 8,87 | 13,80 | 19,90 | 35,40 | 55,40 | 79,80 | 108,00 | 135,00 |

Advantages of metal cable

Metal cable is very popular in the construction industry because it has a number of advantages over other fastenings, namely:

- very durable;

- does not stretch or stretch when attached to a building structure;

- easy to use;

- its price is quite low;

- the service life of the cable is very long, so it is possible to sell it even used;

- very convenient to use where there is a possibility of high temperature changes, since it is not sensitive to their effects and does not lend itself to deformation at high or, conversely, low temperatures;

- is not in danger when winding along the ground;

- The weave of the torso wires is so strong that it never breaks during use.

You can buy metal cable in any quantity on the website. Our products comply with all GOSTs, DINs and have quality certificates, so we guarantee that you will purchase the strongest and most reliable cable for construction work, which will serve you for a very long time.