A hydraulic jack allows car owners to quickly and safely change a damaged wheel on their car.

To do this, every car must have a jack, since the need to replace a wheel can arise at any time and anywhere on the road. Hydraulic jacks vary in load capacity, weight, dimensions, design, pick-up height and lifting height. In this article we will consider in detail the structure, operating principle, and technical characteristics of hydraulic jacks. Here are the most popular models by load capacity.

Purpose of a hydraulic jack

The main purpose of a jack is to lift and secure a heavy load to a small height. A hydraulic jack uses an incompressible fluid that is forced into a hydraulic cylinder using a hydraulic pump. Oil is most often used as a working fluid. This design of the hydraulic jack allows it to work with very heavy loads.

Hydraulic jacks are not intended for moving loads or holding loads suspended for long periods of time. To do this, after lifting the load to the required height, it is necessary to install additional supports on which the load will be supported. Without such supports, you cannot work under a load to avoid injury.

Classification of jacks

- Mechanical - work from the application of human force (rotating a handle or pressing a lever).

- Hydraulic - work due to a hydraulic mechanism.

- Pneumatic - allow you to lift a load by filling a special cushion with air. Industrial models are equipped with a compressor, domestic ones are connected to the exhaust pipe and filled with vehicle exhaust gases.

- Electrohydraulic - connected to the electrical network, which drives the hydraulic pump.

- Electro-pneumatic - they are connected to electricity, for example to a car cigarette lighter, due to which air is pumped into the pillow.

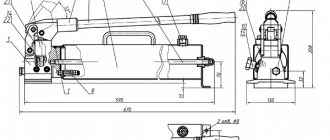

Hydraulic jack device

The hydraulic jack consists of the following elements:

- Frame . The body is made of hardened steel and can be short or long. The housing contains a cylinder with a piston.

- The base of the body is the base on which the jack rests during operation.

- The catch is the uppermost part of the piston, which rests on the load being lifted. It is made of high-strength steel and has a corrugated surface to prevent the load from sliding. It is often equipped with a height-adjustable nozzle, which allows you to place a mechanical initial emphasis on the load without affecting the hydraulics.

- Pressure gauge . Allows you to monitor developing pressure.

- Reserve container in which the working fluid is located. Using a lever system, liquid is forced from the reserve tank into the discharge cylinder, and then into the main one.

- Working fluid . Most often, special hydraulic oils are used as the working fluid in hydraulic cylinders. It is not recommended to fill the hydraulic cylinders with water or brake fluid, as they will cause corrosion of the internal metal elements, which will lead to rapid failure of the jack.

- Oil filter . Needed to clean oil from contamination.

- Main cylinder with plunger. The rise of the plunger is due to the flow of working fluid into the cylinder, the lowering of the plunger occurs when the fluid flows into the reserve tank.

- Discharge cylinder with plunger . Pumps oil into the main working cylinder.

- Inflation valve. Allows fluid to flow from the discharge cylinder into the main cylinder and blocks its reverse movement. That is, it is responsible for the movement of the working fluid in only one direction, preventing its return.

- Pressure relief valve (bypass valve) . After reaching the desired height, the jack must be returned to its original state. To do this, there is a valve that allows the oil to return to the reserve tank and relieve pressure. This valve is needed to drain excess fluid and prevent the jack from being overloaded.

DIY hydraulic jack repair

Hydraulic jack repair begins with removing the lift piston and inspecting it for corrosion and deformation. If these defects are found, it is recommended to replace the piston with a new one.

Then it is washed from dirt and the bypass valve through which oil is pumped under the piston is checked. If traces of deformation or any other flaws are found on it, the valve is simply replaced with a new one from the repair kit.

The valve installed in the seat does not allow fluid to pass from under the piston back into the jack's reserve tank and must be thoroughly cleaned of dirt, and also tightly close the valve hole.

After inspection and cleaning, all parts are washed in kerosene, and those that are faulty are replaced with new ones and installed in their places. And also all sealing gaskets and cuffs are changed. After the lift is fully assembled, fresh oil is poured into it.

Bleeding the system from air

During long-term operation of the jack, air bubbles gradually accumulate in its working fluid, which reduce the piston exit speed.

To do this, you need to open the valve that allows the working fluid to pass from the working compartment of the jack into the reserve tank.

Then, removing the cap from the tank, quickly pump the oil several times. After several pumpings, the air from the working compartment will be completely removed and the tool will work again in its normal mode. If pumping is not successful, the oil should be pumped again.

Filling oil

It consists of two actions - washing and pouring itself. After the old fluid is drained, flushing fluid is poured in instead. It can be freely purchased at a hardware store.

After this, you should pump the jack at least 3-4 times, then, after adding fluid, pump it a couple more times. The flushing liquid is drained in the same way as used oil.

When filling, the piston must be completely lowered into the hydraulic jack body. Oil is poured to the very top of the oil tank hole. Then, after closing the tank lid, you should pump the mechanism about 5 times, while the oil level in the tank will decrease, so after each pumping it needs to be topped up.

After the liquid level stops decreasing after pumping, open the bypass valve and pump the jack a couple more times until the filled oil is free of air bubbles.

Characteristics of hydraulic jack

Material

Hydraulic jacks designed for light weight are usually made of aluminum. More serious models, capable of lifting extra-heavy loads, are made of hardened steel or cast iron. The greater the load capacity the jack is designed for, the thicker the metal used in its manufacture.

Dimensions, weight and lifting capacity of hydraulic jack

All three of these indicators are directly related to each other. Jacks with high lifting capacity are large in size. And accordingly, a large unit has a lot of weight.

Small hydraulic jacks used for passenger cars are small in size, light in weight and have low lifting capacity. Bottle jacks with a lifting capacity of 2 tons have a height of 15-18 cm and a weight of 2-3 kg.

Serious jacks used for trucks, in construction and industry, have a large load capacity - up to 100-200 tons and are large in size and weight. Thus, bottle jacks with a lifting capacity of 200 tons have a height of 40-50 cm and a weight of 130-135 kg.

Limit load capacity

Indicates the maximum weight that the jack can lift. When choosing a jack for a car, you need to add 150-200 kg to the “curb weight” value indicated in the PTS.

Jack lifting height

The lifting height of a jack is the maximum possible height to which a load can be raised. This value consists of two indicators:

- pick-up height

- the smallest distance from the support surface from which the jack can operate; - The stroke of the rod (the stroke of the jack)

is the maximum distance between the highest and lowest positions of the piston.

For most hydraulic jacks, this figure is 30-50 cm. While a mechanical rack and pinion jack can lift a load to a height of 1 meter.

Pickup height

A very important indicator of a specific jack model. Shows the minimum distance from the support to the lifted load (from the ground to the bottom of the car). May vary between models from 6 to 30 cm. A jack with a high lifting height will not be able to be placed under the machine.

Pad diameter

The diameter of the platform is the size of the support platform for resting on the load. Determines the stability of the stop and distributes pressure on the jack to the load. The larger the platform, the greater the stability and optimal pressure applied.

Features of choosing a pneumatic jack

Due to their design features, as well as their powerful load capacity, these devices can be used for various types of vehicles. They are suitable for:

- passenger cars;

- heavy SUVs;

- construction equipment.

Having learned about a pneumatic jack, many car owners will probably think about purchasing it. They, of course, will have a question about how to choose the right device. In order to avoid mistakes when choosing, it is necessary, when considering the models offered in car stores, to focus on the following criteria:

- Price . Air jacks are no longer a new product in automotive stores. Therefore, you should not be afraid that the store will offer you these devices at exorbitant prices. By contacting institutions that sell goods for motorists, every owner of an “iron horse” will be able to find an option that is suitable for the price with optimal quality characteristics;

- Color spectrum . For pneumatic devices it can be different. Standard colors are black and grey. In addition, you can purchase a model that has bright colors: red, yellow or orange;

- When selecting the necessary device, you should pay attention to models that are made of high-quality rubberized materials. This is a guarantee of their high strength and wear resistance. Having purchased such a device, you can be sure that it will last a long time and will not let you down when you need it most. However, you should be prepared to spend a lot of money, since modern models with high quality indicators from well-known manufacturers simply cannot be cheap. Buying a cheap model is not the best solution, since after a year of use the device will become unusable;

- Vehicle body lift height . When selecting a pneumatic jack, this is one of the important points. For most models that are offered in stores for motorists, this parameter is up to 0.5 m. This is quite enough for tire fitting. Devices intended for rigging work have a lifting height of 0.75 m. When working, it is necessary to use a compressor unit;

- Vehicle ground clearance . You should also pay attention to this point when choosing a pneumatic device. You should select a jack that can easily be placed under the car in a deflated state.

If you plan to use a pneumatic jack year-round, then when purchasing a device you need to make sure that it is suitable for use in both summer and winter. Typically, universal models of such devices are equipped with anti-slip pads, which make it possible to conveniently use the jack even in winter, on snowy and icy surfaces.

When going to a car store to buy a pneumatic jack, you should remember that you should only choose a high-quality model from a reputable manufacturer. Of course, it will require quite a significant investment of money, but your operation of lifting a car in order to change a tire or rescue a vehicle from the mud will become safer and easier. The materials used in modern models are not only durable, but also resistant to cuts and punctures, reliable, and the hoses are quite airtight. All this is a guarantee that the purchased jack model will serve you for a long time.

Operating principle of a hydraulic jack

The operation of a hydraulic jack is based on the constancy of fluid pressure in communicating vessels. Inside the jack there are two “vessels” connected to each other. One vessel is the main cylinder with a working plunger, the other is a cylinder with a discharge plunger. This hydraulic system is filled with technical oil.

The injection cylinder is connected to an oil reserve tank and a lever. When the lever is pressed, the injection plunger moves: it lowers and pushes the oil out of the injection cylinder. The oil passes into the main cylinder and pushes the working plunger upward, due to this the load located on the jack’s support platform is lifted.

As a result of each press of the lever, a certain volume of oil is pumped into the main cylinder, equal to the volume of the injection cylinder. The discharge cylinder is filled with oil from the reservoir. Since pressing the lever alone is not enough to lift the load, they usually continue to move the lever until the desired height is reached.

Between the discharge and main cylinders there is a valve that allows fluid to flow in only one direction and prevents it from returning back to the discharge cylinder. The walls of the main cylinder must be designed for the weight of the load being lifted.

After reaching the desired lifting height, the jack must be returned to its initial position; to do this, it is necessary to open the bypass valve. The oil from the main working cylinder will return to the oil reserve tank and the jack will lower.

Advantages and disadvantages of hydraulic jacks

Hydraulic jacks have their pros and cons, which you need to pay attention to when choosing a jack for your car. When buying a car jack, you usually choose between mechanical and hydraulic jacks.

pros

- They have a high load capacity: 2-200 tons.

- A slight effort is required to lift the machine: pressing the lever to pump oil into the main cylinder. At the same time, human energy consumption is minimal, and the rise is fast.

- They have a very high efficiency - at the level of 80%.

- They can operate at sub-zero temperatures, since the oil in the cylinder does not freeze.

- They ensure smooth lifting of the machine, as oil gradually enters the cylinder, the rod rises without jerking.

- Smooth lowering prevents loads from falling and reduces the risk of injury when operating bottle jacks.

- They are highly stable thanks to the wide sole, which provides reliable support.

- Can be placed under any point on the body, since there is no rotating handle.

- There is a very small chance that the car will fall off the support.

Minuses

- They require periodic maintenance, monitoring the oil level, tightness of gaskets and valves, and oil changes.

- They require storage and transportation only in a vertical position, since oil may leak out when turned over.

- They are large in size and weight.

- An even support area is needed.

- The lifting height is greater than that of mechanical jacks, so hydraulic jacks are not suitable for vehicles with low ground clearance.

- The machine cannot be lowered to the specified height.

- They cost more than mechanical ones.

Application of hydraulic jacks

- Hydraulic jacks are widely used in professional car repair shops and tire shops, as well as by owners of jeeps and heavy SUVs. Passenger car owners most often prefer compact mechanical jacks.

- Due to their high load capacity, hydraulic bottle jacks are used in the repair of heavy cargo and agricultural equipment, and in industrial production for lifting super-heavy metal structures.

- In construction for lifting heavy blocks, parts of buildings, tensioning reinforcement using reinforced concrete.

- When laying oil and gas pipelines.

- When carrying out rescue operations and liquidation of consequences of accidents.

How to choose?

Choosing a car rolling jack should primarily be based on the purpose of use. Most motorists need it for situational repairs and minor maintenance. For this, household (or “amateur”) jacks, discussed in the “Rating” section, are sufficient. The determining factor here is the price-quality ratio. All of the listed devices fully meet this ratio and, with some variations in quality, are suitable for any passenger car except SUVs. Bottle or rack jacks are recommended for all categories of SUVs.

To work in auto repair shops, professional rolling jacks are needed. They have a much greater resource, load capacity and height.

Types of hydraulic jack

There are several types of hydraulic jacks, they differ in design.

Classification of hydraulic jacks

- Bottle.

The simplest version of a hydraulic jack, the name comes from its appearance, which resembles a bottle. It has compact dimensions and a large support area. Allows you to work with heavy and very heavy loads: from 2 to 200 tons. Can be used when working with cars and trucks, special equipment, and for lifting houses in construction. It has a fairly high minimum lift, so it is not suitable for cars with a ground clearance of less than 200 mm. You need to work with a bottle jack on a perfectly level support. - Rolling

. There are several modifications for professional and household use. To work with them, you need a hard, even floor covering such as concrete, asphalt, or tiles. They are widely used in professional car repair shops for passenger cars.

- Telescopic.

It has a telescopic piston, which allows you to increase the maximum lifting height. - Double rod or double piston.

Due to the two pistons in the design, it has an increased load capacity. - Low toe hooks

. Used in cases where a minimum pick-up height is required. Capable of lifting a load from a distance of 15 mm from the support, allowing step-by-step adjustment of the lift and securely fixing the load. They are used for raising railway tracks and in industry. - Specialized:

two-level, diamond-shaped.

Model rating

Among rolling jacks for passenger cars with a lifting capacity of no more than 2 tons, the sympathies of buyers are distributed approximately as follows.

Kraft KT 820000

This is an old German brand of tools and auxiliary mechanisms. Made in China. It is considered one of the best in the household segment (for rare minor repairs of passenger cars). Pickup height (start of lifting) – 135 mm, lifting height – 320 mm. Price on average from 2000 rubles. Supplied in a plastic case.

"Zubr 43053-2-K"

The most common rolling jack made in Russia. Reinforced design. Durable and reliable. Raises a passenger car to a height of 330 mm. This is enough to replace wheels of most diameters. Price – from 2300 rubles.

"Belavtokomplekt BAK. 00053"

This brand has been known since Soviet times. Price – from 1600 rubles. Lifting height – 320 mm. The price is tempting, but the quality, according to reviews, is sometimes “lame”.

Autoprofi DP-20K

Russian brand, a brand that is rapidly gaining popularity. These jacks are reliable and durable. Lifting height 330 mm. Suitable for most passenger cars. Price – from 2200 rubles.

Matrix Master 51020

The brand’s homeland is Germany, but the equipment is made in China. Lifting height 355 mm. Consumers note the convenience, compactness and reliability, ease of working with it. Price – from 2300 rubles. Supplied in a case.

Titan 20008

Recently emerged Chinese brand. Price – from 2000 rubles, supplied in a plastic case. The price is attractive, but there are complaints about the quality of the rubber seals and ease of use.

Among the professional devices, it would be worth noting the Norberg N32035 with a lifting capacity of 3.5 tons. Lifting height 558 mm. Price – from 11 thousand rubles.

Rating of the 10 best hydraulic bottle jacks

Hydraulic jack SPARTA 2t 50341 telescopic

Designed for lifting loads weighing up to 2 tons. The base of the jack is made of cast iron and has a protective anti-corrosion coating. Equipped with a safety valve that prevents lifting of loads weighing more than 2 tons. The weight of the lifted load should not exceed 2 tons.

Not intended for moving loads and maintaining the load suspended for a long time. After lifting the load, it is necessary to secure it with stands for support. If there are no supporting stands under the load, you cannot stand and carry out work. To work, it must be placed on a flat horizontal surface. The presence of a telescopic mechanism allows you to lift the load to a height of 410 mm without much physical effort.

The homeland of the SPARTA brand is Germany, assembly is carried out in factories in China and Taiwan, which allows you to combine German quality and low cost of production. SPARTA jacks are durable and inexpensive.

Technical characteristics of the jack SPARTA 50341:

- Load capacity - 2 t

- Pickup height - 170 mm

- Lifting height - 410 mm

- Case material: metal

- Type - double plunger

- Telescopic mechanism - yes

- Horizontal operation - no

- Weight - 3.2 kg

- Case - no

Hydraulic jack 2t Gigant HBJ-2

The hydraulic jack of the Russian brand Gigant is produced at factories in China and Russia. Manufactured according to GOST R 53822-2010. Designed to work with loads weighing up to 2 tons. The jack is not designed to hold a load for a long time. When working under load, it is necessary to use additional supports. The Gigant HBJ-2 jack is distinguished by reliable operation and good stability due to its large support area.

Technical characteristics of the Gigant HBJ-2 jack:

- Load capacity - 2 t

- Pickup height - 181 mm

- Lifting height - 345 mm

- Case material: metal

- Type - single plunger

- Telescopic mechanism - no

- Horizontal operation - no

- Weight - 2.6 kg

- Case - no

Hydraulic jack SPARTA Compact 3t 50332

The hydraulic jack SPARTA Compact 3t of the German brand SPARTA is assembled in factories in China. It has established itself as a reliable and inexpensive tool, thereby gaining great popularity among car enthusiasts. Designed for lifting loads in construction and during automotive repair work. It has a stable cast iron base, a body made of durable steel, and a polished rod that increases the service life of the jack.

It has a small pick-up height of 180 mm, which allows you to work with cars with low ground clearance. The maximum lifting height is 320 mm. After lifting the load to the required height, it is necessary to securely secure the load with supports to ensure the safety of the working person. It is impossible to work without additional supports. The jack is not designed to move a load and hold it suspended for a long time. The weight of the lifted load should not exceed 3 tons.

Technical characteristics of the jack SPARTA Compact 3t 50332:

- Load capacity - 3 t

- Pickup height - 180 mm

- Lifting height - 320 mm

- Case material - steel

- Type - single plunger

- Telescopic mechanism - yes

- Horizontal operation - no

- Retractable screw stroke - 50 mm

- Weight - 2.4 kg

- Case - no

Hydraulic jack BelAK 3t BAK.10040

The BelAK BAK.10040 hydraulic jack has a lifting capacity of 3 tons and is perfect for car repairs. It is produced under the BelAK brand, owned by the Russian production holding BelAvtoKomplekt. Assembly is carried out at two factories in China, where production meets international ISO standards, all products are manufactured in accordance with GOST and undergo final quality control.

The jack is supplied in a case, which makes its storage especially convenient. It has a wide support platform and two handles. Has a low lift of 145 mm. The BelAK BAK.10040 jack has a long service life, low price, and high quality.

Technical characteristics of the jack

BelAK 3t BAK.10040:

- Load capacity - 3 t

- Pickup height - 145 mm

- Lifting height - 285 mm

- Case material: metal

- Type - single plunger

- Telescopic mechanism - yes

- Horizontal operation - no

- Retractable screw stroke - 50 mm

- Base size - 85x70 mm

- Weight - 2.3 kg

- Case - yes

Hydraulic jack KRAFT 4t KT 800014

The KRAFT KT 800014 jack is designed for lifting loads weighing up to 4 tons, and is widely used in the repair and maintenance of vehicles. Belongs to the German brand KRAFT, which has been producing car parts and auto tools for more than 20 years. Assembly is carried out in China, where all products undergo mandatory quality control of international standards DIN, ANSI.

The jack has a safety valve that prevents lifting loads over 4 tons. Frost-resistant oil is used as a working fluid, which does not lose its properties at a temperature of -45°C. The convenient folding handle makes the jack compact. Supplied in a plastic case with a handle, which is convenient to store and transport.

Technical characteristics of the jack KRAFT 4t KT 800014

- Load capacity - 4 t

- Pickup height - 195 mm

- Lifting height - 380 mm

- Case material: metal

- Type - single plunger

- Telescopic mechanism - no

- Horizontal operation - no

- Retractable screw stroke - 60 mm

- Base size - 108x108 mm

- Weight - 3.6 kg

- Case - yes

Hydraulic jack MATRIX MASTER 4t 50754

Hydraulic jack of the German brand Matrix, assembly is carried out at factories in China and Taiwan. All manufactured products undergo strict quality control, which allows us to combine low price, high quality and long service life. Matrix Master 50754 has a load capacity of 4 tons, is made of durable anti-corrosion metal, resistant to rust and mechanical stress.

The jack has a wide base, which allows it to be used on fairly soft ground. Supplied complete with a plastic case with a handle. The case allows you to properly store and transport the jack - in a vertical position.

Technical characteristics of the jack MATRIX MASTER 4t 50754

- Load capacity - 4 t

- Pickup height - 194 mm

- Lifting height - 372 mm

- Case material - steel

- Type - single plunger

- Telescopic mechanism - no

- Horizontal operation - no

- Retractable screw stroke - 48 mm

- Weight - 3.9 kg

- Case - yes

Hydraulic jack SPARTA Compact 5 t 50333

The hydraulic jack SPARTA Compact 50333 is designed for lifting loads weighing no more than 5 tons. Produced in factories in China using German technology in compliance with all necessary requirements. The jack is distinguished by high build quality, durability and reliability. These characteristics, combined with a low price, make the SPARTA Compact 50333 jack an excellent purchase.

The jack is not designed to hold a load suspended for a long time; for this you need to use special supports, without which it is strictly prohibited to work under a raised load. The body is made of durable steel and has a stable cast iron base. The jack is equipped with a polished rod.

Technical characteristics of the jack SPARTA Compact 5 t 50333

- Load capacity - 5 t

- Pickup height - 180 mm

- Lifting height - 340 mm

- Case material - steel

- Type - single plunger

- Telescopic mechanism - yes

- Horizontal operation - no

- Retractable screw stroke - 50 mm

- Weight - 2.9 kg

- Case - no

Hydraulic jack BelAK 5t BAK.00042

Belongs to a Russian brand, assembly is carried out at a factory in China. Designed to lift cargo weighing no more than 5 tons. Despite its large load capacity, it has compact dimensions and, due to its low lift, allows it to work with machines with low ground clearance. The wide base ensures the stability of the jack and reduces pressing into the ground. If it is necessary to hold the load suspended for a long time, it is necessary to install additional supports, without which it is prohibited to work under the load.

Technical characteristics of the jack BelAK 5t BAK.00042

- Load capacity - 5 t

- Pickup height - 175 mm

- Lifting height - 345 mm

- Case material: metal

- Type - single plunger

- Telescopic mechanism - yes

- Horizontal operation - no

- Retractable screw stroke - 60 mm

- Working stroke - 110 mm

- Base size - 75x85 mm

- Weight - 2.9 kg

- Case - no

Hydraulic jack SOROKIN BottLine Jacks 12t 3.12

Designed to lift cargo weighing no more than 12 tons. The jack is of the famous Russian brand Sorokin, whose production facilities are located in China, Taiwan, Russia, and Europe. The jack is assembled in China, which reduces production costs and, accordingly, the final price while maintaining high quality products. It is used for construction, industrial and auto repair purposes.

Not designed to hold a load for long periods of time. After lifting the load to the required height, it is necessary to use additional fixing supports for safe work under the load.

The SOROKIN BottLine Jacks 12t hydraulic jack is easy to use and has a screw rod that makes it easier to place the jack under the supporting surface of the load. There is a metal handle on the side of the case, which is convenient for carrying the jack. At the bottom of the body there is a wide support base that prevents the jack from sinking into soft ground.

BottLine Jack® series bottle jacks are equipped with a telescopic mechanism that allows you to reduce the pick-up height while maintaining or increasing the lifting height compared to classic models.

Technical characteristics of the jack SOROKIN BottLine Jacks 12t 3.12

- Load capacity - 12 t

- Pickup height - 245 mm

- Lifting height - 570 mm

- Case material: metal

- Type - double plunger

- Telescopic mechanism - yes

- Horizontal operation - no

- Retractable screw stroke - 55 mm

- Working stroke - 270 mm

- Weight - 9.5 kg

- Case - no

Hydraulic jack WIEDERKRAFT 20t. WDK-81200

The WIEDERKRAFT WDK-81200 hydraulic jack is designed for lifting loads weighing up to 20 tons. It is used at service stations for freight transport, special vehicles and agricultural machinery. WIEDERKRAFT is a German brand; jacks are assembled in China. High quality is combined with long service life and reliability.

The jack has a handle, which makes it easy to transport. The wide base ensures the stability of the jack during operation. The screw platform is height adjustable.

Technical characteristics of the WIEDERKRAFT 20t jack. WDK-81200

- Load capacity - 20 t

- Pickup height - 226 mm

- Lifting height - 452 mm

- Case material: metal

- Type - single plunger

- Telescopic mechanism - yes

- Horizontal operation - no

- Retractable screw stroke - 150 mm

- Working stroke - 226 mm

- Base size - 144x150 mm

- Weight - 10.6 kg

- Case - no

Tips for use

To extend the service life of the jack, it is recommended to adhere to the following rules:

- It is advisable to change the lifting mechanism oil twice a year. If the jack is used daily, it is recommended to replace it at least once a month with mandatory washing.

- Any replacement oil can be used. But for the winter season, it is recommended to fill only synthetic types of oils.

- To prevent the oil from thickening in winter, the tool should be stored in a warm and dry room.

- If lifting work is carried out in winter, it should be remembered that if the tool is used for a long time in severe frost, it may fail. Therefore, it is advisable to work with it as a last resort and for a limited time.

The best “repair” of the lifting mechanism is prevention to prevent malfunctions, that is, constant care and timely replacement of the working fluid with pumping. After all, you will have to use your time and sometimes some resources to fix any breakdown. Therefore, you should follow all the operating instructions for hydraulic lifting tools, and then they will serve for quite a long time.