Today there are quite a few companies that specialize in the production of beams and welded structures. Beams are the main element of welded frames and the basis of structures made of metal structures. The manufacture of beams is a responsible activity, since a welded beam performs a load-bearing function, which implies a large load on the metal and welds. The durability and safety of the future building made from a welded beam depends on the quality of manufacturing of the beams and welded structure.

Submit your application

| № | Profile | I-beam height, mm | Shelf width, mm | Shelf thickness, mm | Wall thickness, mm | Weight 1 piece 12 m, t | Price according to st3, st09g2s rub/t with VAT |

| 1 | 80B1 | 791 | 280 | 18 | 14 | 1,952 | Submit your application |

| 2 | 80B2 | 799 | 280 | 22 | 14 | 2,166 | Submit your application |

| 3 | 90B1 | 895 | 300 | 20 | 16 | 2,425 | Submit your application |

| 4 | 90B2 | 909 | 310 | 22 | 16 | 5,598 | Submit your application |

| 5 | 100B1 | 999 | 320 | 22 | 16 | 2,776 | Submit your application |

| 6 | 100B2 | 1010 | 325 | 25 | 18 | 3,172 | Submit your application |

| 7 | 100B3 | 1015 | 320 | 30 | 18 | 3,440 | Submit your application |

| 8 | 100B4 | 1019 | 330 | 32 | 20 | 3,802 | Submit your application |

| 9 | 50Ш3 | 494 | 295 | 22 | 16 | 1,909 | Submit your application |

| 10 | 50Ш4 | 500 | 300 | 25 | 16 | 2,104 | Submit your application |

| 11 | 60Ш1 | 591 | 300 | 18 | 12 | 1,654 | Submit your application |

| 12 | 60Ш2 | 594 | 300 | 22 | 16 | 2,081 | Submit your application |

| 13 | 60Ш3 | 600 | 305 | 25 | 18 | 2,381 | Submit your application |

| 14 | 60Ш4 | 605 | 300 | 30 | 20 | 2,735 | Submit your application |

| 15 | 70Ш1 | 694 | 305 | 22 | 12 | 2,008 | Submit your application |

| 16 | 70Ш2 | 695 | 305 | 25 | 14 | 2,229 | Submit your application |

| 17 | 70Ш3 | 711 | 305 | 28 | 18 | 2,731 | Submit your application |

| 18 | 70Ш4 | 714 | 305 | 32 | 22 | 3,198 | Submit your application |

| 19 | 70Ш5 | 727 | 305 | 36 | 25 | 3,626 | Submit your application |

| 20 | 80Ш1 | 781 | 300 | 18 | 14 | 2,009 | Submit your application |

| 21 | 80Ш2 | 794 | 320 | 22 | 14 | 2,328 | Submit your application |

| 22 | 90Ш1 | 880 | 295 | 20 | 16 | 2,389 | Submit your application |

| 23 | 90Ш2 | 890 | 305 | 25 | 14 | 2,556 | Submit your application |

| 24 | 100Ш1 | 989 | 325 | 22 | 16 | 2,783 | Submit your application |

| 25 | 100Ш2 | 1005 | 325 | 25 | 18 | 3,162 | Submit your application |

| 26 | 100Ш3 | 1014 | 310 | 32 | 18 | 3,492 | Submit your application |

| 27 | 100Ш4 | 1012 | 310 | 36 | 20 | 3,889 | Submit your application |

| 28 | 35K1 | 342 | 350 | 16 | 10 | 1,352 | Submit your application |

| 29 | 35K2 | 355 | 350 | 20 | 12 | 1,684 | Submit your application |

| 30 | 40K1 | 395 | 390 | 20 | 10 | 1,812 | Submit your application |

| 31 | 40K2 | 404 | 400 | 22 | 12 | 2,074 | Submit your application |

| 32 | 40K3 | 410 | 400 | 25 | 16 | 2,438 | Submit your application |

| 33 | 40K4 | 415 | 400 | 30 | 18 | 2,875 | Submit your application |

| 34 | 40K5 | 432 | 405 | 36 | 22 | 3,509 | Submit your application |

Stahlberg quality

For Stahlberg specialists, there are no “important moments”. Each part, which includes welded I-beams, plays a huge role in the safe operation of buildings and houses. The production of beams is no exception to Stahlberg's strictly established THREE T standards - Precision. Demandingness. Technologies".

- Welded beams are made only from high-quality steel grades St3sp-5 or 09G2S, strictly complying with design documentation and design loads.

- All design documentation and a working set of drawings for the manufacture of welded beams are prepared in accordance with the technical specifications and GOST standards of the Russian Federation.

- Welded connections are made by certified welders and comply with the certification rules approved by the USSR State Mining and Technical Supervision Department dated June 22, 1971

- After production is completed, the beams are checked by external inspection and tapping with a metal hammer.

- At the customer's request, the welded beam can be additionally treated with primer solutions to protect against corrosion (Grunt GF021)

Application area

Welded steel beams are used in work platforms, bridges, overpasses, crane beams, ceilings and other metal structures. Steel beams are most effective in workshops, long-span structures of industrial buildings and other structures, as they provide significant savings in metal and low loads on themselves.

Our company produces welded steel I-beams for metal structures for various purposes. The metal structures workshop is equipped with modern equipment that allows us to control product quality at every stage of the technological process.

Welded beam manufacturing, beams require precision and accuracy. Our company employs high-level specialists, which allows us to ensure the necessary quality of the final product.

The Tula plant for the production of metal structures produces welded I-beams for structures with mechanical parameters STO ASChM 20-93 type B, Sh, K and in accordance with GOST 26020-83. All structural elements are made from hot-rolled steel, which is supplied in sheets in accordance with GOST 19903, from steel:

- low-alloy (GOST 19281);

- carbon for general purpose (GOST 14637).

All production of welded beams takes place on modern automated equipment, which allows the production of up to 600 tons of welded I-beam per month of various profiles, namely:

Our welded I-beam is considered one of the best in quality. We have been manufacturing welded I-beams since 2007. We have all quality certificates.

| 40B1 | 40B2 | 40K1 | 40K2 | 40K3 |

| 40K4 | 40K5 | 40Ш1 | 40Ш2 | 40Ш3 |

| 45B1 | 45B2 | 45Ш1 | 50B1 | 50B2 |

| 50B3 | 50Ш1 | 50Ш2 | 50Ш3 | 50Ш4 |

| 55B1 | 55B2 | 60B1 | 60B2 | 60Ш1 |

| 60Ш2 | 60Ш3 | 60Ш4 | 70B0 | 70B1 |

| 70B2 | 70Ш1 | 70Ш2 | 70Ш3 | 70Ш4 |

| 70Ш5 | 80B1 | 80B2 | 80Ш1 | 80Ш2 |

| 90B1 | 90B2 | 90Ш1 | 90Ш2 | 100B1 |

| 100B2 | 100B3 | 100B4 | 100Ш1 | 100Ш2 |

| 100Ш3 | 100Ш4 |

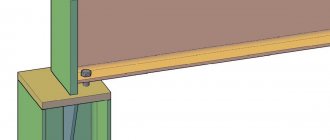

Prices for wooden I-beams

Beam with wooden shelfShelf size, mmLength, mHeight (H), mmOSB thickness, mm Price, rub./linear mBeam CM-14070x45 up to 61409350 rub.Beam CM-24070x45 up to 62409385 RURBeam CM-30070x45 up to 63009400 rubBeam CM-36070x45 up to 63609415 RURBeam CM-40070x45do 64009430 rub.Beam CM-46070x45 up to 64609450 rub. Beam with wooden shelf, length up to 12 metersShelf size, mmLength, mHeight (H), mmOSB thickness, mm Price, rub./linear mBeam CM-140LT72x48 up to 121409485 RURBeam CM-240LT72x48 up to 122409515 RURBeam CM-300LT72x48 up to 123009530 rub.Beam CM-360LT72x48 up to 123609545 rubBeam CM-400LT72x48 up to 124009560 rubBeam CM-460LT72x48 up to 124609575 rub Beam with shelf made of LVL barsShelf size, mmLength, mHeight (H), mmOSB thickness, mm Price, rub./linear mBeam SM-240L64x39do 122409505 RURBeam SM-300L64x39do 123009525 RURBeam SM-360L64x39do 123609535 RURBeam SM-400L64x39do 124009555 rubBeam SM-240L with wide flange 89x39 up to 122409615 RURBeam SM-300L with wide flange 89x39 up to 123009635 RURBeam SM-360L with wide flange 89x39 up to 123609645 RURBeam SM-400L with wide flange 89x39 up to 124009665 RURBeam SM-460L with wide flange 89x39 up to 124609685 RURFree layout and calculation of beams + 7 495 797 05 60

I-beam rafters

I-beam rafters

I-beam floors

I-beam ceiling

I-beams for floors

Individual cost calculation

The metal structures plant offers metal welded beams of any configuration you need. Production is carried out at a modern, automated level, which ensures the highest quality of products. We offer to buy metal welded beams at a competitive price. The specific price of a welded beam depends on the type of product. You can always buy a welded beam from our factory.

The company's production capacity allows us to provide the customer with metal products in full. Selling welded beams of our own production allows us to guarantee the reliability and durability of the product. The production process is carried out under strict quality control of each product.

The best price for producing tons of metal structures.

Welded beam manufacturing technology

Each production has its own standards and technology, the production of welded structures (beams) is no exception. The beam manufacturing technology includes five main points:

- Dividing sheet metal into strips. The metal sheet is cut on CNC machines according to the required parameters. Our modern equipment allows us to dissolve metal into pieces at a speed of up to one meter per minute, which is a fairly fast production.

- Edge milling. Thanks to this procedure, the reliability and required density of future seams and the welded structure itself is ensured. The entire process takes place on specialized equipment.

- Beam assembly. If all elements are manufactured in strict compliance with the design data, then the process of assembling the beam does not present any particular difficulties. It is necessary to strictly observe the symmetry and perpendicularity of the parts.

- Welding of elements. This process is fully automated, welds are controlled by special devices.

- Editing beam geometry. During the manufacture of beams, displacement of shelves and walls is often observed. It is necessary to carefully monitor the entire production process, and when necessary, correct the arrangement of elements.

Possible defects

During welding of an I-beam, due to non-compliance with the technology, crystallization of the steel occurs due to high temperature. Due to phase discrepancies, internal stresses arise in the metal. Strength and rigidity decrease, and the risk of corrosion increases.

When welding steel sheets, other defects are possible:

- violation of the shape of the seam; deviation from the shape of the outer surfaces or the geometry of the joint;

- burns, when the melt flows out of the bath, holes form in the seam;

- undercuts – grooves along the joint boundary;

- cracks forming in places where the seam breaks;

- slag or tungsten inclusions in the diffusion layer; at high welding speeds, refractory oxides are formed.

Metal products with defects are unreliable; they will not withstand heavy bending or torsion loads. They are discarded and boiled again if possible.

Possible problems and features

To avoid major problems, you must ensure that the finished connection is tension-free. The absence of this error in operation prevents unwanted design changes during installation. You can't cook all the parts at once. After connecting the first parts, wait a few minutes to prevent excess stress from building up in the metal.

Design parameters according to the product range

All metal I-beams are made in accordance with the requirements of regulatory documents. In this case, the profiles have a form and composition determined by regulations.

Based on this, you can easily select the parameters of the beams required for a particular structure.

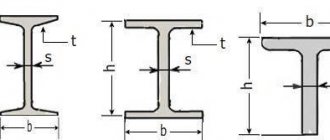

Geometric characteristics:

- height (H) - distance from the top to the bottom flat shelf;

- width (B) - transverse length of the I-beam flanges;

- wall thickness (S) - the thickness of the plane located between the shelves;

- average wall thickness (t) - the shelves narrow towards the edges and widen towards the middle, so the thickness is calculated using the formula: BS/4;

- radius of internal curvature - the size of the curvature of the shelves at the point of attachment to the wall.

In this case, the length of the I-beam is 4-15 meters.

The ratio of the mass and dimensions of the I-beam is needed when calculating the number of beams and choosing a method of transporting building products. How much an I-beam weighs can be found in the table.

Beam welding

Welding technology is used to connect individual beams. To make the connection, the I-beam ends are connected to each other and are then welded using appropriate equipment. To increase the strength of the seam, metal welding is performed using automatic devices that ensure a uniform supply of wire into the active zone. It is advisable to use fluxes - they improve the quality of seams that will withstand heavy loads or high temperatures.

Other advantages of flux:

- When straightening the steel, the flux minimizes metal spattering (all components remain in the active zone). Thanks to this, high-energy metal welding becomes possible (at currents of up to 4,000 amperes).

- Fluxes reliably isolate the core from the influence of the external environment (this minimizes the risk of the formation of oxides that reduce the strength of the weld).

- The use of fluxes allows you to reduce the economic costs of performing work. For example, inert gases can be used to protect the core - however, their losses will be quite significant due to the fact that the I-beam has a large cross-sectional area.

Metal welding can be performed using manual or semi-automatic welding without the use of protective fluxes. To assemble individual elements, it is recommended to use jig installations that will securely fix the parts during welding work. It is possible to use tacks, clamps and other similar equipment for fixation. The main disadvantage of manual and semi-automatic welding is the lower quality of the seam. During work, metal splashing increases with the formation of waste (total losses can reach 20% or more).