Any owner of a country house or summer cottage is faced with the need to dispose of plant waste. The best way to get rid of fallen leaves, dry grass and cut branches is with a garden shredder. Since this type of auxiliary equipment is still gaining popularity among owners of individual farms, it will be useful for interested people to get as much information as possible about it in order to make a truly smart purchase. You will learn how to choose the right garden shredder by reading this article.

Operating principle and purpose of a garden shredder

The principle of operation of this unit resembles a meat grinder or food processor.

Garden shredder device

Each manufacturer tries to give it its own design and construction features, but the list of basic elements remains unchanged:

- Durable metal or plastic housing mounted on a steel frame. To allow movement around the site, wheels are provided;

- A power plant implemented in the form of an internal combustion engine or an electric motor;

- The cutting mechanism is connected by a simple and reliable drive to the motor shaft;

- Funnel-shaped loading box for easy feeding of waste for cutting;

- Output device for crushed mass. It can be adapted for soft or hard containers. Many models simply throw the mixture onto the ground. Some of them allow you to adjust the height and direction of the release.

The resulting granular mass decomposes quickly enough in a compost pit, turning into fertilizer rich in useful substances, or is used as a mulching layer. Even taking it to a landfill turns out to be more convenient than transporting branches. Which garden shredder will best suit your needs depends on your application and processing volume.

Benefits of using a shredder

On a note! Shredded wood can be an excellent raw material for the production of pellets used to load solid fuel boilers.

Classification

Crushers are classified according to grinding/crushing technology:

- Cheek. They consist of a movable and a fixed jaw, located to each other in a wedge-shape, and the narrow part of the wedge must correspond to the parameters of semi-finished wood products that are planned to be manufactured. The moving jaw puts pressure on the wood, which is poured into the crusher from above, bringing it closer to the jaw, which is stationary during operation. Under pressure, the wood collapses to the same size as the narrow part of the cheek, after which it crumbles.

- Impact roller. In such machines, wood is poured into the receiving compartment, hits the rollers rotating towards each other during operation, is destroyed and spills out of the outlet.

- Conical. They consist of a glass and a moving cone-shaped finger. The wood is poured into a glass, a cone-shaped finger enters the glass, breaks the raw material, and upon exiting, destroys it to the required size and crumbles it.

- Drums. The equipment consists of a drum into which wood is supplied. When the equipment is turned on, the raw materials are destroyed by hitting each other when the drum is brought to the required speed.

- Roller. They consist of a roller and a bowl, the roller unwinds, gradually approaching the bowl, the raw material is crushed, falling between the bowl and the roller.

- Hammer. They consist of hammers attached to the rotor. Raw materials are poured on top while the rotor rotates, broken into small pieces with hammers and crumbled.

Wood chipper can be classified according to the size of wood crushing:

- Technological chips. There is a state standard for process chips that reflects the requirements for the final result, namely the size of the chips, quality, mass fraction of residues as a percentage on sieves with different diameters and trays.

- Special shavings. The settings of the machine are important, because the size of the chips used in the manufacture of particle boards depends on this.

- Wood crushed fraction. This includes wood flour, wood dust and other crushed wood fractions, which are used in the production of linoleum, linkcrust, glass and other finished products.

Types of Garden Shredders

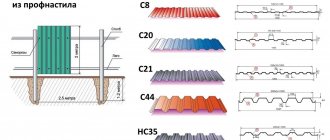

Before you accurately choose a garden branch shredder, you need to determine its technical characteristics. Based on power and the duration of continuous operation directly related to it, productivity and maximum size of processed pieces of wood, all units are conventionally divided into three large groups.

Household model Professional shredder

Experts distinguish between models of household, semi-professional and professional classes. Their comparative indicators are shown in the table:

| Class | Engine power and type | Limit diameter of branches | Own weight | Application area |

| Domestic | Electric motor up to 1.5 kW | 25 mm | Up to 20 kg | House areas and summer cottages with young vegetation. Working with frequent breaks |

| Semi-professional | Internal combustion engines or electric motor up to 3.0 kW | 45 mm | Up to 50 kg | Households with old trees that require regular pruning. Long continuous work with rare breaks |

| Professional | Internal combustion engines or three-phase electric motor up to 9.0 kW | 80 mm | More than 50 kg | Industrial wood processing enterprises, large farms, logging organizations. Continuous work for a full shift |

How to choose an electric garden shredder? To do this, it is necessary to assess the conditions for its upcoming use, and then consider options for the corresponding class.

Advice! You should not purchase equipment with a large reserve of power, so as not to incur unreasonable expenses.

The cutting efficiency is largely determined by the design features of the cutting unit. Based on this component, there are two main types of instruments.

Disc shredders

This type of equipment has one or more knife discs mounted on a powerful shaft. They are made from high-strength tool steel. The rotation speed and grinding intensity correspond to the hardness of the metal and the degree of processing specified during the design. Such a node has its advantages and weaknesses.

Advantages:

- simple design;

- low cost;

- ease of maintenance;

- high performance when chopping grass and small branches.

Flaws:

- wood thickness limitation;

- forced supply of processed mass is required;

- knives quickly become dull on dry, hard branches.

Milling shredders

The working body of such a tool is a rotating cutter - a special part of a complex shape with many cutting edges. It is made from high quality steel grades. For its operation, the transmitted force is more important than the rotation speed. It chews and grinds hard wood without any problems.

Advantages:

- increased maximum diameter of processed branches;

- long-term operation without the need for sharpening or replacement;

- the design itself tightens the supplied material without the use of additional devices.

Flaws:

- more complex design;

- high price;

- Grass and soft fibers from fresh wood often clog the free space of the cutting unit.

The nuances of operating homemade equipment

A self-made shredder is essentially three in one: a chopper for branches, a straw cutter, and a mechanism for cutting grass. It helps to significantly facilitate household work associated with the disposal of plant waste, as well as feeding poultry and livestock.

If you have to process grass in small quantities, for example, for chickens, geese, ducks, then very simple devices that operate on human muscle power, for example, a hand pruner, are sufficient.

For homemade electrical equipment, it is recommended to install a separate differential circuit breaker to provide reliable protection against electric shock in case of unforeseen circumstances. In any case, when making a garden shredder yourself, you must follow safety regulations. It is also worth adhering to them during operation of the mechanism. Before working with equipment, it is recommended to wear goggles, suitable protective clothing and check that the structural elements are securely fastened. When creating a home-made unit, you should take into account the upcoming amount of work, as well as the nature of the vegetation being processed, in order to select an engine of the required power and the desired design of knives. This will allow the completed device to cope with the assigned tasks without any problems.

Main selection criteria

There are many parameters that you should pay attention to during the purchase. Choosing the right characteristics of a garden shredder will provide benefits that you will immediately feel during use.

engine's type

The most common are models with an electric or gasoline engine. Each type has its own characteristics.

Electric model Gasoline shredder

Advantages of electrical devices:

- environmental cleanliness;

- no need for refueling;

- simplicity of design and minimal maintenance;

- efficiency;

- light weight and compact dimensions.

Flaws:

- impossibility of autonomous operation and dependence on cable length;

- the cord touches obstacles;

- undesirability of use in wet weather;

- the need to take breaks from work to cool the engine;

- limited power.

Advantages of gasoline shredders:

- autonomous work;

- high power;

- Can be used in any weather.

Flaws:

- more complex management and maintenance;

- exhaust emissions;

- increased noise level;

- relatively high cost.

We are not mistaken! For periodic work near the house and in the garden, we choose an inexpensive garden shredder with an electric drive. For autonomous use over a large area, you will need a gasoline car.

Type of cutting part

Manufacturers of garden shredders use working units of various designs. They are adapted to different materials and operating conditions. The following options are common:

- With two or more knives. The simplest machines of this type specialize in grass and small branches. Units with 4-6 rotating disks are capable of processing thicker waste;

- With worm type crusher. Their cutting part is similar to the screw of a meat grinder. It easily shreds branches with a diameter of up to 4 cm and copes well with grass, but requires periodic cleaning of adhering residues;

- With cylindrical cutting unit. They have a cutter in the shape of a cylinder or a truncated cone with many side knives. They are placed on universal models for any type of vegetation;

- Cutting shaft. This cutter is designed to grind branches up to 8 cm in diameter. It is reliable and durable, but requires use in conjunction with a powerful engine.

Worm type crusher Operating principle of the device with a shaft

Ease of use

You can decide which wood chipper is best for you only by assessing the ergonomic design features.

The device should be convenient for you

Pay attention to:

- the dimensions of the model so that loading the receiving compartment does not cause you any difficulties;

- the weight of the product must correspond to your physical capabilities;

- the optimal shape of the receiving hopper ensures easy feeding of branches to the cutting unit and eliminates their rebound;

- the location of the handles for transportation should be at a height convenient for you;

- Sufficient wheel width is a prerequisite for using the shredder outside roads and sites.

Reverse and noise level

How to choose a simple garden shredder that won't clog? It should have a reverse function. Reverse rotation ensures removal of the stuck piece and makes it easier to clean the cutter from waste.

Be sure to read the accompanying documentation. Operating a shredder with a noise level of 70-80 dB should not cause significant inconvenience. Powerful models sometimes exceed this figure.

Important! In this case, you need to take additional care of headphones or other noise-protective devices.

Is it possible to chop branches with it?

All grass and leaf shredders must be used only for their intended purpose , because trying to dispose of even thin branches with their help can lead to serious damage.

The line/milling mechanisms are designed to grind material with fragile soft fibers, so a branch that gets inside will break the line or break off several blades , after which you will have to either install a new line or change the impeller.

Therefore, you cannot use devices designed to work with green mass to destroy branches and wood ; for this, there are various wood chippers, crushers and chipping machines.

We have already talked about how to make them inexpensively yourself in this article and here.

Additional features

Really high-quality equipment is distinguished not only by high reliability and performance. It is characterized by a thoughtful approach to ensuring safety and maximum user convenience. Models with the following options have a clear advantage:

- automatic material supply;

- blocking accidental self-start;

- engine shutdown in case of overload;

- noise-absorbing design;

- the ability to regulate the speed of rotation of cutting parts;

- the presence of a standard pusher for garbage disposal;

- intensive processing of material into mulch.

Technical characteristics of the mechanism

A feature of the market economy is a wide range of offers of such equipment from foreign and domestic manufacturers, so the buyer must know the main technical characteristics of the mechanism, which he should pay attention to when purchasing:

- Installation power. This is the basis of productivity.

- Purpose of the unit. Some are necessary for chopping branches and grass, others for crushing logs and trees.

- Type of fuel. Some run on electricity only, while others run on both electricity and gasoline or diesel.

- Installation mobility. The dimensions of the crusher, weight, and speed of operation depend on this.

- Functionality. Universal devices are used, as a rule, in everyday life and have a simple design; in such mechanisms, as a rule, there is one grinding mode; in professional ones, the level of crushing can be adjusted.

If we look at the manufacturers of industrial equipment such as crushers, one of the leading places is occupied by:

- German, "Hombak", "Maier";

- Chinese "Kefid";

- Russian and BioSphere.

Rating of the best manufacturers of garden shredders

Before choosing a garden electric or gasoline wood chipper, it is useful to familiarize yourself with the models available on the market from leading manufacturers. The rating presented here will help you not make a mistake when purchasing and are guaranteed to receive a high-quality unit in the appropriate price category.

The best disc garden shredders

| Model | Characteristics |

| Patriot PT SE 24 A small and convenient model of an American brand from the budget category, it has an electric drive with a rotation speed of 4500 rpm, developing power up to 2.4 kW. With its help, you can chop grass to obtain compost and branches up to 4 cm thick. The extension cord allows you to work within a radius of 50 meters from the connection point. The shredder weighs only 13 kg and is easily moved around the site using a pair of wheels. During operation, it does not require special maintenance, being characterized by high reliability and performance acceptable for domestic needs. Knives will need to be sharpened or replaced periodically. The estimated service life of the product is 6 years with a 2-year warranty. You can buy it for 9-10 thousand rubles. Advantages:

Flaws:

| |

| Bosch AXT 2000 RAPID The effective model of the famous German brand occupies a leading position among equipment in the mid-price category. A 2.0 kW electric motor provides productivity up to 80 kg/hour when processing wood materials up to 35 mm thick. The chopper weighs only 11.5 kg thanks to its durable plastic body. It has two wheels for moving and a stable steel support. The delivery set includes a manual branch pusher. The unit is simple and highly reliable. The cost of 15,000 rubles is reasonable for equipment of this class. Advantages:

Flaws:

| |

| Vicing GB 370 An expensive, but extremely efficient Austrian-made unit is equipped with an American Briggs & Stratton engine, designed for a long service life. It develops power up to 3.3 kW. The belt drive softens the effects of impacts when solid materials enter the grinding unit. The shredder is designed for processing grass, leaves and branches with a diameter of up to 35 mm. All equipment is mounted on a rigid steel frame with two wide wheels. The body is made of durable technical plastic. Its own weight of 43 kg allows you to move the chopper within its area. The cost of this model is 75,000 rubles. Advantages:

Flaws:

|

The best milling shredders

| Model | Characteristics |

| Bison ZIE44-2800 In the budget category of milling shredders, this convenient electric model stands out, capable of grinding up to 150 kg/hour of wooden branches with a diameter of up to 44 mm into small chips. In addition to the unit itself, the kit includes a box for collecting chopped wood, a wheel pair, and a pusher with an ergonomic handle. Product weight 19 kg. The engine develops power up to 2.8 kW. It is provided with overload protection and reverse protection. The main working element is the toothed gear. It copes well with hard wood and does not need to be replaced for a long time. The cost of this model is 11-12 thousand rubles. Advantages:

Flaws:

| |

| Ryobi RSH2845T This unit with a successful design can be classified in the middle price category. It is equipped with a 2.8 kW electric motor. The product is characterized by high stability in the working position and is equipped with a waste collection container with a capacity of 55 liters. A pair of wheels is attached to the metal frame to allow movement. The working element is a milling cutter made of high-strength steel. It processes branches with a diameter of up to 45 mm. The system has automatic material supply and reverse capability. Set weight 29 kg. Cost 18,000 rubles. Advantages:

Flaws:

| |

| Bosch AXT 25 TC Premium category. When equipped with a 2.5 kW electric motor, it reaches a productivity of 230 kg/hour, chopping branches with a diameter of up to 45 mm. The multi-cut turbine cutter rotates at just 41 rpm, automatically drawing fresh material into the cutting zone. The unit is equipped with a 53-liter plastic box, a durable frame and wheels for movement. The total weight of the device is 31 kg. The noise level is 92 dB. The motor is protected from overloads and has the possibility of reverse rotation. The price of the product is 30,000 rubles. Advantages:

Flaws:

|

Assembly instructions for a twin-roll shredder

Work begins with creating a frame. To do this, using an angle grinder, two blanks 80 cm long and four pieces 40 cm long are cut from a profile pipe. Next, short sections are welded between the two long blanks at right angles. The two internal parts must be spaced at a sufficient distance from each other to ensure secure installation of the grinding drum.

Helpful advice! For the device to be mobile, the structure must have wheels for movement. To do this, two racks are welded to the frame, onto which an axle with wheels is attached.

Drawing for assembling shafts of a two-roll grinder

The next step is to create the shafts for the chopping drum. If you plan to install four knives on one shaft, then we use a square metal blank. We make both ends of it round so that they can fit into the bearings. For three knives you will need a round blank in which the central part is sharpened. Three flat cuts are made in it for the subsequent installation of knives.

To create knives, you can take a small piece of a Kamaz spring sheet. Holes for bolts are made in the knives. Then you should sharpen the knives on a sharpening machine, where the cutting edge angle is selected with a value of 35-45 degrees. Next, the sharpened knives are applied to the shaft and their attachment points are marked, in which holes are created, and the thread is cut.

Next, we proceed to create the grinding mechanism. Round holes are made in two metal walls using a welding machine for installing bearings. Using special pads and bolts, we install the bearings inside the metal walls. We insert the shafts into the bearings, securing them securely. They must be located at a sufficient distance to prevent them from touching. Next, the drum walls are connected using threaded metal studs and nuts.

Drawing of the location of the shafts on the frame of a two-roll shredder

Now let's start creating the receiving bunker. To do this, four parallelepipeds are cut from thin sheet metal. Next, each edge is bent by 4 cm. A short section in one direction, a long section in the opposite direction. We connect all the parts using self-tightening rivets or welding. Holes for fastening are made on the bent edges at the base of the box.

Now gears are put on the shafts to synchronize the movement, and the entire structure is installed on the frame and secured with bolts. Then the motor is installed, which is connected to the shaft by a belt drive or chain. It is better to take an engine of high power, but with a low number of revolutions. At the end, the receiving hopper is installed and secured. A protective cover is then placed on all rotating parts of the shredder to prevent foreign objects from entering the shredder.

The main advantages of such a unit are its high power and technical ability to chop thick branches with a diameter of 20 to 80 mm. This will depend on the number of knives and the number of revolutions. Numerous websites on the Internet provide detailed recommendations on how to make a branch chopper with your own hands. Video examples more clearly display the entire process of assembling and installing a homemade device.

Do-it-yourself two-roll shredder

Power units used

There are two types of devices for chopping branches:

- driven by an electric motor;

- powered by internal combustion engines.

For low-power homemade wood waste crushers, an electric motor is mainly used. This is explained by the fact that an engine running on gasoline or diesel fuel most often has more power than an electric one. For example, a scooter engine with a volume of 50 cm³ produces approximately 5 liters. With. or about 3.7 kW.

For infrequent grinding of garden waste, such a power unit is simply not necessary.