Features of vacuum drying of wood

A similar technique is used for processing wood obtained from deciduous and coniferous species. These plants have a large fiber cross-section. Heat treatment is carried out in large chambers.

There are several advantages of this effect. These include:

- Increased speed of processing wood base. In this way, it is possible to reduce the costs of production processes;

- The reduced pressure prevents the formation of cracks, bends and any defects;

- The tightness of the processes prevents the growth and reproduction of pathogenic microflora;

- Simple operation of equipment with drying chambers allows you to control the technological process remotely. In this way, it is possible to independently control the drying speed and drying time;

- Safety. The process of processing lumber in large drying chambers does not harm the environment.

Do not forget about the disadvantages of such a procedure. They are as follows:

- Big costs. For uninterrupted operation of the equipment, large amounts of electrical energy will be required, the cost of which may pleasantly surprise you;

- High cost of construction. On average, the price of vacuum wood dryers varies from 370,000 rubles to 1,000,000 rubles;

- Minimum chamber volume. When using this drying method, it is not possible to process a large amount of lumber at one time.

There are several operating modes of this device. They include:

- Soft. It is used for processing materials in order to preserve the strength and physical properties of wood;

- Normal. Heat treatment allows you to change the color of the fibers of the array, as well as change its wear resistance criteria;

- Forced. The color of the lumber becomes dark and the internal contents become brittle.

Experts recommend taking into account the type of wood, the size of the elements, the level of humidity and the properties of the vacuum dryer.

If the internal contents of the array have a humidity level of more than 25%, then drying must be carried out at a temperature of no higher than 110 degrees.

Thanks to vacuum drying, it is possible to achieve the following humidity indicators. These include:

- Wet fibers. Their humidity level is more than 55%;

- Air-dry. In this case, the percentage of moisture inside the fibers is 10-25%;

- Room - dry. When measuring humidity levels, a coefficient of no higher than 12% is observed;

- Absolutely dry. No moisture is observed in these lumber.

Moisture can be determined by the weight of lumber and the condition of its chips. When calculating these indicators, it is recommended to take into account the coefficient of residual stress of the boards and indicators of humidity changes.

Press-vacuum drying chambers - principle and technology of operation

Wood is used in the production of joinery for house construction and furniture production. This is an excellent natural material, to which there is no alternative, but in order to obtain good quality products, the original high-quality and, most importantly, dry material must be used for production. Raw resinous wood does not lend itself well to such types of processing as milling, sanding, gluing, etc. If paint and varnish coatings are applied to raw, unprepared wood, they will be unstable and unaesthetic. In addition, wet wood is less durable than dry wood and is prone to warping and cracking. That is why, before processing, wood must undergo a certain preparatory process - drying.

Operating principle of press vacuum drying

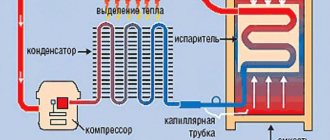

To effectively dry lumber of various types of wood, a press-vacuum drying chamber is used, which is a stainless steel container. Lumber is laid in layers inside the chamber, alternating with aluminum heating plates.

- Camera

- Rubber membrane

- Frame

- Rubber seal

- Wood

- Heat. plates

- Hoses

- Water water pump

- Heater

- Thermal insulation

- Vacuum pump

The water pump circulates water inside the heating plates. The water is heated in a boiler located outside the chamber. The chamber is hermetically sealed with a lid. The tightness is created by a special silicone membrane, which is structurally provided and mounted on the chamber lid.

After loading the lumber, the chamber lid is tightly closed, and the liquid vacuum pump is turned on, pumping air out of the chamber. When a vacuum is created, a silicone membrane presses a stack of lumber, laid out with heated plates, to the bottom of the chamber with a force of up to 10,000 kg/m2. Thus, heating and drying of wood is carried out in a vacuum under pressure.

The practical result of drying wood under pressure is to reduce its deformation in the form of twisting or warping, which often accompanies other types of drying. At temperatures above 80°C, wood plasticization occurs. After press drying, the boards become absolutely flat, without warping or other deformations.

Depending on the type and thickness of the material, the appropriate drying temperature and mode are selected. The heating temperature and vacuum load are designed in such a way that the evaporated moisture does not create concentrators and stresses that could lead to cracking of the wood. If the drying program is followed, the color of the lumber does not change, which can be important when working with valuable wood species.

Compression of a package of boards and heating plates ensures good contact with the heaters and good heat exchange, which increases the speed of drying lumber to the desired condition (furniture humidity 6 - 8%). Increasing the drying speed reduces energy consumption, which accordingly reduces the cost of production.

To ensure the best drying quality, the material must be selected to be the most uniform in size and moisture content, taking into account its storage conditions. The press vacuum drying chamber has the shortest drying cycle compared to other methods. Thus, drying of pine boards 30 mm thick to a humidity level of 6% occurs in 12 hours. For comparison: the duration of drying coniferous wood in the traditional way with gradual heating, blowing and cooling is from 10 to 20 days, depending on the required final moisture content and the purpose of the material.

A press-vacuum drying chamber helps solve another important problem for products made from fir, pine and other coniferous trees. Such a problem is the long-term release of resins during temperature changes in finished products , if they are made from material that has not been processed in a vacuum drying chamber. The resinous compounds of wood consist of two main components -

- from rosin and

- turpentine oil.

Turpentine oil is a volatile component that evaporates in a vacuum at a temperature of about 80°C. The heavier fraction (rosin and other resins), which remains after evaporation of the turpentine, crystallizes at room temperature. Crystalline inclusions no longer stand out on the surface of the wood and are not an obstacle to further processing of the workpieces. Thus, wood dried in a vacuum drying chamber has many advantages that are found when working with this wood.

The press-vacuum drying chamber, manufactured according to the customer’s needs, made of stainless steel, has a long service life and good corrosion protection. The use of drying chambers of this type provides significant energy savings, reduces the cost of products with high quality.

We offer an affordable and high-quality solution - the Redwood press-vacuum drying chamber!

How wood is dried

Vacuum drying of wood is carried out in 3 stages.

These include:

- Elementary. Surface processing of lumber is carried out here. Drying is carried out by heating without using a vacuum. The temperature inside the chamber is selected individually, taking into account the type of wood and its thickness;

- Drying. A special pump is used here, which allows you to quickly remove air masses from a closed space. Thanks to this, it is possible to evenly distribute moisture inside the wood fibers. The vacuum pump prevents deformation and cracking of the internal contents. Excess liquid quickly evaporates or is removed through special channels;

- Conditioning. In this case, the boards begin to cool evenly. In this way they manage to convey strength and endurance. The conditioning stages reduce the risk of deformation. After cooling, the lumber is carefully removed from the vacuum container.

You can monitor the performance of the device using special sensors and a control panel on the equipment body. In this way, it is possible to maintain the performance characteristics of the boards.

It is first recommended to correctly set the pressure level, which will affect the condition of wooden products. For example, to dry oak whose thickness exceeds 30 mm, select a temperature of at least 85 degrees.

The pressure volume should be no more than 520 kg per 1 sq. m. Lumber from this wood will be dried for 30 days.

Vacuum freeze drying

The presented technology is the most advanced at the moment, but more expensive. Vacuum drying of products has another name - sublimation or lyophilization. The principle of operation is based on the displacement of moisture from freshly frozen products under conditions of full vacuum. It is actively used in the production of dried fruits. The method used in the area is:

- pharmaceuticals;

- military industry (dry rations, etc.);

- food;

- astronautics;

- laboratories.

Interesting! A number of experiments with food products have established that only fresh samples undergo the sublimation procedure. Otherwise, the raw material does not withstand such a process and almost completely loses its beneficial properties. Therefore, vacuum drying of vegetables or fruits should only be carried out with fresh products.

VSS (vacuum freeze drying) is distinguished by its ability to preserve the integrity and structure of raw materials: taste, color, aroma and even shape. For example, vacuum drying of berries leaves their composition virtually untouched: 100% of the vitamin C in strawberries was preserved using the BCC method and only 8% of antioxidants were lost. A similar, standard cooling method lost 19% of vitamin C and 23% of the antioxidant.

What is the drying chamber for?

Modern drying chambers for lumber are made in the form of a complex installation, the task of which is aimed at uniformly listening to wooden materials after they are immersed. It is possible to achieve reduced pressure and the desired temperature inside the container.

Such equipment helps reduce the level of heat loss during the processing of boards and the coloring of the internal contents. Modern drying chamber designs have a hydraulic press.

These parts help maintain the shape of the lumber during heat treatment. The presence of a press allows you to reduce the level of deformation of wooden blanks and get rid of serious defects.

The drying chamber device is equipped with an automated mechanism. Thus, working with such equipment is quite simple. The design of the product includes the following elements:

- Automated control system. Thanks to this mechanism, it is possible to set the necessary mode for proper vacuum drying;

- Automated display. The menu of this design displays temperature and humidity levels;

- Light points. Thanks to them, it is possible to avoid incorrect operation of the device, as well as warn about the end of work.

The performance characteristics of the model depend on its manufacturer. The presence of additional options allows you to expand the functionality of the design.