Main components of a garden shredder

To independently assemble a grass and branch chopper (shredder) at home, you must first understand the structure of the mechanism, as well as the principle of its operation. This will help you assemble the equipment correctly and, if necessary, make changes to its design.

A homemade unit, designed for grinding mown grass and sawn branches up to several centimeters thick, has the following main structural components:

- engine;

- knives mounted on the working shaft;

- frame (usually metal);

- protective casing;

- a box designed to receive cut vegetation;

- starting system.

The equipment itself can be made stationary or mobile. To create the latter option, you will additionally need wheels, as well as a handle. To make the frame, use metal corners or ready-made frames from workbenches. Boxes for processed vegetation are made from plastic buckets, tin, and bags. The protective casing around the knives should be thick and durable enough so as not to quickly wear out from the impact of grinding vegetation.

When processing plant debris, crushed pieces may fly out of the opening through which it is fed. Therefore, the neck is covered with a lid or simply with a cloth, for example, a bag.

The operation of the chopper is that rotation from the motor shaft is transmitted directly to the knives or through a chain/belt drive. The vegetation chopped by the blades enters the box. In this case, the final product is immediately ready for use.

According to the principle of operation, some homemade shredders are comparable to a meat grinder (they draw in and then grind organic matter), while others are comparable to a coffee grinder.

Types of DIY Gardening Devices

All homemade products can be divided into 3 types :

- wood chippers;

- mulchers;

- shredders.

Chip cutters are designed for chopping branches and completely dried large green mass, that is, thick stems.

They are poorly suited for processing and grinding fresh or slightly dried green mass, that is:

- leaves;

- herbs;

- tops

More often the chipper is made in the form of a rotary chipper . We talked about how this device works, its operating principle, and how to make it yourself, and showed it on video in these articles:

- Chip crushers;

- Do-it-yourself chipper.

A homemade device of this type effectively grinds branches of a certain thickness, turning them into small chips that can be used as :

- decorative and agrotechnical mulching of garden plots;

- coloring and flavoring when infusing alcohol;

- fuel for smoking various products;

- feeding for animals and birds;

- fuel for boilers and furnaces.

The mulcher is designed for chopping fresh and dried green mass, but is not suitable for processing dry tops and any branches. Its basis is the line cutting module, which we talked about here.

Chopped green mass can only be used as decorative or agricultural mulch , which is where the name of the device came from.

The shredder is designed for coarse chopping of branches, so the finished wood chips are used only for heating.

Industrial shredders provide the ability to produce chips of normal size, but in home-made devices, the most important quality is considered to be simplicity of design and ease of manufacture, which causes an increase in the size of chips.

Varieties of engines for assembling homemade products

Electric and gasoline engines removed from unused equipment are used as a drive for homemade products. Each of these two options has its own advantages and disadvantages. Models with an internal combustion engine are more convenient in that their operation does not require a nearby power supply. But in general, they are more expensive and have a more complex design than their counterparts equipped with an electric motor. Therefore, it is easier to make electrical equipment, and also more compact.

The maximum thickness of cut branches that a branch chipper can grind depends on the power of the electric motor installed on it and the characteristics of the knives.

- Models with a motor up to 1.5 kW are capable of grinding sticks up to 20 mm in diameter. They are designed for low intensity work.

- If an electric motor of 3 to 4 kW is installed, then such units can chop branches up to 40 mm thick.

- More powerful electric motors (over 4 kW) are used to make a shredder for wood with a diameter of 7-15 cm.

The drive of the last category is equipped with equipment if it is necessary to constantly perform large volumes of work associated with the processing of waste of various thicknesses.

To create a homemade shredder, you can use electric motors from an angle grinder, washing machine, or trimmer. They must be adapted to work from a stationary network with a voltage of 220 V. In order to grind material as thick as possible at home, it is recommended to equip the shredder with an electric motor of 1500 rpm with a power of about 3.5 kW. This parameter for internal combustion engines corresponds to 5-6 horsepower.

Motor from an old washing machine

Choice of engine type: electric or gasoline?

When choosing a motor for a homemade shredder, you need to consider the availability of components .

If you have a good gasoline engine of suitable power in your garage (2–5 hp), then it can be installed on most homemade garden wood chippers.

The gasoline engine will make the grinding unit autonomous , so it can be used even where there is no possibility of connecting to an outlet.

If the device will only work near an outlet, then it is better to give preference to an electric motor . Even if you have to buy it, the difference in operating costs will quickly compensate for your costs .

The cost per hour of operation of an electric garden shredder is 7–10 times less than a device with a two-stroke gasoline engine, or 10–12 times less than a device with a four-stroke gasoline engine.

This is due both the difference in the cost of electricity and gasoline , as well as the cost of servicing gasoline engines.

Another factor that influences the choice of engine is the ease of installation . Gasoline engines only work well when their shaft is horizontal.

Therefore, to connect to the vertical shaft of the chopper, and this is how the mulcher shaft is installed, you will need a gearbox that provides a rotation of 90 degrees. That is, you will have to spend money not only on the engine, but also on the gearbox . And the electric motor works well with any shaft position, so you can do without a gearbox.

Types of cutting attachments used

Homemade products, like factory units, are equipped with cutting attachments of various types:

- disc (with three blades);

- milling-turbine (universal).

The first type is flat blades. When they rotate, they grind plant debris. If you have to process branches, then such blades quickly become dull. Milling knives are a cutting shaft in the form of gears from circular saws. They grind dry waste from branches and grass well, and clog the cutters with wet waste. Milling-turbine cutting attachments can cope with thick and undried branches, but making them yourself is difficult.

At home, knives from lawn mowers or made from wood saws are often used.

It should be taken into account that the degree of processing of plant waste directly depends on the installed cutting attachments. The output is pieces of branches from 10 cm long or shavings or dust.

Classification of hammer crushers

These units differ in the following parameters:

- By number of rotors

: with one or two rotors;

- By shaft location

: with horizontal or vertical shaft;

- WITH reverse mode

or without it.

Shredders with reverse mode can rotate their shaft in both directions. If one side of the hammers is worn down, you can reverse the stroke of the shaft to use the impact elements on the other side.

These devices also differ:

- Dimensions of the chamber and rotor;

- Shape of hammers;

- Electric motor power.

Garden shredder from washing machine

An old Soviet-made washing machine with a metal body is a technique that contains almost all the necessary parts for assembling a garden shredder. You only need knives with fasteners, as well as an extension cord.

To make a cutting attachment, you can use an old wood saw.

Tools you will need:

- angle grinder;

- pliers;

- spanners;

- screwdriver;

- electric drill;

- hammer;

- tape measure with marker.

The washing machine motor has a small power (different models have different power), which is indicated in the instructions for the household appliance or on the electric motor plate. Due to the fact that its value usually does not exceed 500 watts, with the help of the created unit it will be possible to grind only straw or grass.

A shredder from a washing machine is made like this.

- The body of the machine is cut to height so that it is convenient to work with the unit.

- At the bottom side, a rectangular hole is cut in it with a grinder, 20 cm wide and 7 cm high, intended for throwing out ground plants.

- Around the slot, a kind of casing is made of tin, which will direct the herbal mass into the collection container, while preventing it from scattering to the sides.

- They make legs.

- Attach the body to the stand.

- 2 holes with a diameter of 7 mm are drilled on the electric motor shaft. Then a threaded bushing is placed on it, as well as holes at the end more than 5 cm long, securing it with bolts.

- An electric motor is secured under the bottom of the box using studs and nuts.

- Inside the casing, knives are secured to a sleeve, placing them above the grass ejection hole or at the same level with it.

- The box is attached by welding or bolts to the stand.

The result will be a technique similar to the one shown in the photo below.

The start button will come from a converted washing machine. You just need to make sure to connect the extension cord of sufficient length.

The design and operation of a grass cutter from a modern washing machine is shown in the video

Operating principle of a wood chipper

Of course, I would like to know what the operating principle of a homemade device is, how it functions, what sets it in motion and causes it to crush its contents.

In fact, everything is much simpler than it might seem at first glance: the chopper works on the principle of a regular meat grinder.

After the material gets inside, it moves to the part of the device where the cutters and cutters are located. And already there it is crushed.

The power rating influences how much raw material a crusher can process in one go. The main thing is that this figure does not exceed 2600 W.

Homemade grass grinder from a grinder

A grass grinder made from a grinder is a fairly simple and quickly implemented option. To implement the project, you will need to stock up on the following parts and materials:

- steel corners;

- metal container (regular boiling);

- homemade or ready-made knives (for example, from a lawn mower);

- fasteners;

- sheet metal.

Tools you will need:

- electric drill;

- welding machine and electrodes for it;

- an angle grinder to cut corners;

- spanners.

To assemble a shredder with your own hands based on an angle grinder, capable of grinding not only grass, but also branches up to 4 cm thick, it is recommended to use a power tool with a power of over 3 kW.

The creation of a grinding unit is carried out in the following sequence:

- cut the corners into pieces with a grinder;

- a frame resembling a chair is welded from them;

- weld a shelf from a piece of sheet metal;

- attach the grinder to the made frame (on the stand) with clamps, placing its shaft towards the top;

- cut a hole about 10 by 10 cm in the side of the boil-out;

- a sleeve, for example, made of tin, is attached to the slot, through which the ground plant mass will be dispensed from the container;

- make a hole in the center at the bottom of the boil;

- install the container on the angle grinder shaft and attach it with bolts or self-tapping screws to the metal frame;

- Place the knife or disc on the angle grinder.

The result will be the design shown in the photo below.

The dimensions of the corners are selected individually to make it convenient to handle the mechanism.

It should be remembered that the frame must be stable. The safety of working with the device will depend on this.

Place a bucket or other container under the pipe for dispensing chopped grass with branches while working with the unit so that the processed plants do not fly away.

The created device can be improved. To do this, you will need a grinder shaft attachment about 15 cm long with two knives: at the upper end and in the middle. The blades are separated by a mesh attached to the casing wall.

Hammer crushers in pellet line

In pellet and briquette production, compact hammer wood chippers are in great demand.

They have a number of significant advantages:

- High service life of working parts: 3-4 months can pass between replacing hammers.

- From a maintenance point of view, this is a simple and unpretentious equipment.

- Higher productivity compared to a pneumatic impact crusher (PIC) with the same engine power. Such mills are often installed in industrial lines with large production volumes.

- Thanks to the design features, the material does not stick to the hammers and does not clog the grates.

- Possibility of grinding wet wood chips.

Grass cutter from trimmer

A garden shredder can be made using a gasoline or electric trimmer. In this case, the tool will work in an upside-down position. To create equipment designed to chop grass and thin twigs, you will need, in addition to a brush cutter with cutting attachments, the following materials:

- plastic or metal container with a volume of at least 50 liters;

- approximately 1 sq.m. steel mesh with small mesh size;

- about 3 meters of metal tube (aluminum or steel) half an inch in diameter;

- a piece of board or moisture-resistant chipboard, plywood of such width that the trimmer fits on it;

- clamps that will attach the brush cutter to the wooden base;

- self-tapping screws, bolts, nuts, washers;

- wooden blocks (5 by 5 cm is enough).

To assemble a chopping mechanism from a trimmer, you will need to use the following tools and devices:

- a screwdriver or screwdriver with bits;

- electric drill with a set of drills for wood and metal;

- an electric jigsaw with files for cutting metal or a manual equivalent;

- hammer;

- open-end or socket wrenches;

- punch;

- an anvil or a flat iron plate.

A punch is needed to make it convenient to drill holes with an electric drill. This tool is pointed at the point where the metal needs to be drilled. Then it is hit with a hammer. The drill does not slip out of the resulting recess when drilling a metal part.

Hole punch set

Preparatory activities

A grass cutter from a brush cutter is manufactured in a number of stages. Initially, they are prepared in a container where the grass and branches will be ground:

- make markings on the bottom (along the perimeter) for four trapezoidal holes with rounded corners;

- drill holes with a cross section of 1 cm in each drawn segment;

- a jigsaw file is inserted into them and trapezoids are cut out;

- process the cuts with a file or sandpaper;

- a hole is drilled in the center of the bottom for the chopper shaft;

- a circle is cut out of steel mesh with dimensions according to the diameter of the bottom;

- using small scraps of boards or blocks, the prepared mesh fragment is secured to the container from below;

- Legs for the container are made from metal tubes, attaching them to the tank with bolts.

The wooden pieces are fixed with self-tapping screws, twisting them from the inside of the tank into metal jumpers between the cut trapezoids. In this way, the mesh is securely attached to the bottom of the container.

The legs are made in the following way:

- bend the tubes in a vice or using a pipe bender in the shape of the letter “P”;

- the ends of future supports are flattened with a hammer;

- 2 holes are drilled into them on each side (6.5 or 8.5 mm cross-section);

- fit the workpieces to the bottom of the container and mark the points of bolted connections;

- drill according to the hole mark;

- using bolts with washers and nuts, attach to the footrest casing.

After preparing the casing, in order to reduce the dimensions of the created mechanism, the following operations are performed:

- disassemble the trimmer, disconnecting the motor, rod and cutting attachment from each other;

- cut off a fragment approximately 20-40 centimeters long from the rod with the cable;

- collect the lawn mower;

- check the performance of the equipment.

Chopper assembly

If the trimmer works well after assembly, then it is used to create a grass grinder.

- The motor of the brush cutter is attached to the board with clamps.

- Fix the bar on a wooden base using clamps and a handle from a brush cutter.

- Connect the cutting attachment to the end of the rod, previously inserted into the hole at the bottom of the casing.

- They start the mechanism and test it in operation.

After these steps, you will get a unit, the photograph of which is presented below.

If the trimmer used to assemble the shredder is equipped with a gasoline engine, then the motor is placed on the base so that it is convenient to fill in fuel, start the device and regulate its operation (speed).

Cutting attachments are equipped with knives or fishing line - this depends on the thickness of the plant stems being chopped.

Self-production

In this section we will present a step-by-step guide to your own shredder and mulcher , and you can find detailed instructions on creating a wood chip cutter here.

The method of making a mulcher depends on the available components.

It can be made from a grinder, installing a fishing line on it instead of a disk, or from a conventional asynchronous motor with a shaft rotation speed of 1.5–3 thousand rpm.

In the first case, you need to place the grinder with fishing line in some kind of pipe or container , which will limit the scattering of the chopped grass , and in the second, you can make a full-fledged chopper.

Mulcher

To make a homemade garden electric mulcher for processing thin branches and grass you will need :

- AC asynchronous motor with a power of 1.5 kW or more with a mounting platform (sole) perpendicular to the shaft;

- steel pipe with an internal diameter of 30–50 cm;

- steel corner with shelf size 15–30 mm;

- steel rod with a diameter of 8–15 mm.

You will also need a steel plate for attaching the electric motor, an adapter for attaching the drum to the shaft, and a drum for the fishing line.

If there is no drum for fishing line or the mulcher will be used to process hard tops, then instead of the drum you can install 1-3 steel strips, placing them at equal angles . It is advisable to sharpen the edges of the strips, this will improve performance and reduce the load on the engine.

The main thing is that the hole for attaching to the shaft is exactly in the middle , otherwise strong vibration will occur, which will lead to a hum and a sharp decrease in the life of the bearings.

Here is the procedure that must be followed to make a mulcher:

- The pipe is cut on both sides at an angle of 90 degrees. The length of the cut section should be 40–60 cm. The plate for mounting the engine is cut to the size of the sole, holes are drilled in the required places (for the shaft and mounting bolts), and then the engine is mounted for testing.

- If everything is normal, then the engine is removed and 3 corners are welded to the bottom of the plate , located relative to each other at an angle of 120 degrees.

- The motor is installed on the plate , fixed with bolts and the drum is attached to it. If there is no drum, then steel strips or metal knives from any trimmer are used instead. You may have to install an adapter that compensates for the difference in the diameter of the shaft or extension and the diameter of the knife hole.

- A plate with welded corners is installed on the upper edge of the pipe , positioned so that the motor shaft is as close as possible to the center of the pipe, then the corners are welded to the pipe and the excess is cut off.

- Instead of welding, you can use a bolted connection , this will complicate the installation, but will greatly facilitate the maintenance of the device. To do this, each corner is cut close to the wall, then a “heel” is welded, that is, a small steel plate with a hole for a bolt, to the back of which a nut is welded. Then they drill holes in the pipe body and bolt the engine mount.

- You can also cut the body (pipe) into 2 parts at the level of the edge of the shaft, then weld fastening plates with nuts to any of the parts , and drill holes in the corresponding places of the other part of the pipe.

- A mesh with a cell size of 3–5 cm is made from a steel rod . If the body is made non-separable and the motor mount is secured by welding, then the mesh is bolted so that it can be removed for cleaning and replacing the fishing line. In an installation with a dismountable housing or a removable engine mount, the mesh can be secured by welding. Sometimes, instead of a mesh, a solid bottom is made, in which a round hole is cut, which plays the role of a sieve.

- The legs from the corner are welded to the bottom of the body , tilting them outward by 20–40 degrees. The length of the legs should be sufficient so that a bucket can be placed under the mulcher. It is advisable to weld a “heel” to the bottom of each leg - that is, a piece of steel plate measuring 5x5 cm. The length of each leg, as well as the angle of deflection, must be the same for the entire structure to be stable.

- Before each start, open access to the drum and check the condition of the fishing line , changing it if necessary. If knives are installed instead of fishing line, check their condition and sharpness in order to replace or sharpen if necessary.

Shredder

Although the shredder's design is much simpler than many other wood shredders, it is quite difficult to make one yourself due to the very high overall cost of the parts, which must be custom-made using certain grades of steel.

Therefore, in everyday life, with homemade knives from car springs and steel corners popular

To make such a homemade electric garden shredder you will need :

- sheet steel 20 mm thick;

- sheet steel 2 mm thick;

- steel gears of the same size and pitch with an outer diameter of 8 cm or more;

- asynchronous electric motor with a power of 3 kW or more;

- powerful gearbox with a gear ratio of 50–100 (the higher the gear ratio, the lower the shaft rotation speed, but the higher the torque);

- steel corner with shelf size 50 mm;

- spring from a passenger car;

- a flat steel rod with a diameter of 40–50 mm (you can use one of the gearbox shafts or a shaft from some other equipment, if its diameter is suitable);

- bearings.

Here's the procedure :

- Cut 2 pieces from the steel rod, one 35–40 cm long, the second 40–45 cm long.

- Cut 4 pieces of corner 25–30 cm long.

- Weld 2 corners onto each rod to make a square shaft .

- 4 circles are cut out of thin sheet steel , the outer diameter of which is equal to the outer diameter of the bearings, and the inner diameter is equal to the outer diameter of the shaft.

- The circles are put on the shafts and welded to the corners .

- 8 pieces are cut from the spring , the length of which is 2 cm less than the length of the shaft, after which one of the long sides is sharpened at an angle of 30–40 degrees. The smaller the angle, the better the knife will cut wood, but the faster it will become dull.

- 3-4 mounting holes are drilled in each knife , then holes corresponding to them are drilled in the corners of the shafts (the diameter of these holes should be slightly smaller so that threads can be cut into them). In this case, each knife should protrude so much that the knives of both shafts touch each other when they meet. Threads are cut into the finished shaft holes.

- Body parts are cut out of a thick . Its size can be any, the main thing is that the width is equal to the distance between the bearings on the shaft, and the height is not less than the distance between the far knives of both shafts. A total of 8 parts are needed - 2 side walls, top and bottom walls, 4 amplifiers.

- Holes for bearings are cut in the side walls . This is a very important operation, so even a 1 mm error will lead to serious problems.

- The side parts are welded to the bottom, then the amplifiers are welded - 2 pieces on top on the front and back sides, 2 pieces on the bottom also on the front and back sides.

- They choose a method for attaching the gear to the shaft - most often, welding or a keyed connection is used for this (this option is only suitable for processing thin branches; an attempt to chop thick branches can lead to the key breaking).

- Connect the drive (longer) shaft to the gearbox . To do this, you can use a chain or gear transmission, as well as an adapter coupling made of thick-walled steel pipe.

- Connect the electric motor to the gearbox.

- If the body turns out to be unstable, then 4 legs are welded , set at an angle of 25–35 degrees and equipped with heels measuring 5x5 or 10x10 cm.

Grinders made from grinders and other tools

can be used as a basis for creating a garden shredder :

- grinder;

- drill;

- trimmer.

Grinder , thanks to its high engine power and high speeds, can chop thin branches and grass, but to do this it must be rigidly attached to a vertical surface and an inlet hole must be made in this surface.

To chop grass, you can use a three-blade knife from a trimmer, and to process branches, the knife will need to be made from tool steel to order. You can make a knife from tough steel, and replaceable blades from the most durable steel.

The drill is used in the same way as the mulcher engine, fixed in any way. Due to the low speed of rotation of the cartridge, it makes no sense to install a drum, so a shaft is made, to which the knives are welded or otherwise attached.

The trimmer is also used in conjunction with the mulcher body, secured so that the drum with fishing line is parallel to the surface of the sieve.

What else can a chopper be made from?

There are many different options for creating garden shredders with your own hands: from the simplest ones, which only allow you to grind grass, to more structurally complex, powerful units designed for wood up to 10 cm thick. Accordingly, the practical implementation of the plan will require different details, different amounts of time and money.

To assemble equipment for processing plant waste, in addition to the considered options for old or unnecessary tools or equipment, you can use the following devices:

- drill or hammer drill;

- an old working vacuum cleaner;

- unnecessary electric saw;

- motor from the pump;

- gasoline or electric walk-behind tractor;

- any electric motor of suitable power.

A drill with a hammer drill, if you use them to chop grass, you don’t need to redo it at all. It is enough to make only a nozzle with blades. The created device will work like a blender, grinding soft plant stems into a container in small portions.

Types of wood chippers

Shredders and crushers come in several types. Their classification is based on the type of material they can process and shred.

For example, they can work with:

- Stones;

- Plastic;

- Metals;

- Wood;

- Garbage.

They are also divided into large-sized (30 cm), medium (10 cm) and small crushing (2 cm).

The nuances of operating homemade equipment

A self-made shredder is essentially three in one: a chopper for branches, a straw cutter, and a mechanism for cutting grass. It helps to significantly facilitate household work associated with the disposal of plant waste, as well as feeding poultry and livestock.

If you have to process grass in small quantities, for example, for chickens, geese, ducks, then very simple devices that operate on human muscle power, for example, a hand pruner, are sufficient.

For homemade electrical equipment, it is recommended to install a separate differential circuit breaker to provide reliable protection against electric shock in case of unforeseen circumstances. In any case, when making a garden shredder yourself, you must follow safety regulations. It is also worth adhering to them during operation of the mechanism. Before working with equipment, it is recommended to wear goggles, suitable protective clothing and check that the structural elements are securely fastened. When creating a home-made unit, you should take into account the upcoming amount of work, as well as the nature of the vegetation being processed, in order to select an engine of the required power and the desired design of knives. This will allow the completed device to cope with the assigned tasks without any problems.

Design of the DM hammer crusher

The ALB company produces these devices for pellet granulation lines, mixed feed and other industries.

We will give you a drawing of a hammer crusher for wood produced by ALB Group.

The diagram shows the design of the DM-22 model.

Fig 1. Diagram of a hammer crusher

It consists of the following main elements:

- Frame (1);

- crushing chamber with crushing drum (2);

- 2-stage fan (3);

- intermediate pipeline system (4);

- sluice gate (5);

- precipitating cyclone (6);

- electric motor (7) drive (8);

- electric motor (9) of the sluice gate drive (10);

- magnetic separator (11);

- suction nozzle (12);

- suction hose (13);

- pressure hose (14).

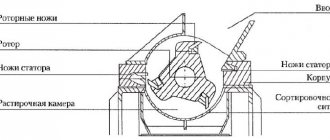

Below is a diagram of the crushing chamber:

Fig 2. Diagram of the crushing chamber

1 – body; 2 – side cover; 3 – shaft; 4 – cover; 5 – disk; 6 – finger; 7 – hammer; 8 – spacer sleeve; 9 – sieve; 10 – clamp; 11 – deck; 12 – fan casing; 13 – rotors; 14 – front cover; 15 – rear cover; 16 – pipe; 17 – pipe; 18 – pipe; 19 – hose; 20 – pulley; 21 – double-row spherical roller bearing 3610 GOST5721-75; 22 – key 18x11x388; 23 – key 14x9x56; 24 – key 14x9x90; 25 – eccentric.

Crushing chamber housing

- This is a welded steel structure with inserted side covers. They are rigidly fastened with bolts and carry the main shaft bearing housings. At one end of the shaft there is a six-strand drive pulley, at the other there is a two-stage fan.

The housing also has an additional cover that is secured with bolts, which serves to replace grates that wear out during operation. Behind the sieve there is a specially shaped neck, which continues with a pipe - they form an ejection (discharge) chamber.

Inside, on the walls of the case, there are two relief cast-iron decks, on which sawdust is crushed.

The main shaft passes through the center of the chamber, on which 6 disks are mounted at regular intervals, forming a crushing drum

. The discs are pierced with steel pins on which sets of crushing hammers are hinged.

Mill electrical equipment

– this is a 22 kW electric motor (for the DM 22 model), an associated control box (with starting, monitoring and protection equipment) and a limit switch. The latter serves as a safety device against starting the device if the camera cover is open. The DM crusher is protected from short circuits, has thermal relays for thermal and zero protection, as well as fuses for control circuits.

Additional shredder options: production instructions

You already understand that a herb chopper is a device similar to a food processor; accordingly, it can also be made mechanically, for example, from electrical tools available on the farm: a drill, an angle grinder and an old vacuum cleaner.

A drill grinder is a primitive and affordable device

The drill motor for the chopper must be high-speed, otherwise there will be no effective processing

To build such a device, you will need an ordinary, but quite powerful drill, circular or flat knives connected into one unit with a bolt, as well as an attachment for an electrical appliance. Before use, the attachment is attached to the drill socket, then the knives are fixed to it. Place the prepared grass in a deep container, lower the drill and start it. Hold the installation so that during movement the knives do not touch the container where all natural material is collected.

Homemade grass grinder from a grinder

From an angle grinder you can make a compact, practical, but not very productive device

Regardless of what the homemade shredder is made of, the principle of its operation is similar to any electric motor. Accordingly, a device made from an angle grinder will be no different from a professional one if it is assembled correctly. For this product you will need a special hopper or a metal case from any device, a protective cover, and a grass cutter with a motor.

To produce a grass grinder, it is better to use special knives that are sold in stores. And if you plan to make it yourself, take a metal plate with one edge sharpened.

Scheme for making a herbal grinder from a vacuum cleaner

Pay attention to the diagram of how the parts should be selected

The use of a Typhoon type vacuum cleaner engine guarantees greater performance than previous devices. The principle of operation of the device is to supply greens through the top hole, and the output of the finished material? through the bottom. Remember that the stand for the unit should not be too high, otherwise the grass will scatter to the sides during processing. The leading role for this will be played by the protective casing for both holes.

DIY hay chopper design

Large farms or livestock production cannot do without a hay chopper. Changing this arrangement helps rationally distribute hay and straw for livestock. If you do not plan to buy such a unit, but want to build it yourself, it is important to remember what is included in the design:

- Electric motor. You can choose the power of the installation yourself, but remember. The higher the consumption rate, the more productive the device will be.

- The body is the basis of the hay chopper. Choose a diameter such that the knives do not come into contact with the walls.

- Shaft with knives . Fixed knives must be made of durable steel and well sharpened.

- Receiving container for finished raw materials . It is better to position it relative to the body at an angle.

- Supports and stands . The ideal implementation of this part of the device is made of metal pipes with a diameter of up to 25 mm.

Common mistakes when assembling a chopper

Incorrect assembly of the wood shredder leads to problems during its operation. The most common mistakes are:

- The shaft diameter does not match the saw hole. If the saws rotate freely, this will create additional vibration, which will lead to destruction or deformation of the shaft.

- Rigid fixation of belt or chain drive. This can lead to rapid belt wear and failure. In addition, the inability to adjust the gear tension makes it difficult to transfer power to the shaft, which degrades the performance parameters of the equipment.

- Incorrect sharpening of knives. This is the most common mistake that craftsmen make when making cutting devices from car springs on their own. You can either entrust this operation to professionals, or independently adjust the rotation parameters of the cutting mechanism with great care.

- No protective cover. This is a disregard for labor protection requirements. Flying wood waste can injure a person (it is especially dangerous if it gets into the eyes).

Thus, it is quite possible to make a shredder for branches and grass yourself. All you need to do is find a drawing on the Internet, purchase or find the necessary materials and carry out the work. Particular attention should be paid to welding and the process of making knives. Most mistakes are made at this stage. If you follow safety rules and assembly instructions, the branch crusher will work for a long time, and your summer cottage will always be clean.

Purpose

A machine for chopping different types of wood is a useful machine. With its help, branches are processed into sawdust. In this process, chips are obtained from more or less large branches, which are used in the production of fuel briquettes, building materials, paper and cardboard. There is also more than one production facility where railroad sleepers and other “dirty” types of wood are processed.

Depending on the type of machine, both branches and large pieces of wood can be used for processing. Crushing turns all wood material into chips, which are then used on the farm.

Also, with the help of a crusher, household waste is recycled. Grinding will turn waste into fertilizer for the garden, or simply make it convenient for transportation.

The crusher provides:

- Recycling. Some materials, after grinding, can be used on the farm.

- Cleanliness. After cleaning and shredding all the debris, the yard will become much cleaner.

Another advantage of the crusher is that it can quickly pay for itself. Neighbors will be interested in shredding, so equipment can be borrowed or rented.