Audi A4 › Logbook › Restoring ball joints

Without delving into the origins and essence of the problem, I will still say that it worries the owners of the notorious, so-called “VAG multi-lever” especially acutely.

On the Internet, however, you can find a bunch of ways to restore these components, but not every lever can be brought back to life using the “old-fashioned method”

There is also, of course, a cool way, in my opinion, of introducing a melt of some polymer into the inside of the ball/tip. Here are examples

And I got confused, as it turned out later, not in vain, in my opinion. The design came to me as simple as a hammer. These are two connecting nuts with Mx12 threads welded end to end (this is our cylinder) and a bolt of the same thread and diameter of sufficient length, which acts as a piston. This resulting screw syringe must be supplemented with a removable tip which, oddly enough, is essentially also an Mx6 bolt drilled along the axis of rotation with a drill D=3mm. Well, then I think many people guessed how and what))

In the body of the worn ball/lever, drill a hole D=5mm, drill straight to the ball and cut an Mx6 thread in it with a short tap. Next, using something like gasoline/kerosene and a medical bulb (I used a regular solvent), we rinse the internal cavity through the resulting hole to remove grease, dirt and other nonsense, not forgetting to first remove the old boot or its remains. Frankly speaking, the process is not fast, but I don’t recommend saving time on it; I will say this - you need maximum cleanliness of the working cavity.

Now, we charge our syringe with material previously purchased from one of the online stores. (The price is not great) I ordered and bought caprolon in the form of a cylindrical blank D = 50mm and so I had to grind it, which, by the way, was not so easy (I sawed it with a hacksaw metal, bit with wire cutters, sharpened with a file, even grated on a kitchen grater))))

Well, the material is crushed, we charge the syringe to its fullest, periodically tightening the bolt and thereby tamping the filling inside. Our lever has already been washed and dried. The syringe filled with material is connected through a thread to a lever. Next, we heat the syringe, the ball pin, and a little of its body with a burner. After making sure that the material is melted, use a crooked wrench or ratchet. Yes, we quickly tighten the bolt with whatever we like until it stops, thereby filling the voids of the working cavity with caprolon. A successful result will be the visible appearance of new material in the gaps between the ball and the old cracker in the place where the boot used to be, i.e. at the bottom. Next, we cool this structure, I did it with water. Strictly speaking, that's all, it's all about new silents and anther.

Several important points that were not covered in the main text, so as not to overload it. 1. I recommend making the tip of the syringe removable and wrapping it on a foam tip, so that you can then easily twist it and drive our cylinder with a tap, and thereby clean it of polymer residues. 2. I determined the required heating temperature with a piece of the same caprolon, when it began to melt on the cylinder, I heated it a little more and started pouring (I don’t have a pyrometer))) 3. Before “tormenting” your own levers, I strongly recommend practicing the skill, a couple of times, on balls that are no longer needed (for example, from classics). It won't be unnecessary! 4.And now about caprolon itself. Studying the assortment of online stores selling similar things, someone will probably pay attention to various modifications of this material, I mean various fillers such as graphite, oil, etc. I did not consider such options, due to the fact that there is no reliable information about how they melt and whether they retain their miraculous properties when transitioning from one state of aggregation to another.

Source

Do-it-yourself device for restoring ball joints - Metals, equipment, instructions

The suspension arm is connected to the center of the wheel (hub) using a ball joint. Symptoms of failure of this unit are: knocking while driving over bumps, “swaying” of the car on a flat road, uneven wear of the tires and creaking when turning the steering wheel all the way. For what reasons can a ball joint fail?

Causes of ball joint wear

The main enemies of the ball have always been water and dirt. They can get to the joints only if the boot wears out - a rubber cover that protects the hinge from external influences. It either wears out during operation (dries out, cracks), or can be damaged mechanically (for example, during suspension repairs).

The service life of the ball joint varies from 15 thousand km to 120. The indicator depends on the operating conditions of the car and the condition of the protective boot.

Self-diagnosis

The best option to find a fault is always a diagnostic stand at a service station. But it is also possible to find the breakdown yourself. To determine the malfunction of the ball joint by ear, you will need an assistant who will rock the car from side to side, while the owner himself carefully listens to all the creaks and knocks that the suspension makes.

Checking the condition of the ball joints visually is much more effective, but you will need an inspection hole or a lift. The assistant holds the brake pedal, and the owner rocks the wheel. If there is play, then the ball joint must be changed or, in order to save money, try to restore it.

Repair and restoration of the ball joint

The ball joint can be either collapsible (for example, in domestic cars) or non-dismountable. Of course, it is much easier to repair a unit that can be disassembled for spare parts. The ball is dismantled, disassembled and worn parts are replaced. As a rule, these are polymer inserts and anther. Then install the unit in place. The repair of ball joints (dismountable) is completed.

If the ball cannot be disassembled, then either a grinder is used to make the support collapsible, but after repair the structure is restored by welding, or they use a more humane method and pour liquid polymer into the ball under pressure.

Many people recommend disassembling the support in any case to grind the axle ball or replace it.

How to disassemble something that cannot be disassembled

Before disassembling the ball joint, it must be removed. For this:

- We jack up the car and remove the wheel.

- Turn the steering wheel all the way.

- Remove the cotter pin from the nut using pliers.

- Unscrew the nut and use a puller to squeeze out the axle.

- Unscrew the ball mount.

- Using a pry bar, press the lower lever, and you can remove the ball.

Now you need to disassemble the support. If it consists of two welded cups, then you need to drill several welding points on one of them, and then use a chisel to separate these cups. Then a finger with an insert is inserted into the body, and the cup halves are welded together. It is worth making sure that this liner does not overheat.

If the body has an inserted bottom, then the flared edges are cleaned with a grinder or emery cloth. Then they hit the end of the axle with a hammer to knock out the bottom.

The outer and inner diameters of the body are measured and a steel ring 10 mm high with thread and plug is made. It is welded to the support body. Insert the finger with the liner and screw in the plug so that it presses the liner.

A 2 mm hole is drilled in the ring as close as possible to the plug and it is secured with a cotter pin.

To install the ball joint in place, you must:

- Attach the ball to the lower arm and secure it.

- Install the pin (axle) into the seat, while pressing the lower lever.

- Tighten the nut onto the pin.

- If the finger rotates at the landing site, use a pry bar to pull the lever up.

When installing the support in place, you will not need a puller. It will be easier to remove and install the ball again if you replace the cotter pin with self-locking nuts.

Liquid polymer application method

Ready-made rods filled with liquid polymer are available for sale to restore ball joints with your own hands. The polymer composition is specially designed for components with increased load.

It withstands pressure over 1000 kg/cm2 and dampens friction. Not affected by lubricants. Ensures the restoration of the ball joint and its operation for another 100,000 km.

This repair method can be used several times.

The technology of this method is quite simple. Using an extruder with pneumatic force, the polymer is injected through a special hole into the assembly body. It fills the voids inside, completely follows the contour of the support pin and takes on all the loads.

Ball joint repair machine

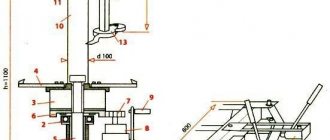

To correctly perform work on restoring the ball joint, you must use a machine. It is designed to measure the temperature of the polymer and correctly feed it into the ball housing.

A standard machine for restoring ball joints consists of:

- from the control unit;

- extruder;

- compressor;

- pneumatic cylinder;

- thermal pencil;

- several adapter nozzles;

- polymer.

The extruder with the polymer inside is screwed to a pneumatic cylinder. A threaded hole is made in the worn support and an adapter nozzle of the required size is inserted into it, which is connected to the extruder with a nozzle.

After the polymer material becomes soft, a pneumatic cylinder is launched, which squeezes it through the plunger and nozzle into the support. If the material is filled incorrectly, the ball will last about 30,000 km.

It is worth considering that overheating a polymer material deprives it of all its necessary properties. Therefore, you should carefully read the instructions supplied with it and monitor the temperature according to the machine readings.

You can construct equipment for restoring ball joints yourself: make an extruder on a lathe, and buy the remaining parts at a hardware store.

The only reason why this technology cannot be used is corrosion and mechanical damage to the metal structure itself. In this case, the ball joint is not subject to any restoration and, accordingly, to further use.

Restoring the ball joint. Including liquid polymer, we repair it ourselves

I already wrote about the design of the ball joint, you can read it here . In that article, I briefly touched on the problem of repair, but many of my readers began to write - is it possible to restore it yourself.

At first I thought that this was not the right saving, but after understanding the problem, it turns out that sometimes it is much more profitable to repair.

Once again I emphasize much! The thing is that the supports are currently installed in the levers and cannot be removed! This is not the same structure as it used to be on our VAZs...

That is, the ball joint used to be removed in 95% of cases, it was physically unscrewed from the suspension arm (in our VAZs they were called “burdocks”), and in many foreign cars of the 90s - 2000s they were often removable. Now many manufacturers weld supports into the lever or into the steering rack. They are not removable.

Thus, you not only need to change the “ball” but also the entire lever! And this can be very expensive in terms of money. For example, on Mitsubishi the cost of one can reach up to 20 - 25,000 rubles for the original, for BMW - up to 50,000! Therefore, whether willingly or not, the question of restoration arises.

Repairing ball joints with polymer using the sjr method: how and why?

Every owner of his own car dreams of saving on its maintenance. Replacing ball joints is one of the expense items, especially taking into account our roads. And if the suspension design involves simultaneous replacement of the ball and lever, the question becomes a pretty penny. To help drivers, SJR technology was invented - restoration (repair) of ball joints with polymer.

Why is ball joint repair necessary?

The suspension arms hold the steering knuckle with the hub using ball joints. This is actually the steering axis of the wheel. The unit experiences loads from all sides and wears out quite quickly on uneven roads. Play in the ball joint leads to loose suspension, and, more dangerously, to inaccuracy in the steering. Critical wear can lead to the destruction of the support - and then the car’s wheel will simply fall off. Probably many have observed a similar picture.

Of course, the wheel does not always fall over, especially on foreign cars, but VAZs suffer from this

It’s good if this happens on an unloaded road and at low speed. What if it’s on the highway and high? The consequences can be dire. Therefore, when minimal play appears, you should try to determine possible malfunctions of the ball joints.

Do-it-yourself machine for restoring ball joints - Metalworker's Guide

Every owner of his own car dreams of saving on its maintenance. Replacing ball joints is one of the expense items, especially taking into account our roads.

And if the suspension design involves simultaneous replacement of the ball and lever, the question becomes a pretty penny.

To help drivers, SJR technology was invented - restoration (repair) of ball joints with polymer.

Why is ball joint repair necessary?

The suspension arms hold the steering knuckle with the hub using ball joints. This is actually the steering axis of the wheel. The unit experiences loads from all sides and wears out quite quickly on uneven roads.

Play in the ball joint leads to loose suspension, and, more dangerously, to inaccuracy in the steering. Critical wear can lead to the destruction of the support - and then the car’s wheel will simply fall off.

Probably many have observed a similar picture.

Of course, the wheel does not always fall over, especially on foreign cars, but VAZs suffer from this

It’s good if this happens on an unloaded road and at low speed. What if it’s on the highway and high? The consequences can be dire. Therefore, when minimal play appears, you should try to determine possible malfunctions of the ball joints.

Polymer restoration using SJR technology

Did the diagnostics reveal a dangerous gap between the ball and the support liner? A dilemma arises: change or restore. Let us briefly describe the structure of the ball joint.

In the areas marked in red, wear is maximum

The unit consists of two parts, a cage and a rotating ball. Between them is a polymer that dampens hard impacts and reduces friction between metal parts. The system works on the principle of a joint capsule in the human legs. It is this polymer that wears out over time, and dangerous play appears.

Since it is impossible to disassemble the ball joint to replace the liner, there is only one thing left to do - melt the polymer and pour it inside. This is the essence of the sjr method.

Pouring polymers can be of different types

- A hole is made in the outer casing (clip) of the ball joint. You can use a ready-made grease fitting, if available.

- Using a gas burner, the ball joint is heated to the melting point of the polyamide.

- At the same time, blanks (cartridges) made of polyamide, similar to the standard one, are heated in a special extruder.

- Using an extruder under high pressure, the melt is injected into the cavity between the holder and the moving ball. Moreover, all the cracks, crevices and hollows of the standard liner are filled.

- The polymer hardens, taking the shape of the gap. The play has been eliminated, the ball joint has been restored.

Advantages of this method:

- Versatility and affordability.

- Compactness and mobility of equipment.

- Can be used both in a small service station and in your own garage.

- Available consumables.

There are also methods using stationary equipment. The repair technology is close to the factory one used in the manufacture of new ball joints. The cost of repair is approaching the price of a new unit, which makes the process unprofitable.

What is needed for the work

The economy class set is shown in the photo:

The cost of the kit will be recouped only after a while. Rarely does anyone buy it at once - it’s unprofitable

- The most important part of the kit is the extruder. It heats up and forms the consistency of polyamide.

- Transition fittings, with the help of which the melt is poured under pressure into the ball joint.

- A gas torch or a hair dryer to heat up the ball joint (if this is not done, the polymer will harden when pouring, and there will not be 100% filling).

- Remote thermometer to control heating.

- An air compressor that creates pressurized air for the extruder.

A more advanced version has a piston that creates pressure for the extruder without the use of compressed air.

As you can see, there are also many types of equipment

There is no need to buy a compressor, but the kit itself is more expensive. But you can control the heating temperature using your own thermometer (again, there is no need to purchase one). A gas torch or hair dryer is still needed to warm up the ball joint before filling.

Important! The mobile kit allows you to perform work directly under the bottom of the car without removing the ball joint.

However, this is not recommended, since local heating using a burner is impossible, and there is a danger of damaging the brake hoses or rubber boots.

Therefore, do not be lazy to dismantle the ball joint and carry out the work on a workbench.

The workbench will provide convenience and safety

Making an extruder with your own hands: details about the complex

If you have a home locksmith workshop, you can make the device yourself; in extreme cases, you should use the services of a turner.

- It is necessary to make a tightly fitted piston and cylinder.

Diameter 10–15 cm, length 20–30 cm. The part should not be too bulky - O-rings can be made of rubber, but in most cases a thick grease will suffice.

Make O-rings from quality rubber - A fitting for supplying compressed air is connected to the cylinder on the blind side.

It is equipped with a ball valve. Hook up the air injection fitting - An adapter is screwed into the open part of the air cylinder.

It is equipped with a lock for fixing the cylinder in which the polymer is heated. Equip the device with an adapter - The polymer cylinder is smaller.

Due to the difference in diameters, the pressure when pressing the polymer is higher than that supplied from the compressor. Pay attention to the proportions of the polymer barrel and the extruder body itself

An extruder is sometimes called a remanufacturing machine or stand.

Restoring balls using a homemade extruder

Once the extruder is assembled, you simply load the polymer cartridge into the barrel and connect it to the prepared hole in the ball joint.

While simultaneously heating the ball body and the cylinder with polyamide, you shake the ball pin for uniform penetration of the melt. Once the air cylinder in the extruder stops, the process is considered complete.

Allow the polymer to harden inside the part, and you can install the ball joint on the car.

Filling balls on a Toyota Corolla: video

There is no need to remove the polyamide from the cylinder after work. It will melt again when the next part is restored.

By making such a device, you will not only be able to save on suspension maintenance, but also earn money by providing similar services to friends. The cost of purchasing components for the extruder is recouped after rebuilding a pair of ball joints.

Ball joint restoration machine

» Machine » Machine for restoring ball joints

Ball joints prevent the vehicle's front wheels from turning outward, keeping them upright. The supports constantly withstand enormous loads, so they have to be changed quite often.

Moreover, for some models, they can only be replaced together with the control lever, and this is an expensive and complicated procedure.

There is a technology for restoring supports that saves money for car owners and even machines that craftsmen make with their own hands.

Ball joint device

The ball joint is the front suspension element that bears the main load. It can be lower or upper. The main part is a finger with a round head. The head is enclosed in a dirt-proof cover with lubricant.

The entire device is hidden in a plastic case, which over time begins to let dirt through. Getting between the head and the cover, sand and earth scratch the head and the protective shell of the cover.

Penetrating moisture causes rust.

Modern restoration technology allows you to repair the supports yourself, without disassembling the car.

Under pressure, a special type of molten polymer is injected into the housing of the support assembly.

Polymer restoration using SJR technology

Did the diagnostics reveal a dangerous gap between the ball and the support liner? A dilemma arises: change or restore. Let us briefly describe the structure of the ball joint.

In the areas marked in red, wear is maximum

The unit consists of two parts, a cage and a rotating ball. Between them is a polymer that dampens hard impacts and reduces friction between metal parts. The system works on the principle of a joint capsule in the human legs. It is this polymer that wears out over time, and dangerous play appears.

Since it is impossible to disassemble the ball joint to replace the liner, there is only one thing left to do - melt the polymer and pour it inside. This is the essence of the sjr method.

Advantages of this method:

There are also methods using stationary equipment. The repair technology is close to the factory one used in the manufacture of new ball joints. The cost of repair is approaching the price of a new unit, which makes the process unprofitable.

What is needed for the work

The economy class set is shown in the photo:

A more advanced version has a piston that creates pressure for the extruder without the use of compressed air.

As you can see, there are also many types of equipment

There is no need to buy a compressor, but the kit itself is more expensive. But you can control the heating temperature using your own thermometer (again, there is no need to purchase one). A gas torch or hair dryer is still needed to warm up the ball joint before filling.

Important! The mobile kit allows you to perform work directly under the bottom of the car without removing the ball joint. However, this is not recommended, since local heating using a burner is impossible, and there is a danger of damaging the brake hoses or rubber boots. Therefore, do not be lazy to dismantle the ball joint and carry out the work on a workbench.

Removal and installation

If after carrying out diagnostic measures it becomes clear that the unit is worn out, it must be repaired. Many novice car owners cope with all the work and restore the ball joints with their own hands. To remove and install the support after repair, you will need several tools:

- Special puller for supports.

- Car stand.

- Jack.

- Mount.

- Pliers.

- A set of keys.

Most often, ball joint pullers are not universal. If you cannot find the required tool, you can solve the problem using a hammer. Moreover, its weight should be about 600 grams. In addition, you need to know the place where you should strike so as not to damage the node.

There is no need to try to knock your finger out of the seat. The blow should be directed perpendicular to the finger along the eyelet. To remove the ball joint, you first need to loosen the front wheels and jack up the car. After this, the wheel is removed.

If the nut on the pin has a cotter pin, it should be removed using pliers. This will allow you to unscrew the nut and use a puller or hammer to squeeze out the pin. After this, you should unscrew the housing mount and, using a pry bar, press the lower lever to remove the support.

To install the unit after repair, you first need to attach the housing to the lower arm. After tightening the fasteners, use a pry bar to release the lever and return the pin to the socket. Then the nut is screwed onto it and tightened. If after this the finger rotates, then the lower lever must be pulled up. The last step will be to install the cotter pin on the nut or replace the old one with a self-locking one.

Making an extruder with your own hands: details about the complex

If you have a home locksmith workshop, you can make the device yourself; in extreme cases, you should use the services of a turner.

Pay attention to the proportions of the polymer barrel and the extruder body itself

An extruder is sometimes called a remanufacturing machine or stand.

Equipment operation diagram on video

Restoring balls using a homemade extruder

Once the extruder is assembled, you simply load the polymer cartridge into the barrel and connect it to the prepared hole in the ball joint. While simultaneously heating the ball body and the cylinder with polyamide, you shake the ball pin for uniform penetration of the melt. Once the air cylinder in the extruder stops, the process is considered complete. Allow the polymer to harden inside the part, and you can install the ball joint on the car.

Filling balls on a Toyota Corolla: video

There is no need to remove the polyamide from the cylinder after work. It will melt again when the next part is restored.

By making such a device, you will not only be able to save on suspension maintenance, but also earn money by providing similar services to friends. The cost of purchasing components for the extruder is recouped after rebuilding a pair of ball joints.

Source

Repairing ball joints with polymer using sjr technology, how to make an extruder with your own hands

Every owner of his own car dreams of saving on its maintenance. Replacing ball joints is one of the expense items, especially taking into account our roads. And if the suspension design involves simultaneous replacement of the ball and lever, the question becomes a pretty penny. To help drivers, SJR technology was invented - restoration (repair) of ball joints with polymer.

What is needed for the work

The economy class set is shown in the photo:

The cost of the kit will be recouped only after a while. Rarely does anyone buy it at once - it’s unprofitable

- The most important part of the kit is the extruder. It heats up and forms the consistency of polyamide.

- Transition fittings, with the help of which the melt is poured under pressure into the ball joint.

- A gas torch or a hair dryer to heat up the ball joint (if this is not done, the polymer will harden when pouring, and there will not be 100% filling).

- Remote thermometer to control heating.

- An air compressor that creates pressurized air for the extruder.

A more advanced version has a piston that creates pressure for the extruder without the use of compressed air.

As you can see, there are also many types of equipment

There is no need to buy a compressor, but the kit itself is more expensive. But you can control the heating temperature using your own thermometer (again, there is no need to purchase one). A gas torch or hair dryer is still needed to warm up the ball joint before filling.

Important! The mobile kit allows you to perform work directly under the bottom of the car without removing the ball joint. However, this is not recommended, since local heating using a burner is impossible, and there is a danger of damaging the brake hoses or rubber boots. Therefore, do not be lazy to dismantle the ball joint and carry out the work on a workbench.

The workbench will provide convenience and safety

Making an extruder with your own hands: details about the complex

If you have a home locksmith workshop, you can make the device yourself; in extreme cases, you should use the services of a turner.

- It is necessary to make a tightly fitted piston and cylinder.

Diameter 10–15 cm, length 20–30 cm. The part should not be too bulky - O-rings can be made of rubber, but in most cases a thick grease will suffice.

Make O-rings from quality rubber - A fitting for supplying compressed air is connected to the cylinder on the blind side.

It is equipped with a ball valve. Hook up the air injection fitting - An adapter is screwed into the open part of the air cylinder.

It is equipped with a lock for fixing the cylinder in which the polymer is heated. Equip the device with an adapter - The polymer cylinder is smaller.

Due to the difference in diameters, the pressure when pressing the polymer is higher than that supplied from the compressor. Pay attention to the proportions of the polymer barrel and the extruder body itself

An extruder is sometimes called a remanufacturing machine or stand.

Restoring balls using a homemade extruder

Once the extruder is assembled, you simply load the polymer cartridge into the barrel and connect it to the prepared hole in the ball joint.

While simultaneously heating the ball body and the cylinder with polyamide, you shake the ball pin for uniform penetration of the melt. Once the air cylinder in the extruder stops, the process is considered complete.

Allow the polymer to harden inside the part, and you can install the ball joint on the car.

Filling balls on a Toyota Corolla: video

There is no need to remove the polyamide from the cylinder after work. It will melt again when the next part is restored.

By making such a device, you will not only be able to save on suspension maintenance, but also earn money by providing similar services to friends. The cost of purchasing components for the extruder is recouped after rebuilding a pair of ball joints.

- Vladimir

Why is ball joint repair necessary?

The suspension arms hold the steering knuckle with the hub using ball joints. This is actually the steering axis of the wheel. The unit experiences loads from all sides and wears out quite quickly on uneven roads. Play in the ball joint leads to loose suspension, and, more dangerously, to inaccuracy in the steering. Critical wear can lead to the destruction of the support - and then the car’s wheel will simply fall off. Probably many have observed a similar picture.

Of course, the wheel does not always fall over, especially on foreign cars, but VAZs suffer from this

It’s good if this happens on an unloaded road and at low speed. What if it’s on the highway and high? The consequences can be dire. Therefore, when minimal play appears, you should try to determine possible malfunctions of the ball joints.

Replacement of ball joints and restoration (restoration): what you need to know - Auto Service

The ball joints carry the load of the front end of the vehicle, including the weight of the engine. At the same time, when moving, they receive constant impacts from the wheels in any direction. No matter what durable material these parts are made of, their service life is limited. It’s good that in many cases restoration with your own hands is possible.

Is it possible to drive with faulty ball joints?

Of course not, this is directly related to security.

- When the ball joint is dismembered, the wheel breaks and its rotation is blocked.

The car instantly leaves the trajectory. The consequences can be fatal. Weak ball joints pose a real safety hazard! - Moving with play in the ball joint leads to loss of controllability. At the right moment, you may not have time to make a maneuver.

- At the first signs of wear on these components, it is necessary to undergo suspension diagnostics.

Thus, having determined the symptoms of a malfunction, conclusions are drawn about the repairability of the part. Once critical wear is detected, the ball joints must be replaced. However, their cost is quite high, especially if they are integral with the suspension arm. Therefore, many car enthusiasts prefer to make repairs.

How can I restore functionality?

It is important to know! After repair, the ball is not restored to the condition of a new part. The service life will be shorter. But you don’t have to worry about operational safety.

There are many recovery methods. A fairly popular repair method is the SJR technology, when molten polymer is pumped into the cavity between the holder and the ball.

We will consider repairs with disassembly of this unit.

To understand the mechanism of operation of the support, look at the diagram:

Often the problem occurs due to damage to the boot, and not to the metal itself

Only the polymer liner is subject to wear. It is when it is abraded that backlash appears. If you continue to drive with a loose ball joint, the top of the cylinder will also break, and then the pin may fly out of the race.

Inserts are sold in car dealerships as consumables. If your ball joint is collapsible, you can easily pull out the bottom and replace the polymer inside the product.

Consumables can be sold in a store at a more reasonable price than buying a new spare part

Ball restoration options

First of all, the assembly must be removed correctly. The finger sticks so tightly to the suspension arm that it is practically one piece with it. Beforehand, preferably one day before, the joint is treated generously with penetrating liquid. Use WD-40 or regular kerosene. There are two ways to remove your finger from the eyelet:

- Press out with a ball joint remover.

This is the most painless and reliable method, but a puller is not always at hand. There are no universal devices, and the designs for fastening the ball joint are different. Example of a ball joint remover - The second method is more universal, but there is a risk of damaging the thread on the support pin. It is necessary to screw a nut made of strong steel (hardness 9.8) onto the tip of the ball and knock the ball out of the eye with precise short blows of a hammer.

Important! Do not hit the finger directly. You will rivet the threaded connection, and it will be impossible to screw on the working fastening nut.

So, the ball joint is in your hands. The outer cylinder (cage) is a monolithic structure. It is impossible to remove the finger.

Ball joint options for different car models

Making a serviceable cover

The blind part of the support body is made removable. At the same time, you can change the plastic inserts many times, each time restoring the functionality of the support. The removable bottom allows for routine inspection without removing the ball joint from the suspension.

Plug: do it yourself

- A hole the size of a finger ball is drilled in the bottom (with a small gap, of course). It is drilled out - it is said conditionally. A milling machine is required.

Don’t be afraid to damage the plastic liner when boring, you will still need to change it.The thread is cut inside. This is a rather complicated procedure due to the large diameter.

But in any tool shop they will do this kind of work for a nominal fee.

Entrust the work to professionals if you are not one yourself

- Then a threaded plug is made for this hole, repeating the shape of the standard bottom.

Tip: To make the plug accurately, use two ball joints. Cut the bottom off one using a grinder and use it as a template for the shape. - On the manufactured bottom, you must cut slots for the key, otherwise it will be impossible to firmly tighten the repair unit.

Replace on a clean surface, otherwise the meaning of the work is lost. - Now for repairs it will be enough to unscrew the plug, remove the pin (checking its geometry) and replace the plastic inserts.

Important! It is necessary to ensure that the thread is locked, otherwise the bottom may unscrew during operation.

Repair glass: everything ingenious is simple

The principle is the same as in the first case - to make a replacement bottom. Only the execution is different.

If the bottom of the support is too thin to make a full threaded connection, it is necessary to make a repair cup. It is turned on a lathe from a steel circle of suitable diameter.

The same hole is made in the bottom of the glass and a thread is cut. And finally, the support replacement bottom is made.

Then the bottom of the cylinder is cut off from the ball joint using a grinder or a hacksaw. A repair glass is welded in its place. The method is more labor-intensive, but it does not allow the finger to heat up during the dismantling process.

Scheme for manufacturing a product variant

Further operation follows the same scheme: when play appears, unscrew the repair plug, remove the pin, change the plastic inserts.

It is worth noting that spare parts manufacturers produce many options for repair ball joints. Replacement inserts and new pins are sold for these collapsible housings. However, in our article we are considering self-production.

Welding as an alternative to replacement

The fastest option for restoring a ball joint. The rear (supporting) part of the cylinder is simply cut off. The method doesn’t matter - you can use a hacksaw, or you can use a grinder, but there will still be a temperature effect afterwards.

Having gained access to the cylinder cavity, you can change the polymer liners.

Important! Before installing new liners, be sure to remove any burrs formed during cutting. Torn metal edges will quickly split the liners during use.

After installing the new liners, the bottom is carefully welded. In this case, it is necessary to compensate for the production of metal formed during cutting with the thickness of the seam. Usually it is 1.5–2 mm.

Welding is one of the most painstaking options

Important! Use a welding method that minimizes temperature effects. The polymer liner inside may reach the melting point. Therefore, until it cools completely, do not apply any loads to the finger to avoid deformation of the liner.

Flaring as a repair method

This technology requires professional equipment, so it is impossible to flare a ball in a garage. A crimp ring is cut to fit the diameter of the finger ball.

Turning work will find its place here too

The seat and ball are cleaned of dirt and polished. New liners and a crimp ring are selected or machined from caprolon.

It happens that caprolon is not available, but replacing it with steel is not recommended. It’s better to spend money on this material once than to replace it more often than it could be

After assembly, the crimp ring is pressed in and rolled on a press. When crimping, special inserts-clips are used according to the diameter of the ring.

Inserts can also be found in car dealerships.

Which restoration method is better?

- The threaded plug looks preferable since there is no temperature effect on the support. However, this method requires a thick bottom, which is not always present on compact parts.

- A glass with thread is the golden mean. Welding occurs without affecting the plastic, but the strength characteristics of the metal deteriorate.

- Welding is the simplest, but ineffective method. After treatment at high temperatures, new polymer inserts lose their properties and their service life is reduced.

- Flaring is an ideal method from a quality point of view. You actually get a new ball joint, manufactured using factory technology. However, this technique does not work at home.

Reviews on ways to repair the mechanism

mogui

https://forums.drom.ru/habarovsk/t1151615673-p2.html

Zhornic

https://www.land-cruiser.ru/index.php?showtopic=120678

ArxivatoR

https://www.drive2.ru/l/1354317/

maleid

https://forum.onliner.by/viewtopic.php?t=1118334&start=40

To decide how to repair your suspension, just calculate the cost of restoration. In some cases, it makes sense to buy a new unit; sometimes repairs will be more cost-effective. In any case, a variety of options gives you a chance to save money.

Restoration and strengthening of ball joints — Community “Mercedes SUV Club” on DRIVE2

Let me make a reservation right away... the technology is not cheap and is “sharpened” mainly for the restoration and strengthening of suspension parts of “fresh” cars, where “unit-by-unit” assembly is already used and the replacement of suspension parts during repairs begins to bite even far from poor people, although the installation new does not mean quality and durability. Here is a simple example: both parts are original!

- On the left is a freshly purchased original, on the right is an old (2000) original part.

Zoom

Both balls are original

Zoom

Is there a noticeable difference in the manufacturing process?

Zoom

The diameter of the new ball is 4 mm smaller than the old original

After reading a bunch of information on various restoration methods, we created our own, and not without reason, we believe that the 100,000 km guarantee that we give at the initial stage is far from the limit of “mileage”. It’s just that we don’t yet have developed analytics with higher mileage... To be continued... I’ll continue this post while I have the opportunity...

- Each ball and/or lever is completely disassembled, defective and sent for revision...

Zoom

These are the fingers we extract from the ball ones...

Zoom

Their condition leaves much to be desired...

Zoom

Due to the specifics of the conveyor processing technology, all balls do not have a bottom part, which, when assembling the ball on a conveyor, leaves a cavity underneath, which is one of the factors in support wear

How to lubricate ball joints

Various extraneous noises that irritate the driver when driving often have the same cause - insufficiently lubricated ball joints (BJ). Should we treat this as an unfortunate inevitability, or is it better to lubricate the supports? Each driver decides for himself, but there are proven recommendations based on practical experience. It is preferable to follow them if you do not want to spend extra money due to problems with such an important car part as ball joints.

To lubricate or not?

Do ball joints need to be lubricated before installation and during operation? To give the correct answer, it is worth understanding the principle of construction of any of these supports. It can be designed in different ways, but it must have a ball joint, as well as a pin. The base serves to support the hinge; the boot covers the support on top.

During operation, the hinge constantly shifts, which contributes to its rapid wear. In addition, dirt often accumulates in the empty space between the base and the boot, which interferes with the operation of the part. An alarming sign in this case is the appearance of knocks and creaks. To prevent this from happening, the space under the boot must be completely filled with auto-lubricant. It is very important to know what is the best way to lubricate ball joints for the most durable operation.

How to lubricate ball joints

How to lubricate the ball joint before installation? The most common options are:

Among lithium auto lubricants, Litol-24 and CIATIM-201 are popular. They contain oil and lithium soap in different proportions, and they also differ in the composition of additional additives.

The stabilizing substances present in Litol-24 ensure good preservation of the hinge and low lubricant consumption during its operation. However, this auto lubricant does not tolerate low temperatures well. CIATIM-201 stabilizes SHO to a lesser extent, but it better protects them from frost, and is cheaper.

Device and purpose

The ball joint allows for a reliable movable connection between the wheel hub and the suspension arm. The assembly includes a housing, a ball pin , and an insert made of plastic. The body most often has a welded structure - two parts with a stamped spherical recess for the finger are connected using spot welding.

Essentially, this element is a thick-walled glass made of metal into which an insert with a finger is then inserted. To make the housing structure non-separable, its edges are flared. Often the liner is not manufactured separately, but the area between the walls of the housing and the ball surface of the finger is filled with a special polymer material. To protect the unit from dirt and water, a boot is placed on top.

It should be noted that active wear of the ball joint begins after the boot is damaged . Until this happens, the unit is practically not subject to wear. Thus, if you monitor the condition of this element and replace it in a timely manner, you can significantly increase the life of the unit.

However, it is worth remembering that the weld joints do not have sufficient tightness and even with an intact boot, water can get inside. To avoid this, the case should be filled with lithol.

Polymer restoration using SJR technology

Did the diagnostics reveal a dangerous gap between the ball and the support liner? A dilemma arises: change or restore. Let us briefly describe the structure of the ball joint.

In the areas marked in red, wear is maximum

The unit consists of two parts, a cage and a rotating ball. Between them is a polymer that dampens hard impacts and reduces friction between metal parts. The system works on the principle of a joint capsule in the human legs. It is this polymer that wears out over time, and dangerous play appears.

Since it is impossible to disassemble the ball joint to replace the liner, there is only one thing left to do - melt the polymer and pour it inside. This is the essence of the sjr method.

Pouring polymers can be of different types

Advantages of this method:

There are also methods using stationary equipment. The repair technology is close to the factory one used in the manufacture of new ball joints. The cost of repair is approaching the price of a new unit, which makes the process unprofitable.

Equipment for repairing ball joints using SJR technology — obd2scan.ru on DRIVE2

The In-Place Ball Joint Repair (Ball Joint Remanufacturing) system has been designed to rebuild the front suspension and steering of all types of vehicles to maintain tr. The device is in working order and easily manageable. The use of the system can be considered an innovative, cost-effective method for vehicle owners in carrying out a maintenance program, and this method is transferred from passenger cars to heavy-duty vehicles, military vehicles, all-terrain vehicles, etc.

This system was developed, copyrighted and distributed in the USA. This system allows the mechanic to restore almost all tie rods, ends, ball joints, links, etc., included in the steering and front suspension systems of large and small vehicles and can be used in almost all auto repair shops to restore parts that are not completely worn out .

A special polymer is injected into the assembly, which is supplied in the form of ready-made rods and which is formulated to withstand high pressure (compressive force up to 18,000 ft per 1 sq. in. (1,300 kg/sq. cm.), approximately 130 MPa and torsion 12,000 feet per square inch). This material is designed to absorb dynamic impact and friction, is not affected by lubrication, and guarantees a range of up to 100,000 km. in the USA (for passenger cars) or 6 months. guarantees subject to complete suspension repair in Russia.

The molten polymer is injected into the assembly through the lubrication hole (if there is none, the hole is drilled and a thread is cut for the fitting) under high pressure (100 atm.) using a special device. After injection, the polymer becomes an ideal liner with high compression ability, lubricating properties, and also absorbs friction. Repairs can be made on the same unit more than once. After restoration, the quality of the unit is comparable to the original spare part.

Restoring ball joints using the SJR system is a great addition to the services of your car service!

The delivery set includes: 1 Extruder (machine) 2 Adapters 3 pcs. 3 Pressure regulator 4 Pyrometer 5 Polymer 10 pcs.

6 Blow gun

Additionally, to get started you will need: - Pneumatic compressor (pressure 8-10 atm, performance does not matter - extruder volume is about 1 liter); - Gas burner or hot air gun (heating temperature 180-200 degrees C); - Equipment for drilling holes and thread cutting M6 (required for some ball joints) You can purchase equipment for repairing ball joints in Krasnodar at the address: st. Hakurate 12, office 05.

Or order with delivery by a transport company in Russia on the website www.obd2scan.ru

Consumable polymers are always in stock.

www.drive2.ru

Equipment for restoring ball joints

The quality of our roads does not need any additional description and is well known not only to all drivers, but also to passengers. The first thing that suffers from its low level is the ball joints, which experience destructive influences from all sides while the vehicle is moving. The diagram shows in red the zones of maximum load exerted on the node connection: The node itself consists of two elements:

Between them there is a special polymer, which:

All problems, including turning the wheel on its side, are possible if the polymer liner wears out, which is inevitable over time. Well, on the CIS routes this time comes too quickly.

SJR technology allows you to avoid such a catastrophic outcome and, subject to timely intervention, maintain the performance of the ball joint almost indefinitely. What is it? Let's figure it out.

Equipment for restoration and restoration of ball joints

Ball joints prevent the vehicle's front wheels from turning outward, keeping them upright. The supports constantly withstand enormous loads, so they have to be changed quite often. Moreover, for some models, they can only be replaced together with the control lever, and this is an expensive and complicated procedure. There is a technology for restoring supports that saves money for car owners and even machines that craftsmen make with their own hands.

Ball joint device

The ball joint is the front suspension element that bears the main load. It can be lower or upper. The main part is a finger with a round head. The head is enclosed in a dirt-proof cover with lubricant. The entire device is hidden in a plastic case, which over time begins to let dirt through. Getting between the head and the cover, sand and earth scratch the head and the protective shell of the cover. Penetrating moisture causes rust.

Modern restoration technology allows you to repair the supports yourself, without disassembling the car.

Under pressure, a special type of molten polymer is injected into the housing of the support assembly. All voids and cracks that appear in the body are filled with plastic, which creates an additional lens-shaped gasket in the required places. Restoration takes only 15 minutes, equipment based on American designs is used in most auto repair shops.

Ball joint restoration machine

The technology described above is implemented using a machine. It consists of:

- control unit with a display showing the current and final temperatures;

- extruder;

- 6 atm compressor;

- pneumatic cylinder;

- thermal pencil;

- set of injector adapters;

- polymer.

Additionally, you need to purchase a gas burner and plumbing tools.

Restoration of support

machine for restoring ball joints

An extruder, which already contains a polymer, is screwed onto the thread of the pneumatic cylinder. A threaded hole is drilled in the support body. Using this thread, a nozzle is screwed on, which is attached to the extruder through a nozzle.

As soon as the polymer becomes soft, it is necessary to start the pneumatic cylinder, squeezing the material through the plunger into the nozzle and then into the support cavity. The soft polymer fills all the potholes, gaps and cracks, creating a ball liner with increased resistance to impact. Even if the polymer is not poured quite correctly, the new liner can withstand about 30 thousand kilometers.

It is quite possible to assemble such equipment for restoration with your own hands. The extruder can be ordered from a turner. A brake chamber from a ZIL or an old cylinder from a clamshell excavator can be used as a pneumatic cylinder. All other spare parts are sold at any hardware store.

Disadvantages of DIY equipment

- When overheated, the polymer completely loses its properties, and in the presented homemade device it is heated by a burner; it is almost impossible to measure its temperature.

- The result of the work largely depends on the experience of the master; it is difficult without the skills to warm the material, support and carefully pour the polymer into the cavity.

In factory devices, heating occurs under electronic control, and the ball nozzle is attached without threads. However, many craftsmen achieve quite decent results using home-made equipment.

The video demonstrates the operation of a factory machine:

stanokgid.ru

What is needed for the work

The economy class set is shown in the photo:

The cost of the kit will be recouped only after a while. Rarely does anyone buy it at once - it’s unprofitable

A more advanced version has a piston that creates pressure for the extruder without the use of compressed air.

As you can see, there are also many types of equipment

There is no need to buy a compressor, but the kit itself is more expensive. But you can control the heating temperature using your own thermometer (again, there is no need to purchase one). A gas torch or hair dryer is still needed to warm up the ball joint before filling.

Important! The mobile kit allows you to perform work directly under the bottom of the car without removing the ball joint. However, this is not recommended, since local heating using a burner is impossible, and there is a danger of damaging the brake hoses or rubber boots. Therefore, do not be lazy to dismantle the ball joint and carry out the work on a workbench.

The workbench will provide convenience and safety

When is ball restoration justified?

Typically, the ball joint is pressed into the body of the suspension arm and steering rod, being one with them. Therefore, complete replacement of hinges is an expensive procedure due to the replacement of an entire structure.

To save money, you can try to restore the ball joint, although this part is considered unrepairable:

Many experienced repairmen recommend disassembling this element in any case to grind the ball of the pin axis. This approach will ensure the durability of the repaired part. In addition, in this case, you can evaluate the condition of the finger itself and replace it if necessary.

Restoration does not make sense in the case when the finger dangles inside the body and is even removed from the hinge without disassembly and special effort.

Making an extruder with your own hands: details about the complex

If you have a home locksmith workshop, you can make the device yourself; in extreme cases, you should use the services of a turner.

The part should not be too bulky Make sealing rings from high-quality rubber Hook up the air injection fitting Equip the device with an adapter Pay attention to the proportions of the polymer cylinder and the extruder body itself

An extruder is sometimes called a remanufacturing machine or stand.

Equipment operation diagram on video

Do-it-yourself ball joint: replacement, diagnostics, restoration

It happens that a do-it-yourself restored ball joint can last longer than cheap duplicates. Even a novice car enthusiast can replace this unit.

Design and purpose of the node

The ball joint is designed for reliable movable fastening of the wheel hub to the suspension arm. The ball joint consists of a ball pin, a housing and a plastic insert.

The body of the ball joint is either spot welded from two halves with stamped, spherical recesses with a hole for a finger in one of them, or it is a thick-walled metal cup into which an insert with a finger is inserted, after which the bottom is placed, and the edge is rolled so that the structure does not disassemble. Sometimes the liner is not made, but the gap between the body and the ball is filled with softened polyamide plastic. An extruder is usually used for this. It is also used as the main equipment in companies for the restoration of ball joints. To protect the mating surfaces of the hinge from water and dirt, put a rubber boot on top.

As long as the boot is intact, the ball joint practically does not wear out. Intensive wear of the ball begins after the boot becomes unusable, with dirt getting inside. Therefore, keep an eye on the boots, since timely replacement of an unusable boot will extend the life of the unit.

True, the joint of the welded body is not airtight, so water gets into the body through it, even with a whole boot. Therefore, if the assembly body consists of two parts, it is advisable to fill it with lithol through a grease fitting.

Diagnostics

If you hear knocking or creaking noises from the suspension while driving your car on rough roads, these sounds may be coming from worn ball joints.

It is better to determine the source of unpleasant sounds together: one person goes down into the inspection hole and puts his hand on the ball, and the other rocks the car. When you feel the sound with your own hands, remove the support, clamp it in a yew, and check the hinge play.

The finger should not move from slight efforts, but it should not bite either, otherwise the unit will require repair or replacement.

This check must also be carried out in the following cases:

Removal & installation

The ball puller is usually not universal. If you do not find a suitable puller, it can be successfully replaced with a hammer. You just need to know where to hit. There is no need to knock your finger out of its seat.

The blow should be perpendicular to the finger, and it should be hit on the eye (since the conical finger, a slight landing pressure will squeeze it out of the eye). Hammer is a universal puller.

It should not be too heavy or too light; 600 grams will be just right.

Removal: Loosen the wheel. Raise the car on a jack. Remove the wheel. Turn the steering wheel so that it is convenient to work. If the pin nut becomes cotter, remove the cotter pin using pliers. Unscrew the nut.

Take a puller and squeeze your finger out with it. Unscrew the ball housing fastening. Using a pry bar, press down the lower arm and remove the ball joint. Removing and repairing tie rod ends and ball joints is no different, you just need to use another puller.

The recovery methods are identical.

Installation: Attach the hinge body to the lower arm, tighten the fasteners, use a pry bar to press the lower arm, insert the pin into the seat. Screw the nut onto the pin and tighten it.

If the finger rotates, pull the lever upward (the pin with the seat is conical, so when the finger is pressed in, it stops turning in the seat). Don't forget to tighten the nut. No puller is needed for installation.

The next replacement of supports will not force you to fiddle with cotter pins if you change the nuts to self-locking ones.

Recovery

Restoration of supports can occur in two ways:

Of course, you shouldn’t buy equipment for a one-time repair, but you can quickly make a simple extruder with your own hands from an old brake master cylinder by attaching a lever to it to press the piston. You can heat it to soften the plastic with a torch or blowtorch.

Carrying out work

Repair and restoration in the first way begins with dismantling the supports. To disassemble a body welded from two cups, you need to drill out welding points on one of the cups and separate the cups using a chisel and hammer.

On a body with an inserted bottom, grind off the flared edges using emery or a grinder, and knock out the bottom with a hammer to the end of the finger.

An insert with a finger is inserted into the body of two cups, the halves are pressed against each other and several tack welds are made, trying not to overheat the insert.

For a case with the bottom removed, measure the outer and inner diameters and make a steel ring in accordance with these dimensions, about 10 mm high with a thread inside and a plug screwed into it. Weld the ring to the body, cool, insert the insert with the pin into the body, screw in the plug, press the liner with it, drill a Ø 2 mm hole in the ring close to the plug and secure it with a cotter pin.

Do-it-yourself repair and restoration using the second method usually takes place without disassembling the unit.

A hole with a diameter of about 6 mm is drilled in the bottom of the body, its size depends on which extruder is available to you. The gap between the ball and the liners is cleared of dirt and blown with compressed air to remove sand and chips.

Through a hole drilled in the bottom, using an extruder, softened plastic is injected into the gap between the pin ball and the body. Let it cool and the repair is ready.

The disadvantage of this method is that you cannot see whether the geometry of the ball has been preserved and you cannot polish it to remove traces of corrosion, so the restoration results will be short-lived.

Useful tips

Restoring ball joints: repair using SJR technology and dismountable restoration method

Ball joints take on the weight of the front part of the vehicle, including the power plant. Also, during movement, this unit is exposed to constant shock load.

It is quite obvious that in such conditions the service life of the support is limited, even if it is made of the most durable alloys.

As a result, many car owners are faced with the need to restore ball joints.

The ball joint allows for a reliable movable connection between the wheel hub and the suspension arm. The assembly includes a housing, a ball pin , and an insert made of plastic. The body most often has a welded structure - two parts with a stamped spherical recess for the finger are connected using spot welding.

Essentially, this element is a thick-walled glass made of metal into which an insert with a finger is then inserted. To make the housing structure non-separable, its edges are flared.

Often the liner is not manufactured separately, but the area between the walls of the housing and the ball surface of the finger is filled with a special polymer material. To protect the unit from dirt and water, a boot is placed on top.

It should be noted that active wear of the ball joint begins after the boot is damaged . Until this happens, the unit is practically not subject to wear. Thus, if you monitor the condition of this element and replace it in a timely manner, you can significantly increase the life of the unit.

However, it is worth remembering that the weld joints do not have sufficient tightness and even with an intact boot, water can get inside. To avoid this, the case should be filled with lithol.

Node diagnostics

You can find out about the need for restoration work on ball joints through diagnostics.

As soon as you hear a creaking and knocking sound from the suspension while driving on an uneven road, the unit is worn out and needs to be restored.

To accurately determine the source of these sounds, it is better to carry out diagnostics together - one person enters the inspection hole and puts his hand on the ball joint, and the second begins to rock the car.

If the sound is felt by hand, then the support must be removed and checked for play in the hinge joint, securing it in a vice. It should be remembered that the finger should not move under the influence of light forces, but at the same time it should not bite. It is also recommended to carry out a similar check in the following situations:

- A squeaking sound is heard when turning the steering wheel.

- When driving in a straight line, the car spontaneously wobbles.

- To turn the steering wheel you have to apply quite a lot of force.

If after carrying out diagnostic measures it becomes clear that the unit is worn out, it must be repaired. Many novice car owners cope with all the work and restore the ball joints with their own hands. To remove and install the support after repair, you will need several tools:

- Special puller for supports.

- Car stand.

- Jack.

- Mount.

- Pliers.

- A set of keys.

Most often, ball joint pullers are not universal. If you cannot find the required tool, you can solve the problem using a hammer. Moreover, its weight should be about 600 grams. In addition, you need to know the place where you should strike so as not to damage the node.

There is no need to try to knock your finger out of the seat. The blow should be directed perpendicular to the finger along the eyelet. To remove the ball joint, you first need to loosen the front wheels and jack up the car. After this, the wheel is removed.

If the nut on the pin has a cotter pin, it should be removed using pliers. This will allow you to unscrew the nut and use a puller or hammer to squeeze out the pin. After this, you should unscrew the housing mount and, using a pry bar, press the lower lever to remove the support.

To install the unit after repair, you first need to attach the housing to the lower arm. After tightening the fasteners, use a pry bar to release the lever and return the pin to the socket.

Then the nut is screwed onto it and tightened. If after this the finger rotates, then the lower lever must be pulled up.

The last step will be to install the cotter pin on the nut or replace the old one with a self-locking one.

Repair work

It should be immediately noted that after the repair is completed, the ball joint will not be completely restored and its service life will be shorter. However, if everything was done correctly, then you don’t have to worry about the safety of the unit’s operation. There are several ways to restore the ball's functionality. At home, two technologies are most often used:

- Repair of ball joints with polymer using SJR technology.

- Collapsible - the body is converted from a non-separable one into a collapsible one, after which the ball surface of the pin is polished and the liners are changed.

Using polymer

The essence of this method is to inject heated polymer material into the housing. In this case, the support does not need to be disassembled, but an extruder must be manufactured. It is worth noting the main advantages of this method:

- Since the housing structure is not destroyed, high reliability of the factory connection is ensured.

- The polymer fills all the voids and wear-out areas that caused the support to fail.

- When the material hardens, it forms a solid liner, the characteristics of which are at least as good as the factory part, and sometimes even superior.

- The polymer contains special ingredients that provide high-quality dry lubrication of the finger.

- High strength under impact loads is achieved.

To use this technology, a hole must be drilled in the lower part of the body, the diameter of which is selected in accordance with the extruder used. It is necessary to thoroughly clean the gap between the liners and the ball surface of the pin from dirt, and also blow the assembly with air to remove chips and grains of sand.

The polymer is injected into the housing using an extruder through a pre-drilled hole. Once the plastic composition has hardened, the repair work can be considered complete. The only drawback of this technology is the inability to check the geometry of the spherical surface of the finger.

Collapsible method

After the support is removed, it is necessary to disassemble the housing. To do this, you will need to drill out all the welding points in one half, then divide the part into two parts using a hammer and chisel.

Then the flared edges are ground down and a blow is applied to the end of the pin to separate the bottom of the body.

After measuring the inner and outer diameters of the body, a ring with similar dimensions and internal threads is made, as well as a plug that is screwed into this part. The height of the ring should be about 10 cm.

After this, a new liner and the restored finger are placed in the body. Having connected the two parts of the body, they should be secured by welding. Care must be taken to avoid overheating the liner.

Then the previously made ring must be welded to the body. After this, all that remains is to screw the plug into the body to tighten the liner and drill a small hole in it (diameter about 2 mm) for the cotter pin.

Restoring balls using a homemade extruder

Once the extruder is assembled, you simply load the polymer cartridge into the barrel and connect it to the prepared hole in the ball joint. While simultaneously heating the ball body and the cylinder with polyamide, you shake the ball pin for uniform penetration of the melt. Once the air cylinder in the extruder stops, the process is considered complete. Allow the polymer to harden inside the part, and you can install the ball joint on the car.

Filling balls on a Toyota Corolla: video

There is no need to remove the polyamide from the cylinder after work. It will melt again when the next part is restored.

By making such a device, you will not only be able to save on suspension maintenance, but also earn money by providing similar services to friends. The cost of purchasing components for the extruder is recouped after rebuilding a pair of ball joints.

How to avoid problems when replacing ball joints on a Renault Logan Why increase the car's ground clearance and how to do it yourself

BALL JOINT REPAIR PROFESSIONALLY RESTORED

Are you the owner of a luxury Mercedes, Audi, BMW, Volkswagen, Jaguar, Bentley, Porsche, Maserati car or a rare treasure? Well, you've arrived very successfully! Our site is something that may be useful to you.

Our company is engaged in factory restoration of car parts. We repair car ball joints in Moscow to factory condition. Often, ball joints are molded into the body of the lever; in this case, restoration of ball joints is possible in three ways; we suggest considering each method separately!

Method No. 1 (the easiest method) Repairing ball joints with polymer using SJR technology

Repairing ball joints with polymer using the SJR technology is very reliable, but only if the lower cracker of the ball joint remains intact, under high pressure and temperature a polymer is driven into the ball joint from above, which creates the upper cracker, usually the load goes to the upper part of the cracker and it is the ana that wears out more often Total! The lower part fails less often, but due to damage to the boot, then corrosion of the ball joint pin occurs; in this case, restoration of the ball joints is not possible without opening it, for this there are two remaining options.

Method No. 2 Restoration of ball joints by opening the rolling and rolling after restoration

The second method of repairing a ball joint is suitable for those who do not want to see traces of tampering with the part, very suitable for retro cars

After assembly at the manufacturer’s factory, the ball joint device has a rolling place, so this will help us:

1. We open the rolling on a special machine, flare it 2. We disassemble the ball joint

3. Grind the steel pin, change the pin if necessary 4. Make the lower and upper crackers 4. Assemble the ball joint 5. Roll it, the ball is ready

Method No. 3

Restoration of ball joints with production of a serviceable upper part

Restoring the ball joints of the levers in this way is the best option because, having a collapsible ball joint, you can easily tighten the ball joint, service it, replace the upper and lower joints. The essence of the repair is as follows: they cut off the rolling from the factory ball joint, then grind out a cup with a lid to fit the size of the ball joint, then change the lower cracker and the upper one, grind or change the steel pin, then assemble it with a torque wrench, the restoration of the ball joint is complete!

Repair of ball joints in Moscow

Repair work

It should be immediately noted that after the repair is completed, the ball joint will not be completely restored and its service life will be shorter. However, if everything was done correctly, then you don’t have to worry about the safety of the unit’s operation. There are several ways to restore the ball's functionality. At home, two technologies are most often used:

- Repair of ball joints with polymer using SJR technology.

- Collapsible - the body is converted from a non-separable one into a collapsible one, after which the ball surface of the pin is polished and the liners are changed.

Using polymer

The essence of this method is to inject heated polymer material into the housing. In this case, the support does not need to be disassembled, but an extruder must be manufactured. It is worth noting the main advantages of this method:

- Since the housing structure is not destroyed, high reliability of the factory connection is ensured.

- The polymer fills all the voids and wear-out areas that caused the support to fail.

- When the material hardens, it forms a solid liner, the characteristics of which are at least as good as the factory part, and sometimes even superior.

- The polymer contains special ingredients that provide high-quality dry lubrication of the finger.

- High strength under impact loads is achieved.

To use this technology, a hole must be drilled in the lower part of the body, the diameter of which is selected in accordance with the extruder used. It is necessary to thoroughly clean the gap between the liners and the ball surface of the pin from dirt, and also blow the assembly with air to remove chips and grains of sand.

The polymer is injected into the housing using an extruder through a pre-drilled hole. Once the plastic composition has hardened, the repair work can be considered complete. The only drawback of this technology is the inability to check the geometry of the spherical surface of the finger.

Collapsible method

After the support is removed, it is necessary to disassemble the housing. To do this, you will need to drill out all the welding points in one half, then divide the part into two parts using a hammer and chisel. Then the flared edges are ground down and a blow is applied to the end of the pin to separate the bottom of the body. After measuring the inner and outer diameters of the body, a ring with similar dimensions and internal threads is made, as well as a plug that is screwed into this part. The height of the ring should be about 10 cm.

After this, a new liner and the restored finger are placed in the body. Having connected the two parts of the body, they should be secured by welding. Care must be taken to avoid overheating the liner.

Then the previously made ring must be welded to the body. After this, all that remains is to screw the plug into the body to tighten the liner and drill a small hole in it (diameter about 2 mm) for the cotter pin.