Physical properties of tungsten

The tungsten content in the earth's crust is 1·10-4%. Not found in a free state. From industrial minerals Of importance are scheelite CaWO4 and wolframite (Fe, Mn) WO4.

The tungsten crystal lattice is body-centered cubic with a period a = 3.1652 A; density 19.35 g/cm3; melting point 3395 ± 15° C; boiling point 5900° C.

Heat of fusion 61 cal/g; heat of evaporation 1183 cal/g; vapor pressure (mm Hg): 1.93 x 10-15 (1530° C), 6.55 x 10-5 (2730° C) and 0.76 (3940° C); temperature coefficient linear expansion (temperature 0-500° C) 4.98 10-6 deg-1, coefficient. thermal conductivity (cal/cm sec X deg): 0.31 (20° C), 0.28 (827° C), 0.24 (1727° C).

Heat capacity (cal/g deg): 0.031 (20°C), 0.0365 (1000°C), 0.043 (1400°C) and 0.048 (2100°C); electrical resistivity (ohms cm 106): 5.5 (20° C), 27.14 (300° C), 40.00 (1200° C) and 66.00 (2000° C).

Electron emission (ma/cm2): 1.5 10-10 (830° C), 2.3 10-1 (1630° C), 1.0 (1730° C), 298 (2230° C) and 1690 (2427° C); energy emitted during incandescence (W/cm2): 18.0 (1600° C), 64.0 (2200° C), 153 (2700° C) and 245 (3030° C).

Tungsten is paramagnetic; Thermal neutron capture cross section is 19.2 barns.

As presented in nature

The native non-ferrous metal tungsten is not found on the planet. It is presented in the form of ore or minerals.

Ores consist of compounds of tungsten with iron, manganese, calcium, and sometimes other elements, including rare earths.

Minerals are inclusions in granites (up to 2%). Of these, wolframite (tungsten with iron and manganese) and scheelite (with calcium) are of industrial importance.

Each ton of the earth's crust contains 1.30 g of tungsten.

Mechanical properties of tungsten

The mechanical properties of tungsten depend on previous processing. The Brinell hardness of a sintered ingot is 200–250, for a forged one 350–400.

The tensile strength of a forged rod is 35–150, of unannealed wire (depending on the diameter) 180–415, of annealed wire 110 kgf/mm2.

The yield strength of unannealed wire (0.1-0.5 mm in diameter) is 149.1, annealed wire (of the same diameter) is 71.4-82.6 kgf/mm2; elastic modulus of wire 35,000–38,000, single-crystalline thread 39,000–41,000 kgf/mm2.

Chemical properties of tungsten

Under normal conditions, tungsten is chemically resistant. The compact metal begins to oxidize in air at a temperature of 400-500° C to trioxide WO3.

Water vapor oxidizes it at a temperature of 600-700°C to WO2 and WO3. At temperatures from 800 - 1000 ° C, carbon-containing gases carbonize B.” small impurities of bound carbon in the metal reduce electrical conductivity.

Tungsten does not interact with hydrogen. With nitrogen at a temperature of 2300° C it forms nitride WN2, with silicon and boron at a temperature above 1400° C - respectively, silicides W3Si, W5Si3 (W3Si2) and WSi2 and borides W2B, WB, WB2 and W2B5 - refractory solid compounds with pre-im. covalent type of interatomic bonds.

With halogens at high temperatures, V. forms halides (fluorine interacts with powdered V. at room temperature) WСl6, WCl5, WCl4, WСl2, WF4, WBr6, WBr6, WBr2, WJ4 and WJ21 in the presence of oxygen or moisture - oxyhalides WО2Cl2, WOCl4, WOF4 and WО2F2.

When tungsten interacts with carbon, starting from a temperature of 1000-1500 ° C, solid refractory compounds are obtained - carbides WC (melt 2600 ° C) and W2C (melt 2750 ° C).

General information:

| 100 | General information | |

| 101 | Name | Tungsten |

| 102 | Former name | |

| 103 | Latin name | Wolframium |

| 104 | English name | Tungsten |

| 105 | Symbol | W |

| 106 | Atomic number (number in table) | 74 |

| 107 | Type | Metal |

| 108 | Group | Transition metal |

| 109 | Open | Carl Wilhelm Scheele, Sweden, 1781 (named), Juan José Elhujar Lubize and Fausto de Elhujar, Spain, 1783 |

| 110 | Opening year | 1783 |

| 111 | Appearance, etc. | Hard, refractory, shiny, silver-gray metal |

| 112 | Origin | Natural material |

| 113 | Modifications | |

| 114 | Allotropic modifications | 2 allotropic modifications: — α-tungsten with a cubic body-centered crystal lattice, - β-tungsten with a cubic crystal lattice, called phase A15 |

| 115 | Temperature and other conditions for the transition of allotropic modifications into each other | |

| 116 | Bose-Einstein condensate | |

| 117 | 2D materials | |

| 118 | Content in the atmosphere and air (by mass) | 0 % |

| 119 | Content in the earth's crust (by mass) | 0,00011 % |

| 120 | Content in seas and oceans (by mass) | 1,2·10-8 % |

| 121 | Content in the Universe and space (by mass) | 5,0·10-8 % |

| 122 | Abundance in the Sun (by mass) | 4,0·10-7 % |

| 123 | Content in meteorites (by mass) | 0,000012 % |

| 124 | Content in the human body (by weight) |

Tungsten compound with substances

With sulfur it forms sulfides WS2 and WS3. With me. With metals, tungsten forms alloys and intermetallic compounds.

In the cold, tungsten is stable in acids and alkalis; when heated, it is corroded by nitric acid and aqua regia, and dissolves in a mixture of nitric and hydrofluoric acid.

Tungsten in molten alkalis in air or in the presence of oxidizing agents (NaNO3, KClO3) dissolves to form tungstates.

Effect on the human body

Tungsten practically does not enter the body with water or food. There may be a risk of inhaling tungsten particles in the air at work. However, despite belonging to the category of heavy metals, tungsten is not toxic. Tungsten poisoning occurs only among those associated with tungsten production. At the same time, the degree of influence of the metal on the body varies. For example, tungsten powder, tungsten carbide, and a substance such as tungstic anhydrite can cause lung damage. Its main symptoms are general malaise and fever. More severe symptoms occur with poisoning from tungsten alloys. This occurs when inhaling alloy dust and leads to bronchitis and pneumosclerosis.

Metal tungsten, entering the human body, is not absorbed in the intestines and is gradually excreted. Tungsten compounds, which are classified as soluble, can pose a great danger. They are deposited in the spleen, bones and skin. With prolonged exposure to tungsten compounds, symptoms such as brittle nails, peeling skin, and various types of dermatitis may occur.

Production of tungsten

The raw materials for the production of tungsten are wolframite and scheelite. Tungsten ores are pre-enriched to obtain concentrates containing 50-60% WO3.

By chemical decomposition of enriched ore concentrates - sintering or alloying with alkalis, soda, autoclave decomposition with soda solutions (scheelite) or decomposition with caustic soda solutions (wolframite) - sodium tungstate Na2WO4 is obtained.

From the resulting aqueous solution of sodium tungstate, calcium tungstate CaWO4 (artificial scheelite) is precipitated, which is decomposed with hot hydrochloric or nitric acid.

The resulting tungsten acid H2WO4 is purified by dissolution in an ammonia solution and crystallization of ammonium paratungstate (evaporation or neutralization).

Calcination of this salt gives pure tungsten anhydride WO3. Scheelite concentrate can also be directly decomposed with hydrochloric or nitrogen acid, followed by ammonia purification with the resulting technical tungsten acid.

Tungsten reserves in various countries

The largest tungsten resources are found in Russia, Canada and China. According to scientists' forecasts, about 943 thousand tons of this metal are located in domestic territories. If we believe these estimates, the vast majority of reserves are located in Southern Siberia and the Far East. The share of explored resources is very small - it is only about 7%.

In terms of the number of explored tungsten deposits, Russia is second only to China. Most of them are located in the regions of Kabardino-Balkaria and Buryatia. But in these deposits it is not pure tungsten that is mined, but its ores, which also contain molybdenum, gold, bismuth, tellurium, scandium and other substances. Two-thirds of the volumes of tungsten obtained from explored sources are contained in difficult-to-process ores, where the main tungsten-containing mineral is scheelite. The share of easily processed ores accounts for only a third of all production. The characteristics of tungsten mined in Russia are lower than abroad. The ores contain a large percentage of tungsten trioxide. There are very few placer metal deposits in Russia. Tungsten sands are also low quality, with a lot of oxides.

Tungsten powder

Tungsten powder is produced by the reduction of tungsten anhydride with hydrogen at a temperature of 850–1200° C (depending on the required grain size) or with carbon at a temperature of 1400–1800° C in the production of hard carbide alloys.

Compact metal is obtained by ch. arr. using powder metallurgy (pressing and sintering billets from tungsten powder in a hydrogen environment).

The resulting tungsten lends itself well to pressure processing (forging, drawing, rolling, etc.) when heated below the recrystallization temperature.

Vacuum melting of metal blanks and its alloys with other refractory metals is being developed.

How to use

The properties of tungsten identified the main consumer. This is metallurgy. It creates end products and sources for other industries.

Powdered tungsten is the basis or component of hard, heat-resistant, wear-resistant alloys and premium steel grades.

Metal, alloys

A wide range of products are created from refractory metals and alloys:

- Components and parts of aircraft and rocket engines.

- Elements of electric vacuum devices (picture tubes, incandescent filaments).

Tungsten filament - Vacuum furnace heaters.

- Electrodes for argon-arc welding. They do not melt and create a strong weld. Suitable for materials of any composition (non-ferrous metals, alloy steels, etc.).

- Containers for radioactive products. Here the advantages of the metal over lead turned out to be decisive.

- Surgical instruments.

The characteristics of the metal suited the defense complex: tank, torpedo armor, large-caliber shells, bullets. As well as super-high-speed rotors of gyroscopes that control the flight path of ballistic missiles.

Tungsten ingots

Connections

The range of applications for tungsten compounds is wide:

- Without ditelluride, it is impossible to convert heat into electricity.

- Carbide is the basis of alloys and composites for machining metals and non-metals. For miners, oil workers, gas workers - for drilling wells.

- Sulfide is a heat-resistant (up to 500°C) lubricant.

- Trioxide is a material for creating the electrolyte of fuel cells operating at elevated temperatures.

Tungsten compounds are purchased by manufacturers of varnishes, paints, and textiles.

Other forms

Isotope W184 is a component of alloys with uranium isotopes. They are used to make nuclear-fueled rocket engines.

A radionuclide of artificial origin (W185) is in demand as a radiation detector (including X-rays) in the nuclear segment of physics and medicine.

Applications of tungsten

Most of the mined tungsten is used in the production of tungsten steels and alloys. The most common are tungsten high-speed steels.

Sintered hard alloys based on tungsten carbide (and also in combination with other carbides), characterized by high wear resistance, are used for cutting and forming metals, drilling wells, etc.

Heat-resistant alloys of tungsten with other refractory metals (molybdenum, niobium, tantalum, rhenium) are used in aviation and rocket technology; Tungsten-rhenium alloy is used for high-temperature thermocouples.

Tungsten is also used in electrical engineering, radio electronics, for the manufacture of electrodes of electronic devices and gas-discharge tubes, anticathodes and cathodes of X-ray tubes, heaters for high-temperature furnaces, breaker contacts in automobile engines, for coating, etc.

Some metal compounds (for example, Na2WO4) are used in the paint and varnish and textile industries, as part of dry antifriction lubricants (WS8, WSe3), etc.

Nomenclature of metal grades

Based on tungsten or with its participation, metallurgists smelt products of dozens of names and brands.

Among the most common are pure tungsten (HF) and alloy with rhenium (HR).

The classification of tungsten grades is based on the composition of the additives:

| Brand name | Type of additive |

| VA | Aluminum + siliceous alkali |

| VM | Thorium + siliceous alkali |

| IN AND | Yttrium oxide |

| VT | Thorium oxide |

| VL | Lanthanum oxide |

Characteristics of elements

When considering the lower elements of the subgroup, attention is drawn to the growth of the ionization potential with a practically unchanged atomic and ionic radius.

This means densification of the electron shells of atoms. The proximity of the radii makes molybdenum more similar to tungsten than these metals are to chromium.

The stability of their oxidation states is different than that of chromium. The +2 state is almost never found in it, and +3 is uncharacteristic for W; +4 and +6 are more stable.

The similarity with elements of the VIA subgroup is manifested in the formation of compounds SF6, WF6 and SO ions, the bonds in which are largely covalent.

Processed products

Due to its unique properties, primarily hardness and refractoriness, tungsten has found a wide range of applications since its discovery. As a refractory material, it is widely used in metallurgy. Although other industries cannot do without such valuable material.

Lighting

Due to their low electrical conductivity and low evaporation rate, at one time tungsten filaments made it possible to make a technical revolution in the entire industry of creating electric lighting devices, and also began to be used in the manufacture of electronic vacuum devices.

Shells

The high level of density of this material, reaching up to 19.3 g/cm3, along with its strength, provided gunsmiths with an excellent means of destroying armor. Today, tungsten is one of the main chemical elements that make up the heavy alloy cores of armor-piercing bullets and shells.

Tungsten scrap

Electrodes

Non-consumable tungsten electrodes are used as a welding material for a process carried out using gases. Helium or argon protects the connection point from atmospheric influences, and the electrode at this time withstands significant temperatures and a long service life. This allows you to create optimal working conditions while avoiding unnecessary costs.

Properties of simple substances and compounds

Tungsten is a metal characterized by exceptional refractoriness. In its pure form, it is a dense, hard, white and shiny substance. They are well processed by rolling, stamping and other methods.

When exposed to air, they become covered with a dense oxide film and are therefore resistant to conventional corrosive agents.

Tungsten reacts with acids: it dissolves in aqua regia, hot concentrated hydrochloric, sulfuric and nitric, as well as in oxidative-alkaline melts (for example, in a mixture of NaOH and KOH).

Tungsten dissolves only in a mixture of hydrofluoric and nitric acids, and the fusion of CO with alkalis leads, similarly to molybdenum, to the formation of salts - tungstates. For tungsten, a similar “tungsten blue” is known.

Tungsten reacts with nonmetals under significant heating, forming strong carbides, silicides, sulfides, halides and a number of oxides, the most stable of which are higher WO3.

They correspond to Na2WO4 salts of tungstic acids. In an acidic environment, the anions of these salts are capable of condensation, and a series of polytungsten acids are formed. Some of them can be highlighted.

For example, when a solution is heated and strong acids are added, yellow tungstic acid H18[W4O21], or more precisely 4WO3 · 9H2O, precipitates from the solution. The composition of tungstate solutions strongly depends on the pH of the medium.

Receipt and use

Tungsten in its pure form is very difficult to obtain from ores. Therefore, ferrotungsten, the main raw material for the metallurgical industry, is most often isolated from polymetallic or molybdenum- and tungsten-iron ores.

To obtain pure metals, they are fired to form oxides or chlorides and then reduced.

Metals are used to create high-quality alloy steels - heat-resistant, structural, tool, high-speed.

An important property of such steels is maintaining hardness at high temperatures. Similar alloys are used to make filaments in electric lamps.

The addition of metals to steel dramatically changes its structure and gives it the ability to withstand temperature loads and corrosive agents.

Tungsten filament manufacturing technology and its history.

The production volumes of tungsten wire have a small share among all tungsten applications, but the development of the technology for its production played a key role in the development of powder metallurgy of refractory compounds.

Since 1878, when Swan demonstrated the eight- and sixteen-candle carbon lamps he had invented in Newcastle, a search had been going on for a more suitable material for making incandescent filaments. The first coal lamp had an efficiency of only 1 lumen/watt, which was increased over the next 20 years by modifications in coal processing methods by two and a half times. By 1898, the light output of such bulbs was 3 lumens/watt. In those days, carbon filaments were heated by passing an electric current in an atmosphere of heavy hydrocarbon vapors. During the pyrolysis of the latter, the resulting carbon filled the pores and irregularities of the thread, giving it a bright metallic shine.

At the end of the 19th century. von Welsbach was the first to produce metal filament for incandescent lamps. He made it from osmium (Tm = 2700° C). Osmium filaments had an efficiency of 6 lumens/watt, however, osmium is a rare and extremely expensive platinum group element, so it was not widely used in the manufacture of household devices. Tantalum, with a melting point of 2996° C, was widely used in the form of drawn wire from 1903 to 1911 thanks to the work of von Bolton of Siemens and Halske. The efficiency of tantalum lamps was 7 lumens/watt.

Tungsten began to be used in incandescent lamps in 1904 and replaced all other metals in this capacity by 1911. A conventional incandescent lamp with a tungsten filament has a glow of 12 lumens/watt, and lamps operating under high voltage - 22 lumens/watt. Modern tungsten cathode fluorescent lamps have an efficiency of about 50 lumens/watt.

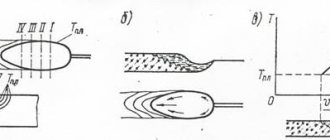

In 1904, they tried to apply the wire drawing process developed for tantalum to more refractory metals such as tungsten and thorium. The rigidity and lack of malleability of tungsten did not allow the process to proceed smoothly. However, it was later shown in 1913–1914 that molten tungsten could be rolled out and drawn using a partial reduction procedure. An electric arc was passed between a tungsten rod and a partially molten tungsten droplet placed in a graphite crucible coated inside with tungsten powder and located in a hydrogen atmosphere. Thus, small drops of molten tungsten were obtained, about 10 mm in diameter and 20–30 mm in length. Although with difficulty, it was already possible to work with them.

During the same years, Just and Hannaman patented a process for making tungsten filaments. Fine metal powder was mixed with an organic binder, the resulting paste was passed through dies and heated in a special atmosphere to remove the binder, resulting in a thin thread of pure tungsten.

In 1906–1907 the well-known extrusion process was developed and used until the early 1910s. Very finely ground black tungsten powder was mixed with dextrin or starch until a plastic mass was formed. Using hydraulic pressure, this mass was forced through thin diamond sieves. The resulting thread was strong enough to be wound onto spools and dried. Next, the threads were cut into “pins,” which were heated in an inert gas atmosphere to a red-hot temperature to remove residual moisture and light hydrocarbons. Each “pin” was secured in a clamp and heated in a hydrogen atmosphere until it glowed brightly by passing an electric current. This led to the final removal of unwanted impurities. At high temperatures, individual small particles of tungsten fuse and form a homogeneous solid metal filament. These threads are elastic, although fragile.

At the beginning of the 20th century. Yust and Hannaman developed another process that was notable for its originality. A carbon filament with a diameter of 0.02 mm was coated with tungsten by heating in an atmosphere of hydrogen and tungsten hexachloride vapor. The thread coated in this way was heated to a bright glow in hydrogen at reduced pressure. In this case, the tungsten shell and the carbon core were completely fused with each other, forming tungsten carbide. The resulting thread was white and brittle. The filament was then heated in a stream of hydrogen, which reacted with the carbon, leaving a compact filament of pure tungsten. The threads had the same characteristics as those obtained during the extrusion process.

In 1909, the American Coolidge managed to obtain malleable tungsten without the use of fillers, but only with the help of reasonable temperature and mechanical processing. The main problem in producing tungsten wire was the rapid oxidation of tungsten at high temperatures and the presence of a grain structure in the resulting tungsten, which led to its brittleness.

Modern production of tungsten wire is a complex and precise technological process. The starting material is powdered tungsten obtained by reducing ammonium paratungstate.

Tungsten powder used for wire production must be of high purity. Typically, tungsten powders of different origins are mixed to homogenize the quality of the metal. They are mixed in mills and, to avoid oxidation of the metal heated by friction, a stream of nitrogen is passed into the chamber. The powder is then pressed in steel molds using hydraulic or pneumatic presses (5–25 kg/mm2). When contaminated powders are used, the compact becomes brittle and a fully oxidizable organic binder is added to eliminate this effect. At the next stage, preliminary sintering of the bars is carried out. When heating and cooling compacts in a hydrogen flow, their mechanical properties improve. The compacts still remain quite fragile, and their density is 60–70% of the density of tungsten, so the bars are subjected to high-temperature sintering. The rod is clamped between contacts cooled by water, and in an atmosphere of dry hydrogen, a current is passed through it to heat it almost to the melting point. Due to heating, tungsten is sintered and its density increases to 85–95% of the crystalline density, at the same time the grain sizes increase and tungsten crystals grow. This is followed by forging at high (1200–1500° C) temperatures. In a special apparatus, the rods are passed through a chamber, which is compressed with a hammer. During one pass, the diameter of the rod decreases by 12%. When forged, tungsten crystals elongate, creating a fibrillar structure. After forging, wire drawing follows. The rods are lubricated and passed through diamond or tungsten carbide screens. The degree of drawing depends on the purpose of the resulting products. The diameter of the resulting wire is about 13 microns.

Frequently asked questions and answers?

How does the tungsten production process work?

The process of obtaining tungsten goes through the substage of separation of trioxide WO3 from ore concentrates and subsequent reduction to metal powder with hydrogen at a temperature of about 700 °C.

What is the density of tungsten?

The high density of tungsten makes it suitable for protection against ionizing radiation.

Despite its higher density compared to traditional and cheaper lead, tungsten protection turns out to be less heavy with equal protective properties or more effective with equal weight.

What is tungsten for welding?

Tungsten is used as electrodes for argon-arc welding. Alloys containing tungsten are characterized by heat resistance, acid resistance, hardness and abrasion resistance.

What is tungsten in the periodic table?

Tungsten (W) (Wolframium) is a chemical element of group VI of the periodic table, atomic number 74, atomic mass 183.85. The name is from the German Wolf wolf and Rahm cream (“wolf foam”).

Is tungsten metal or not metal?

It is a refractory heavy metal with a light gray color. In compounds it exhibits oxidation states from 2 to 6; compounds with an oxidation state of 6 are the most stable.

How much does tungsten cost?

As of 01/18/2022, the cost of tungsten: Tungsten up to 2300 rubles. Price for 1 kg. Pure tungsten up to 2000 rub. Price for 1 kg. Furnace tungsten 1550 rub. Price for 1 kg. Tungsten shavings 1200 rub. Price for 1 kg. Tungsten VND 5/5 (Ni 5%, Cu 5% rest W) 850 rub.

Article on tungsten

How it was opened

People's acquaintance with tungsten dates back to the Middle Ages.

Prospectors

Tungsten was also obtained by European miners during the recovery of tin. But it was considered “garbage” clogging a valuable element. Under the influence of tungsten ore during the reduction process, part of the tin turned into slag, reducing the proportion of the pure substance.

Hence the saying that appeared among prospectors: “Tungsten eats tin like a wolf eats a lamb.”

The science

The history of the discovery of tungsten is associated with several chemists:

- In the mid-18th century, Swede Axel Frederik Kronstedt discovered a heavy metal, which he called Tung Sten (in Swedish - heavy stone).

- 30 years later, his compatriot, member of the country’s Academy of Sciences Karl Scheele, took up the matter. In his free time from working at the pharmacy, he devoted his time to experiments in his home laboratory. He is considered the “father” of not only tungsten. The list also includes barium, manganese, oxygen, and chlorine. From tungsten ore (tungsten) he isolated an acid salt that was not listed in the registers.

- He entrusted further work on the connection to his Spanish colleagues, the Eluard brothers. Which received a new element.

The name and symbol of the metal – Wolframium and W – were proposed by Jens Jakob Berzelius.

The etymology of the name tungsten has German roots: Wolf Rahm (“wolf cream”).

And tungsten was renamed in honor of the scientist - scheelite.