Reliable fastening of the workpiece is a guarantee of the accuracy and quality of engraving or milling processing.

Each CNC machine is equipped with a universal work table designed for installing workpieces of various configurations. For this purpose, they are provided with longitudinal grooves into which clamping screws are inserted. With their help, the workpiece is pressed against the table surface and subsequently does not move due to the forces created by the rotating cutter.

Standard work tables of machines with a movable portal are not suitable for processing large-sized sheets of MDF, plywood, plastics, and composite materials. Part of the machined surface is covered by clamping bars, and there is a risk of damaging the workpiece when tightening the screw. Problems often arise with thin sheets: due to low rigidity, they are deformed when touched by a cutter. Many manufacturers of mechanical engineering equipment equip milling machines with vacuum tables. Most often, this device is offered as an additional option, and its cost is quite high.

Do-it-yourself vacuum table for CNC: step-by-step instructions

To work on a CNC milling machine with large parts, a large vacuum table is required. Such equipment is very expensive due to the complexity of transportation and is not always suitable for certain tasks, but you can design a table yourself, to suit your individual size and needs.

Vacuum tables for CNC are designed for milling machines that work with large sheets of wood or metal. Most CNC machines use curved machining. To work on milling machines, you need a surface that reliably holds the workpieces.

The vacuum table presses the products to the surface, preventing them from moving, making work on the milling machine more accurate and comfortable. In addition, complete equipment provides heating to the required temperature.

It is more versatile than a magnetic table, which is only suitable for processing metal products.

Quite often, CNC milling machines come complete with a vacuum table, but if it is absent or is not large enough, another device is required. In this case, you can buy a used device of questionable quality or make it yourself.

Required materials and tools

To make a vacuum table for a milling machine, you need to find all the components. To create functional equipment you will need:

- wooden or metal sheet of appropriate size;

- metal profile;

- Vacuum pump;

- a heating element;

- Control block.

Tools you will need: drill, screwdriver, wrenches, soldering iron. The remaining tools are used optionally, if available.

Manufacturing stages

After purchasing all the necessary materials and tools, you can proceed to assembling the table yourself.

Manufacturing of working surface and box

At the beginning of making a vacuum table for CNC, you need to create a working surface with your own hands. To do this, take a pre-prepared sheet of material.

Holes are carefully drilled in it, in a checkerboard pattern, using a drill or screwdriver. Later, from the back, the surface will be adjacent to the vacuum pump, which serves to securely fasten the products.

To increase the reliability of the structure, partitions are installed. They prevent the table from deforming during use.

Box

The most significant thing here is the height, since the table is designed for a numerically controlled machine.

A stable structure is assembled from metal and wooden parts to secure the working surface. The surface above the working area will act as a holder for the heating element.

It is desirable that the box be collapsible: this will facilitate further work, setting up equipment or transporting the table in the future.

The desktop should be as stable and reliable as possible. Therefore, it is advisable to avoid short-lived or moving connections in the design. To make it easier to move the tool, you can use adjustable height feet. This will allow you to work on uneven surfaces, providing stability.

A heating element

Vacuum forming of plastic also requires a special table. During operation, the product is exposed to a vacuum field and a heating element, which heats the plastic to the required temperature.

To do this, a heating panel is installed above the table. Nichrome thread has proven itself best as a heating element.

However, due to the high cost of the material, as well as the difficulty of finding it on the open market, halogen lamps are usually used for self-production.

Among the advantages of use, it is worth noting uniform heating, as well as high-quality lighting of the work area.

A sheet of metal is taken as a workpiece. Holes for lamps are also drilled in it, after which the heating elements are secured and the electrical part is installed. All lamps must be connected in parallel.

With a more complex design, the electrical part is output to a controller or separate switches to heat certain parts of the work area. The connection is made using soldering and copper wires.

To reduce wiring, have a more pleasing appearance, ease of operation and greater wiring reliability, it is recommended to use a printed circuit board or several small circuit boards. The design of the light panel should also be dismountable for maintenance.

Vacuum pump

The most important piece of equipment. Serves to create a vacuum and securely fix the part. It is best to use a specialized vacuum generator with a pressure gauge. If a dedicated vacuum pump is not available, several vacuum fans will do. It is possible to replace them with industrial vacuum cleaners, but in practice their efficiency is lower.

Table manufacturing stages

Before starting to purchase the material, determine the location in the workshop for future installation. When the future design will be used occasionally, then portable tables are chosen. But if there is a lot of space in the carpentry workshop, then a wide milling table, convenient for processing boards or panels of 2 meters, is productive.

Manufacturing of bed and table top

By frame we mean a frame with a support, but which also houses the tabletop itself. It is customary to assemble a bed from whatever is spared. No particular preference. You need to achieve rigidity and stability.

Before assembling the frame, it is advisable to take care of the operator’s comfort. Typically, the lower part of the frame deepens 10-20 cm from the lid itself. It’s more comfortable and therefore safer.

If you study the drawings and design features, it is not difficult to fit a convenient carpentry workbench under an old router. We remember that vibration occurs from the operation of the machine, so we are considering this option if the workbench is firmly standing.

It is customary for homemade products to use a reliable, stable, motionless frame, and it is advisable to weld it from a profile, since the entire load is transferred to the base. Fits:

- Steel pipe.

- Corner (trimmings).

- Channel.

Only then wooden beams and chipboard.

It is inexpensive to assemble a milling table for periodic use from a 25x25 or 40x20 profile pipe. Using an angle grinder, cut the profile into 4 legs, a rectangle (frame) and lower connecting parts. All this is strictly in size.

Then the profile is welded into a frame, complementing the structure with a pipe. The latter is necessary for the parallel stop. 4-6 legs must be framed with a profile or corner. But this is after installing the table top itself. Plus, the metal frame makes it possible to pre-weld a limiter for electrical equipment.

DIY vacuum table for a milling machine

A vacuum table for a milling machine remains the most popular method of fastening sheets and workpieces.

The dimensions of such a surface may differ depending on the dimensions of the machine, and the working surface itself is divided evenly into sectors.

What is it?

A vacuum table is necessary for working on a CNC milling machine with large sheets and workpieces. This surface securely fixes the parts and presses the product to the surface. Since the workpiece is securely fixed, operation of the machine becomes more accurate and convenient.

The table operates using a vacuum pump. This is expensive equipment, sometimes it comes complete with the machine, but if you wish, you can make it yourself.

Design features and operating principle

Vacuum is a term that characterizes the area of rarefaction that is formed between the vacuum table and the workpiece fixed on it. In fact, it is not vacuum that acts on the part, but atmospheric pressure. It presses the workpiece to the table surface.

The strength of the vacuum may vary depending on the power of the installed pump, but it will never be greater than atmospheric pressure. At the moment, there are several types of vacuum tables.

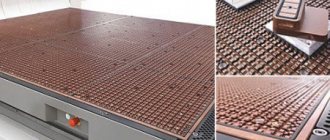

Lattice

This device creates a closed loop for the workpiece. The grooves on the working side are made in the form of gratings. Suitable for non-through processing of parts. The grid table includes an aluminum alloy plate with a grid of grooves on the working side, as well as a special hole for pumping air from under the workpiece and vacuuming.

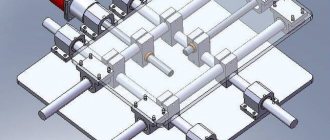

Rotary for CNC

The principle of operation is no different from the previous model, but it is designed in such a way that it can be rotated. This significantly speeds up and simplifies the workflow. The vacuum hose can be connected both in the central part of the stove and at its end.

This allows you to make vertical, transverse and longitudinal movements on the treated surface. Also, such a slab model can create the desired angle of inclination. this allows you to work with round or spiral blanks in different planes.

Splined

This table is necessary for working with small blanks, as well as with parts that have many holes. This table is distinguished by an increased coefficient of friction, which creates a high vacuum force. This reduces the possibility of the blank shifting during operation and increases the accuracy of its processing.

With porous inserts

The plate of this table is designed for blanks of any shape and size. The fixing force depends on the area of the treated surface. Porous slab blocks can be made of aluminum, steel or bronze and eliminate the need for foil or other thin material during the process. There is also no need to reconfigure the table when the type of work changes.

Is it possible to do it yourself?

Buying a finished stove is quite expensive, so you can make it yourself. This is not a complicated process, but it is necessary to have all the necessary tools and parts in the kit.

Workpiece alignment

To ensure that the workpieces being processed do not copy the unevenness of the slab, the table must initially be perfectly flat. Therefore, the prepared sheet of metal should be leveled. It is enough to make 1-2 passes with a spiral cutter until it touches completely. The diameter of the cutter is 20 mm.

We make the work surface and boxes

The first step is to create a working surface. In the prepared and leveled sheet, it is necessary to make neat holes in a checkerboard pattern using a drill. The back side of the sheet is intended for adjoining the pump.

To make the structure more reliable, it is necessary to install partitions on the working surface. Their main function is to protect the future table from deformation during operation.

DIY groove cutting

The grooves should be cut in accordance with the selected pattern. Be sure to order the sealing cord in advance and cut grooves depending on its diameter. To begin with, it is better to make the depth of the grooves 2.5 -2.7 mm. If necessary, you can increase it. In operating condition, the cord should not protrude above the surface, otherwise there may be a loss of vacuum.

Making the route

You will need a PVC pipe with a diameter of 25 or 32 mm. The purchased equipment has through holes through which the pipes are routed to the circuit. If the working surface is continuous, you will have to make a slab of two parts, seal the joint and feed the route from the end.

For each branch you will need a separate ball valve, with which during operation you can use only those zones that are necessary.

Drilling holes

The holes in the plate have different purposes. The number of different holes also varies:

- each zone has 1 hole for supplying vacuum at the intersection of the grooves;

- along the centers of the squares to secure to a standard table, and the quantity will directly depend on the rigidity of the slab;

- to fix the workpiece at the ends - holes in the center of the squares.

Pump selection

This is the main detail in the entire design and special attention must be paid to the selection of the pump. If the stove itself is made according to a certain pattern, then you can see which pump is in the original. If this is not possible, then you will have to select equipment experimentally.

The cheapest option for a DIY table would be vortex blowers. Their advantages: do not require shutdown when the maximum vacuum threshold is reached, small size, ease of installation.

Control block

This is the electronic part of the table, which is necessary to regulate the heating of the working area. As a result, the workpieces are more securely fixed. The control unit has several types of implementation, and which one is suitable largely depends on the CNC machine to which the table is being made.

The main differences between professional equipment and homemade equipment

A homemade table has several specific advantages:

- it is cheaper than the factory version;

- can be made to individual sizes and for certain functional features;

- easy to maintain, since it is easier to get all the necessary spare parts for repairs.

At the same time, the factory model has original parts and can last longer than a homemade one. At the same time, creating a vacuum table with your own hands requires effort and time.

The vacuum table for the milling machine makes work more convenient and fixes the workpiece. Some equipment models allow you to rotate the workpiece at the desired angle. If the CNC machine does not include a table, then you can make it yourself using the available diagrams and drawings.

Matrix (lattice) work tables of a CNC machine

Matrix tables are made of sheet composite material based on phenolic resins and synthetic fibers.

The surface of the working table is divided by blind channels in the form of a lattice, to which vacuum is supplied through special holes. In order to create a vacuum area for fixing a part on the work table of a CNC machine, it is necessary to insert a sealing cord into the channels around one or more vacuum supply holes. In this case, the cord should not protrude beyond the perimeter of the workpiece being secured, and its ends should be tightly closed to prevent air leaks. The remaining unused openings of the worktable vacuum supply system are closed with rubber plugs.

This method of attaching a workpiece to a CNC machine table is most effective when processing the upper plane of a part with cutters. However, if in the process of manufacturing MDF facades it is necessary to process the sides of the workpiece, or to perform a curved cut, when the lower edge of the cutter should extend beyond the workpiece, then in order not to damage the surface of the work table, a so-called “sacrificial” substrate is used.

Any available porous materials can be used as a “sacrificial” substrate. As a rule, this is sanded chipboard, rough MDF or HDF.

Due to the porosity of the substrate material, by the force of the vacuum system, air is quickly pumped out of its internal structure, and a vacuum area is created on the surface. Thus, if you place the laminated part blank on this substrate, it will be pressed tightly against it and securely fixed.

Using a “sacrificial” substrate on the desktop of a CNC machine, you can mill individual parts, as well as cut and process large-format sheets using Nesting technology.

However, it is worth noting that when cutting large-format sheets on a CNC milling machine in this way, you can encounter a strong loss of vacuum in the area of the cuts and, as a result, small parts and scraps are displaced or fly out from under the tool. To minimize the likelihood of such situations occurring, before using a “sacrificial” substrate, you should make sure that the vacuum pump has sufficient power and the supply elements of the vacuum system have sufficient throughput.

The design features of a matrix-type work table will help solve the problem in a situation where you need to process small workpieces on a CNC machine, or eliminate the possibility of parts moving when processed using Nesting technology. The fact is that manufacturers of woodworking CNC milling machines practically offer a worktable design consisting of several autonomous matrix worktables separated by T-slots.

The effect of dividing the working surface into separate zones is achieved when, in accordance with the programmed order of processing parts from large-format panels, by opening or closing the valves of the vacuum system, all the power from the operation of the vacuum pump is not distributed over several zones, but is transferred to the area where processing is currently being done.

T-shaped grooves on the working surface of the CNC machine allow you to fix the workpiece without using a vacuum system, using mechanical clamps (clamps). On the one hand, this method allows you to reliably fix small parts. On the other hand, turn off the vacuum pump and save energy when processing workpieces using the engraving method, when the entire process can take several hours.

It should also be noted that some CNC machine manufacturers offer a set of vacuum suction cups, similar to those used on console tables, as an additional option for the matrix work table.

DIY vacuum press. Part III. Vacuum table

Making a vacuum table is the most critical stage in constructing a thermal vacuum press with your own hands.

At the design stage, it is necessary to determine the dimensions of the table, select the material for its manufacture, and think over ways to fix and seal detachable elements to maintain internal negative pressure (vacuum). The vacuum table is made with the same basic set of tools as the press bed.

Further in the text, we will call a vacuum bath a part of a vacuum table - a steel container, inside of which the workpieces to be coated are located, and from which air is pumped out.

By working dimensions (dimensions) of a vacuum bath we mean its useful volume, measured by internal dimensions.

We will agree to call the vacuum table the entire structure as a whole, consisting of a vacuum bath, an upper (movable) pressure frame, clamps and other smaller elements.

Illustration of external and internal (working) dimensions of a vacuum bath.

External and working dimensions of the vacuum bath

Let's consider the general principles for choosing the size of a vacuum bath, and outline specific numbers for our press.

The longer the vacuum bath, the more workpieces can be placed in it, or a larger workpiece can be veneered. On the other hand, the longer the bath, the more film has to be consumed in one working cycle, the larger the dimensions of the machine, which entails a greater consumption of room space. You need to find the optimal size.

As experience has shown, the optimal working length of a vacuum bath intended for the manufacture of standard furniture facades and decorative door trims can be considered to be from 2.4 to 2.6 m.

We will make a vacuum bath 2500 mm long, the working length of which will be 2500 - 40 x 2 = 2420 mm (40 mm is the width of the short wall of the profile pipe).

The width of the bath is directly related to the width of the PVC film used. Depending on the film manufacturer, there may be different widths, the most common is 1.4 m, which is what we will focus on.

Let's choose the width of the bath equal to 1400 mm, the working width will be 1400 - 40 x 2 = 1320 mm.

When facing tall workpieces, for example, for curved (radius) facades, the width of the bathtub must be reduced (made smaller than the width of the film), but to work with such workpieces a press of a different design is needed, so these issues will not be considered.

The working height of the bathtub should be calculated based on the requirement that there is a small free space between the upper surface of the facades and the covering film. In other words, the film stretched over the workpieces should not touch them before air is pumped out. The calculation is as follows.

Firstly, the vacuum (breathable) tabletop, which will be the first to be placed on the vacuum table, will be made of 10 mm thick MDF board. Secondly, the linings for the facade blanks will be small pieces of MDF board 16 mm thick (this is the simplest, most common and optimal option for linings).

Thirdly, the thickness of the veneered blanks will range from 8-10 mm (door linings) to 16-32 mm (facades and other furniture elements). Fourthly, the sealing rubber will add about 2 mm to the depth of the bath. As a result, the maximum height of the entire “pie” inside the bathtub will be: 10 + 16 + 32 = 58 mm.

To make a vacuum bath, we will use a profile pipe with a cross-section of 60×40 mm, placing it on the short side. At the same time, the height of the free space will be no less than: 60 + 2 – 58 = 4 mm, which is quite enough.

Elements of a vacuum table.

Vacuum bath

The bottom of the vacuum bath will be a sheet of steel 2 mm thick. To minimize the deflection of the sheet under the influence of negative internal pressure, and to give the table surface an even shape (close to an ideal plane), it is necessary to make a rigid frame. To make the frame we will use the same profile pipe 60x40x2.

The pre-cut pipe, in accordance with the design, is laid on the slipway, rigidly fixed with clamps, and all connections are welded. After making the stiffening frame, a steel sheet is welded on top of it.

This is the most critical stage of welding work; it requires a continuous weld to be hermetically sealed (it is recommended to perform double penetration).

To avoid warping of the sheet under the influence of prolonged high temperatures, you can use the following alternative method of welding the sheet to the stiffener frame.

Before laying the steel sheet on the stiffening frame, it is necessary to apply a sealing compound that can withstand high temperatures along its perimeter (for example, high-temperature silicone sealant), and welding should be carried out not with a continuous seam, but with small regular fixing tacks with a pitch of about 50 mm.

This method is designed to ensure that short-term, local welding effects will not damage (burn out) the entire sealant, but only a small part of it in the immediate vicinity of the tacks, while most of the sealant, after curing, will perform its direct function.

Vacuum table dimensions.

Detailing of the stiffening frame and the procedure for assembling the vacuum bath: the stiffening frame is welded, a steel sheet is welded to it, a stationary (lower) frame with a part of the hinge joint for attaching the lifting (upper) frame is hermetically welded around the perimeter of the steel sheet.

Photo of the vacuum table from below. The stiffening frame is made partly from an angle profile.

Lifting (clamping, upper) frame

Frame material - profile pipe 60x40x2 mm. The dimensions of the pressure frame must be exactly the same as those of the vacuum bath.

If it was not possible to find a sufficiently even (not bent, not twisted) profile, then it is necessary to pre-select in pairs several of the smoothest rods from which the parts of the vacuum table will be made tightly adjacent to each other.

The clamp frame will rise thanks to adjustable hinge joints. The adjustment of the hinges is carried out after gluing the seal - strips of sheet rubber of medium hardness, about 2 mm thick.

Pressure frame hinge. Welded washers are needed to increase the friction area. The hinge pin is a D12 steel rod with threaded ends.

Photo of the clamping frame hinges.

To hold the clamping frame in a raised state, gas lifts can be used. For safety reasons, it is recommended to install four gas lifts (two per side) and ensure that any three of them can support the frame.

If the opening angle of the frame (45°) turns out to be insufficient, the frame will cause significant inconvenience in operation; it can be raised as high as possible at an angle of slightly more than 90°, using the thermal module parked behind as a support (gas lifts are not used).

The lifting frame rests on the thermal module.

Clamps

To securely and tightly hold the film during vacuum pressing, it is necessary to firmly and evenly press the upper frame to the perimeter of the vacuum bath, ensuring that the rubber seal fits everywhere.

For these purposes, you can use various ready-made clamps, or make them yourself.

To make homemade clamps operating on the eccentric principle, you will need the following rolled steel: half a meter of DN50 pipe (external diameter about 60 mm), two meters of rod with a diameter of 10 mm, and approximately the same amount of profile pipe with a cross-section of 20x20x2 mm.

Firstly, the DN50 pipe is cut into 8 equal 60 mm sections. Each pipe section is finished with a semicircular central cutout having a width of 10-11 mm and an arc length equal to 3/4 of the length of the outer circumference of the pipe. We get 8 pieces of eccentric rotary cylinders, to which we need to weld a handle 220 mm long from a square profile 20x20 mm.

Secondly, the steel rod is cut into 16 pieces: 8 pieces 190 mm long (for studs) and 8 pieces 55 mm long (for kingpins). An M12 nut (or M10 with a drilled thread) must be welded to one end of the stud so that it can rotate freely on the pivot, and an M10×50 thread must be cut at the other end.

Thirdly, to complete the manufacture of the clamp, we weld the ends of the kingpin (with a nut with a welded pin pre-installed on it) to the inner surface of the eccentric rotary cylinders.

To install the clamps on the vacuum table of the press, at eight points of the table, according to the design, through holes with a diameter of 10 mm are drilled. After which, the upper holes are enlarged, giving them an oblong shape.

The clamps are adjusted by installing combination nuts in the desired location on the stud thread, followed by fixing them with locknuts.

This operation is performed at the last stage of manufacturing the vacuum table, after gluing the rubber seal.

Operation of the eccentric clamp.

Elements and dimensions of the hinge clamp.

Eccentric clamp in the table. The hooks for the clamps are made from 50x50x3 angle steel.

If you cannot achieve a flat table surface

If during the welding process the sheet has undergone significant deformations that go beyond the permissible values, then there is no need to pick up a grinder and cut off the welds and redo everything again.

You can ensure a perfectly flat plane of the vacuum table by additional measures, namely by using epoxy leveling compounds, which are used in the manufacture of poured floors.

To do this, the vacuum table is set strictly according to the level, the required volume of the filling mass is determined (for example, by test filling with water), the bottom of the vacuum bath is cleaned of rust, and it is primed. Fill with the prepared epoxy mixture according to the manufacturer's instructions.

For reasons of economy, the mixture can be diluted with some cheap filler, for example, quartz sand. To speed up the curing of the mixture after pouring, the table can be controlled from above with heat from the thermal module. It makes sense to carry out this filling leveling operation after the vacuum press is fully ready, test samples of products have been manufactured, and a decision has been made about the need to improve the geometry of the working surface.

Estimate for material for a vacuum table

Name Length, mm Quantity, pcs. Purpose

| Profile 60×40 | 2500 | 6 | Rigidity frame. Bath. Lifting frame. |

| Profile 60×40 | 1380 | 4 | Rigidity frame. |

| Profile 60×40 | 1320 | 4 | Bath. Lifting frame. |

| Profile 60×40 | 1001 | 6 | Rigidity frame (diagonals). |

| Profile 60×40 | 753 | 3 | Rigidity frame. |

| Profile 60×40 | 250 | 4 | Hinge. |

| Profile 60×40 | 180 | 2 | Hinge. |

| Profile 60×40 | 150 | 2 | Clamp support. |

| Profile 60×40 | 140 | 2 | Hinge. |

| Corner 50x50x3 | 50 | 8 | Lifting frame (clamp hook). |

| Profile 20×20 | 220 | 8 | Clamp. |

| Pipe DN50 | 60 | 8 | Clamp. |

| Rod D10 | 190 | 8 | Clamp. |

| Rod D10 | 55 | 8 | Clamp. |

| Rod D12 | 150 | 2 | Hinge. |

| Nut M10 combi | 8 | Clamp. | |

| Nut M10 | 12 | Clamp Table mount. | |

| Nut M12 | 16 | Clamp Hinge. | |

| Washer d12 | 12 | Hinge. | |

| Bolt M10×60 | 4 | Table mount. | |

| Sheet 2500x1500x2 | 1 | Table (bottom of the bath). | |

| Gas elevator | 2 | Lifting frame. |

Upon completion of the main scope of work, the vacuum table is installed on the frame (on specially provided supports) and fixed in the corners with four bolts, as shown in the figure, after which they move on to minor work: installing and adjusting the clamps, adjusting the lifting frame hinge, gluing the seal.

Mounting the vacuum table on the frame.

Vacuum table in operation.

The metal structure is beginning to take on the shape of a future thermal vacuum press, but it still lacks many elements: a vacuum system, a thermal module, an electrical control unit, which will be discussed in the following articles.

How to make a vacuum table for a milling machine with your own hands?

Often CNC (Computer Numerical Control) machines are sold with a vacuum table. It is designed for fastening sheet parts with their subsequent processing. As a rule, processing of such workpieces is curvilinear in nature.

In this case, parts can be made from a variety of materials - chipboard, veneer, plywood. Most often, vacuum tables are used on milling machines that process solid sheets (for example, in the manufacture of furniture).

What does a vacuum table look like?

This device is a processing surface with a coating divided into sectors. Special suction cups and grooves are evenly distributed over the area of the device, which secure the workpiece in the required position. The larger the area of the vacuum table, the more functional and expensive it is.

The workpieces are fixed using a special vacuum pump. It is he who is responsible for reliable fastening of the workpiece to the table surface. Thanks to this invention, curved processing of sheet parts with large dimensions became possible.

It is noteworthy that vacuum vacuum cleaners are preferably used for processing wooden workpieces. If there is a need to perform similar work with metal, then magnetic tables are used for these purposes.

It is worth noting that depending on the size and functionality, the price of vacuum tables can vary significantly. At the same time, even the cheapest factory vacuum table will cost the buyer at least 150-170 dollars.

You can also purchase a used device, but the quality of such a table will always be in question. It is because of the factors listed above that many craftsmen create vacuum tables at home.

Vacuum clamp for plastic molding

It is possible to make such a device at home, but it is not an easy task. You need to understand the specifics of the device’s operation and the principles of its structure. Any stable sheet material, for example MDF, is suitable for forming a vacuum table. We create the contours of the table like a box and drill holes on the front side of the panel using an ordinary drill.

We attach special legs to the same box and install partitions with holes with a diameter of 7 to 8 centimeters. We do all this to add stability to our table and prevent it from deforming during use.

Non-chrome wire is often used as a heater. This approach entails quite high costs, and it is also quite difficult to find suitable material. As an alternative, you can use halogen lamps. It is better to sacrifice the heat level, but get affordable and effective heaters for your homemade vacuum table.

Halogen lamp sockets should be installed in pre-drilled slots in the metal sheet.

We make tracks for conducting current from printed circuit boards, install them on the base and only then solder them. Otherwise, you will have to spend a lot of time soldering the tracks.

The panel with light bulbs must be in a box with a lid that will allow servicing of the device.

This approach to creating a heat source allows you to heat the entire area, and, if necessary, only individual areas. But to make such a “smart” device, you need to pay more attention to connecting the lamps.

Key Vacuum Table Controls:

- Symmetrical thyristor with operating parameters from 20A and 240V. Its function is to regulate the heating process and coordinate the operation of the fan.

- Front panel with liquid crystal display. The table interface should display the status of each heating row. The panel also contains the device activation key and an emergency shutdown button.

- Board with electromechanical relays (6 pieces). 5 relays activate the heater lines, and the sixth one activates the fan.

- Table temperature indicator.

- Neutral relay board. It consists of electromechanical relays (7 pieces). Their function is to connect the heater lines to the neutral cable.

- Microcontroller with board (ATmega644). It is to this device that the temperature sensor, pressure indicator, display, mode switch, and relay board are connected.

- AC control unit. Its function is to compare the signal from the microcontroller, the symmetric thyristor and the AC lines.

Installation of supports for heaters is carried out on a box that has been prepared in advance. After this we install the heater panel. It is also necessary to install a special frame for plastic. We insert it into the supports on special bearings. To better secure the frame around the perimeter of the table, use insulating tape.

The key element of the vacuum table is the fan, which must be attached to the underside of the box. It is worth noting that the vacuum source can be mounted using an additional plate and neoprene gaskets.

After the final creation of all the key elements of the vacuum table, you can begin its installation. Before testing, you should check the quality of all connections, the uninterrupted and safe operation of the electrical equipment of the machine and table.

A similar type of table, only without heating lamps, is also suitable for a milling machine. Thus, we have described for you the independent development and installation of the most complex type of vacuum tables designed for plastic processing. To work with metal or wood, it is enough to correctly make only the lower part of this device.

Instead of a fan, a powerful pump can be used as a source of vacuum. In the place where the heating elements are located at the plastic table, you should have a milling machine.

: vacuum table.

Important nuances

- A special vacuum generator can be used as a source of vacuum. It looks like a small box with a hole for air outlet and vacuum inlet. Also, for devices of this type, an indicator must be installed to measure vacuum indicators.

- The ejector and its level of performance depend on the speed and volumes of air that fly past it. That is why it has little to gain compared to a conventional vacuum pump. After all, to create a high-quality vacuum, you should also use a high-quality compressor. The fact is that to fasten a large part over the entire area of the table, a fairly weak compressor is enough, but to fix a small plate, you need to use a more powerful unit.

- An ordinary industrial vacuum cleaner is poorly suited for creating vacuum clamps, since it is not very suitable for working with a completely closed hose. That is why it is recommended to use a special vacuum pump.

Do-it-yourself vacuum table for CNC: step-by-step instructions | mk-soyuz.rf

To work on a CNC milling machine with large parts, a large vacuum table is required. Such equipment is very expensive due to the complexity of transportation and is not always suitable for certain tasks, but you can design a table yourself, to suit your individual size and needs.

Vacuum tables for CNC are designed for milling machines that work with large sheets of wood or metal. Most CNC machines use curved machining. To work on milling machines, you need a surface that reliably holds the workpieces.

The vacuum table presses the products to the surface, preventing them from moving, making work on the milling machine more accurate and comfortable. In addition, complete equipment provides heating to the required temperature.

It is more versatile than a magnetic table, which is only suitable for processing metal products.

Quite often, CNC milling machines come complete with a vacuum table, but if it is absent or is not large enough, another device is required. In this case, you can buy a used device of questionable quality or make it yourself.

The difference between factory equipment and individual equipment

Creating working equipment allows you to adapt the tool to individual needs. Self-designed vacuum tables can be adjusted to the required dimensions and include all functions from milling to forming work. The main advantages of such a table are:

- saving money,

- individual sizes and functional features,

- ease of maintenance due to the availability of spare parts.

The main disadvantages are the large expenditure of time and effort, less high reliability compared to factory analogues and the lack of warranty service.

Loading…

Features of choosing a router design

The capabilities of modern CNC equipment are enormous. But no machine is universal. Each model has its own characteristics and preferred area of application. Before choosing a specific design, you should clearly determine what the machine will be used for. An attempt to combine everything in one will lead to large material and physical costs, without guaranteeing results.

Today, there are two directions in the design of desktop routers. The first, the simplest, is focused on processing wood, plastic and other soft workpieces. Such machines do not place high demands on structural materials and are simple and low in cost. They are available for self-production, without the use of additional equipment. Metal products on such devices are usually not milled. In rare cases, only soft non-ferrous metals are sharpened at low feed rates.

The second direction of milling cutters is focused on working with metal workpieces. These machines have a significant mass and consist of parts that can only be completed using a serious machine park.

The second most important parameter of the machine is the dimensions of the processed parts. Beginners immediately want a large field where they can do whatever they want

But the larger the machine, the more technical problems will have to be solved during its design. And its cost will not be the most optimal. If there are no specific tasks for a large machine, then it is recommended in the first project to limit the processing field to the size of a standard A4 paper sheet. The maximum you can choose is A3.

Do-it-yourself vacuum table for CNC - Metalworker's Guide

To work on a CNC milling machine with large parts, a large vacuum table is required. Such equipment is very expensive due to the complexity of transportation and is not always suitable for certain tasks, but you can design a table yourself, to suit your individual size and needs.

Vacuum tables for CNC are designed for milling machines that work with large sheets of wood or metal. Most CNC machines use curved machining. To work on milling machines, you need a surface that reliably holds the workpieces.

The vacuum table presses the products to the surface, preventing them from moving, making work on the milling machine more accurate and comfortable. In addition, complete equipment provides heating to the required temperature.

Quite often, CNC milling machines come complete with a vacuum table, but if it is absent or is not large enough, another device is required. In this case, you can buy a used device of questionable quality or make it yourself.