Cover the silver piece with resin and make a masterpiece

Silver and bronze paints are used to create decor. To do this, just paint the selected item with a brush and apply 2 layers. After complete drying, polyester resin is applied on top. Metal powder takes on the appearance of real silver or gold. The glossy appearance is maintained for a long time. After approximately 3 years, the resin coating is renewed.

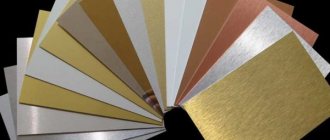

Silver paint

Secrets of applying silver paint

There is nothing complicated about applying silver. In order to begin this process, you must first thoroughly clean the working surface from the previous layer of paint, metal, lime, etc. The metal surface should be cleaned of rust and scale. If you can’t remove layers of old paint, the surface can be primed.

If you are going to coat wooden materials with silver, you should first sand them thoroughly. For painting, you can use any tools that are more convenient for you to work with - a sprayer, a brush, a roller. Silver should be applied to the surface in two, or better yet, three layers. When choosing a brush as a tool for painting, you should remember that you need to be very dexterous and nimble, because if you hesitate even a little, the paint may have time to dry. As a result, everything will be painted unevenly.

Advantages and disadvantages

Serebryanka is very popular due to many advantages:

- It does not flake, although the paint layer is thin.

- Protects materials from the negative influences of the surrounding atmosphere.

- Used for various types of materials (cement, metal, wood).

- Long service life.

- Does not release toxins.

- Resistant to high and low temperatures.

- Dries quickly.

- Has a beautiful color. When using pigments, many shades are achieved.

The disadvantages of silver oxide include its explosiveness, so storage is provided in a dry place, in a tightly closed container, away from sources of fire. It is not recommended to keep silverfish near food, as its smell is quickly absorbed.

In addition, silver is not compatible with oil and alkyd substances. Also, it is not applied over nitro enamel and NBC, as it will peel off quickly.

How to age metal yourself

The choice of method for creating an interior style, which assumes the presence of traces of antiquity in the design, is quite wide. For connoisseurs of this style, it is not always affordable to purchase real old items. The way out of this situation is to imitate ancient metals. How to properly paint antique metal with your own hands? Coloring is carried out in stages:

- Preparing the surface for painting. We get rid of dirt, rust and traces of grease by grinding and solvent treatment.

- Metal priming. In this way we achieve the formation of roughness on the surface for better adhesion of the paint. We choose a primer special for metal.

- Application of selected metallic paint. Experts advise performing the process using a regular brush, this way aging is achieved in the best possible way.

- Aging stage. When the paint has dried, coat the surface with a special craquelure varnish. It is after this step that the metal object becomes covered with cracks, which create the effect of an old product.

On video: master class on applying patina to forged metal.

Surface preparation and painting

Before proceeding with painting, it is necessary to carefully prepare the surface. Rust, remnants of old paint, and scale are removed from metal using abrasive paper or metal brushes (nozzles). Silver has good adhesion to objects being painted, but the effect will be better if you prime them once.

How to paint with silver? It is applied evenly over the entire surface in 2-3 thin layers. The wood is also sanded. It is especially important to remove remnants of other types of paint, otherwise the silver may peel off.

Concrete and brick surfaces are cleaned of lime and chalk. It is recommended to prime once, but if thoroughly cleaned, it can be applied without prior priming. The walls must be dry. Silver paint dries quite quickly (up to 4 hours), but sets faster. Therefore, it is better to correct defects when painting before it is completely dry.

To remove random stains from silverfish, use a solvent. If it is not completely dry yet, you can soak the stain in vegetable oil and then wipe it off.

Types and composition of silverfish

In fact, the paint got its name not because of the presence of silver particles, but because of the corresponding color. Serebryanka is a fine aluminum powder of a light gray steel shade. This powder product is used for diluting and painting various surfaces. Thus, the paint base is obtained from aluminum waste by crushing. There are no other components in the silver itself.

There are two types of silverfish - PAP1, PAP2. Difference in particle size, material dilution proportions. The first option is made from larger particles, the second - from the smallest. Both production methods comply with GOST 5631-79. Also, recently a ready-made thick material has appeared in stores - PD silver paste. It costs more, but it is much more convenient to use for painting surfaces - you just need to dilute it. There is already diluted paint BT-177 on sale, it is completely ready for application.

Liquid glass for concrete waterproofing

In construction, they often resort to diluting liquid glass in a concrete mixture to improve its quality. To obtain the desired high-quality effect, the features of the process should be taken into account:

- It is unacceptable to add liquid glass to the finished mixture; they start by preparing the mixture, and add glass to the water, mix them, then pour them into the dry mixture;

- The ratio of materials can be varied in order to obtain various properties, so the recipe is selected according to the situation, and then strictly adhered to;

- Adding liquid glass helps improve the solution, but the curing process will be shortened, so it is recommended to prepare a small amount at a time.

The ratio of materials can be varied to obtain different properties.

Features of aluminum paint, characteristics

The base for the composition is selected based on the material and place of application. In addition to drying oil, aluminum powder is diluted in varnishes:

- alkyd;

- organosilicon;

- bitumen.

We paint the details with silver

Drying oil should be preferred when covering wood and for obtaining matte paint. The consumption of silver will decrease if the surface is first coated with a primer.

Organosilicon varnish is widely used to paint cables and electrical appliances operating in tropical climates and under high heat. Silver on this basis has high anti-corrosion resistance, antistatic and electrical resistance.

The process of breeding on drying oil

Serebryanka has a number of undeniable advantages:

- lies on the base in an even layer;

- it is resistant to mechanical damage and high temperatures;

- dries quickly;

- has a long shelf life and operation;

- has a wide scope of application;

- non-toxic;

- has a creative design.

However, despite the impressive list of advantages, this paint has a number of disadvantages:

- the mixture in dry form is explosive;

- the paint is not intended for application to alkyd or oil bases, since in reaction with them it bubbles and does not adhere well;

- it is not used for painting galvanized coatings, since such compositions are also susceptible to rust.

The process of diluting silver with drying oil is divided into three stages:

1. Preparation. Before proceeding with the procedure, you need to prepare the necessary tools and devices. For these purposes you will need rubber gloves, an unnecessary jar and a brush. In addition, you need to prepare drying oil, which you will directly use to dilute the silverfish in the required proportion. Drying oil must withstand temperatures up to 350 degrees.

2. Making the mixture. When mixing the ingredients, the paint should not be thick enough. If the density is higher than normal, white spirit or another solvent should be used.

Proportions

How to properly dilute silver linseed oil? In order for the composition to be stable and lay evenly on the surface, certain proportions must be observed. As mentioned earlier, the dilution ratio depends on the type of silverfish:

- pap1 – Take one part of powder for five parts of drying oil;

- dad2 – Take one part of powder for three or four parts of varnish.

The mixture is mixed well and a solvent is added at the end of the procedure.

Breeding Features

In addition to the listed nuances of diluting silver linseed oil, there are some features of this procedure:

- Synthetic varnishes are more suitable for diluting paint, but you need to work with them in an open, well-ventilated area.

- If you want to make a heat-resistant composition, then KO185 varnish is more suitable for such purposes. This paint is excellent for covering fireplaces and is diluted in a ratio of two to five (five varnishes, two powders).

- After mixing these components, the solution will still be quite thick. In order to correct the situation, white spirit, solvent, turpentine, toluene or other solvent mixtures are used.

- If the work is carried out with a brush or roller, then the proportions of paint and solvent are taken in a ratio of ½ to 1. If a spray gun is used, then the dissolution should be one to one.

- You need to stir the solution until it becomes homogeneous and small lumps are eliminated. On average, this process takes about ten minutes.

The process of diluting silver powder with drying oil is not particularly complicated. The main thing in this procedure is strict adherence to proportions and sequence of actions. Otherwise, the paint will lose its properties, will apply unevenly and will last much less.

Dilution of paint

Silver can be easily diluted with varnish. The thinner is heat-resistant varnish BT-577, which is intended for PAP1 powder. For PAP2, any varnish can be used. The order of dissolution of PAP1 is as follows:

- pour 2 parts of dry material into a container;

- add 5 parts of varnish;

- Mix the product well until you get a homogeneous mass.

Varnish BT-577 further increases the heat-resistant properties of silver, therefore it is recommended to use it if the paint will be applied to surfaces exposed to heat. In other cases, you can use PAP2. It needs to be diluted in a different proportion: take 3-4 parts of varnish for 1 part and mix well (about 5-7 minutes). If the portions of the product are large, it is better to use a construction mixer or drill with an appropriate attachment.

Silverfish can also be diluted with synthetic drying oil. The only downside is that the finished product will not have the heat resistance it does after adding varnish. Natural drying oil is not suitable; it will not provide sufficient uniformity of the paste. PAP1 is diluted with drying oil 2:5, PAP2 - 1:3 or 1:4.

Next, you can bring the paste to a state in which it is suitable for painting. You will need to dilute it with turpentine or solvent, as well as another organic solvent. The ratio with thinner depends on the paint application method.

If you decide to work with a roller, then you need 2 parts of paste to 1 part of solvent. For application with a brush and spray gun, the proportion is 1:1. To dilute ready-made store-bought paint that has thickened a little, use solvent 646 (up to 20% of the total paint volume). To change the color, special pigments can be introduced into silver.

Universal heat-resistant paint of the Soviet era

Manufacturers offer a wide selection of heat-resistant materials for coating metal, stone and wood. Silver powder still remains among them. The two-component composition has its own characteristics that make it competitive for decades.

We paint calipers and brake discs with silver

- lays down in a thin layer, repeating the texture of the surface;

- beautiful decorative appearance;

- moisture resistant;

- anti-corrosion;

- non-toxic;

- low consumption;

- heat resistant;

- dries quickly;

- applied to different materials;

- easily removed.

For high-quality coating, you need to know how to dilute silver. Depending on the desired result, varnishes or drying oils are used as a base. The proportions are determined by the base and size of the aluminum fraction - silver grade.

A little theory

Initially, you need to understand the composition of silver paint in order to have at least the slightest idea of what you will have to work with.

Here are a few points to help you figure it out:

- It is a mistake to think that it consists of silver - it is not there in any form. It is present only in the name, but then the question is - why is the paint called that? Of course, because of the color it has, which, in turn, is obtained by finely grinding pure aluminum and its waste (mostly from waste, since solid aluminum is expensive to use).

- Before the preparation of silver paint begins, it is a powder (aluminum powder), which is diluted with special means.

It is divided into two categories:

This is what the paint looks like in its original form before it was stripped

- PAP-1 is the first category, the powder particles are much larger.

- PAP-2 – second category, smaller fractions.

Note! The size of these very particles does not in any way affect the quality of the diluted paint. Categories are important for separating the industries in which silver is used.

- The pristine powder can be not just paint, but also have heat-resistant properties. Here, the material that serves as the basis for cooking plays an important role.

Important! Very often, unscrupulous manufacturers mix various “additives” into the paint, which deprive it of its original properties, so our advice is to make silver with your own hands. This makes the price lower and the quality higher, if, of course, it is prepared in the correct proportions.

We do it ourselves

The following will describe detailed instructions on how to make silver paint at home:

- After you buy the necessary materials, prepare dishes (containers) that you won’t mind throwing away, since it will be impossible to wash off the paint.

- Pour the powder into a container and pour in varnish or drying oil (this is the answer to the question - how to dilute silver for painting).

- The ratio should be 2 to 5.

- The varnish is poured gradually, with frequent stirring.

For your information! Builders prepare the mixture using a mixer, but at home you can use an ordinary oblong object, unless you have to stir vigorously for 10-15 minutes.

If the composition is too thick, you should add white spirit to it, but be careful, if you make the paint too thick, it will be unevenly distributed on the surface.

Important! Before preparing silver paint, protect your face and skin of your hands - glasses and rubber gloves are required when working with the solution.

Pros and cons of silver

The material has a lot of advantages. It is perfect for interior work, because after drying it becomes non-toxic and 100% harmless. Although there is a smell during operation, so safety precautions must be observed. Other advantages of paint:

- adheres securely to the base, has good adhesion, and lasts a long time;

- can dry quickly and will not require long-term absence of residents from the premises;

- gives the metal anti-corrosion properties and resistance to UV radiation;

- The paint is easy to apply, it does not leave streaks or drips;

- You can paint any material with silver, not just metal;

- the finished paint is stored in an airtight container for up to 6 months, dry powder does not deteriorate much longer;

- The paint can be diluted in different proportions with the solvent, due to which the finished shades will differ;

- The decorative properties of the material are high; it improves the appearance of metal and old wood.

Now some types of silver contain additional additives (for example, liquid glass), which provide enhanced fire-fighting properties. The paint itself is heat-resistant, it can even be applied to stoves, potbelly stoves, radiators, radiators, and pipes. In industry, it is used for painting boiler rooms, bridges, underwater parts of ships, various tanks, and parts. You can paint with silver those products that are used outdoors under the influence of temperature changes, in aggressive conditions.

The disadvantages include the inability to paint with silver when the windows are closed. You will definitely have to buy a respirator and gloves. The powder itself is explosive before application. After drying, the surface will be vulnerable to contamination; it is difficult to wash due to its non-smooth structure. Also, the material will not adhere to oil, alkyd paints, or nitro enamels; they will have to be completely removed.