Nowadays, sandwich pipes have gained the most popularity when arranging gas ducts. They have excellent performance characteristics. Therefore, these designs are in great demand.

The production of sandwich pipes for chimneys is a profitable business. In this article we will analyze the main aspects associated with the manufacture of these products.

Organizational aspects

To begin production of the products in question, it is necessary to select a good premises for production. Its area must be at least fifty square meters. In such an area you can compactly place the necessary equipment.

It is important that the air temperature in such a workshop is not lower than eighteen degrees. Equipment for the production of sandwich pipes will largely coincide with that used for the production of air ducts and ventilation ducts.

Welding machine

To open a business you must have:

- welding machine;

- folding machine;

- mobile walk-through sheet bender;

- folding machine;

- equipment for rolling stiffeners;

- machine for cutting rolled metal.

Smoke exhaust ducts are joined using corrugated elbows. Therefore, it is wise to purchase equipment to make these fittings.

This machine comes in two types: semi-automatic and automatic. In the first case, your employee will have to manually reinstall the workpiece and restart the equipment.

Who should sell finished products to?

The price of a machine for making a profile pipe will pay off the faster the sooner sales channels are established. And the main bet here should be placed on the wholesale buyer. After all, this will allow the entrepreneur to immediately ship the manufactured products, rather than storing them while waiting for customers.

In any field, it is quite difficult for beginning entrepreneurs to conclude profitable contracts with wholesalers. Surely, first you will have to adapt to the client, reducing product prices.

And even making a profile pipe with your own hands in an empty garage will require a certain amount of advertising from the businessman. What options are possible here? You can try advertisements in newspapers, articles in specialized magazines, or your own website on the Internet.

Cutting machines

To manufacture steel products, it is necessary to trim it. For this purpose, laser machines or guillotines are most often used. For small production, the latter option is more preferable. Their prices are affordable. Plus, they take up little space.

To operate a manual guillotine, you do not need to connect to an electrical outlet. The device works through the use of physical force. It is convenient for cutting sheets up to 1.5 mm thick.

A good choice would be a pneumatic guillotine model. Such devices are equipped with a special pneumatic drive. If you are switching to mass production of sandwich pipes, it would be wise to purchase a mechanical model. Electric analogues are suitable for working with sheets whose thickness does not exceed ten millimeters.

Mechanical models are characterized by certain functionality that makes it easier to perform production tasks.

A good guillotine should have:

- control over hydraulic clamps;

- conveyor for receiving finished products;

- complex of support.

Most models have a capacity of 5 sheets/hour. The difference between them lies only in the thickness of the cut sheets.

Manufacturing of corrugated pipes

a line for the production of corrugated pipes is expensive.

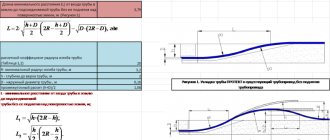

The corrugated pipe has a relief surface, which in longitudinal section resembles a ridge. This type of plastic pipes is widely used in construction for carrying out engineering systems - sewerage, water supply, electrical, ventilation. The advantages of this type of product are versatility of use, lightness and compactness during transportation, plasticity, and low cost. The manufacturing process is similar to the technology of ordinary plastic pipe and is carried out using a corrugated pipe production line. This line is complemented by a special device - a corrugator, which sets the general nature of production. The corrugator is located near the extruder head and consists of two halves with a channel for the flow of cooling water; at the working area, both halves merge, forming a closed space.

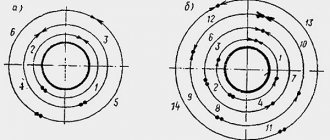

Corrugator operation diagram

The workpiece from the extruder enters the working space, where under air pressure it is pressed against the surfaces and hardens, and a certain shape is set - a corrugation. Next, the pipe is ready for winding. Unlike the PVC pipe production line, baths are omitted here; cooling occurs in a corrugator. Main characteristics of the line:

- dimensions – 9*1.9*2.5 m;

- power – 65 kW;

- weight – 2.5 t;

- speed – 1 – 12 m/min;

- productivity – 60 – 80 kg/h;

- diameter of the finished product – 16 -63 mm;

- cost – 2,800,000 rubles.

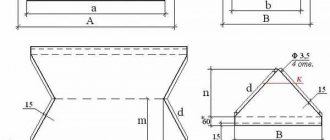

Rolling of stiffeners

To strengthen the design of products, you need to use special machines to create stiffeners. The process is carried out by bending the walls of the seal in increments of about twenty centimeters.

Such equipment includes two components that guarantee an even profile: a forming device and a welded bed. The first part most often looks like rollers with rollers.

The creation of stiffeners occurs simultaneously along the entire length. The key feature of this equipment is that the workpiece being processed is not subject to deformation.

Selecting a room

A workshop with an area of 100-300 square meters, located outside the city, is suitable for locating production facilities. An important point here will be the availability of convenient access for special equipment, trucks and cars.

Production workshops must be connected to the main utility networks, ventilation, air conditioning and heating systems, security and fire alarm systems.

Additionally, you need to take care of the arrangement of utility rooms and locker rooms for technical staff and an office for administrative workers.

Folding machines

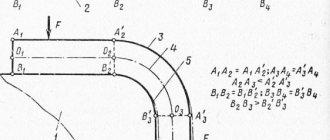

The folding method is much more practical for joining metal parts than welding or adhesive.

The key purpose of the machine in question is to create a perfectly smooth joint between several components. This equipment allows you to create various types of connections. Including double and single.

Folding machine

The operating principle of the device is quite simple. The forming part pulls the metal sheet along the equipment. This produces double-type folds. They allow you to create a reliable locking connection between two parts.

When choosing this technique, you need to clearly know what thickness of metal you will have to work with. Mobile types of units are characterized by simple maintenance.

There are models in which it is possible to change the settings of the profiling rollers. They allow you to create connecting elements and slats. The functionality of the equipment is reflected in its price.

Manual folding machines are designed to work with stainless steel sheets up to 0.7 mm. To produce sandwich pipes, it is necessary to use more powerful models that allow processing structures not only made of stainless steel, but also galvanized and copper.

To bend the fold, folding machines are used. It is advisable to select equipment with an electric drive. Such models have twice the productivity of manual counterparts. Using this machine you can produce up to a thousand workpieces in one shift.

Profitability of plastic pipe production

Calculation of production profitability will be considered using the example of manufacturing PVC pipes 50 * 1.8 mm, weighing one meter - 0.6 kg.

There are many sizes of PVC pipes and fittings

The technical capability of the line is production of 80 kg/h, which is 133 m3/h. Provided that the equipment is fully loaded, 95,760 m3 will be produced per month. This will require 34 tons of raw materials, the price per 1 kg will be 44 rubles (SG-5 brand, China), which for the monthly norm will be 1,496,000 rubles. The salary for four workers, two per shift, will be 70 thousand rubles. Products can be sold at a price of 50 rubles per 1 m2 - with full sales of monthly output, the revenue will be 2,300,000 rubles - net profit - 750 thousand rubles. This amount will be reduced by the amount of rental premises, utility bills, transport and organizational expenses - approximately 200 thousand. There remain 550 thousand rubles, which will cover capital investments monthly. With a starting capital of 4,500,000 rubles for the purchase of a line for the production of plastic pipes, the payback period will be 12-18 months. To do this, it will be necessary to ensure full sales of finished products, and it is better to work on pre-orders, then there will be no excess production.

Mobile sheet bending machine

This technique must be chosen especially carefully.

Pay attention to points such as:

- Power indicator.

- Price.

It is important that the equipment has a good power reserve. Otherwise, the equipment may quickly fail under constant operation conditions.

Look for a model that can handle sheets that are thirty percent or more thicker than you actually need. The price of units depends on their category.

The equipment in question can be of the following types:

- hydraulic;

- electromechanical;

- manual.

The latest version of the technology does not have a mechanical drive. It comes in two types: stationary and mobile. For the production of sandwich pipes for chimneys, it is better to use a mobile version. There are models equipped with cutting blades. They make it possible to use equipment both for bending workpieces and for cutting them.

Hydraulic and electromechanical options are characterized by high cost. But without them it is impossible to create mass production. The simplest models of this type are suitable for processing steel sheets from 1 to 1.5 mm. More powerful analogs are used to work with workpieces with a thickness of up to twenty millimeters.

Machine tools are often equipped with a CNC complex. For a small business, purchasing this equipment is quite expensive. The average price of such systems is about eighteen thousand dollars. In addition, highly qualified personnel are needed to operate such a machine.

Main characteristics of plastic pipes

Polyvinyl chloride (PVC) pipes today are widely used in various sectors of the economy, mostly, of course, in construction. This type of pipe has replaced metal pipes and is increasingly pushing them out of the market. It is not surprising that today more and more people are investing in the development of this business. The main cost item is the line for the production of plastic pipes, but high productivity and low cost of consumables quickly pay for the investment.

Plastic pipes are suitable for: water supply, sewerage and heating

The high demand for plastic pipes is due to a number of distinctive characteristics:

- they are not subject to corrosion;

- lightweight – 5-7 times lighter than metal analogues;

- not affected by high and low temperatures;

- limescale is not deposited on them;

- long service life - up to 50 years;

- they do not affect the taste of the water.

Such quality advantages allow the use of pipes in heating and sewer systems, water supply and gas systems.

Folding machines

These units are used for the purpose of upsetting the seam in the manufacture of hollow cylindrical parts. There are models operating both manually and electrically. You should choose a machine whose pressing rollers are made of high-quality hardened steel. In the electromechanical version of the equipment, the clamping level is usually adjustable. This type of technology is quite diverse.

The difference between the models is:

- cost;

- productivity;

- the length of the folded seam;

- installation method;

- type of drive for moving the forming part.

Equipment with the same rebate lock length is characterized by an almost identical level of performance. The units under consideration allow processing up to fifty elements per hour.

Types of equipment for manufacturing

Equipment for the production of polypropylene pipes (exruders) are machines of the following types:

- Screw. They function similar to a juicer or meat grinder.

- Screwless. They are used to produce blanks from mixed materials. The main part in these mechanisms is the disk.

- Combined. In these mechanisms, the screw part is combined with a disk.

IMPORTANT! The screw type of machine is considered the most common equipment for the production of plastic products.

In addition to the extruder, lines for the production of plastic pipes also have the following equipment:

- Raw material supply system.

- A machine that cuts blanks.

- Container for calibrations and cooling.

- Pulling mechanism.

- Mixer.

- Conveying tape.

- Vacuum forming.

- An accumulating mechanism that stacks workpieces.

Important Details

Basalt or stone wool should be used as insulation. Use quality material if you want your products to have a good reputation. The fastening of two pipes of different diameters must be reliable. It is not enough to insert one element into another and fill the space between them with insulation.

Product Installation

Also, to produce sandwich pipes for chimneys, you need to use special software to design the products. If the workshop is well equipped and the work process is properly organized, then up to 500 finished products can be produced in one work shift.

Watch the video:

Estimated price of production line

Here it is worth considering the prices directly for the lines of the extruder and auxiliary equipment for the production of HDPE, PVC and other pipes, since these technological units are the main ones.

You can get acquainted with the estimated cost of lines for the preparation of plastic waste in the relevant sections on equipment in this article.

The leaders on the Russian market are representatives of Chinese companies. European models are also widely represented. For a manufacturer with minimal experience, their choice should be Asian-made machines.

The line price usually includes:

- extruder (single screw or twin screw);

- die (of a given diameter);

- calibrator;

- cooling, pulling and cutting devices.

| Trade company | Price |

| AsiaPlast (Dzerzhinsk) | 35-120 thousand dollars |

| InsTerra (Chelyabinsk) | 980 thousand rubles |

| TechnoPlast (Tomsk) | 3650 thousand rubles. |

| World Equipment (Podolsk) | 5585 thousand rubles. |

| Winter Delta (Krasnodar) | 3650 thousand rubles. |

Such a wide range of prices is explained by the different productivity of the machines. Conventionally, more expensive machines produce a larger volume of finished products per hour (in linear meters) and are more automated in control.

The presented equipment is quite versatile and can be used for the production of polyethylene and other pipes of various diameters, as well as for the production of other molded products.

What are specialized products and what types do they come in?

Profile pipes are manufactured for the assembly of metal structures of various sizes and purposes: frames, hangars, temporary and permanent greenhouses. Standard rolled metal with a round cross-section is not suitable for such purposes, just as profile pipes for water and gas pipelines are not suitable.

To ensure the feasibility of producing profile pipes, it is worth familiarizing yourself with the wide list of areas of application of these products:

- profile pipes of standard configuration. The scope of use has expanded to the construction of scaffolding, pipelines, protection of cable equipment, formation of irrigation systems or fencing.

- main profiles. They are used in the construction of large-sized pipelines with frequent pressure drops as support segments (these pipes are most often manufactured according to the manufacturer’s specifications and for individual orders).

- profile rolled metal with increased resistance to chemical compounds. In demand in the food, pharmaceutical and chemical industries.

- mechanical engineering profiles. They are used in the production of automobile pistons, shafts, cylinders, and bearings.

The types of sections of profile products are also different. It can be oval, flat-oval, square, rectangular, polygonal. On a separate order, the company may be able to produce profiles with a cross-section in the shape of a triangle, hexagon, etc.

In the construction industry, square and rectangular pipes are in demand

There are several ways to make profiles. Depending on the production method used, the properties of the product will differ:

- Seamless hot-rolled profile products: used in environments that require increased strength. Usually anti-corrosion, resistant to any aggressive acids and substances.

- Cold-rolled profiles or standard ones: more elastic structures that can withstand significant pressure changes.

- Cold-rolled electric-welded profiles: strong and durable structures, but only if operating standards are observed.

Mass production of pipes for various purposes requires adjustments in the list of required equipment. Below is a diagram for the production of standard profile pipes, which should be varied in accordance with the developed business plan.

Foreign pipe manufacturers

The following are popular among foreign manufacturing companies:

- Ekoplastik, Czech Republic. The company produces PP materials for industrial and domestic pipelines. Pipes are characterized by good weldability and resistance to low temperatures;

- German manufacturing companies - Rehau, Wefatherm, Banninger. The products are distinguished by high quality polypropylene, but clearly overpriced;

- Valtek, Italy. High quality material. Installation is possible using crimp, brass press fittings.

In addition to products from the European Union, polypropylene pipes made in China, but under the British brand Blue Ocean, are popular. The quality is practically the same as in Europe, although the price is lower, plus a 10-year warranty on products.