Recently you can often hear the expression “ high-speed steel”. What is it? Essentially, these are special alloys designed for the manufacture of metal-cutting tools that operate at high speeds. The characteristics of such a metal should include high strength, wear resistance and resistance to temperature changes.

High-speed steel blanks.

Characteristics of high-speed steels

High-speed alloys have appeared relatively recently. Before their appearance, ordinary steel cutters were used to turn wood or non-ferrous metal products, and some difficulties arose when using them. They had a very short service life due to rapid wear and became very hot, making work at high speeds impossible.

The problem was solved in 1858 after the production of an alloy in which tungsten and manganese were used as the main alloying additives. Over the next decades, through numerous experiments, several types of super-strong metals were obtained, which made it possible to significantly increase the speed and productivity of metal-cutting machines.

The category of high-speed steels includes a large group of alloys that contain alloying elements that make it possible to achieve resistance to wear and high heat. They are distinguished from conventional carbon alloys by their high strength index, which allows the use of tools made from them for processing hard materials.

Quick cut blade.

High-speed cutters have a number of remarkable characteristics by which they can be distinguished from other grades of steel, these include the following:

- Maintaining hardness at high temperatures , so-called hot hardness. Any objects heat up when rubbed. The temperature of a cutting tool operating at high speeds increases very quickly to high levels. When exposed to such heating, ordinary steels are subjected to tempering, which is why they lose their working properties. High-speed steel is not subjected to similar processes, since its composition allows it to withstand temperatures of up to 6000 degrees Celsius without loss of strength.

- High red resistance is a parameter of an alloy, characterized by a time period during which it is able to work at high temperatures without losing its original properties.

- Resistance to destructive processes . In addition to resistance to extreme heat, high-speed cutters must have increased mechanical properties compared to conventional metals. Tools made from such alloys, even under high pressure, do not crumble or break, due to which they are actively used for the manufacture of drills and cutters.

Areas of use

- Manufacturing of cutting tools (drills, taps, milling cutters, reamers, replaceable inserts for countersinks).

- Production of structural parts with high wear resistance at elevated temperatures (for example, rings and inserts for automotive valves).

- Die steels for cold deformation processes with a noticeable influence of contact friction (drawing, heading, pressing, extrusion).

Under the stated conditions, high-speed steel must meet the requirements:

- Red brittleness.

- High hardness.

- Compressive strength.

- Impact strength.

- Wear resistance.

To meet these requirements, high-speed cutters often contain cobalt, an active carbide-forming element that is especially active during tempering.

Decoding the designation of steel grades

High-speed steel was first invented by specialists from Britain. Since tools made from this material required work at high speeds, such alloys were called “rapidsteel” (which means fast steel in Russian). This name, invented in England, was the reason for the modern marking of all high-speed cutting grades with the letter “P”.

According to international regulations, the first digit following P indicates the tungsten content in percent, which is a fundamental element that determines the key characteristics of the entire alloy.

In addition to tungsten, high-speed cutters are characterized by the presence of components such as cobalt, vanadium and molybdenum, which are displayed in the markings by the corresponding letters: K, F and M. Each such letter is followed by a number indicating the percentage of the total chemical composition. As you can see, a person who knows a little about steels, even despite the description, can tell all the basic information about the alloy.

An example of decoding steel grade 12Х18Н10Т

12Х18Н10Т is a popular austenitic steel, which is used in welding machines operating in dilute acid solutions, in solutions of alkalis and salts, as well as in parts operating under high pressure and in a wide temperature range. So, what do these mysterious symbols in the name mean, and how to combine them correctly?

The two numbers at the very beginning of the alloy steel grade are the average carbon content in hundredths of a percent. In our case, the carbon content is 0.12%. Sometimes, instead of two numbers, there is only one: it shows how much carbon (C) is contained in tenths of a percent. If there are no numbers at the beginning of the steel grade, this means that there is a fairly decent amount of carbon in it - from 1% and above.

The letter X and the number 18 following it indicate that this brand contains 18% chromium. Please note: the ratio of an element in fractions of a percent expresses only the first number at the beginning of the mark, and this only applies to carbon! All other numbers present in the name express the number of specific elements as a percentage.

Combination H10 follows. As you may have guessed, this is 10% nickel.

At the very end there is the letter T without any numbers. This means that the content of the element is too small to pay attention to. As a rule, about 1% (sometimes up to 1.5%). It turns out that in this grade of alloy steel the amount of titanium does not exceed 1.5%. If suddenly at the very end of the brand you find a modestly standing letter A, remember that it plays a very important role: this means high-quality steel, the content of phosphorus and sulfur in which is kept to a minimum. Two letters A at the very end (AA) indicate that this grade of steel is especially pure, i.e. there is practically no sulfur and phosphorus here.

In the course of a simple analysis of combinations of letters and numbers, we found out that the steel grade 12Х18Н10Т (structural cryogenic, austenitic class) reports the following information about itself: 0.12% carbon, 18% chromium (X), 10% nickel (N) and a small content titanium (T), not exceeding 1.5%.

Production and Processing Methods

Tools made from high-speed steel are produced using two main technologies:

- The classic method involves casting hot metal into special molds and then further processing and hardening it.

- Powder metallurgy method : molten steel is sprayed under the influence of a nitrogen stream and then melted again.

Powder metallurgy is more complex than traditional metallurgy. The production process involves the production of steel powder, which is blown into a special mold and fused in it. This makes it possible to prevent the occurrence of carbide segregations and make the steel structure more uniform and stable, which has a positive effect on all working properties.

This is what molten steel looks like.

The powder method has a number of advantages that allow it to replace more expensive types of processing, such as casting, stamping and forging:

- cost-effectiveness - even waste, for example, scale, can serve as the starting material for the production of powder, moreover, this method requires less financial costs compared to the classical one;

- achieving more accurate product shapes - parts created by this method do not require further cutting processing;

- high wear resistance.

The production process is necessarily followed by a hardening process . Hardening of high-speed cutting tools takes place at temperatures that contribute to the most favorable decomposition of alloying components in them, but at the same time to the growth of grains in the molecular lattice. After hardening, the structure of high-speed alloys is characterized by a content of up to 30% austenite, and this negatively affects all operating parameters. To reduce the negative impact of austenite to minimum values, two different technologies are used:

- several cycles of heating, holding at a uniform temperature and subsequent cooling are carried out, the so-called multiple tempering;

- Before tempering, the part is cooled to very low temperatures.

Features of heat treatment

The result of high-temperature processing of high-speed steels is a change in the structure of the material to obtain certain physical and mechanical properties required when working with this tool.

Annealing

HSS steel after the rolling and forging process acquires increased hardness and internal stress. In this regard, the workpieces are preliminarily annealed. Annealing relieves the internal stress of the material, improves machinability and prepares it for hardening.

The annealing process occurs at a temperature of about 850-900°C. However, one should be wary of excessively increasing the temperature and duration of exposure, because this may cause the steel to become more hard. Due to the reduced thermal conductivity of the alloy, heating is carried out slowly and evenly.

The products are loaded into the oven at a temperature of 200-300oC, while subsequent heating is increased at a rate of 150-200o/hour. The process ends with slow cooling: first in an oven to 650 ° C, and then to room temperature in the open air.

To protect against decarburization, annealing is carried out in closed boxes with a neutral environment.

Machine-building plants subject a small number of workpieces to isothermal annealing. They are heated to 880-900oC for a short time, and then transferred to an oven with a temperature not higher than 720-730oC for 2-3 hours. To protect against the appearance of excessive internal stresses, the workpieces are cooled in an oven to 400-450°C and then left in the open air.

Conventional annealing takes longer than the isothermal process. Subsequently, the workpieces undergo mechanical processing, and then the tool undergoes the final heat treatment process - hardening and tempering.

Hardening

Tools made of high-speed steel are hardened at temperatures above 1300°C. After the hardening process, repeated tempering occurs at 550-560°C. This temperature is necessary to dissolve a large number of carbides in the austenite to obtain highly alloyed austenite.

With further cooling, highly alloyed martensite is obtained, which contains large amounts of tungsten, vanadium and chromium. Martensite does not disintegrate when heated to 600°C, which gives high-speed steel red-hardness.

To obtain high red-hardness values, the temperature during hardening must be very high. However, there is a limit, when exceeded, rapid grain growth begins in high-speed steel and melting occurs.

Vacation

Hardened high-speed steel must undergo a tempering process. At a temperature of 550-560°C, a multiple process is carried out at intervals of 1 hour. The purpose of tempering is to transform austenite into martensite. High speed steel goes through two internal processes:

- When heated and subsequently tempered, ground carbide is released from the retained austenite. As a result, the alloying of austenite is reduced, which facilitates easy transformation into martensite.

- During cooling at 100-200°C, martensite is obtained. This also relieves the internal stress that arose during hardening.

Nowadays, factories most often use the process of accelerated tempering of steel, which takes place at elevated temperatures.

Improving product performance

Tools made from high-speed cutters are subject to high demands, and in order for them to meet them to the fullest, their surface is processed. Various methods are used for this, including:

- The surface layer of the part is subjected to nitriding. Such treatment can be carried out in a gaseous environment consisting of either 80% nitrogen and 20% ammonia, or 100% ammonia. The process takes 10-40 minutes at a temperature of 550 – 6600 degrees. This operation makes the top layer less fragile.

- The surface is saturated with carbon and nitrogen - the so-called cyanidation , which occurs by immersing the part in molten sodium cyanide. Depending on the final purpose of the part, cyanidation takes place at different temperatures. The longer the time and the higher the temperature, the thicker the layer becomes.

- Sulfidation is performed in a liquid sulfide melt with the addition of sulfur. This process is carried out from 45 minutes to 3 hours at temperatures from 450 to 5600 degrees Celsius

All of the above procedures are performed with a ready-made tool: the cutting part is sharpened, the surface is polished and hardened.

High speed steel knife.

Where are high speed steels used?

The scope of wear-resistant metal depends on the composition that determines its working properties. Basically, this is a tool that has high demands on strength, heat resistance, and long service life.

- Production of drills, cutters, cutters, taps;

- Manufacturing cutting edges for tools, which in some cases can be removable;

- Parts for metalworking machines and equipment;

- Manufacturing of tools used for finishing hard-to-cut metal products.

Experts give the following recommendations on the use of these metal grades:

- Tungsten-molybdenum compounds are suitable for tools intended for roughing products, manufacturing cutters, broaches and shaver.

- Cobalt compounds are used for processing heat-resistant and corrosion-resistant products in difficult conditions.

- Vanadium alloys are used for finishing materials.

- The P9 grade is used to create equipment elements that are not subject to excessive load.

- Grade P18 is suitable for tools with complex shapes and shaped products with increased wear resistance requirements.

The range of metal products is represented by square, circle, strip, and sheet metal. Most often, cutting tools are made from a circle. Square steel is used for the production of electric planers, knives, and turning tools. If you have doubts about the correct choice of a suitable alloy, it is better to contact specialists. Specialized companies will be able to select high-quality rental products with the required performance characteristics.

Decoding: what do the marking symbols mean?

It was already described above what data can be extracted from the name of any brand of high-speed cutters. For greater clarity, let’s consider the decoding of one widely used high-speed steel R9F5:

- R - understandable, designation of high-speed alloys, from the English "rapid" - speed;

- 9 – percentage of tungsten in the alloy;

- F – indicates the presence of vanadium in the steel;

- 5 – percentage of vanadium.

If we analyze the abbreviation R9F5 further, then its decoding may contain other letters. For example, if the metal is obtained by electroslag remelting, another letter appears - “Ш”.

With the introduction of modern technologies, namely the use of nitriding, you can find the following marking R9AF5.

Imported analogues of high-speed cutters have the following marking - HSS, which stands for High Speed Steel, translated into Russian as high-speed steel:

- Germany - 1.3343;

- Japan - S600/S601;

- USA - M2.

Steel marked R9F5.

GOST and TU

Production requirements, technical characteristics, heat treatment process and elemental composition of high-speed steels are regulated by special standards. There are a large number of regulatory documents, since each type of product has its own standard:

- TU 14-11-245-88 - cold-formed high-precision shaped profiles;

- GOST 1133-7 - forged circles or squares, assortment;

- GOST 2590-88 - hot-rolled wheels;

- GOST 7417-75 - calibrated rod;

- GOST 14955-77 - wheels with special surface finishing .

These standards are applied in almost all Russian industries.

Difficulties in hardening high-speed steel

Heat treatment of high-speed cutters has a number of difficulties associated with the specific application and requirements. For example, heat treatment of P6M5 is complicated by the decarburization property of this alloy (its hardening requires a quarter of the time than similar alloys P18 and P12). The hardening temperature of this metal is 1230 degrees. First, tempering is carried out at 200 and 300 degrees with an hour exposure. Further processing is carried out in 3 stages:

- 3 minutes – 690 degrees;

- 3 minutes – 680 degrees;

- 1.5 minutes – 1230 degrees.

The steel is then cooled in saltpeter, oil and air. Subsequent processing involves three temperings with exposure for 90 minutes at a uniform temperature of 560 degrees. At the tempering stages, the alloy is enriched with alloying additives.

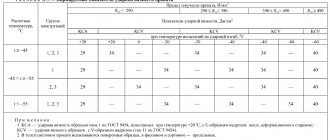

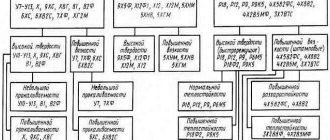

4.3.1 Steels of normal heat resistance.

These include tungsten and tungsten-molybdenum steels (Table 4.1).

Composition and properties of normal high-speed steels

Chemical composition (average), wt%

For steels of this group, it is advisable to consider the principles of alloying high-speed steels with tungsten and molybdenum.

The chemical composition of the classic P18 BRS was formed by 10-15. XX century. Composition 18-4-1 (W,Cr,V) turned out to be very successful. This steel has entered the standards of almost all countries (S18-0-1-Germany, NS18-0-1-Italy, Z80WCV18-04-01-France, VT1 - Great Britain, T1 - USA, SKH2 - Japan).

The success of the composition is not accidental. When the ratio of tungsten to carbon is 18 – 0.8 (wt.%), the main carbide in the steel structure is, in accordance with the “Fe–WC” phase diagram, Me6C carbide.

Work on the study of the influence of tungsten on the structure and properties of BRS containing up to 2% vanadium (slightly more than in P18 steel), carried out at the Department of Metal Science of MSTU STANKIN by L.S. Kremnev and Yu.A. Geller, showed that the increase The increase in tungsten content in steel is accompanied by an increase in the amount of Me6C carbide. At the same time, an increase in the tungsten concentration to 12–13% increases both the weight and volume amount of carbide, and then only its weight amount practically increases.

Me6C carbide has a complex composition. In addition to the atoms of the main element - tungsten, atoms of iron, chromium, and vanadium are dissolved in it. Its composition can vary from (Fe,Cr,V)4W2C to (Fe,Cr,V)2W4C. This change in the chemical composition of the carbide leads to its density increasing (the atomic weights of Fe, Cr and V are 55.85; 52.01; 50.95, respectively, while W is 183.92).

Thus, an increase in tungsten concentration to 12–13% leads to the formation of new carbides (their volume fraction increases), and a further increase leads mainly to “heavier” carbide. In this case, tungsten is spent not on the formation of new portions of carbide particles, but on replacing atoms of lighter elements in existing carbides, and the weight amount of carbide naturally increases.

The results of these studies made it possible to substantiate the composition of P12 steel. The properties of steels R18 and R12 are almost the same, and the content of expensive tungsten in steel R12 is 1.5 times less. Thus, the optimal tungsten content in tungsten couplings is 12 – 13%.

The creation of P9 steel is based on the fact that when P18 steel is hardened, only about half of the tungsten goes into solid solution. Thus, a hypothesis arose about the excessive tungsten content in P18 steel. A consequence of this hypothesis is the idea of reducing the tungsten content by half so that all the tungsten “works” - goes into solid solution. However, this hypothesis was not justified. And in this case, it is not possible to dissolve all carbides in austenite (for more details, see low-alloy high-speed steels). At the same time, P9 steel has sufficient heat resistance and, despite its reduced technological properties (see below), has found application due to the low level of tungsten alloying.

R6M5 steel is tungsten-molybdenum. Molybdenum and tungsten are chemical analogues. The atomic weight of molybdenum (95.95) is less than that of tungsten (183.92), therefore, to obtain the same amount of carbide phase (% vol.), its mass fraction in the BRS must naturally be less.

Analysis of the “Fe–Mo-C” phase diagram shows that with a carbon content of 0.8%, Me6C carbide will be the main one if the molybdenum content in the steel is 12% (in the “Fe–WC” system this is achieved at 18%W ). Those. The molybdenum content in the BRS should be approximately 1.5 times less than tungsten.

Thus, R6M5 steel meets the above-formulated optimal content of the main alloying components in the BRS (on average, W + 1.5 Mo = 13.5%).

The carbides of tungsten-molybdenum couplings are smaller in size than those of tungsten ones. This is due to the lower crystallization temperature of these steels and their higher hot ductility.

Due to the lower crystallization temperature, the eutectic acquires a finer structure (smaller carbides). When obtaining the same cross-section during hot plastic deformation, the better ductility of tungsten-molybdenum BRS determines the smaller amount of heating that causes the growth of carbides.

The basic operational properties of steels in this group are similar. Tungsten couplings have slightly greater heat resistance compared to tungsten-molybdenum ones, but their mechanical properties are lower.

Cutting tools made from these quick-joints are intended for processing steels (sup to 80 - 100 MPa) and cast irons (with hardness up to 250 - 280 HB) and non-ferrous metals and alloys with good machinability (copper, aluminum, zinc).

Under the cutting conditions used, differences in the properties of steels have virtually no effect on tool life (up to 40 m/min when processing ferrous metals and up to 80 m/min when processing non-ferrous metals).

The choice of steels for specific processing conditions and type of tool is determined by the differences in their technological properties

.

R6M5 steel has greater hot ductility compared to tungsten steels, but is less technologically advanced during heat treatment. It has a greater tendency to decarburize when heated, and is characterized by a narrower range of quenching temperatures.

Smaller carbides and their better distribution in R6M5 steel determine the feasibility of its use for tools with large cross-sections.

Products that find a place in everyday life and in production

Due to its positive properties, high-speed steel is actively used in knife production . Such cutting tools have all the necessary characteristics. Due to the high resistance of the surface to external loads, they can easily cut thick ropes, wood, bones, etc. They can handle steel plates several mm thick.

A quick-cut knife retains its sharpness for a long time even with intensive use, but it is worth considering that due to its high strength properties it is difficult to sharpen, especially at home.

Quick cutters are widely used in industry. The most striking example is the manufacture of drills for a variety of purposes: from wood to heavy-duty metals. The following parts of industrial mechanisms are made from them:

- hacksaw blades;

- countersinks;

- borax;

- slotting cutters;

- crowns

How to sharpen quick cutter products

Even high-speed cutting steel is subject to wear and dullness, despite its impressive strength properties. If we take into account the information about the use and properties of these alloys, we can safely say that it will not be possible to sharpen them using grinding wheels from electrocorundum - the surface after such treatment still remains rough, and the cutting qualities do not improve. What then can we say about manual sharpening?

The most correct option would be to send the product for sharpening to a specialized workshop that has CBN wheels at its disposal. Having such cars in your garage is an unaffordable luxury and simply not advisable. It is better not to try to sharpen it in a garage, as there is a chance of damaging the tool beyond its original state.

Cost of metal in products

Let's look at the cost of metal using the example of one of the most popular high-speed cutters on the domestic market - R6M5. It is not difficult to buy finished products; they are widespread everywhere, but the cost of steel is quite high. Below is an approximate price list.

Depending on the thickness of the sheet, the tool wheel will cost accordingly:

- 2 mm - 1350 rubles per kg;

- 4 mm - 1200 rubles per kg;

- 16 mm – 600 rubles per kg.

The above prices are relative average values. They may change depending on many factors: terrain, economic situation, etc. The high price of high-speed metals makes them popular in the sale of scrap metal. The cost of such secondary products is much higher than that of ordinary alloys.