Possible complications during work

The actual bending of such a pipe is the process of giving the element a curved-smooth configuration. This can only be done under pressure, since the part has high strength. To reduce the pressure force required for bending, you can use heating of the bent fragment.

Despite the apparent simplicity of the operation, bending does not always result in elements of the desired configuration. Problems arise quite often. The most common complications include three.

The first is that the inner side of the profile folds in peculiar folds that resemble corrugation. In the correct version, it contracts evenly.

The industry produces many types of profile pipes. They differ in cross-sectional shape, profile height, wall thickness

The second difficulty is the rupture of the outer wall of the profile pipe. During bending it stretches. Sometimes the metal cannot withstand the force and bursts. The third problem is that the pipe, changing its shape, can lose the alignment of the elements.

This means that its fragments in a bent state will lie in different planes. And this is unacceptable. Practice shows that all difficulties occur due to the wrong choice of bending method.

To choose it correctly, you need to take into account the plastic capabilities of the profile pipe. They are determined by the size and shape of the section, as well as the thickness of the walls of the product. Based on these values, you can calculate the minimum possible radius of curvature. Trying to make a round with a smaller radius is strongly discouraged.

To determine the minimum radius, we need the height of the section. It is calculated as follows. The height of the profile is measured, and twice the wall thickness of the product is subtracted from it.

The resulting number will be the desired height, let's denote it h. For pipes with a cross-section in the shape of a rectangle and square, the following rule applies. If the profile height is above 20 mm, the part can withstand bending in a section whose minimum length is hx3.5.

Products with a profile below 20 mm can be bent over a length of hx2.5 or more. This rule applies to all pipes. However, the wall thickness of the part also affects bending limitations.

The thinner it is, the higher the likelihood of a rupture or crushing of the part. Experts strongly do not recommend trying to bend wide products with wall thickness less than 2 mm. In this case, it is optimal to use a welding machine.

When bending a profile pipe, it is very important to perform all actions correctly and carefully, otherwise the part may lose alignment or become wrinkled. This pipe cannot be used

One more thing to be aware of. Pipes made of low-alloy and carbon alloys are very elastic and, after bending, can seem to “spring”, trying to take their previous shape.

This involves additional work with the product, since it will have to be adjusted again according to a pre-made template. Therefore, it is recommended to find out the value of the plastic moment of resistance of a given profile pipe and carry out bending taking this indicator into account. The smaller it is, the less the part will “spring”.

How to bend a pipe without preheating

You can bend a profile pipe yourself without preheating it, either with or without filler. Pipes whose profile height does not exceed 10 mm do not require filling with sand or rosin.

The nuances of bending small-sized thin-walled pipes

There is another technique that involves using a spring with tightly wound coils instead of a filler, which is inserted into the internal cavity of the corrugated pipe and protects the walls of the product from deformation, as well as from excessive changes in their thickness during the bending process.

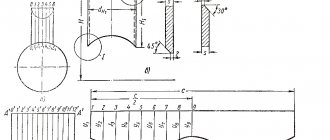

Drawing and details of a mechanical pipe bender for profile pipes

The design of a basic pipe bending device is simple and accessible for self-production

For those who need to bend profile pipes with their own hands without heating them first, you can use the training video and the following simple recommendations.

- You can obtain the required bend on profile pipes using the simplest devices - a vice, mandrels, bending plates.

- You can use a manual pipe bender for products with a round profile. In this device, it is necessary to remake the working rollers, the shape of the recess in which must correspond to the profile of the pipe.

- The most efficient and accurate way to bend pipes is with a roll forming machine, which you can purchase or make yourself.

Features of different profile bending methods

There are two main methods of bending profile pipes: cold and hot. The first assumes that the bending process is carried out without preliminary temperature exposure to the part.

While the second is carried out only with a preheated pipe. It must be admitted that heating the part significantly increases its ductility and facilitates the bending process.

There are no standards strictly regulating the use of cold and hot bending methods for profile products. They are only available for pipes with a round cross-section. According to these standards, hot bending is used for parts whose diameter is 100 mm or more. For rectangular and square pipes, slightly different rules apply.

If you have a one-time job of bending a pipe, you can buy, but it is better to rent a hydraulic pipe bender with a manual drive:

Image gallery

Photo from

Manual hydraulic pipe bender

Replaceable bending segment

Devices for fixing a bent pipe

Bending steel pipes with high force

Plumbers recommend cold bending only all pipes with a profile height of less than 10 mm. Products with a profile height of 40 mm and above are hot bent.

How to bend parts with a profile height from 10 to 40 mm is up to the performer to decide. To avoid mistakes, you can perform a trial bending. In general, if you have a pipe bender, you can use it to bend the pipe without any heat.

If there is no special tool, it is worth performing a trial bending of the profile pipe. To do this, one edge of the part is firmly clamped in a vice. A pipe with a diameter larger than that of the product being bent is put on the other end.

The resulting “shoulder” should be pulled strongly, bending the product. If the part bends, you can use the cold bending method. If not, bending with preheating is used.

The principle of using a pipe bender

It is not always possible to bend a profile pipe (especially for large-diameter products) with your own hands. For these purposes, there are special devices - pipe benders. A standard pipe bender is equipped with a drive wheel, which, moving along one of the edges, carefully bends the pipe section in the required direction.

We recommend that you read: What is the difference between HDPE corrugation and PVC and which is better to choose?

There are two types of pipe benders:

- Manual. The wheel of the device is operated manually using a special handle. Well suited for pipes with a small cross-sectional area.

- Electrical. The use of such devices is justified in cases where the volume of work is quite large, and the pipes themselves have substantial dimensions. The device is connected to a standard power supply, and the wheel moves by means of an electric drive. Allows you to obtain smoother products with significant time savings.

If the work is one-time, purchasing your own pipe bender may not be profitable. In this case, you should consider renting the device, or consider one of the alternative bending methods.

Subtleties of hot bending

Bending of a fragment of a profile pipe occurs after it is heated. It is advisable to perform the operation in one approach, since repeated heating of the metal is undesirable. A product that has cooled to a light cherry color may rupture.

Therefore, this method is ideal for performing a single corner bend. To bend a profile into a rounded arch, it must be used with caution, since repeated heating in this case is inevitable.

It is good to use sifted and calcined sand as a filler for pipes during hot bending. It is poured inside the part using a funnel

To correctly bend a profile pipe using a hot method, you should use a filler. This will prevent possible crushing of the part. Sand is usually used as a filler.

The best option is medium-grained construction sand. If this is not available, material from a children's sandbox will do. First, you need to clean it of unnecessary impurities.

To do this, sand is sifted through a sieve with cells measuring 2-2.5 mm. This will help you get rid of large pebbles and debris. If during the bending process such an inclusion ends up directly next to the pipe wall, it will form a relief that is completely unnecessary.

Too small grains of sand are also not needed. During the heating process, they can sinter, which is undesirable. Therefore, the sand will have to be sifted again, this time through a fine sieve. Its cell size should be about 0.7 mm. We calcinate the sifted sand.

The filler is ready. Now you can work on the detail. First you need to anneal the pipe in the area where bending will be done. Then you can start making the plugs.

You will need two parts of the same size that will cover both ends of the profile pipe so that the sand in it does not spill out. The plugs are made only from wood; no other material can be used.

Let's decide on the size and shape of the parts. These must be pyramids, each ten times longer than the width of the base. The dimensions of the base itself should be almost twice the size of the hole that will be closed with this plug. The prepared products need to be tried on the pipe.

The profile pipe is closed with wooden plugs. In one of them, recesses must be made to allow the release of gases formed inside the heated part.

If everything is fine, we make a longitudinal groove on each side of one of the plugs. The gas accumulated during heating will escape from the workpiece through these grooves. You can start filling the pipe.

To do this, take a plug without grooves and install it in place. A regular funnel is inserted into the opposite end of the part. If the pipe is long, it is placed at an angle to the ground, if it is short, it is placed perpendicularly.

Sand is poured in small portions through the funnel. After each portion, take a rubber or wooden mallet and thoroughly tap the part from below, helping the sand to be distributed as evenly as possible and compacted. Once a dull sound is heard when tapping along the entire length of the pipe, work must be stopped. This means that the part is completely filled with sand.

The sand-filled workpiece is closed with a second plug. Now you need to chalk out the boundaries of the area that will be heated. Its length must be equal to at least six workpiece diameters.

The part is securely fastened in a clamp or vice. If the pipe is welded, it must be secured so that the seam is outside the bend. If it is inside, the part may burst.

Now you should heat the pipe fragment to a red-cherry color. This can be done with a blowtorch or a gas soldering torch. Important point. The entire area should be heated evenly.

Do not allow individual fragments to overheat. If this does happen, such areas should be cooled. An indicator of a sufficiently heated pipe will be scale bouncing off it.

Experts strongly recommend performing hot bending of a profile pipe in one step. Repeated heating of a part can lead to its rupture

After the workpiece is heated, a piece of pipe with a larger cross-section is put on its end. So that the edge of the part does not reach the future bend a little. After which the pipe is carefully bent to the desired shape.

This must be done in one step with a smooth translational movement in a vertical or horizontal plane. The resulting bend is checked against the template.

The bent pipe must cool, after which it should be compared again with the template and make sure that the given shape is correct. If so, the plugs are knocked out. This is often difficult to do, then you can simply burn out the wooden plugs and pour out the sand.

To ensure a clear bend, without folds or tears, you need to pack sand into the pipe as tightly as possible and heat the part evenly.

Foundation options for vertical profile posts

There are several ways to install vertical racks:

1. A hole is dug 50-60 cm deep and 40x40 cm in size. Crushed stone or small stone is placed at the bottom of the hole. The lower end of the rack is treated with anti-corrosion paint. The stand is installed in a vertical position, fixed with supports, and the hole is filled with concrete.

The simplest example of concreting a stand, but it cannot be called the most practical

2. The prepared pit is filled with concrete and an embedded part is installed, to which a vertical stand is subsequently welded.

Sectional view of the foundation with embedded part. The vertical stand is installed and welded to the mortgage, and, if necessary, reinforced with welded gussets.

3. Actions similar to the second point are performed, only anchor bolts are installed instead of the embedded part.

The use of anchor bolts allows you to level the rack during installation by adjusting the tightening of the nuts and placing metal plates of various thicknesses

On a note. Horizontal tying pipes on which the trusses will be installed are mounted along the long sides of the canopy; if necessary, they can be reinforced with bevels made from the profile.

Making a bending machine with your own hands

A person with plumbing skills is completely capable of assembling his own pipe bender without the help of others. You need to prepare:

- Three rollers or shafts that perform the bending function in the device.

- An iron channel or corner for creating a support frame.

- Chain.

- Drive mechanism.

Assembly sequence of a homemade bending machine:

- Assembling the support frame. To do this, individual rolled metal elements are combined into a single structure with a longitudinal configuration. The assembly is created by welding or bolted connections. The main task of the machine support is its stability and strength. To ensure this condition, the structure is firmly fixed to the floor.

- The installation of 2 shafts with the axis of rotation is created at the required distance, slightly above the table level, the 3rd shaft is fixed in the middle a little higher. The shafts are secured to the support with bolts and nuts.

- Shafts or rollers located in a horizontal plane are installed at a distance that determines the radius of the bend. To regulate the angles of deformation, limit rollers and a stopper are installed.

- To transmit torque, the machine is equipped with a chain drive. There can be two options for installing the chain: using gears or installing it directly on the shafts.

To create rotating forces, a handle is attached to the machine, performing the function of a manual drive.

Bending profile products using a spring

This method is perfectly suitable for duralumin pipes with a profile section, as well as metals with a huge ductility coefficient. First you need to make a spring from metal wire with a diameter of 2 mm. The shape of the wire twist coincides with the shape of the profile blank. The spring is inserted into the cavity and bent to a given radius. To increase the bending speed, the workpiece is slightly heated.

The spring is previously secured to the nearest end with a piece of wire.

Inner spring

You can achieve an even bend - without kinks or creases - using a spring placed inside the pipe, made independently from steel wire with a diameter of up to 4 mm.

Its strength should be greater, the thicker the pipe walls are.

The wire should be wound around a piece whose cross-section is similar to the pipe profile, but has slightly smaller dimensions.

As a result, the resulting spring should fit into the pipe, as they say, “tightly.” The coils of the spring are laid tightly - no gaps are allowed between them.

The finished spring should be inserted into the pipe so that it falls into the bending zone. All that remains is to bend it after preheating the pipe.

Please note that when exposed to a blowtorch, not only the bend area will heat up, but also the entire pipe. Therefore, before starting work, it is better to prepare pliers and thick gloves.

The disadvantage of this method - labor intensity - is compensated by the possibility of reusing the spring, which greatly simplifies the production of several arcs.

The presented methods, as you can see, are extremely simple, but still require some skill.

If you lack experience, it is better to first practice on unnecessary pieces of pipe, if, of course, there are any.

If you have to make parts from pipes by bending quite often, but still don’t have the money to buy a pipe bender, you can assemble it yourself, because such a machine has a simple design.

Kalde is the most popular brand of polypropylene pipes around the world. Calde pipes - application and technical characteristics will be discussed below. You can also read customer reviews.

You can familiarize yourself with the technical characteristics of polyethylene pipes in this section.

Canopy size

The size of the canopy depends on whether the structure is designed for one or two parking spaces. If it is enough for you to make a structure for one car, then it is quite possible to make it 3 meters wide by 3 meters.

For two parking spaces, a size of 7 meters wide and 3 meters long is taken into account, when the cars will stand parallel to each other and have free access. If the location of buildings on a summer cottage does not allow for a wide canopy, then you can install a canopy 3 meters wide and 5 meters long, where one of the cars will block the other.