Metal chasing is a type of decorative and applied art and a type of cold metal processing. It is the process of applying a flat or three-dimensional pattern to a metal sheet using a special tool and execution techniques.

At its core, it is a process of artistic metal processing. Both varieties are used to decorate the facades and interiors of public and private houses, paintings, weapons, kitchen utensils, everyday items, and items made of precious metals.

Metal embossing is widely used by designers and builders in their work. Nowadays, this is a popular type of artistic product, which is in demand and amazes with its diversity. Requires the highest skill from the performer.

It’s not difficult to do embossing with your own hands if you know the types of craftsmanship, the nuances of manufacturing, the materials used and develop your own style.

Essence of the process

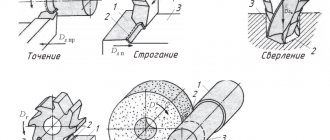

The essence of the embossing technique is the impact of the hammer on the embossing tool. An imprint corresponding to its type remains on the metal.

By performing multiple blows, a relief is obtained that matches the sketch. The shape of the design is conveyed with great expressiveness and accuracy, depending on the tools used by the embosser during the work process. At the same time, the quality of work depends on his qualifications and skill.

Each master has his own style of work. Metal stamping on non-ferrous and ferrous metals differs in type and technology.

Materials and tools used

The metal on which it is planned to mint must have toughness, plasticity, the ability to change shape under the influence of force without breaking, and be polished. It includes sheets:

- copper;

- aluminum;

- brass;

- cupronickel;

- nickel silver;

- iron for roofing;

- low-carbon and soft stainless steel (decapira);

- gold;

- silver;

- foil.

Materials for embossing have different thicknesses; it varies widely from 0.5 to 3 mm and depends on the type of metal used.

The tools used by embossers and DIY enthusiasts are specially shaped hammers, hammers and scribers.

The work uses coins made of alloy tool steel grade U7 or U8, with a diameter of 12÷15 cm of different diameters to create:

- convex spherical imprint (tube);

- a solid line in the form of continuously running points (bypass or consumables);

- the outline of the future design and finishing the background with dots (kanfarniks or crushers);

- leveling the background (patterns with a rough or smooth surface);

- background cuts (cuts with different types of blades: semicircular, flat);

- punches from the inside out (puroshniki);

- imprint (curly).

Every embosser should have his own tool; you can make it yourself.

To do this, you need to buy a steel rod of a certain diameter and make a coin. Before shaping the rod, it must be heated to a bright red color, cooled, and only after these steps begin to make the tool. After production, the coinage must be hardened. At home, this operation can be performed using a blowtorch.

Heat until red again and place in machine oil to cool slowly. Sometimes they use hammers made of wood, so to strike such an instrument you will need a wooden hammer called a mallet.

Hammers for coining must have a special hammer shape, handle and a certain weight. The working surface of the components is polished. The handle is made of wood, always from non-layered species, and must be curved with rounded ends. The weight must correspond to the strength of the chaser.

This allows you to comfortably place the tool in your hand and perform tapping and striking with the necessary force. A scriber is necessary to transfer the design of future coinage onto metal.

In addition, you may need metalworking tools such as rasps, needle files, files, metal scissors, jigsaws, pliers, and punches. A number of other devices are used: dishes for cooking resin, baths for tinting, tool stands, a vice, an emery wheel, sanding and copy paper, and plasticine.

When performing work, you will need auxiliary devices, such as substrates and bags of different densities, as well as consumables that are used to give the product protective properties, strengthen and decorate it, and, if necessary, allow you to beautifully design your work.

Wooden hemp from birch or linden, felt, rubber or plasticine mats, and lead slabs are used as a substrate.

Artistic metal engraving

The so-called planar engraving is the application of a linear pattern or relief on metal using a cutter. With planar engraving (two-dimensional), only the surface of the metal is processed.

This is a widespread technique in the artistic processing of metal. Its purpose is to decorate the surface of a product by applying a simple pattern or complex portrait, multi-figure or landscape compositions, inscriptions and type works. Graphics with a cutter on metal are even more subtle and perfect than with a pencil or even a pen, since the strokes of the cutter are much thinner and clearer than the lines drawn with a pen.

Engraving technique

Excellent for engraving brass, silver, and some steels. Bronze, zinc, and nickel alloys are well engraved. Worse - gold, platinum, aluminum. The surface of the metal that is planned to be engraved should be matte (polished) and not shiny (polished) - excessive shine will be blinding.

The transfer of the design to the metal is carried out in the same way as during minting. Before work, small jewelry and medals are attached to a board larger in size than the workpiece or product. Small blanks are secured with sealing wax or rosin. The main tool of the engraver is the graver (cutter). The total length of the graver ranges from 100 to 130 mm; it is made from the best grades of tool steels that can hold an edge. Jewelers of the Kubachi craft (as well as craftsmen of the Caucasus in general) brilliantly engrave spectacular jewelry - examples of their work with blackened engraving can be seen above, in the minting section..

Main stages of minting

Work in this technique is performed in the following order:

- make a sketch of the drawing;

- cut out a plate from the selected metal corresponding to the size of the picture, with the addition of allowances (for fastening and framing at the end of the work);

- if necessary, the workpiece is fired and leveled;

- perform a degreasing operation;

- cover one side with gouache or white paint;

- transfer the sketch using carbon paper and a scriber to the workpiece;

- coated with nitro varnish (optional);

- work out all the contours and lines with coins of the appropriate type, controlling the positions of the coin and the part where the minting is performed;

- perform decorative finishing.

Particular attention is paid to the position of the coinage. It should be slightly tilted back, held in the left hand between the fingers so that the little finger is not involved.

The elbow does not rest on anything, it is suspended. This ensures good manipulation of the tool. The hammer blows are applied moving forward, while it is held in the right hand.

Specifications

Metal embossing is done on a so-called substrate, which is placed under the workpiece.

The substrate should be pliable and not absorb shock under hammer blows. Craftsmen usually use a cross-section of hardwood - this could be a birch log, an oak butt, or a linden ridge. For embossing on particularly thin metal sheets, felt, a thick rubber plate or a thick tarpaulin bag filled with river sand is used. The latter method is used if the area of the source material is more than half a square meter. For smaller items, professional embossers prefer a lead plate, which allows them to achieve the finest strokes and lines in the image. Embossing (photos are presented in the article) comes in two versions: volumetric, with a fairly high relief, and flat, in which the relief indicators are insignificant. Each type has its own advantages. The relief image is more impressive from the point of view of story aesthetics, since there is a convergence with the 3D format, and this is considered a positive factor. But flat metal chasing can be done in an openwork version, which is an indisputable sign of artistic style.

Do-it-yourself artistic embossing

Do-it-yourself embossing will decorate any interior, it is a good gift for friends and colleagues, and can even become a profitable business.

And you don't have to be an artist. Nowadays you can find many drawings on the Internet. By adding your own taste, imagination and mastering the basics of embossing, you can create unique masterpieces. For beginners, it is recommended to first emboss with a simple pattern. This way you can learn how to transfer a drawing onto a plate, trace the outline of an image with a consumable, lower the background with a quilt, create volume with a powder brush, and trim the background with camphor.

And only after trying all the tools in action and getting a positive result, you can begin to decorate your work of any complexity. The design is minted only with the right tool, so you need to buy it or make it yourself, as well as choose the right accessories and execution technique.

But don’t forget about arranging your workplace. It should be comfortable and well lit.

About the profession of Artistic Products Engraver

Bachelor's and specialty3

Universities3

The embosser of artistic products performs work on embossing relief on jugs, vases, cups, jewelry, as well as embossing multi-faceted relief and high-relief sculptural images, assembling and installing products.

Depending on the category, a chaser of artistic products can perform simple or more complex work:

- Embossing a simple ornament on parts of artistic objects cast from aluminum using a simple embossing tool.

- Manufacturing of stands and

The embosser of artistic products performs work on embossing relief on jugs, vases, cups, jewelry, as well as embossing multi-faceted relief and high-relief sculptural images, assembling and installing products.

Depending on the category, a chaser of artistic products can perform simple or more complex work:

- Embossing a simple ornament on parts of artistic objects cast from aluminum using a simple embossing tool.

- Manufacturing of stands and linings: frames, drawers, boxes, cups, hoops, etc. for products for minting.

- Cleaning castings before processing, manually stripping weld seams on parts of sculptural works made of non-ferrous sheet metal.

- Chilling, pickling and washing of blanks for minting, tarring of blanks, filling containers for minting with resin.

- Preparation of resin nests for three-dimensional artistic products.

- Cutting defective areas for welding.

- Regrinding of the embossed semi-finished product with its intermediate firing and bleaching.

- Chasing and punching out large floral designs on simple art objects and architectural castings.

- Chasing the contour with consumables of various styles and sizes.

- Cutting the background with canfares.

- Combing the background with hammered chisels.

- Drawing the outline of a design on metal using a canter.

- Embossing places for fastening parts of artistic products during assembly.

- Preparing metal or castings for embossing, leveling and cleaning the surface.

- Preparing plaster molds for filling with babbitt and resin.

- Cleaning welds with mechanical tools.

- Annealing of copper sheets.

- Preparing a drawing, marking it and transferring it to metal.

- Chasing and punching of geometric and floral patterns on artistic products and their details of medium complexity and architectural casting.

- Embossing of unimportant places of bas-reliefs, table sculptures.

- Marking, knocking out parts of medium complexity from sheet metal.

- Preparing hammered parts for boiling.

- Preparation of frame parts according to finished sizes.

- Embossing and punching on complex artistic products with independent cutting, replanting and drawing of sheet metal and model.

- Embossing multi-faceted relief and high-relief sculptural images, ornaments of geometric and floral shapes with the intersection of relief planes (with undercuts) on a plane and on three-dimensional objects of complex configuration.

- Embossing on architectural and decorative casting of multifaceted floral and geometric ornaments and fonts with a pattern rise of 1 to 3 cm, three-dimensional sculptural high reliefs and bas-reliefs.

- Chasing the contour along the back side of the workpiece with punching out the relief details of the pattern.

- Minting of products with small (fractional) relief.

- Processing and embossing of welds in accordance with the texture of the model.

- Embossing on particularly complex artistic products multidimensional, floral and geometric ornaments and fonts, parts of three-dimensional sculpture, portrait figures in a complex compositional pose with a complex texture; high reliefs and bas-reliefs, rich in sculptural images.

- Punching, cutting and embossing from sheet non-ferrous metal especially complex sculptural works and details of architectural modeling (coats of arms, order badges, floral and geometric ornaments) with a rise in the design from 3 to 5 cm and torsos to particularly complex portraits and decorative figures.

- Chasing, punching and installation in separate blocks of unique and exhibition art products and details of architectural modeling: portrait bas-relief, high-relief and counter-relief images with detailed elaboration of texture.

- Minting of high reliefs, bas-reliefs, artistic and decorative castings and molds depicting ornaments and figures.

- Decoration of portrait images, cutting and embossing of particularly complex floral and geometric ornaments from metal with a rise in the pattern of more than 5 cm and finishing of the texture.

ExpandCollapse