Cutting sheet metal is one of the most popular technological operations used in industrial production. To accomplish this, different tools are used. One of the most common is the guillotine. The technical characteristics and performance indicators of such equipment depend on the features of its design and power.

Application of guillotines for metal

The scope of application of guillotine machines is the metalworking industry. Equipment of this type is used to perform direct cuts of rolled steel, as well as rolled steel made of non-ferrous metals and alloys, with the need to divide one sheet into several parts of the same standard or different sizes.

Depending on the technical parameters and type of drive, the guillotine can be used for the manufacture of products both in piece production and in mass production.

Recommendations

- R. Po-chia Hsia, Lynn Hunt, Thomas R. Martin, Barbara H. Rosenwein, and Bonnie G. Smith, The Making of the West, Peoples and Cultures, A Brief History, Volume II: Since 1340,

Second Edition (New York: Bedford/St Martin's, 2007), 664. - Janes, Regina. "Decapitation". Performances No. 35. Special Issue: Monumental Stories (1991): 21–51. JSTOR. Internet. February 26, 2015. Page 24

- ^ a b

(French) Legislative Act No. 81-908 of October 9, 1981, abolishing the death penalty Archived July 31, 2013 Wayback Machine. Legifrance.gouv.fr. Retrieved April 25, 2013. - Khan, L. Ali. "Beheading in France." CounterPunch

. Retrieved November 3, 2022. - ^ a b

The High History of the Grail, translated by Sebastian Evans ISBN 9781-4209-44075 - History of the Guillotine Archived September 6, 2015 Wayback Machine, Guillotine Headquarters 2014.

- Maxwell, H Edinburgh, An Historical Study

, Williams and Norgate (1916), pp. 137, 299–303. - "Virgo". nms.ac.uk.

_ National Museums of Scotland. Retrieved August 2, 2022. - "The Origins of the Guillotine". Snopes.com

. Retrieved June 5, 2022. - Sanson, Charles-Henri (1831). Mémoires de Sanson

. Volume 3. pp. 400–408.CS1 maint: location (communication) - R. F. Opie (2003) The Guillotine

, Gloucestershire: Sutton Publishing Ltd, p. 22, ISBN 0750930349. - ^ a b c d

Executive Producer Don Kambu (2001).

Modern Wonders: Devices of Death

. A&E Television Networks. - Parker, John William (26 July 1834). "Halifax Gibbet Law". Saturday Journal

(132): 32. - Crocker, John Wilson (1857). Essays on the Early Period of the French Revolution

. J. Murray. item 549. Retrieved October 21, 2010. - Edmond-Jean Guerin, "1738–1814 - Joseph-Ignace Guillotin: Historical Biography of a Single Saint Figure" Archived July 20, 2011 Wayback Machine, Histoire P@ssion

website, accessed June 27, 2009, cited by M Georges de La Bruyère in

Le Matin

, 22 August 1907 - Memories of the Sansons, from personal notes and documents, 1688–1847. / Edited by Henry Sanson. pp. 260–261. "Archival copy." Archived from the original May 11, 2014. Retrieved May 9, 2014.CS1 maint: archived copy as title (link) accessed April 28, 2016.

- "Crime Library". National Museum of Crime and Punishment. Archived from the original on February 1, 2009. Retrieved June 13, 2009. [In] 1792, Nicholas-Jacques Pelletier became the first person to be executed by guillotine.

- Chase's 2007 Events Calendar

. New York: McGraw-Hill. 2007. p.291. ISBN 0-07-146818-8. - Scurr, Ruth (2007). Fatal purity

. New York: H. Holt. pp. 222–223. ISBN 0-8050-8261-1. - Abbott, Geoffrey (2007). Where to go

. New York: St. Martin's Griffin. item 144. ISBN 0-312-36656-6. - Criminal Code before 1981, Article 12: “Anyone sentenced to death shall be beheaded.”

- Code of Military Justice until 1971, Article 336: "Judgments of the judiciary declaring the armed forces à la peine capitale sont fusillés dans un lieu désigné par l'autorité militaire."

- Criminal Code before 1981, Article 13: “With the exception of Article 12, when the death penalty is imposed for crimes against the security of the state, execution is carried out by shooting.”

- Arasse, Daniel (1989). "Guilloine and the Terror"

. London: Penguin. pp. 75–76. - Higonnet, Patrice (2000). "Kindness Beyond Virtue: The Jacobins During the French Revolution"

. Cambridge, MA: Harvard. item 283. - Leonard Cottrell (1952) Madame Tussauds

, Evans Brothers Limited, pp. 142–43. - Robert Frederick Opie (2013). Guillotine: The Wood of Justice

. History Press. paragraph 131. - “According to Nazi records, approximately 16,500 people were executed by guillotine between 1933 and 1945, many of them resistance fighters and political dissidents.” https://www.history.com/news/8-things-you-may-not-know-about-the-guillotine

- Scholl, Inge (1983). White Rose: Munich, 1942–1943

. Schultz, Arthur R. (Trans.). Middletown, CT: Wesleyan University Press. paragraph 114. ISBN 978-0-8195-6086-5. - Rolf Lamprecht (September 5, 2011). Ich gehe bis nach Karlsruhe: Eine Geschichte des Bundesverfassungsgerichts - Ein SPIEGEL-Buch

. Deutsche Verlags-Anstalt. paragraph 55. ISBN 978-3-641-06094-7. - Jörg Osterloch; Clemens Vollnhals (18 January 2012). NS-Prozesse und deutsche Öffentlichkeit: Besatzungszeit, frühe Bundesrepublik und DDR

. Vandenhoeck & Ruprecht. item 368. ISBN 978-3-647-36921-1. - John O. Koehler (August 5, 2008). The Stasi: The Untold Story of East Germany's Secret Police

. Basic books. paragraph 18. - Gazet van Mechelen, 8 May 1956

- Bolmstedt, Åsa. "Englamakerskan" [Creator Angel]. Popular Historia

(in Swedish). LRF Media. Archived from the original October 5, 2017. Retrieved December 1, 2015. - Rystad, Johan G. (1 April 2015). “Änglamakerskan i Helsingborg dränkte åtta fosterbarn” [The creator of angels in Helsingborg drowned eight pupils]. Hemmets Magazine

(in Swedish). Egmont Group. Archived from the original on December 8, 2015. Retrieved December 1, 2015. - Nguyen Thi Dinh; May W. Elliott (1976). There is No Other Way: Memoirs of Mrs. Nguyen Thi Dinh

. Cornell University Southeast Asia Program. paragraph 27. ISBN 0-87727-102-X. - Farrara, Andrew J. (2004). Around the World in 220 Days: An American Traveler's Odyssey Abroad

. Buy books. item 415. ISBN 0-7414-1838-X.

. from the original on December 1, 2022. Retrieved November 21, 2022.CS1 maint: archived copy as title (link)- Wren, Christopher S. A LITTLE FRANCE FROM THE COAST OF CANADA. New York Times

July 27, 1986. "Archive copy." Archived from the original on December 1, 2022. Retrieved August 29, 2022.CS1 maint: archived copy as title (link) Accessed July 13, 2017. - Krusel, John (November 1, 2013). "Bring back the guillotine." Slate

. Retrieved January 30, 2022. - “Georgia House of Representatives - Sessions 1995/1996 HB 1274 - Death Penalty; provisions on the guillotine." General Assembly of Georgia. Archived from the original on October 4, 2013. Retrieved October 3, 2013.

- "Death by guillotine was suicide." BBC News

. April 24, 2003. Archived from the original September 27, 2008. Retrieved September 26, 2008. - Sulivan, Anne (16 September 2007). "A man kills himself with a guillotine." Newsletter

. Tennessee. Retrieved September 11, 2016. - Staglin, Douglas. “Russian engineer committed suicide using a homemade guillotine.” USA Today

. Retrieved September 11, 2016. - Buncomber, Andrew (3 December 1999). "Guillotine for suicide." Independent

. Archived from the original January 2, 2022. Retrieved September 11, 2016. - Dr. Boriyo. " Report since 1905.

"

History of the Guillotine

. Archived from the original on January 25, 2010. Retrieved October 17, 2020. - Clinical Journal

. Medical Publishing House. 1898. p. 436. - abbaye de monte-à-regret: definition avec Bob, dictionnaire d'argot, l'autre trésor de la langue Archived March 14, 2014 Wayback Machine. Languefrancaise.net. Retrieved April 25, 2013.

- ^ a b c d f g hr December

15, 2012 Wayback Machine. Medarus.org. Retrieved April 25, 2013. - ^ a b c d f g gram hour

Guillotine du XIVeme arrondissement Archived September 8, 2013 Wayback Machine. Ktakafka.free.fr. Retrieved April 25, 2013. - Guillotine Archived October 4, 2012 Wayback Machine. Whonamedit. Retrieved April 25, 2013.

Design and principle of operation

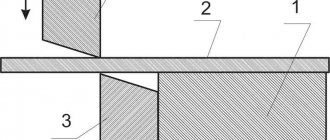

The design of guillotines may be different, but its main elements remain unchanged. These include:

- The working part is an inclined knife, which is mounted on a special movable beam. This item is replaceable.

- A frame that is designed to connect all structural components into a single whole and ensure their interaction. Typically this device consists of a channel and two vertically located racks, which, in turn, are also connected by channels in the upper and lower parts.

- Table. Mounted on racks using a bolted connection. The lower knives are fixed on its surface. The table is equipped with extensions with T-shaped grooves, in which stops are attached for cross cutting. These elements are removed during longitudinal felling.

- Drive unit. This component of the design is responsible for the movement of movable knives, which move up and down in a vertical plane. The drive has sufficient power to overcome the resistance force of the material, with a certain margin.

- Pressure beam. Designed for fixing metal sheets at the workplace. It is equipped with automated protection devices that protect the worker’s hands from possible injury.

- Rear support. This element holds the sheet of metal in place during the slitting process. The device is equipped with two movable slats that can be installed closer or further from the cutting edge. Adjustment is made by manually rotating the corresponding flywheels.

- Balancer for guillotine knives. Used to fix the knife beam in the upper position at the end of each working or idling stroke, as well as for the purpose of repairing or replacing the device.

- Intermittent brake. Ensures that the moving elements of the machine stop in the uppermost position and compensates for their inertia.

An electromagnetic device is used to control the guillotine. It is started by pressing a special button or pedal. There are several operating modes of the machine: single stroke or cyclic movements.

The technology of cutting metal using a guillotine is highly efficient. The process of dividing a sheet into parts consists of exposing the material to an inclined knife with an optimal level of sharpening. The cutting element is made of high strength tool steel.

The pressure force of the knife significantly exceeds the tensile strength of the metal sheet. Under its influence, the structure of the material is destroyed in the narrowest possible area. The resulting cut does not require additional processing.

One person is enough to operate the guillotine machine. The operating algorithm of this type of equipment is based on the operating principle of ordinary scissors. It is as follows:

- Automatic feeding of the workpiece to the work table and its alignment (for transverse cutting - along the stops, for longitudinal cutting - along the stops).

- Fixing the sheet in a given position using a clamping beam.

- Pressing a button or pedal to turn on a drive that acts on the knife directly or through a special mechanism.

- Starting the movement of the knife in the downward direction, cutting the metal sheet, reaching the lower position with the knife and returning the cutting element to the initial position by moving it in the opposite direction.

- Automatic lifting of the pressure beam with release of the workpiece and its subsequent removal from the work table or movement to the stops to make the next cut.

The entire described cycle of operation of a guillotine machine, taking into account the preparatory stage, takes a few seconds. Therefore, this equipment is most suitable for mass production.

High cut quality and preservation of the metal structure contribute to a significant reduction in time and energy costs.

Principles of classification

Guillotine shears are distinguished by the following characteristics:

- By type of drive. In industrial production, as well as when cutting thick sheets, driven metal guillotines are more common. In this case, the control can be mechanical or hydraulic. In individual business practice, as well as in private workshops, manually driven machines are found.

- According to the execution of the main actuator. An electromechanical guillotine is most often equipped with a crank mechanism, while manual machines often have a lever mechanism.

- According to the method of pressing the workpiece to the supporting surface of the table. Guillotine shears can have mechanical (spring) or hydraulic clamping.

- According to the control method, cutting shears with non-automated feeding and removal of cut strips are distinguished, and automated complexes based on sheet shears, where all technological operations are carried out without human intervention.

Despite all the design and technological differences, these machines have one thing in common: the angle of inclination of the knives at which they cut. The fact is that at a zero inclination angle, penetration is carried out simultaneously across the entire width of the sheet, which causes increased energy costs and becomes the main reason for the increased drive power. Since the schedule of the technological operation of separating sheet metal has a peak of effort only at the beginning of the introduction of knives, and then rapidly decreases, it is much more profitable to ensure the gradual introduction of the tool into the workpiece. The force is significantly reduced, and the working displacement, although increased, is not much (due to the small thickness of the processed rolled profiles). Therefore, the knives of equipment for cutting sheet profiles are always inclined. The tilt angle ranges from 1.5...3.5°; it is larger for more powerful equipment. When cutting a harder product, for example, stainless steel, the gaps, on the contrary, are reduced. Increasing the gaps for ductile mild steel or copper degrades the quality and accuracy of the cut because the material being cut is pulled into the gap between the blades and forms burrs. Burrs are also a sign of a dull tool.

According to the classification accepted in our country, mechanically driven guillotine shears have the symbol H31__, H32__, H34__ or H33__ (the last two digits of the designation indicate the maximum thickness of the sheet metal being cut). Hydraulic shears are designated H37__. In practice, there is also marking of drive units for cutting sheet material according to its thickness and width. A typical example would be German-made machines, designated, for example, as follows: ScTR16×3150 (the first number is the maximum thickness, the second is the greatest width).

What to look for when choosing a guillotine?

When choosing a guillotine, it is recommended to be guided by the following parameters:

- maximum thickness and length of cut;

- production volumes (piece or mass);

- required performance and cutting accuracy indicators;

- optimal list of functions.

It should be taken into account that multifunctional equipment with high power has certain features:

- high price;

- large dimensions;

- Possibility of installation only in rooms with a large area;

- high energy consumption.

Inventor of the execution weapon

For a long time in France, criminals were burned at the stake, quartered or hanged; only privileged people were executed by beheading with an ax or sword to reduce their suffering. Dr. Guillotin, a member of the National Assembly, in 1791 first proposed carrying out executions using the same method, without dividing the people into ordinary and aristocrats. In his opinion, the guillotine is an excellent way to relieve a condemned person from physical and moral pain, because the weapon was quickly brought into action and took a life in a matter of seconds.

J. Guillotin submitted a corresponding proposal to the Constituent Assembly in 1789. Much controversy followed, but in the end the majority of the members agreed with the doctor, and in 1791 this method of execution was officially introduced into the criminal code. At first, the murder weapon was tested on corpses, but already in the spring of 1792 the first execution took place on Place de Greve using this mechanism. For a long time there was an opinion that the inventor of the guillotine himself suffered from his own creation, but this is not true. Guillotin died of natural causes in 1814.

Working rules and safety precautions at work

In order to avoid injuries at work when working with a guillotine, it is important to comply with the following requirements:

- Availability of protective clothing: protective apron, glasses, dry shoes with non-slip soles. Before work, it is necessary to remove all protruding or hanging objects, such as watches, bracelets, rings, etc.

- Equip the work area with fencing structures.

- Before starting up the machine, make sure it is in good working order and, if necessary, take repair measures. Check the quality of the lubricant, the integrity and performance of the components. Inspect the work surface, clean it if necessary or replace it if damage is found.

- Before turning on the equipment, remove unnecessary tools, fixtures and other foreign objects from the workbench.

further reading

- Carlisle, Thomas. The French Revolution in Three Volumes, Volume 3: The Guillotine

. Charles K. Little and James Brown (Little Brown). New York, New York, 1839. No ISBN. (First edition. There have been many reprints of this important story over the past two centuries.) - Crocker, John Wilson (1853). History of the Guillotine

. London: John Murray. - Gerould, Daniel (1992). Guillotine;

His legend and traditions . Exploding books. ISBN 0-922233-02-0.

Examples from the catalog

Saber-type guillotine MG-1300 METAL MASTER. Specifications:

- model - MG-1300 METAL MASTER;

- bending length - 1300 mm;

- thickness of processed metal - 1 mm;

- LxWxH (mm) - 1700x300x800;

- weight - 85 kg;

- article - 068–2660–1;

- brand - Metal Master.

Manual guillotine Stalex Q01-0.8x2540. Specifications:

- width - 1320 mm;

- maximum cutting thickness for galvanized steel - 1.5 mm;

- material feed limiter - up to 840 mm;

- LxWxH (mm) - 1680x760x1150;

- weight - 491 kg.

General characteristics of hydraulic shears

Chopping of workpieces with a guillotine is carried out in different modes and with different parameters for the material. For these reasons, a different type of powered shear is used for each application. Equipment that uses a hydraulic drive system for scissors is distinguished by the fact that their productivity is much higher and their safety margin is greater. Most often, such equipment is used when it is necessary to establish serial or piece production of rectilinear blanks with straight edges from rolled metal with a thickness of 2 to 20 mm and a cutting length of 1 to 3 meters.

It is worth noting that in enterprises the hydraulic guillotine can be strengthened. In other words, it is capable of making workpieces up to 6 meters long, and the thickness can exceed 20 mm. However, such equipment is most often produced in single units, and the weight and dimensions are quite large.

General characteristics of the pneumatic drive

This equipment is also industrial, and it operates under the influence of compressed air. It is worth noting that such machines are superior in productivity to hydraulic ones, and are practically no different from electromechanical ones. In order to power such a machine, either a compressor or a central line with compressed air inside is used. Most often, such guillotines are purchased only by large enterprises that are engaged in mass production of rolled metal blanks.

There are some things in common between hydraulic, electromechanical and pneumatic models. All these guillotines are stationary. They are equipped with tables with a large area, containers for assembling ready-made workpieces, as well as automated devices that supply material for processing. Many models with pneumatic drive also have the addition of CNC. Due to the fact that the speed of metal processing increases, as well as the cutting accuracy, these machines with electronic control are considered one of the best.

Models for cutting metal workpieces

A manual guillotine for metal, hydraulic, pneumatic or electromechanical, is the equipment that is currently quite common. This is largely due to the fact that cutting metal in our time is one of the most popular operations. In addition, they are used not only by large enterprises, but also by home craftsmen. Due to such wide demand, manufacturers of this equipment produce it in a variety of configurations. Thanks to this, it is possible to select a model that will precisely meet the requirements necessary for cutting certain workpieces.

The high popularity of guillotine machines is also ensured by the fact that they all have a fairly high level of accuracy and productivity. It is worth paying attention to the fact that not only metal can be cut. Copper, brass, aluminum and other similar materials can also be processed on such machines. Another common advantage that all machines have in common is ease of use. The operation of these machines is quite simple, which means that after a short introduction and performing several operations, even a home master will be able to fully use such equipment.

It is worth paying attention to the fact that if the master has sufficiently high plumbing qualifications, the necessary tools and materials, the possibility of assembling such guillotines on his own cannot be ruled out. However, this process is still quite complicated, and therefore more often such machines are simply purchased ready-made.