In this subsection of the “Forge” section materials about blacksmith tools (do not be confused, there are also subsections with devices and equipment, what is the difference, see here). For more detailed information follow the links.

Hand tools and other equipment for cold metal forging

Hammers, forks and chisels are used to work not only with hot, but also with cold metal.

In addition, a wide range of equipment is used for cold forging, which in most cases is divided into four groups, depending on the technical characteristics of the equipment:

- universal units with high productivity make it possible to produce elements of different shapes; they are used in the production of companies specializing in the mass production of decorative parts;

- machines for cold forging , which include bent, snail, wave, twister, globe (volumetric), flashlight, forging block for rolling out goose foot;

Cold forging machine PROMA Gnutik 0005

- hand tools;

- homemade devices.

What tools and equipment the craftsman will need depends on the configuration of the elements required for manufacturing.

The main technological tool for machine forging

The main tools used in forging on hammers and presses include strikers, axes with different shapes of the working part, squares, clamps, rolling, crimping, piercing, extensions, mandrels for broaching and rolling.

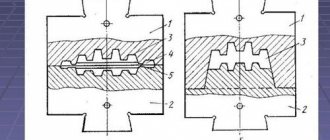

Strikers (Fig. 13) are used mainly for broaching, as well as upsetting, piercing, bending and some other forging operations. The kit includes two strikers: a lower, fixed one, which also serves as a support; upper, movable, through which the deforming load is transmitted to the workpiece from a hammer or press. There are universal strikers that have flat working surfaces (Fig. 14, a) and cut-out (shaped) (Fig. 14, b–d), distinguished by a special profile.

Rice. 13. Strikers: a – lower and upper cutouts; b – top flat and bottom cut-out

The larger the area the cutout (caliber) of the strikers covers the surface of the workpiece being processed, the less the workpiece widens during forging and the more intense the broaching process occurs. However, the required force for broaching increases significantly.

The working surfaces of flat and contacting surfaces of cut-out and shaped strikers are made strictly horizontal and tightly adjacent to each other, without gaps. Various potholes and dents are not allowed on the working surfaces of the strikers. To avoid cutting the fibers in the forging

the edges of the working surfaces of all types of strikers at the points of their intersection with the side surfaces are rounded along the radius.

For forging in the lower cutout and upper flat strikers, the lower striker is often made as a composite with inserts. Inserts allow you to quickly change the size and shape of the cutout to the required size. In addition, as the liners wear out, they become easier to replace.

Solid strikers and replaceable inserts are made by forging, depending on operating conditions, from steels 50, 50G, 40ХН, 5ХНВ, 5ХГМ. After mechanical treatment, they are subjected to heat treatment to a hardness of 40...45 HRC.

Axes (Fig. 15) are used to carry out operations of cutting off parts of the original or forged workpiece or cutting them into dimensional pieces. In Fig. Figure 16 shows a diagram of the operation of cutting off a part of a workpiece with a blacksmith's axe. Depending on the purpose, the designs of axes used in blacksmithing are varied.

Axes are made by forging from steel 18ХНВА or steel 50, steels 35ХМ, 5ХНВ, 7X3, 8X3, 5ХНМ, subjected to heat treatment to a hardness of 40...45 HRC.

Rice. 14. Working surfaces of the strikers: a – flat at the upper and lower strikers; b – flat at the top and cut-out at the bottom strikers; c – cutout at the upper and lower strikers; d – shaped at the upper and lower strikers

Rice. 15. Blacksmith axes: a – trapezoidal ax for chopping in a cut-out head; b – an ax with a solid forged handle; c – semicircular

Ax handles are made of steel 20 or St 3. Large, heavy axes are made with quick-change handles or handles suspended from the crossbar of the press. To make working with such axes easier, manipulators are often used.

Clamps are used to create single or multi-sided recesses for the subsequent formation of ledges or pinch on the workpiece.

Recesses on the workpiece (notches) serve to fix (or mark) the volume of metal that should be subjected, for example, to broaching in order to obtain the required geometry of the workpiece after forging. Notches are usually made by pressing a round or rectangular rod into the workpiece. To increase the depth of the notch, for example, until a ledge is formed on the workpiece, clamps of various geometries are used.

Rice. 16. Cutting off part of a workpiece with a blacksmith’s axe: 1 – workpiece; 2 – ax; 3, 4 – strikers

In Fig. 17 shows a diagram of the clamping operation, and Fig. 18 – technological sequence of manufacturing step forging by broaching using clamping. Clamps are made from steels 40, 45, 40X.

Rice. 17. Clinching pattern: a – round rolling; b – triangular clamping; 1, 2 – upper and lower strikers, respectively; 3 – tool; 4 – workpiece being processed

Rice. 18. Technological sequence of manufacturing a three-dimensional T-shaped workpiece: a – initial workpiece; b – workpiece after pressing from four sides; c – workpiece after broaching

Rice. 19. Acceleration: 1, 2 – strikers; 3 – workpiece; 4 rolling out (pressing)

Rolling (pressing) is a tool used to make local indentations and straighten metal. By expansion (Fig. 19) we mean an increase in the width of the workpiece or its diameter by local compression of adjacent sections of the workpiece with a decrease in its thickness. The predominant flow of metal during acceleration is always perpendicular to the direction of movement of the striker. After acceleration, the resulting wavy surface is smoothed with a flat (pressing) striker. The tool used - rolling - is made of various shapes (Fig. 20) from steels 50, 40, 45, 40Х, etc.

Rolling handles are made of low-carbon steel, for example St 3 or steel 10.

Crimpers are used to redistribute metal along the axis of the workpiece (rolling) or finishing forgings, as well as in the manufacture of forgings on hammers and presses. According to their design, crimps are divided into detachable (Fig. 21, a) and one-piece (Fig. 21, b), mounted on one common handle. They are made from steels 40, 45, 50, U7, 40X.

Rice. 20. Some types of rolling

Rice. 21. Crimping: a – rolling detachable; b – rolling spring

Rice. 22. Stitches: a – cylindrical; b – conical; c – hollow; g – wedge-shaped

Piercing tools (Fig. 22) are the main tool for piercing - a forging operation of making holes in forgings by displacing material. For ease of working with piercings, cylindrical through or blind holes are made on their surface, into which transport or installation pins are inserted. The piercings are made from steels 40Х, 50Х, 5ХНВ with a hardness of 40…45 HRC.

Do it yourself: for the forge, at home and more

Hand tools for hot forging are quite easy to make with your own hands. This option will allow you to save money and make equipment “for yourself.”

Detailed instructions for making tools are presented in a separate section of our website. Craftsmen clearly demonstrate the production process of pliers and other equipment.

Types of forging machines

The advantages of cold metal forging include the absence of the need to create a forge and install equipment and devices, without which it is simply impossible to work.

Cold forging of metal can be done automatically, and without any particular difficulties. This ensures increased efficiency in the production of products. Even manual production makes it possible to increase labor productivity, that is, to produce entire batches of parts according to the selected sample. There is always the possibility of organizing small-scale and mass production. This is beneficial when placing large orders, for example, in the manufacture of fences, window bars, etc.

To set up a cold forging workshop, you do not need to have large areas.

During cold forging, there is no change in the internal structure of the metal. The product retains high strength and characteristics. When cold forging metal, there is the possibility of artificial aging, which makes it possible to produce antique parts.

We can say that the use of cold forging technology allows us to produce inexpensive products with maximum quality.

Basic forging elements

Often the principle of creating a curl from metal is twisting and bending.

- currency

- chervonka

- bagels

Twisting, performed on the longitudinal axis or winding a round curl around the center, are the main types of this operation and make it possible to obtain a cone-basket object. Including a metal press, it is possible to produce textures of different reliefs:

- crow's foot element,

- dome peak

- faceted lance.

- clamp strip

[Show slideshow]

Characteristics of the site

A modern forge shop is a combination of several sections. This includes production and auxiliary departments, warehouses, as well as service and household areas.

If we talk about each individually, then production departments are areas where they prepare parts, as well as rooms where forging hammers and presses, stamping hammers and other main equipment for work are located. Auxiliary areas include workshops that repair main equipment. This also includes power plants, heating plants, laboratories, technical control of finished parts, etc.

The warehouses of the forge shop usually store metal, blanks, forgings, burrs, spare parts, etc.

Advantages and disadvantages of hot forging

The hot forging method does not involve the production of similar products. Since this labor-intensive work requires significant human resources, unique artistic compositions are not cheap.

Table 2. Advantages and disadvantages of hot forging

| Advantages of hot forging | Disadvantages of hot forging |

| Product exclusivity: there are no absolutely identical products | Low production speed |

| Wide range: it is limited only by the imagination of the blacksmith and the customer | High labor costs |

| It is possible to produce a product of any design complexity | Low accuracy when maintaining size |

| There are no strict requirements for the selection of source material | Impossibility of mass production |

| After hot forging, the metal is strengthened | High price |

| Hot-processed metal is slightly susceptible to corrosion and oxidation | |

| Hot forging products have a high prestige |

Hot forging technology may involve the use of equipment such as a machine, steam or hydraulic hammer. But the main work is still done by hand.

Technological process

Today, the forge shop, like any other area of production, needs to develop a technological process for efficient operation. For workshops of this type, there is one main criterion by which the production process is selected. This criterion is the lowest cost per ton of forgings, which will fully comply with the required quality. In second place when choosing the main production technology is the required volume of parts, as well as possible special requirements for the elements.

Most often in a forge shop, the technological process is divided into the following stages:

- dividing the required material into pieces of the required length;

- This is followed by heating the workpiece and its heat treatment;

- processing the material with high pressure to give it the desired shape;

- this is always followed by separation-type processes, after which finishing work is usually required to remove possible burrs and so on.

Hot steel forging technology

Forging begins with heating the workpiece in a muffle furnace or forge, then the hot metal is sprinkled with forge flux. When processing steel, the following operations are performed:

- according to the required dimensions, the red-hot semi-finished product is divided into parts;

- cutting is carried out - external processing of the surface of the workpiece;

- excess fragments are cut off from the metal, resulting in a rough version of the product;

- drawing is performed, after which the workpiece becomes longer and narrower;

- using special tools, holes of various shapes are punched;

- if required, the workpiece is given the desired bend using a template (or without it);

- at the final stage, after additional operations, finishing is performed.

During hot forging, upsetting, upsetting, broaching, rolling, rolling, piercing and straightening are performed. As sedimentation work progresses, the workpiece increases in cross-section and decreases in height. When planting, a thickening is made on the surface. In this case, the length of the semi-finished product is also reduced. Broaching is another blacksmithing technique in which the workpiece is lengthened and thinner.

During rolling, the heated material takes on a cylindrical shape: during hot forging of this type, the workpiece is wrapped around its axis. Rolling involves processing a ring-shaped semi-finished product, which changes its internal and external diameters during processing. As it accelerates, the metal object becomes wider.

Attention: Firmware is an operation that produces a through hole using a punch.

Products obtained from forging elements

Having understood the variety of objects created using artistic forging, it is worth mentioning the finished goods obtained using this craft. Non-standard forged products, with graceful curves, created taking into account the image of the room, be it an apartment or a country house, will miraculously fit into a modern design solution and into a traditional interior, adding an ancient gloss designed to create a feeling of completeness. In skillful hands the following can be created:

- gates,

- fences,

- stairs,

- window bars,

- balcony railings,

- lanterns,

- lamps,

- furniture.

Forged grille

Wrought iron staircase

Forged gates

Heating the material

When working in a forge, increased attention is paid to the process of heating the workpiece. To successfully complete this stage, it is necessary to very accurately determine the thermal conductivity of the material. Thermal conduction refers to the process during which heat passes from the outer walls of the workpiece inward. This parameter depends on the heat capacity and density of the metal. Therefore, the higher this indicator, the faster the heat will penetrate inside, which means the less time it takes to warm up. In addition, thermal conductivity is also affected by the type of metal, its chemical composition and the temperature at which the workpiece is exposed. It is worth noting that most often at temperatures of 700–800 degrees Celsius, the thermal conductivity coefficients of different steels become equal.