Chamber furnaces

This type of unit is used in the firing of ceramics, porcelain, in the preparation (heating) of metal blanks before forging, rolling, and various types of heat treatment. In this case, the products being processed are motionless.

They vary in design and are divided into vertical, bell-type, pit, bogie, heating well, and so on. The temperature inside the unit can be constant or gradually change, ensuring uniform heating (cooling) of the products. Gas, liquid fuel, or electricity can be used as a heat source. Electric power supply provides more even heating. The most widespread are chamber furnaces with a fixed hearth. They are installed in forge shops.

Principle of operation

The temperature difference between the axis of the workpiece and the surface affects the uniformity of heating of the material, which plays an important role in plastic deformation. The plastic properties of the material depend on the heating temperature, and therefore uneven heating can cause deformation. Reducing the temperature difference increases the quality of rolled products and the heating time of billets, reducing furnace productivity and increasing metal waste.

Muffle furnaces

To prevent heated objects from coming into contact with fuel and combustion products, they are placed in a special compartment - a muffle. Such furnaces are called muffle furnaces. The muffle is made of fire-resistant materials; the air inside it is heated to a certain temperature, which is then maintained at a constant level.

Since their use does not require high temperatures, they usually operate from an electrical network. Such units have a wide range of uses: for firing ceramic products, in jewelry, chemical, medical production, and the food industry. They are equipped with replaceable muffle chambers for working with different materials.

Classification by type of working environment

Muffle furnaces can provide heating of workpieces in various environments:

- Air

- Inert gas

- Vacuum

The simplest type of muffle furnaces are heaters with a traditional air chamber . The heating chamber in such furnaces is simply a hollow space into which the workpiece is placed.

In many cases, the presence of air is not critical for heat treatment. But there are still some technological operations for which the presence of air in the heating chamber is either undesirable or unacceptable.

When hardening many grades of steel and various alloys, air reacts with the surface layer of metals, which worsens the performance characteristics of the workpieces. Furnaces with inert gases or carbon dioxide supplied to the heating chamber have been developed especially for such cases . Neutral gas displaces air, creating a reliable protective layer.

Furnaces that are adapted for melting metals are often equipped with a heating chamber with a vacuum sealer. Metal melted under vacuum conditions acquires a particularly high-quality structure. Aluminum is often melted in a vacuum.

Additionally, muffle furnaces with different types of heating chambers are often equipped with an exhaust hood . Ventilation removes combustion products, moisture and other vapors from the heating chamber, the presence of which is undesirable during heat treatment.

How to choose a muffle furnace based on heating temperature.

Muffle furnace SNOL

SNOL muffle furnaces are widely used for heat treatment (heating, hardening, calcination) of various materials and samples in research and industrial laboratories. Their volume can be different, depending on the purpose, starting from 1 liter, and the operating temperature can be in one of the ranges:

- moderate – 100-500°C;

- average – 400-900°C;

- high – 400-1400°C;

- ultra-high 400-2000°C.

They differ in the material from which their heating elements are made, it can be a high-quality alloy, silicon carbide heater or lanthanum chromium. The element may be partially or completely pressed. To make a muffle - working chamber, use:

- ceramics;

- fibrous material KTM;

- mullite-silica;

- corundum.

SNOL ovens are equipped with a digital microprocessor thermostat, which is used to regulate and control the temperature, which ensures the accuracy of the technological process. In this case, it is possible to set the duration of heating and holding time. Some models have additional features that allow for more complex programming.

Mechanized and semi-mechanized ovens

A type of furnace, loading and unloading of workpieces into which is carried out using additional mechanisms.

Mechanized chamber furnaces can be installed in a production line along with other equipment due to the rhythmic delivery of workpieces. The simplest in terms of operation and design are pusher furnaces.

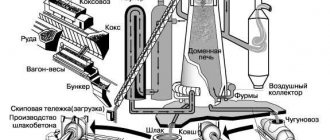

The designation of an arc steel-smelting furnace usually includes its capacity in tons (for example, EAF-12). The range of furnaces varies from 1 to 400 tons. The temperature in the chipboard can reach 1800 °C. An arc steel furnace (ASF) consists of a melting bath (working space), an arc power regulator and auxiliary technological mechanisms that allow you to open (close) the furnace roof, collect slag and release molten metal. Drum furnaces

Drum kilns (drum rotary kilns) are industrial furnaces used for heat treatment (firing and drying) of various raw materials and materials in order to change their physical and chemical properties. A drum rotary kiln is a cylinder (cylindrical chamber), located horizontally, which slowly rotates around its longitudinal axis. During rotation, the material is mixed inside the furnace, as well as its transportation; for this, the cylindrical chamber is installed at a slight inclination. The material or raw material is fed from above and slowly falls down, subjected to heat treatment by hot gases, which, as a rule, pass from the bottom up or go in the same direction. The fuel for drum furnaces is most often natural gas, although they can operate on a wide variety of fuels. The main components that make up drum furnaces: Furnace frame - it includes supporting frames and frames, which are made of durable steel. The furnace drum (cylindrical chamber) is a metal drum that is mounted on support rollers and lined with refractory materials. Furnace bandage (bandage rings) - most often the drum has 2-3 bandages, which are made of cast steel and have a smooth surface without joints. The furnace bands are mounted on support rollers and attached to the furnace drum with special brackets. Various rollers (control, support) allow you to control the position of the furnace. Electric drive and drive mechanism - the furnace drum is driven by an electric motor through a gearbox and gear drive. An additional electric motor (auxiliary) must be installed at the production site, which is used during furnace repairs, during ignition and shutdown. In those industries where stopping a hot furnace due to a sudden failure of the drive is unacceptable, an additional electric motor is installed, which has separate, independent power sources. Heads - Combustion (hot) head - the fuel-air mixture and gas outlet are supplied through it. Burner - installed in the combustion head. Refrigerator - used to cool the processed material. To increase the productivity of furnaces, various devices and mechanisms are built into them to improve heat transfer, and are also connected to heat exchangers. Classification of drum rotary kilns. 1. According to the principle of heat exchange: - Furnaces with direct flow (hot gases flow in parallel with the material being processed); — Furnaces with counterflow (hot gases rise towards the material being processed). 2. By heating method: — Direct heating ovens; — Indirect heating furnaces; — Furnaces with combined heating Application of drum rotary kilns: Drying (dehydration) of various materials. Firing of refractory materials. Production of sintered materials: charges for the production of alumina, cement clinker, fireclay, magnesite. In metallurgy, in the production of secondary non-ferrous alloys and in the production of ferrous alloys. When extracting zinc and lead. Production of silicate lime. Oxidative, reduction, chlorinating firing. Incineration of waste. They are used for burning liquid industrial waste, less often for burning solid unprepared waste. Automation of drum rotary kilns. The task of the furnace automation system is to ensure stable and precise control of technological processes. The furnace automation system allows you to increase the efficiency of furnaces, reduce fuel consumption, and reduce the use of manual labor. The correct operation of the stove is “monitored” by various elements of the automatic control system: - Sensors and flow regulators: control the supply of fuel and air to the combustion system; — Measuring instruments and actuators; — Alarms: sound signals when emergency situations occur and when various indicators deviate from the norm (increase or decrease in pressure, power outage, etc.); — Safety valves: shut off the gas supply; — Control panels: instrument readings are displayed on them. To make it easier to control the operation of the furnace, a computer system is installed in production. With its help, you can monitor all processes on one screen, which significantly simplifies the work of maintenance personnel, allows you to process data faster and more accurately regulate the operating mode of the furnace. All this ultimately reduces costs, increases the productivity and efficiency of the furnace.

Carry-out ovens

A bogie furnace is an industrial batch furnace for heat treatment of a product, the main feature of which is a trolley (roll-out hearth) that rolls out of the furnace on rollers. The processed products are placed and heated on a cart (roll-out hearth), which is lined with highly efficient materials. Products are placed on a trolley (roll-out tray) and removed from it using specialized equipment (for example: a workshop crane) or manually. Large products are placed on special linings and placed on a roll-out tray, while small parts are processed in special baskets and grates. Furnaces with a rolling hearth are most often used for processing large and heavy products that cannot be placed on a cart manually. Application of bogie hearth furnaces: - Heat treatment (annealing and firing) of finished products (ceramics, metal); — Heat treatment of castings and welded structures. Furnaces with bogie hearths have an operating temperature range mainly from 250 to 1250 C; there are also specialized furnaces with a temperature range of up to 1350 C and higher. Furnaces can be equipped with special cooling systems that allow the entire heat treatment cycle, including cooling of the processed products, to be carried out directly in the furnace, without opening it and without rolling the cart (roll-out underneath) out. Furnaces with a rolling hearth are available with different volumes of the working chamber. Furnaces with a rolling hearth differ according to the heating method: - Electric; - Gas. Electric furnaces with a rolling hearth. Heating elements are installed on the walls and in the roll-out hearth, and are powered using flexible cables. They are mainly used in industries where it is necessary to process large-sized products and fire heavy, large cages. Gas furnaces with a rolling hearth. The burners are installed at the bottom of the side walls in one or two rows. The correct selection of the type of burners (burners with cold combustion air, recuperative burners) and their location allows for uniform heating of the charge and intensive circulation of air and smoke. Smoke is removed from the furnace through special channels. The burners operate on liquid or gaseous fuel. Cooling of the processed products occurs in two ways: - Inside the furnace, in this case all the heat of the furnace is lost and the cooling process itself takes several days. - On open air. This method is used if the processing technology allows it. In this case, the furnace design provides for two roll-out hearths: while the processed products are cooling on one, the second is loaded into the furnace. At the same time, the heat of the furnace is consumed more economically. Advantages of bogie hearth furnaces: — Wide range of operating temperatures; — Ability to process various materials and products that differ in shape and size. Automation of furnaces with rolling hearths. Furnace automation includes a control and safety system. Sensors installed directly in the furnace that monitor various operating parameters (temperature, gas flow, gas content in the exhaust air) transmit all received information to devices that process and record the received data. To make it easier to control the operation of the furnace, a computer system is installed in production. With its help, all processes can be monitored on one screen, including remotely, which significantly simplifies the work of maintenance personnel and increases safety, allows faster data processing and more precise adjustment of the furnace operating mode. All this ultimately reduces costs, increases the productivity and efficiency of the furnace.

Drying units

Drying units (dryers) are designed for drying (dehydration) of various materials, raw materials and products. Drying units have a variety of characteristics and are widely used in a wide variety of industries: - in the food industry and agriculture: for drying fruits, vegetables, grain, fish, meat, etc., when obtaining fertilizers; -in brick and ceramic production: drying of finished products; -in construction: for drying sand, crushed stone, clay, etc. -in woodworking: drying lumber and finished products; -in the chemical industry: drying of polymers. Classification of drying units: By design: 1. Chamber dryers 2. Drum dryers 3. Conveyor (belt) dryers 4. Tunnel (corridor) dryers 5. Shaft dryers, etc. According to the method of heat supply: 1. Convection dryers - heat is supplied to them using any drying agent (air, flue gases, superheated steam). In this type of drying units, moisture comes out along with the drying agent under constant convection. 2. Contact dryers - in them we dry the product and heat it up on the surface, the temperature of which can reach 100C 3. Infrared dryers - in them heat transfer occurs using infrared rays. Operating temperature from 40 to 60C. 4. Dryers using high frequency currents - in them the product is heated from the inside, while the moisture first comes to the surface and then evaporates. By drying agent: 1. Air dryers 2. Flue gas dryers 3. Using superheated steam By direction of the drying agent: 1. Direct flow dryers - the drying agent moves in the same direction as the product being dried. 2. Counterflow dryers - the drying agent moves towards the product being dried. 3. Reversible dryers - the drying agent and the product being dried alternately move in the same direction. 4. Cross dryers - the drying agent moves perpendicular to the product being dried. According to the method of heating the drying agent: 1. Dryers with steam heating. The maximum heating temperature of the drying agent is 145°C 2. With gas heating. The maximum heating temperature of the drying agent is 200-350 °C 3. Electrically heated dryers. 4. Dryers with flue gases. There are also installations with natural and artificial circulation of the agent, continuous and periodic action, etc. The main components of almost all existing drying units: - frame - drying chamber - loading installation - unloading installation - heat generator. Brief description of the main types of dryers.

Chamber dryers

In chamber dryers, the drying of the product occurs in special drying chambers, rectangular in shape, the length of which can reach 15 m and a height of 3 m. The cameras are combined into blocks of up to 30 cameras. The drying agent is most often heated air; it is supplied from the bottom up through the supply channels and, passing through the product being dried, is saturated with moisture, falls and exits through the exhaust channels. Thanks to special grilles installed at the bottom of the chamber, air is distributed over the entire area of the product being dried. All chambers in one block have common exhaust and supply channels. Advantages of chamber dryers: simplicity of design and ease of maintenance. Disadvantages of chamber dryers: they do not always allow the product to be dried evenly throughout the entire volume, which increases the drying time. Drum dryers. Drum dryers are most often used for drying bulk materials. In drum dryers, the working chamber is a drum, which is mounted on support rollers and has a slight inclination relative to its longitudinal axis. The product to be dried is fed through a loading device into the drum, during which special blades rotate and mix the product and distribute it throughout the drum. The product is dried with a drying agent (usually hot air), constantly mixing and moving into the unloading device. Advantages: simplicity of design and maintenance, cost-effectiveness and high efficiency.

Tunnel dryers

Tunnel dryers are chambers in which trolleys with the product to be dried move. The drying chambers on both sides are tightly closed with doors, which are periodically opened to allow trolleys with wet product in on one side, and trolleys with dried product out on the other. The trolleys with the product move along the rails and, as they pass through the chamber, they meet the drying agent (most often they are hot air and flue gases), the moisture evaporates and the trolleys with the dry product come out from the opposite side of the dryer. The advantage of this type of dryer is continuous operation. The disadvantage of tunnel dryers is uneven drying.

Conveyor dryers

Conveyor dryers are most often used for drying finished products, where it is necessary that the drying process be included in a continuous production scheme. As a rule, conveyor dryers operate on the principle of convection or using infrared radiation. The dried product moves inside the drying chamber on special conveyor belts. The drying agent is hot air, and the length and width of the conveyor belts depends on the drying time. Advantages: possibility of inclusion in a general continuous production scheme, high productivity, cost-effectiveness, ease of maintenance.

Mine dryers

Mine dryers are designed for drying grain and other free-flowing materials that have little moisture or are already dried. Mine dryers can be batch or continuous. They got their name due to the fact that the drying chamber is a vertical shaft, round or rectangular in cross-section. The product to be dried is fed from above, and the drying agent is fed from below, or from the sides and, passing through the product, dries it and is removed through the upper fitting. The disadvantage of this type of dryers is their bulkiness, since the height of the shaft can reach 25 m, and, as a result, the costs of its construction are high. It also requires additional equipment to capture grain dust (since it is fire and explosive), and this incurs additional costs. Automated control and monitoring system. Each drying unit has an automated control and monitoring system. An automated system, using various devices and a sensor, allows you to monitor drying parameters (such as humidity, temperature), allows you to control the supply and removal of the drying agent, loading and unloading of the product being dried. An automated control system for a drying unit can be included in the overall production management system, which allows you to monitor all processes from one computer, as well as remotely set, change and control all parameters. All this significantly simplifies the work for maintenance personnel, increases safety, efficiency, and allows you to instantly respond to any changes in the system and deviations from the norm. All this ultimately increases the productivity and efficiency of the entire production.

Hardening and tempering units

Hardening is a type of heat treatment in which materials (most often various metals and their alloys) are heated above a critical temperature and then cooled sharply. The quenching medium where the material is cooled can be oil, water or salt solutions. After hardening, the material changes its properties: it becomes harder. In this case, the material often becomes less ductile and more brittle. To fix this, vacation is used. Tempering is a type of heat treatment that involves heating and slowly cooling hardened metals or alloys. This reduces their fragility and increases their ductility. Hardening and tempering of materials is carried out in various ways, depending on the material and its final properties that need to be obtained. Quenching and tempering units are designed for heat treatment of products, most often in the metallurgical industry; they allow both types of heat treatment to be performed. Hardening and tempering units are used in mechanical engineering and metallurgy in the production of various parts and products: knives, tools, bolts, nuts, machine parts and much more. The main parts of the hardening and tempering unit: - Heating furnace - Hardening device - Tempering chamber - Loading and unloading devices - Burners For preliminary washing and drying of parts and products, a washing machine is installed in production. If the material is hardened in an oil environment, then an additional washing machine must be included in the production line, where the material will be cleaned of oil with special cleaning solutions. There are conveyor-type quenching and tempering units, where the processed material or product passes through all stages sequentially, using a special conveyor. Automation of the hardening and tempering unit. An automated system can be installed on each hardening and tempering unit, which will allow you to control all technological processes and operations from one computer. An automated monitoring and control system collects, records and processes data that comes from various sensors and devices. The automated system monitors the temperature conditions at all stages, the duration of technological processes, monitors the movement of the processed material, and in the event of an emergency or if any indicators deviate from the norm, it gives a signal and can turn off a separate device or even the entire unit as a whole. The automated system improves efficiency, safety and economy and reduces costs and improves working conditions.