Metal spraying makes it possible to improve the characteristics of parts operating under conditions associated with severe wear and concentrated mechanical loads. Metallization of surfaces increases stability and increases service life. In addition to solving technical problems, spraying is used during the production of decorative items, jewelry, in the food, pharmaceutical and chemical industries. Various metals can be used for spraying; the specific choice depends on the technical specifications.

Chemical chrome plating

Used for processing parts with complex geometric shapes, the process is based on the reduction of chromium from salt solutions using sodium hypophosphite. The sediment is gray in color, the shine is acquired after polishing. Chemical chromium plating takes place in baths with this composition of solutions.

Composition of solutions for chemical chromium plating

- Chromium fluoride, g - 17

- Chromium chloride, g - 1.2

- Sodium citrate, g - 8.5

- Sodium hypophosphite, g - 8.5

- Water, l - 1

- Temperature, °C — 70-87

The speed of the chrome plating process can reach 2.5 microns/hour; resistant plastic is used to make the baths. Metallization is accompanied by the release of toxic chemical compounds; solutions have a negative effect on human skin. During work, safety regulations must be observed; forced ventilation is installed to clean the air environment. The ventilation power is calculated based on the volume of the room or work area, taking into account the minimum exchange rate.

At industrial enterprises, plastic ventilation is installed; it allows you to maintain the recommended technological parameters with minimal financial losses. For industrial chromium plating using the chemical method, specially developed solutions with improved performance are used.

Industrial solutions for chemical chromium plating

When preparing solutions, chromium chloride dissolves first. Then, according to the scheme, sodium citrate and chromium fluoride can be dissolved. To speed up chemical processes, oxalic acid is added to the composition. Chromium ions form a chemically active ion with it, the coating speed increases to 7 µm/h or more. The percentage of ingredients is adjusted by technologists taking into account the final tasks for processing the parts.

To obtain calculated coverage, the following requirements must be met:

- High-quality surface preparation. Parts are cleaned mechanically and chemically, and if necessary, surfaces are ground.

- The equipment must ensure maximum automation of the process to eliminate the harmful influence of the human factor.

- Constant monitoring of the state of the solution, filtering, maintaining a given concentration, timely replacement of the cathode.

Violation of the recommended technology can cause peeling of coatings or the formation of deep cavities. The need to correct defects leads to a significant increase in production costs.

Chemical chromium plating line

Visual control of chemical processes is carried out by determining the amount of hydrogen released; to improve the process, technologists recommend simultaneously coating parts made of several metals. Too intense release of hydrogen can cause the appearance of shells; the speed of the process is adjusted in each specific case.

Gas plasma spraying

Gas plasma spraying allows you to obtain a clean coating with high adhesion rates. The process takes place at temperatures up to +50,000°C, the jet speed is 500 m/s, the surface temperature of the workpiece is no more than +200°C.

Gas plasma spraying of metals

The surface roughness of the sprayed parts is up to 60 Rz, the blowing zone should be 2–5 mm larger than the nominal size of the sprayed area. For work, powders of the same size fraction are used, untreated areas of the part are covered with special screens. Before the process, the surface of the parts is preheated to operating process temperatures.

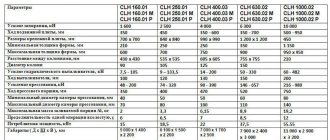

Operating modes of equipment for gas plasma spraying

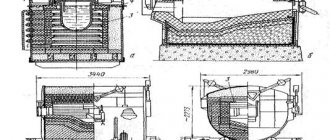

Spray equipment diagram

Equipment for powder spraying consists of a gas supply (1), plasmatron cathode (2), cathode housing (3), heat insulator (4), anode housing (5), powder feeder (6), carrier gas supply (7), plasma arc (8) and power source (9).

Gas plasma spraying allows finishing of coatings to improve the characteristics of parts; in this case, the thickness of the coating must take into account mechanical grinding.

Vacuum spraying

The transfer of sprayed metals is carried out at a vacuum of 10 -2 Pa; sputtering can be cathodic, magnetron or ion-plasma. Vacuum increases the adhesion strength of surfaces. Equipment for the technology can be multi-chamber or multi-position single-chamber. The first lines consist of several installations, in each of which a certain deposition of metals is performed; the units are interconnected by technological lines for transporting parts. Multi-position ones have several separate spraying posts in one volume. Vacuum deposition is carried out in the following stages:

- Creation of a vacuum of a given depth. Powerful compressors pump air out of the chamber, and metallization is controlled by automatic devices.

- Spraying coating material. Depending on the characteristics of the process, metal spraying can be performed in several ways.

- Transportation of parts depending on their condition.

Vacuum spraying installation

Technological definitions Vacuum deposition is a complex technological process that depends on several parameters:

- Critical temperature point of spraying. Above this value, the entire volume of directed particles is reflected from the surface of the part, and metal deposition is stopped. The parameter depends on the metal of the part, the condition of its working surface and the properties of the sprayed materials.

- Critical pressure density. The minimum density at which the sedimentary film is adsorbed and becomes unable to accept metal atoms, deposition stops. Critical density monitoring in installations is carried out continuously, and if necessary, the conditions parameters are adjusted. Depending on the composition, films can be mono- or polycrystalline and amorphous.

To increase productivity, vacuum equipment is equipped with mechanisms for automated transportation of parts into and out of the chamber, screens and manipulators, dampers and other mechanisms. Spraying is carried out in semi-automatic mode.

The use of vacuum equipment makes it possible to obtain metal spraying with a maximum adhesion coefficient, the speed of the process increases, and coatings are characterized by increased hardness and chemical resistance. The disadvantage is the high energy intensity of the process. In addition, vacuum deposition is not recommended for parts with complex surface profiles.

The issues of effective protection and decorative design of the surfaces of products made of various materials are quite relevant both for manufacturers and for many home craftsmen. Chemical metallization, which you can do yourself, allows you to effectively solve such problems.

Read also: 7805 Datasheet in Russian equivalent

Chemical metallization technology can be used on virtually any hard surface

Equipment used

Most often, devices equipped with a supersonic nozzle are used for spraying. A small electric heater powered by compressed air is also used. A special feature of the latest model is the ability to raise the temperature to 600 °C. Until recently, the use of standard devices that resemble air guns in their operating principle was complicated by the fact that particles wore out the tool tips.

Modern equipment, thanks to which metal spraying is carried out, uses the principle of a spray gun. This means that at the moment the working gas medium passes through the jet supply channel, the flow speed increases as the pipe narrows. At the same time, the static pressure also drops.

This operating principle reduces wear and increases the operating life of the devices.

Types of metallization

Metallization of products, as the name of this process implies, involves applying a thin metal layer to their surface. Not only metal, but also plastic, wood, glass and other materials can be subjected to such processing. The most popular and well-known types of this process are metallization with chromium (chrome plating), coating the surface of the product with a layer of zinc (zinc plating), less known is aluminizing, during which a layer of aluminum is applied to the surface.

Chemical metallization. Mirror frame

Depending on what equipment and what technology is used for metallization, this processing is divided into various types. Thus, today the following methods of applying metal coating are well developed and actively used:

- galvanic metallization, performed in baths with a special electrolyte;

- electric arc metallization, in which the coating is applied to the surface to be treated by electric arc melting of a metal electrode and subsequent spraying of the molten metal using a jet of compressed air;

- gas plasma spraying, in which, as with arc technology, the metal is applied to the surface of the product in a molten, finely dispersed state (like electric arc metallization, gas plasma spraying is a rather complex technological process, so they are used mainly in production conditions);

- cladding – application of a layer of metal to the surface and its subsequent hot rolling;

- diffusion metallization, the essence of which is that atoms of the applied metal, under the influence of high temperature, penetrate into the surface layer of the workpiece;

- hot metallization - the formation of a coating by immersing the product in a bath of molten metal;

- chemical metallization.

It is worth dwelling on the latest technology in more detail, since it is optimally suited for applying metal coatings to various products with your own hands at home.

Gas flame treatment method

If the previous technology provides for careful preparation of the base that must be coated, in this case special attention is paid to metallization particles. Modern flame spraying can be performed using polymer powder, wire or cord material. This mass is directed into the flame of an oxygen-propane or acetylene-oxygen burner, in which it melts and is transferred to the sprayed base by compressed air.

Next, the composition cools, forming a coating ready for use.

Using this technique, it is possible to provide materials with anti-corrosion resistance and mechanical strength. The active material can be used to process aluminum, nickel, zinc, iron and copper alloys. In particular, flame spraying is used to improve the performance of sliding bearings, insulating coatings, electrical parts, etc. In addition, the technology is used in interior and architectural design to provide structures with decorative properties.

Technological features of chemical metallization

Chemical metallization can be carried out for various purposes, the main of which is to improve the decorative characteristics of the processed product. In addition, the coating obtained by chemical metallization makes it possible to hide such defects of the treated surface as small pores and microcracks. In some cases, this technology is used to restore the surface.

If we summarize the goals of using this processing method, they all consist of improving the characteristics of the material from which the product is made. Such characteristics include, in particular:

- decorative properties;

- corrosion resistance;

- hardness;

- wear resistance, etc.

At the same time, by applying a metal layer to the surface using a chemical method, it is possible to obtain a coating with the required characteristics.

The chemical metallization process is divided into several stages, which can be easily carried out in any paint and varnish production.

The main task that needs to be solved when performing chemical metallization is to provide optimal conditions for the occurrence of redox reactions. When such conditions are provided, atoms are released from the composition of the chemical substance, the redox potential of which is at a higher level. Of course, such a process is difficult to control visually, but its result - a change in the color of the treated surface - will be noticeable immediately.

The technology itself for performing metallization using a chemical method is as follows: special chemical reagents are applied to the product, which begin to react with each other. As a result, a thin layer of metal is formed on the treated surface. A metal coating obtained by a chemical method can be made not only in a specific color, but also have several shades with smooth transitions between them. The method of catalytic chrome plating of products, known to many specialists and home craftsmen, by the way, is also performed using chemical metallization technology.

If you watch the implementation of chemical metallization on video, you will notice that this method is not complicated. From the outside, this method of applying metal coating resembles simple surface painting.

Enterprises in the Moscow region

Moscow region, Sergiev Posad, Red Army Ave., 212B, bldg. 8

Experience (years): 11

Employees:

20

Area (m²):

1400

Machines:

30

Slotting Tool sharpening Countersinking holes Gear shaping Gear hobbing Gear grinding work Jig boring work Thread rolling Thread cutting Surface grinding work Reaming holes Locksmith work Automatic lathe work Electrical discharge machining Hardening ka HDTV Volume hardening Aluminizing Anodizing Gas-dynamic spraying Oxidation Cementation Laser cutting Plasma cutting Gas welding Gas-press welding Diffusion welding Arc-press welding Resistance welding Forge welding Robotic welding Manual arc welding Submerged arc welding Thermite welding Powder coating Working with stainless steel Ultrasonic testing

Moscow region, Istra, st. Panfilova, 11

Experience (years): 61

Employees:

500

Area (m²):

10000

Machines:

86

Horizontal boring work Countersinking of holes Jig boring work Cylindrical grinding work Mechanical processing on a machining center Thread rolling Thread cutting Surface grinding work Broaching Reaming holes Thread grinding work Drilling holes on CNC machines drilling holes on universal machine tools Locksmith work Turning on CNC machines Turning on universal machines Automatic lathes Milling on CNC machines Milling on universal machines Honing Slitting milling Electrical discharge machining Dispersion hardening High-frequency hardening Normalization Volume hardening Metal annealing Metal tempering Surface hardening Sorbitization Metal improvement Boroalitizing Gas dynamic spraying Gas thermal spraying Electroplating with copper (copper plating, copper plating) Electroplating with nickel (nickel plating) Electroplating with chromium (chrome plating) Electroplating with zinc (zinc plating, galvanizing) Carbonitration Nitrocarburizing Thermal diffusion galvanizing Metal etching Chemical phosphating Chromoalitizing Chromosiliconization Laser cutting ka Shaped cutting of pipes Rolling of sheet metal metal Profile rolling Rolling of rod metal Profile bending Bending of rod metal Pipe bending Argon (argon arc) welding Gas welding Gas press welding Contact welding Metal cutting Sheet stamping Metal perforation Metal punching Rolling Manufacturing of parts according to customer drawings Manufacturing of non-standard metal structures Laser engraving Aluminum processing Titanium processing Painting brush painting spray gun Powder painting Working with stainless steel Working with galvanized steel

Moscow region, Mytishchi district, Krasnaya Gorka village, st. Shkolnaya, 38

Experience (years): 6

Employees:

?

Area (m²):

?

Stankov:

?

Turning on CNC machines Disperse hardening High-frequency hardening Cryogenic treatment Normalization Volume hardening Metal annealing Metal tempering Surface hardening Sorbitization Metal improvement Nitriding Aluminizing Anodizing Boriding Boronating Gas dynamic spraying Gas thermal spraying Electroplating with copper (copper plating, copper plating) Electroplating with nickel (nickel plating) Electroplating chrome (chrome plating) Electroplating with zinc (zinc plating, galvanizing) Carbonitration Multi-layer plating with copper and nickel Multi-layer plating with copper, nickel and chromium Nitrocarburizing Oxidation Plating Siliconizing Thermal diffusion galvanizing Metal pickling Chemical phosphating Chromo-alitizing Chromo-silicining Cementation Cyanidation Electrochemical metal polishing Gas/gas-flame /oxygen cutting Waterjet cutting Laser cutting Plasma cutting Transverse cutting of coiled steel Longitudinal cutting of coiled steel Longitudinal-transverse cutting of coiled steel Cutting reinforcement Cutting on a band saw Cutting with press shears Cutting on guillotine shears Figured cutting of pipes Rolling of sheet metal Profile rolling Rolling of bar metal Pipe rolling 3D bending pro sheet metal bending dies Press bending Profile bending Rod metal bending Pipe bending Argon (argon arc) welding Gas welding Gas press welding Diffusion welding Arc press welding Contact welding Forge welding Laser welding Surfacing Soldering Semi-automatic arc welding Robotic welding Manual arc welding Reinforcement welding Explosion welding Semi-automatic welding flux layer Friction welding Welding pipes Thermite welding Ultrasonic welding Chemical welding Cold welding Electron beam welding Drawing Metal cutting Forging Sheet stamping Volume stamping Metal perforation Straightening of flat rolled metal Metal pressing Metal punching Metal rolling Rolling-drawing Rolling-pressing Punching Rolling Metal cutting on a coordinate-punching press Khudozhe natural forging Visually -measurement control Manufacture of parts according to customer samples Manufacture of parts according to customer drawings Manufacture of non-standard metal structures Manufacture of standard metal structures Inspection by penetrating substances Laser engraving Magnetic particle testing Plasma marking Aluminum processing Tumbling drum processing Titanium processing Rewinding of metal rolls Sandblasting Brush painting Spray gun painting Powder forged painting Working with reinforcement Working with stainless steel Working with galvanized steel Development of 3D models from drawings Ultrasonic thickness gauging Ultrasonic testing Chemical analysis

Gas dynamic spraying

The main goal of gas-dynamic metal spraying is to impart certain properties to the surfaces of workpieces. This procedure is performed not only for metal workpieces, but also for other materials. It is aimed at increasing strength characteristics, electrical and thermal conductivity. This technology provides protection against corrosion and restores geometric dimensions. Enterprises providing gas-dynamic metal spraying services in Moscow

, cope with this task perfectly, because they have high-tech equipment at their disposal.

In most cases, surfaces are metallized, and the applied coatings have excellent adhesive properties. The adhesion to the base is as reliable as possible, and the products gain additional strength. Only metal powders or substances containing, in addition to metal, also a ceramic component in certain dosages can be sprayed. This significantly reduces the cost of the powder coating formation technique and does not affect its characteristics. The essence of the cold gas-dynamic spraying technique is to apply and fix solid metal particles or mixtures of materials on the surface of elements. Their size is 0.01-50 microns. They accelerate to the required speed in air, ozone or helium. Such material is called powder.

These are aluminum particles, nickel particles, combinations of aluminum with zinc. The medium used to mix the material can be hot or cold. In the first case, the maximum heating is 700 degrees. When interacting with the surface of the product, a lamellar transformation takes place, the kinematic energy is transformed into adhesive and thermal energy. Due to this, a durable surface layer is formed. The powder is applied not only to metal surfaces, but also to concrete, glass, ceramic, and stone. This significantly expands the scope of use of the technique for forming surfaces with specific properties.

Gas dynamic spraying can be high or low - this depends on the pressure level. In the first case, the working medium that moves the powder is nitrogen and helium. Moving metal particles have a pressure of over 15 atm. In the second case, compressed air is used, supplied at a pressure of no more than 10 atm. The differences between these types also lie in the heating power and the consumption of the working medium. Spraying is performed in several stages, including:

- Preparing the surface for applying powder (using a mechanical or abrasive method).

- Heating the working environment to the required temperature.

- Supply of heated gas into a special nozzle under the required pressure (gas is supplied along with the powder).

- The powder acquires enormous speed and comes into contact with the surface of the product.

The cost of gas-dynamic metal spraying services in the Moscow region is quite affordable.

Materials and equipment used

Chemical metallization, as mentioned above, can be done with your own hands and in a home workshop. Moreover, products that are small in size and simple in shape are processed using this method even without the use of special equipment. If you have such equipment at your disposal, then you can chemically apply a layer of metal even to large parts of complex configurations.

When performing this procedure yourself, you should be extremely careful, as this involves using chemicals that are hazardous to health. If you properly prepare the equipment and materials for performing chemical metallization, then you can obtain coatings on various products with your own hands at home, the quality of which is practically no different from those formed at the factory.

Reagents for chemical metallization

The kit for chemical metallization must contain reagents that have the properties of an activator and a reducer. To perform this procedure, you will also need a primer, which is applied to the surface to be treated, and a varnish that protects the finished coating from the negative influence of external factors. To apply the final varnish coating, you should choose a material that has high hardness and wear resistance.

To color the applied metal layer in the desired color, you can use a special color toner. The primer mentioned above is necessary in order to improve the adhesion of the applied metal layer to the material from which the product being processed is made. The result of do-it-yourself chemical metallization may not always be of high quality. However, the applied coating can be removed using special removing solutions.

The chemical metallization unit is designed for coating any hard surface

The essence and purpose of gas dynamic spraying technology

Using a special device - a gas spraying machine - metal particles are supplied to the metal surface using the aerosol method. The device is a complex device to which a high-pressure gas (nitrogen) line and a cylinder with metal powder, usually a copper-zinc or zinc mixture, are connected. In the case when a melt is supplied to the surface, the method is called hot. Cold metal spraying is a method of supplying fine metal dust, which, under pressure and at high speed, is included in the composition of the surface metal grid.

In addition to the gas line, the device contains vibration channels that use frequency electric current to pulse the flow of metal particles. As a result, a substance is supplied through the nozzle socket at a speed of up to 1000 m/s at a distance of 2 to 10 cm.

Important!

The use of a device for gas dynamic spraying must be accompanied by the use of personal protective equipment. In addition to portable installations, more powerful stationary spraying machines are used.

Chemical metallization at home

If you decide to do chemical metallization yourself, you should not only study the theoretical material, but also watch a training video on this topic. Naturally, it is necessary to prepare a set of equipment and consumables to carry out this technological process.

For chemical metallization, chemical reagents that are hazardous to health are used, and when working with them, safety requirements must be strictly observed. The technology of chemical metallization itself, as mentioned above, is not particularly difficult and resembles conventional painting. The main thing is to strictly adhere to a certain sequence of actions. You can learn more about this technique in videos that are easy to find on the Internet.

Read also: Press for garage drawing

The simplest installation for chemical metallization may consist of an enamel container and a blowtorch. To perform the treatment, you will need the appropriate reagents and knowledge of chemistry to mix them correctly. Having studied the theoretical material, watched the corresponding video and prepared your apparatus for chemical metallization, you can proceed to the metallization itself.

The algorithm of actions in this case is as follows:

- Carry out thorough cleaning of the treated surface from contaminants.

- Perform degreasing. This stage should be approached very responsibly, since the characteristics of the applied coating largely depend on the quality of its implementation. This procedure can be carried out using an alkaline solution or a high-quality detergent, which allows you to remove all organic contaminants from the surface of the product.

- Wash the grease-free surface with water.

- If not the entire product is subjected to chemical metallization, then those areas of it that will not be coated must be insulated with lead that is resistant to the effects of an electrolytic solution.

- The product is attached to a wire through which electric current will be supplied to it, and lowered into a container with an electrolytic solution. The product should be kept in this solution for an hour.

- The treated product is removed from the solution, dried, cooled and, if the quality of the applied coating is high enough, polished.

At home, you can use a mini-installation for chemical metallization, powered by a compressor

In order to obtain a high-quality metal layer on the surface being treated without harming your health, you should follow certain recommendations.

- Before starting the procedure, you need to check the reliability of all electrical contacts that will bear the main load.

- When performing all stages of chemical metallization (especially when removing the workpiece from an electrolytic solution), you should use rubber gloves that will protect the skin of your hands from chemical and thermal burns.

- The room in which chemical metallization is performed must be well ventilated. This requirement is explained by the fact that when this procedure is performed, intense gases are released and fog is formed, which irritates the mucous membranes of the respiratory and visual organs.

- When performing chemical metallization, it is advisable to use a respirator and safety glasses.

Metallization using standard spray equipment

In general, if you properly prepare for chemical metallization, carefully study all the theoretical aspects of this process and watch the corresponding video, then as a result you can obtain high-quality decorative coatings that also have excellent protective properties. Using this technology, even at home you can make various decorative products, restore the surfaces of worn parts, and apply a coating to them that protects them from the negative influence of the external environment.

It is important that such a process does not require the use of complex technological equipment, special knowledge and experience, or significant financial investments. You just need to study all aspects of the technique, and also strictly adhere to technological recommendations and safety requirements.

Coating parts with a layer of metal is carried out using different methods and for different purposes. Accordingly, the operating technologies differ. Chemical metallization is not difficult to perform, which is why it is used more widely, especially at home. We’ll look into all this in detail about what the meaning of this method is, what reagents and equipment are needed, what should be taken into account.

When engaged in independent processing of metal samples in everyday life, they usually focus on their appearance, which they will acquire as a result of the technological operation. That is why, when they talk about chemical metallization at home, it is a priori understood that this is chrome plating. This is where the emphasis will be placed. It is the technique of coating various parts (mainly wheel rims) with a thin layer of Cr that interests most car owners.

The author draws attention to the fact that the simplicity of chemical metallization, no matter what is stated in articles on this topic, is apparent. In practice, the home handyman will have to face a number of problems. What are these “pitfalls”, is it possible to overcome them - let’s figure this out first.

Anodizing various types of metal

Anodizing metal can be performed for different types of materials:

Anodizing technology

- aluminum It is carried out quite often, for which the part is lowered into an acidic environment, and a positive current source is supplied to it;

- titanium. Often used in industry, but requires special treatment to increase wear resistance and anti-corrosion qualities;

- steel. An alkaline or acidic environment is used, which gives the metal excellent strength;

- copper It is performed by placing the parts in an acidic environment through which an electric current is passed.

Anodizing of metals

Features of chemical metallization at home

- The part being processed is placed in a tank (bath). Conclusion No. 1 - chrome plating has limitations associated with the dimensions of the sample. While it is still possible to select a container for the same disks, metallization at home, for example, the bumper of a passenger car, is unlikely to be possible.

- During operation, intense release of toxic fumes occurs. It is not recommended to engage in metallization even outdoors, since it is impossible to predict when and how the wind will change. And if there is none at all, complete calm? Conclusion No. 2 - when planning to chrome-plate something at home, you need to take care of choosing a room, and organize forced ventilation there, since natural ventilation will clearly not be enough.

- After the chemical metallization process is completed, the electrolyte remains. The liquid is quite aggressive. Where should I put it? Conclusion No. 3 - it is necessary to decide in advance on the disposal of production waste.

Based on the above, the reader who expects to carry out chrome plating somewhere in the kitchen will be disappointed. The phrase “at home” should not be taken literally. It is understood that metallization is not done in production, on special equipment, but on one’s own, using simple reagents and accessories.

Therefore, you will have to move to a garage, barn or somewhere else, having previously prepared a workplace. As an option - a balcony or an open loggia, but only on the condition that a relatively small workpiece is supposed to be coated with chrome, using a small amount of electrolyte.

What you need for chrome plating

The premises have already been mentioned. Now about equipment and materials.

Constant voltage source

Metallization technology involves the use of various electrolytes and containers commensurate with the dimensions of the sample being processed. Therefore, if we are not just talking about chrome plating a single part, then it should be possible to adjust the current strength. The simplest homemade power supply used at home is a transformer + rectifier + rheostat.

Read also: DIY wheel gearbox

Electrical circuit elements

This mainly concerns the cross-section of wires. Practice shows that 3 “squares” is quite enough for home chrome plating of parts. It is also necessary to prepare the clamps with which they will be fastened to the electrodes. There is a crocodile type on sale. The cost is cheap, and the ease of working with them is maximum.

The approximate time for chrome plating is known, so constant presence near the tank is not necessary. But for this you will have to assemble a small electronic circuit. For those who do not understand this, this option is unacceptable.

Bath

Its material must be neutral with respect to liquids, especially aggressive ones. Therefore, glass is best. But this applies mainly to small-sized parts that can fit, say, in a standard 3-liter jar. As an option - containers from industrial batteries with thick walls. Aquarium enthusiasts often raise fry in such aquariums. But getting these vessels is quite difficult.

"External" capacity

You need to assume that the selected glass vessel will be installed in it, which will be lined with insulation on the outside. What can you use? For example, a barrel, a can, a box or a box (even a wooden one).

Thermal insulation material

The choice is large, depending on the size of the containers - sawdust, mineral wool, sand, fiberglass. The goal is to achieve the “thermos” effect. Therefore, it is necessary to make a lid that should completely cover the “outer” tank. If this is a box, then a fragment cut from FC, OSV or something similar will do. It is only necessary to provide waterproofing of the cover from the inside if it is made of a material that includes wood. What to consider? Whatever the cover is made of, it should not be conductive!

A heating element

To make your task easier, you can purchase it. The range of heating elements is quite large, so choosing according to configuration, size and power is not a problem.

Electrodes

They can be plate or rod (for example, made of brass, copper). As a “minus” at home, a clamp is usually used to hold the sample being processed.

bracket

This “detail” cannot be avoided. The workpiece, which is placed in the electrolyte for metallization, must be in a suspended state. Otherwise, the part that will be adjacent to the bottom of the vessel will remain unprocessed. The design of the bracket and the method of its fixation are chosen independently, depending on the work conditions.

Drying cabinet

At the last stage of metallization, the part must be subjected to heat treatment. Otherwise, you will not achieve the characteristic (and desired) shine.

Historical reference

The first and most important of these was the development of the anodizing process, which transformed the aluminum surface into an extremely strong, durable and corrosion-resistant material.

Aluminum alloys are highly valued as low-maintenance materials that, due to their high temperature control and versatility, can be used in a wide range of applications, from the kitchen segment to aircraft and spacecraft.

These are not very hard materials. However, unlike pure aluminum, they are not passivated, so they are more susceptible to corrosion and rust. To maximize the benefits of aluminum and improve its durability, hardness, and corrosion resistance, these and other industries resort to the process of anodizing aluminum.

Procedure for preparing electrolyte

There are quite a lot of methods, as well as the reagents used. For chrome plating at home, the most common electrolyte option is based on sulfuric acid and chromic anhydride. Component ratio: 2.5 g H2SO4 + 250 g CrO3 per 1 liter of clean water.

- First, the bath is filled. Water (distilled is the best) is poured in approximately ½ full. Its optimal temperature is 60 – 65 ºС. Under such conditions, the dissolution of the chromium compound will occur faster. Load CrO3 and mix thoroughly until all grains disappear. If necessary, add a certain amount of water (to the required volume), then add sulfuric acid.

After mixing the resulting solution, it is subjected to “processing”. It consists in passing a direct current through it. Its strength is calculated from the ratio: 1 liter - 6.5 A. Visually, the readiness of the electrolyte can be determined by its shade. It should turn dark brown in color. After this, the solution settles in a dark and cool place for at least 24 hours.

Preparing the part for metallization

While the electrolyte is settling, it's time to do this.

Removing contaminants

In order for chrome plating to be of high quality and inexpensive, the layer covering the part must be uniform and thin. This can be achieved if the surface is cleaned down to the very base. How to remove foreign fractions and degrease is up to you to decide. For samples with smooth edges, as a rule, “sandpaper” is sufficient. In other cases, you will have to think about how and with what to remove dirt and rust.

Degreasing

This is the second preparatory stage. Limiting yourself only to traditional means - gasoline, white spirit, solvent “666” or something similar - means you will not achieve high-quality metallization. Chrome plating on such a surface will not last long.

Additional processing is carried out in a solution that is specially prepared for these purposes. There are many recipes, but the most popular for metallization at home is the following:

150 (caustic soda) + 50 (soda ash) + 5 (silicate glue).

*Based on g/l of water.

The pre-treated workpiece is immersed in this solution, which must be brought to a temperature of 85 (±5) ºС. The exposure time depends on the relief of the part and the degree of its residual contamination (from ⅓ to 1.5 hours).

Anodic oxidation technology

The whole process, carried out with your own hands, can be divided into stages:

- The surfaces of disks and other metal parts are well cleaned of dirt, washed, and polished.

- Degreasing is carried out with white spirit or acetone.

- The required time is maintained in the alkaline solution (it is calculated by the equation based on the structure of the material).

- After this, the disks or other metal products are immersed in an electrolyte, where the anodic and cathodic reaction of growing an oxide film is carried out.

- If the product was cold processed, then after removing it from the container it should be thoroughly rinsed from acid and dried. After completion of this process, it is provided with long-term reliable protection against corrosion.

- During the thermal process, the film will be porous, soft, requiring additional strengthening, carried out by dipping in clean boiling water or by exposure to hot steam. Then you need to rinse it well.