Bone glue in most variations is an appropriate base based on organic components. They allow you to effectively connect elements made of wood, cardboard, hardboard and other similar materials. The connection itself is characterized by maximum strength; even if the structure is destroyed, you can notice that it is not the adhesive layer that is deformed, but the adjacent layers of wood or analogues. The mixture in question includes safe organic components that are approved for use in educational institutions and children's rooms.

Types of bone glue

To prepare the base composition, several main types are used, differing in the main components:

- Flesh option.

- Fish composition.

- Pure bone glue.

The latest version is the most common, the composition is obtained from animal bone waste. The most valuable specimens are considered to be pellets obtained from horns. The set includes collagen, gelatin and cysteine, which have excellent viscosity and are capable of firmly gluing products made of wood and similar materials.

The leather analogue is made from waste from the leather industry. In fact, the main part of the material consists of subcutaneous tissue, cut off during the tanning of hides. Oligopeptides and natural leather trimmings are often added to the composition of this glue. Output – scales, tiles, powder.

Fish bone glue is prepared from bones, heads, scales, entrails, and fins. This substance is the most expensive, but it was often used for icon painting and other works that required maximum care and accuracy. A composition is produced for fastening dissimilar parts, produced in the form of granules or flakes. Let's consider the features of all variations, as well as the features of their operation.

Preparation

Carpenter's bone glue is mainly sold in dry form. The mass is small brown or yellow granules, sometimes this material is presented in the form of small slabs. Can the quality of the composition be determined visually? The purer and lighter the material, the better the product. The cooking process is also extremely important. For example, a tile needs to be crushed into crumbs, and then used for its intended purpose. The preparation of bone glue is divided into the following stages:

- Soak. Powder or granules are poured with cold, pre-boiled water. Tap liquid can negatively affect the quality of the finished mass. Fill the container so that all elements of the adhesive composition are covered. Soaking is considered correct if the substance becomes soft and gelatinous. The soaking process takes from 4 to 12 hours, depending on the amount of product being processed.

- Cooking. The swollen glue should be boiled for about 15 minutes in a steam bath. Maintain the temperature at about 60-80 degrees. The result should be a homogeneous liquid mixture without lumps. It is important not to heat the mass over an open fire and not to bring it to a boil. Otherwise, the protein from which the granules are made will begin to deform, and the adhesive ability will decrease. After a thin film has formed on the surface, the adhesive mixture is ready.

How to make wood glue with your own hands?

Now let’s look at the popular question of how to make wood glue at home. It is prepared in several ways. Let's look at some of them:

- Ordinary carpentry compound must be soaked in water until it turns into a sticky mass reminiscent of jellied meat. Place the resulting mass in a separate bowl and send it to melt. Only very low fire is allowed. Stir the mixture constantly with a wooden stick. Next, add vodka to the composition: for 720 grams you will need about a liter of vodka. Also, for every hundred grams of the adhesive mixture, add 12 grams of powdered alum.

- Casein adhesive is prepared as follows: degrease the cottage cheese by soaking it in a soda solution for about twenty minutes. Afterwards, rinse it under running water, squeeze it out and dry it in a dry and warm place until completely hardened. Grind into powder, thereby extracting casein. Dissolve it in water and let it swell. The resulting mass is used as casein glue.

- Mix carpentry adhesive and water in a ratio of 1 to 1. Boil and grind the resulting mass. Then put it on a plate and cut into pieces. This product can be stored for a long time. Before proceeding directly to repairing the wooden surface, dissolve the tiles in a mixture of water and vodka and boil for a minute over low heat.

Peculiarities

The readiness of bone glue for wood can be checked in another way. The stick used to stir the substance is raised above the composition. If the product drips down in drops, the process is not completed; complete readiness is indicated by the flow of the mass in a monotonous stream.

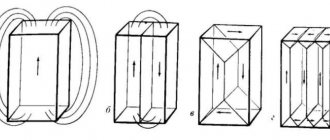

To cook natural glue, a special device is used - a glue gun. It consists of two vessels of different sizes, one of which is inserted into the other. A large container is filled with water, and the second reservoir contains the resulting glue. At the next stage, a small vessel is placed in a large tank and placed on fire. The optimal manufacturing material for the glue is copper.

Recommendations

You can prepare glutinous glue yourself. To do this, you will need to take two containers of different sizes. The outer shell could well be a tin can. Insert a tin can attached to a wire inside it.

The quality of the adhesive composition can be improved by adding various fixing substances. This will allow you to use glue for fastening not only wooden surfaces, but also other analogues.

Among the components used, the most popular, along with efficiency, are the following materials:

- Drying oil. About 10 grams of linseed oil or 40 granules of natural drying oil are added to the composition. This component allows you to increase the resistance of the working seam to moisture.

- Glycerol. An equally effective component makes it possible to use glue when processing leather surfaces. Added at the rate of two teaspoons per liter of finished substance.

- Chalk powder combined with wood ash. After sifting this mixture, add it in small quantities. The paste improves putty properties,

- Phenol, ammonia, borax. These components are an excellent antiseptic that prevents the formation of fungus and mold.

The best PVA-based wood adhesives

Below is a selection of the best adhesives from different manufacturers, created on the basis of PVA. It will help you understand which glue is better.

Eskaro PVA B3

Estonian best glue for wooden products with high water resistance class (D3). Suitable for gluing the following items:

- leather shoes;

- porcelain;

- linoleum;

- parquet

Suitable for repair:

- entrance and interior doors;

- window frames;

- garden furniture.

The seam is transparent and elastic. Consumption - 1 l per 7 m2.

Artelit WB 330

Waterproof adhesive for all types of wood from Poland, class D3, suitable for hot and cold work. Used for gluing:

- stair railings;

- doorways;

- window frames;

- doors;

- furniture.

The seam is transparent and strong, the price is reasonable.

Moment Joiner

Heat-resistant, quick-drying, non-toxic wood glue made in Russia is used for gluing wood parts with:

- rough fabrics;

- veneer;

- plastic;

- cardboard;

- plywood;

- foam rubber.

Suitable only for work in low humidity conditions at an air temperature of 5°C.

Rakoll ECO 4

One-component, heat- and water-resistant PVA wood glue made in Germany is suitable for cold and hot work. It is characterized by rapid hardening (12 minutes). Can only be stored at temperatures above 10°C.

Kleiberit 303.0

German-made PVA wood adhesive is suitable for working with wood of any species. It is frost and moisture resistant. The seam is white. Operation is only possible at temperatures above 10°C.

Krass PVA PVA D3

High class Polish product (D3) used for gluing:

- chipboard;

- plywood;

- veneer;

- timber;

- doors;

- windows;

- garden furniture.

The seam is strong, elastic and resistant to moisture.

Kiilto PVA D3

One of the best carpentry adhesives from a Finnish manufacturer. It is characterized by economical consumption, absolute safety, resistance to moisture, cold and fire.

Moment Super PVA D3 moisture resistant

PVA carpentry glue for a wide range of applications with a neutral odor and increased resistance to static loads. It has a fast setting time (15-20 minutes) and is resistant to moisture. Suitable only for work at positive temperatures.

Storage

Natural protein-based adhesives have their own characteristics. Users who use such formulations for the first time should take into account some features.

Among them:

- Adding boiled water. This is necessary if you want to make the mass thinner or extend the cooking time of the composition.

- The optimal operating temperature varies from 30 to 70 degrees Celsius. After this, the finished adhesive mass retains its properties for two hours (provided the ambient temperature is 20-25 degrees). Then the composition begins to cool, and its properties are lost.

- Ready-made wood glue cannot be stored for long periods of time. Within a day it loses its properties. In this regard, to use it, it is necessary to use as many granules as required for a specific operation. On the third day, the composition begins to decompose and smell unpleasant, which is due to its protein base. The glue is applied in layers no thicker than 0.2 millimeters. A thicker layer simply will not set properly.

Advantages and disadvantages

Fish glue has many advantages:

- long-term preservation of adhesive properties;

- long service life of the finished adhesive joint;

- ease of use;

- quite fast setting;

- adhesion strength;

- possibility of application even for dissimilar materials, versatility;

- high ductility and elasticity;

- affordable price;

- absence of harmful components in the composition;

- invisibility of the seam, colorlessness;

- high binding indicators.

Wood glue and ordinary fish glue have a significant disadvantage - low resistance to moisture, while high-grade products tolerate high air humidity and even short contact with water. Also among the disadvantages is the lack of heat resistance: even when heated to 80 degrees, the structure of the glue begins to collapse, and the adhesion of the elements is lost. Adhesives based on fish raw materials do not contain antiseptic additives, so they are susceptible to the growth of mold, insects, and bacteria. The price of Karluk is quite high, so it cannot be called an affordable remedy for home use.

Exploitation

Casein glue can serve as an analogue for gluing wooden furniture. It consists of sodium fluoride, kerosene, copper sulfate and slaked lime. This composition is not used very often because it has a short shelf life and is prone to drying out, changing color and decreasing in volume.

Working with wood glue is somewhat different from using synthetic analogues (for example, PVA (polyvinyl chloride analogue), which is also used for gluing cardboard and wood).

The best polyurethane adhesives for wood

Compositions of this type are also widely used both on an industrial scale and at home. The selection below will help you choose which wood glue is best.

Chimiver Adesiver Elastic

Eco-friendly and economical polyurethane adhesive with a wide spectrum of action. Glues wood with various materials:

- metal;

- tiles;

- concrete;

- marble.

Has increased resistance to fire, moisture, cold. Work is only possible at temperatures above 15°C.

Ceresit R710

The glue is of a high hazard class, so when working with it it is necessary to use special clothing, a respirator, gloves and goggles. It is used when laying floor coverings - metal, vinyl, ceramic, rubber, wood. Withstands mechanical loads well.

Bostik Tarbicol PU 1K

Heat-resistant adhesive made in France, with increased resistance to cold and moisture. Suitable for laying wooden floor coverings on substrates of any material. The main disadvantages are high toxicity during operation and high cost.

CHEMOLAN B45

An adhesive composition that ensures adhesion even when working with wet surfaces. Suitable for work with:

- sheets of plasterboard;

- asbestos cement blocks;

- mineral slabs;

- roofing felt;

- polystyrene foam;

- PVC;

- concrete;

- metal.

The seam is elastic, heat-resistant, water-resistant.

SOUDAL 66A

Suitable for working with all types of materials. Excellent resistance to moisture and high temperatures. Cons: strong expansion and high price.

Akfix PA370 D4

Wood glue, not subject to humidity and temperature changes, reliably bonds wood to different types of materials:

- concrete;

- polystyrene foam;

- metal;

- plastic.

Suitable for working with complex structures. The only drawback is that it is fire hazardous.

Titebond Polyurethane Wood Glue 2300

A universal-purpose moisture-resistant product that can be used to fasten parts made of any materials. Sets quickly (within 20 minutes), tolerates moisture and cold well.

Kleiberit PUR adhesive 501.0, D4

Furniture adhesive that is suitable for both indoor and outdoor use. Tolerates temperature changes well. Provides gluing of wood to a wide variety of materials:

- ceramics;

- mineral slabs;

- PVC;

- concrete and others.

This wood glue can only be used in a room with good ventilation, as it has a pungent odor. Not suitable for gluing food containers.

Preparation

The operating algorithm can be derived as follows:

- The glue is prepared according to the above method, with precise control of the cooking temperature.

- All bonding surfaces must be dry and clean. The maximum moisture content for wood is no more than 10 percent (veneer - half that).

- The adhesive mass is applied with a bast or bristle brush to both surfaces, the thickness of the seam is 0.1-0.2 mm.

- You need to wait three minutes. This will allow the adhesives to grip securely and not be squeezed out when connecting the parts.

- After fixing the elements, you will need to grind them together.

- It is advisable to tie the parts to be processed with twine or compress them with a clamp.

- Full use of the product is allowed no earlier than after six hours of exposure.

conclusions

All of these types of wood glue are environmentally safe. It is better to carry out construction operations with the hide version or PVA. These substances have excellent setting parameters and are affordable. For restoration and gluing of delicate and thin surfaces, glue made from fish raw materials is suitable.

Basic criteria for choosing wood glue:

- The lighter and more transparent the granules or tiles, the better the quality of the raw materials used.

- The most expensive and best glue is made from fish waste. It meets the highest standards. Used for restoration work and joining delicate surfaces.

- Bone and flesh composition is used for routine repair work.

Areas of application

Fish glue has a specific area of use. Its use is especially frequent in the following industries:

- Reconstruction and restoration works. The product is included in primers, primers, and paints used to restore paintings, icons, and antiques. It is also suitable for the manufacture and restoration of frescoes and mosaics.

- Woodworking. The composition is suitable for gluing wood and creating environmentally friendly types of fiberboard and chipboard.

- Finishing and construction. Fish glue is often used to lay expensive types of parquet.

- Winemaking. Fish glue can serve as an absorbent; it allows you to filter wine, drawing out harmful impurities and sediment from it.

- Furniture manufacturing. The compositions are widely used for the manufacture, repair and restoration of furniture made of wood, lumber and combined materials.

Fish collagen for beer clarification

The product is also used for the production of expensive musical instruments and in light industry. Cheap wood glue is used in matchmaking and printing production, as well as in everyday life.