The design of compressors built to air a septic tank

Compressor units for domestic use are made in the form of a working pair and an electric motor. The working pair for pumping air flow can be in the form of a piston mechanism with a valve system, a screw device in the form of two rotating cylinders with a complex profiled surface, or the simplest option is a flexible oscillating membrane with a valve.

The highest service life and discharge pressure are for piston systems. The simplest and cheapest to manufacture are membrane compressor circuits. Screw mechanisms have a high service life, but at the same time low operating pressure and efficiency.

An AC or DC motor is used as a drive; in some designs of membrane compressors, an electromagnet is installed instead of an electric motor. In this case, the operation of the membrane compressor becomes almost silent.

Screw systems are unpretentious, but can be very noisy during operation. The piston designs of compressors have considerable dimensions; during operation they can be noisy and produce strong vibration.

The most popular compressor models

The trendsetters and style makers in the construction of compressor systems for septic tanks are Japanese manufacturing companies. Their equipment is highly reliable, unpretentious and stable.

Among the membrane designs, one can find SECOH EL-60n. The first compressor was produced famously and, in fact, became a classic pumping mechanism for a septic tank. The productivity of the working unit of two membranes is 60 l/min, under a pressure of 2 atm. The size of the device is slightly larger than the dimensions of a parcel box - 28x19x17 cm.

The second compressor has similar characteristics, but has an increased service life due to the use of a powerful electromagnet instead of a motor.

The price of compressors is from 6 thousand rubles and above.

All elements, except for the injection system, are made of polypropylene and acrylic, which perfectly withstands heat and moisture. Any compressor designs for septic tanks are manufactured with protection against overheating and moisture ingress, are equipped with filters and are designed for at least 5 years of operation. Repair of membrane compressors of septic tanks comes down to replacing the membrane itself, made of reinforced rubber or rubber, and, if necessary, replacing the crank support bearing.

To avoid water hammer, when the unit is turned off, the compressors are equipped with dampers and cut-off valves that allow the pressure in the working chamber to be released gradually, over several minutes, and at the same time prevent water from entering the air duct cavity.

Features of compressor operation

To ensure reliable and uninterrupted operation, the air unit must be installed in a separate waterproof box with grounding. Vapors and gases released from the septic tank well should not enter the suction tract and the compressor cooling system.

Any evaporation from the sewerage system, as a rule, is saturated with a large amount of volatile organic substances that can cause corrosion and oxidation of metal parts. If gases enter the suction tract of a compressor, then within two to three weeks an accumulation and deposition of organic matter occurs inside the working couple, which can damage any compressor unit.

The first sign of such a situation will be constant overheating of the motor and activation of the thermal relay. Contamination can only be eliminated by completely disassembling and washing the device.

When choosing a compressor for a septic tank, pay attention to the maximum air pressure. It should be at least 2.5-3 atm. A reserve of power and pressure is necessary for periodic blowing of the aeration device located at the bottom of the septic tank.

Is it possible to make a compressor for aerating a septic tank with your own hands?

Most often, the question of a homemade compressor arises for small-volume sewer septic tanks. For example, for a Topas type installation with a chamber volume of 300 l, you will need a unit with a productivity of up to 20 l/min, which is a record for microbiological cleaning stations.

Most often they try to use old automobile and refrigeration compressors for a septic tank. The pressure and air flow allow air to be pumped into the septic tank for a short period of time. But most often such devices are not designed for long-term operation, and fail after 30-40 hours of operation. The reason is that the lubricant leaves along with the air flow into the septic tank. Even with the installation of oil traps, the reliability of operation of such compressor systems leaves much to be desired. More powerful compressor devices are connected to a homemade receiver from a gas cylinder. In this case, it is possible to ensure normal aeration of the active zone of the septic tank, but the energy costs will be approximately 4-5 times higher than when operating a compressor unit specially manufactured for the needs of the septic tank.

Design features and principle of operation

A well airlift is a specialized air pump that is designed to pump water out of a hydraulic structure without the use of water pumps. The equipment is characterized by increased productivity and environmental safety, since during its use the well is filled only with air.

The first prototypes of such systems were developed back in the 18th century, but they became widespread in the industrial sector only in the 90s. last century. The design features of airlifts include the following parts:

- A suction mechanism that promotes a balanced supply of air mixture into the pipeline system.

- The pipe through which the working mixture moves.

- Air separator. This part is used to separate the hydraulic mixture from the well into several components.

- Pipeline. Through this system, a compressed air stream from a compressor is delivered to the mixer.

Mixer. Designed to connect the working medium and compressed air.

The operating principle of airlifts is as follows:

- A pipe is immersed into the hydraulic structure from which water will be pumped.

- Another pipe is connected to the lower elements of the line for pumping compressed air.

- During the delivery of the compressed air stream, a working mixture of air bubbles and liquid is formed.

- As the mixture rises to the top, it is separated into a number of components.

Areas of application of airlift

Modern airlifts are used in a wide variety of sectors of human activity. Among them:

- Construction of industrial water treatment plants that require a constant supply of chemically active substances.

- Pumping oil deposits out of the ground.

- Lifting water from a deep well to the surface.

- Carrying out work to clean septic tanks from sludge and wastewater.

The use of an airlift for pumping water from a well or borehole is carried out using 2 technologies:

- By supplying compressed air through a thick pipe.

- By pumping air mass through a small diameter pipe. In this case, a large number of small air bubbles form.

The first option is suitable for the oil refining industry, and the second is for pumping low-density liquids.

Why is an aerator needed in the cleaning system?

It is this element that provides air supply inside the cleaning chamber, which increases the activity of microorganism colonies

The design of the water purification system is aimed at processing and purifying waste sewer streams from accumulations. The structure consists of a tank containing:

It’s clear why pumps and pipes are needed, but compressors for septic tanks raise questions. But it is this element that provides air supply inside the cleaning chamber, which helps to increase the activity of colonies of microorganisms responsible for processing and decomposing waste. Compressors for septic tanks, as shown in the video, force air masses inside, accelerating the process of dissolving biological accumulations.

Popular brands

Biological treatment plants of many domestic manufacturers are equipped with an installed air compressor. With rare exceptions, these are membrane-type models from Japanese brands Secoh and Hiblow. The specialization of both companies is the production of power plants and units using innovative technologies. Thanks to constant updating and improvement of design, brand products are distinguished by stable quality, reliability, and reasonable prices.

Secoh models are distinguished by:

- Low power consumption.

- Minimal pulsation with continuous air supply.

- Silencer chamber provided by design.

- Light weight.

- Compact.

- Waterproof housing.

- No overheating during long-term uninterrupted operation.

- Easy to maintain without professional training.

Characteristics of the well-known model EL-60: air flow - 60 l/min, maximum pressure - 2.5 atm, power consumption - 42 W, noise level - 33 dB, dimensions - 268.5x201x216 mm, weight - 8.5 kg. Options of higher power, without a significant increase in size, are obtained by integrating two compressors into a single housing.

The Hiblow HP-60 model of the same performance is characterized by the following parameters: pressure - 1.47 atm, power - 51 W, noise - 35 dB, dimensions - 280x190x171 mm, weight - 7 kg.

Compressor equipment from the following manufacturers also deserves attention: Friess and Thomas (Germany), Faggiolati and Doseuro (Italy), Matala (Taiwan), Hydrig (Russia).

Advantages and disadvantages

The main advantages of airlifts include the following points:

- Simple design features and no rubbing or moving mechanisms.

- Possibility of storing liquid in unlimited volume.

- Ease of installation and dismantling of equipment - the working parts of the system are connected using threads.

- Reliability and resistance to overgrowth.

- Ability to withstand exposure to chemical reagents and aggressive environments. This advantage is due to the use of special alloys in the production of airlift pipes.

In addition to the advantages, airlifts also have negative sides. Among them:

- Relatively low efficiency.

- A number of difficulties when pumping liquid from shallow wells.

The installations are also unable to pump out water in uniform portions, and the supply of sand and silt deposits remains uncontrolled.

Productivity does not depend on the intensity of the compressed air flow into the hydraulic structure, but on the thickness of the supply pipe and the depth of its immersion. When calculating an airlift, experts determine the optimal ratio of such parameters in order to obtain the highest percentage of efficiency.

Operating rules

The impeccable functionality of compressors for septic tanks depends on the correct operation of the system

The impeccable functionality of septic tank compressors depends on the correct operation of the system. Here are some tips from the professionals:

The efficiency of wastewater treatment depends on the reliable operation of the compressor for a septic tank system, so it is not recommended to make a compressor for a septic tank with your own hands. However, if necessary, you can take the device from a vacuum cleaner or refrigerator; a compressor is ideal for a septic tank, but the easiest way is to purchase exactly the required device to ensure uninterrupted operation of the entire system. And to understand even better the rules for choosing compressors for septic tanks, watch a video from professionals.

How to make your own airlift

If desired, every craftsman can make an airlift with his own hands, without turning to specialists for help. But to obtain a high-quality system, it is necessary to perform a series of mathematical calculations and determine the following properties:

- Depth of immersion of the mixer into the well.

- The thickness of the pipes supplying air to the well and pumping water out of it.

The height of liquid lift depends on the drilling depth.

To calculate the immersion depth of the mixer, you need to use the following formula: H = kh.

To make an airlift faster and more efficiently with your own hands, you should follow these instructions (it is suitable for pumping water from a well 20 m deep):

- To supply water, you need to take a 22-meter pipe with a thickness of 1.4 inches. It is immersed to the optimal depth, leaving the upper part above the ground.

- At a distance of 0.5 m from the ground, you need to make a hole in the pipe, and then fasten a tee with an internal thread. A short tube will be screwed into it to supply liquid.

- A 1 m long pipe is placed in the upper outlet of the tee. A hose will be passed through it to a depth of 20 m to supply compressed air flow. The inner hole of the hose has a diameter of 10 mm.

- The remaining part of the hose is connected to the outlet fitting of a compressor with 2 cylinders.

After completing the assembly of the structure, you need to start the compressor and supply a compressed air mass into the well in order to begin withdrawing liquid upward. Using a similar technology, you can create a homemade compressor for a septic tank that will pump out wastewater with silt and sediment. It is impossible to make a pump without first calculating the parameters.

Initial conditions

aazinusFORUMHOUSE Member

The house stands on a bolt, the floating foundation is a caisson until it leaks. High water: off-season – 30 cm; in summer - 70 cm, in drought, it went up to 1.5 meters. Five people live in the house, sometimes seven. It had to be done in winter. I refused to pour concrete. In addition, pouring concrete into a swamp requires good pumps for pumping. According to calculations, the volume of discharge is 7×150=1050 liters, in total – cubic meters. Safety factor (cleaning time) – 3.5 days. The volume of the septic tank (more correctly, local treatment station, VOC) is 3-3.5 m³.

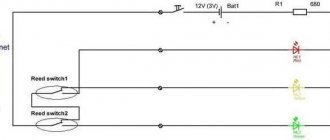

After studying the forum, aazinus chose a design scheme with aeration:

- the first cube is a settling tank;

- the second is aerated;

- the third is aerated, but weaker, so that the sludge settles.

How to make an airlift for a septic tank yourself

It is no secret that the best solution to the issue of wastewater treatment in areas where there is no central sewerage system is to install a septic tank or biological treatment system. But in order for treatment plants to operate as efficiently as possible and to be distinguished by high productivity, it is necessary to use additional equipment, in particular, an airlift or an airlift.

An airlift is a kind of jet pump that ensures the movement of liquid from the septic tank receiver to the aeration tank - a chamber populated by bacteria. It can work with a clean environment, and in cases where it contains certain impurities, sludge, so in the situation under consideration it will function without problems. In general, such devices are used not only for septic tanks. They are installed in wells and used at industrial facilities - wherever it is necessary to organize the rapid movement of liquid. Depending on the purpose of use, airlifts may differ in technical parameters, but in any case, their design will include the same elements; there are no changes in the principle of operation.

Structurally, the airlift consists of:

In order to more accurately understand what the operation of the device in question will be like, it is necessary to carefully consider all its features. They are as follows:

We see that airlifts are simple, reliable and functional devices. And yet, many doubt the need to install them in a septic tank.

Why do you need an airlift for a septic tank?

Considering the features of the operating principle, we can distinguish two main functions of an airlift in a septic tank. The first is the acceleration of the movement of wastewater from the receiving chamber to the aeration tank. Of course, you can wait until the filling level of the tank reaches the point where the wastewater itself will flow into the adjacent container through the connecting pipe. But in this case, the functionality of the treatment plant will decrease, and problems may arise in its operation, for example, an unpleasant odor in the area. When wastewater is transferred to an aeration tank, the stench is not felt, because here it quickly disappears as a result of fermentation and processing of wastewater.

The second function of the airlift is to maintain the required amount of bacteria in the wastewater, due to which fermentation occurs, which is an integral stage of the purification process. We all know that bacteria are anaerobic and aerobic. The latter exist only in an environment where oxygen is present. If there is not enough of it or none at all, the microorganisms die. Regarding the septic tank, this situation is unacceptable, because it will lead to a slowdown in wastewater processing. The minimal consequence is the spread of an unpleasant odor throughout the area. To avoid such developments, airlifts are used.

How to choose an airlift or make it yourself

Of course, the easiest way is to buy an airlift from a specialized company, because its price is quite affordable for anyone who has a treatment facility in the form of a septic tank on their site. It is important to understand that the maximum cost limits can reach quite high levels. It all depends on the characteristics of the airlift itself:

You should also pay attention to the purpose. The device can be universal or made for specific septic tank models, for example, TOPAS.

The compressor for air supply is purchased separately. When choosing it, you need to pay attention to the brand, which determines the reliability of the device, as well as productivity and power, comparing it with the characteristics of the treatment plant and the volume of wastewater entering it.

You can make an airlift with your own hands.

To work, you will need a pipe to lift the wastewater and move it to another chamber, and a pipe to supply compressed air. It is important to correctly determine the diameters, because the performance of the system depends on them. Manufacturing companies offer models with diameters of 25-32 mm. You can take a smaller section, for example, 20 mm. It is important to understand that the larger the diameter, the higher the performance of the system, but more compressed air will be required, therefore, the requirements for compressor power will increase. In general, the cross-section will depend on the depth of immersion of the pipe in the liquid, as well as the height of the rise of the working medium. In order not to waste time on calculations or viewing the corresponding tables, you can simply take products of the same diameters as in ready-made airlifts sold on the market. The air supply tube must have a diameter within 10 mm.

Conclusion

As Topicstarter notes, a homemade aeration unit is a workable option if there is no money for. Especially if there is a danger of compression from frost heaving. However, carefully thought out and implemented homemade products are effective even in harsh conditions. And whether to assemble a “constructor” or install a ready-made aeration unit – as usual, everyone chooses for themselves and on their own.

All the details about the construction and maintenance of a homemade power plant are in the author’s topic, where you can also find other examples of the construction of similar treatment facilities. When groundwater is far away, you can get by with a homemade septic tank made of reinforced concrete rings. The video shows the features of choosing and installing a factory septic tank.

Subscribe to our Telegram channelExclusive posts every week

Modernization of the settling chamber

If the settling chamber is to be upgraded with a compressor, the septic tank is supplemented with an aeration tank

If the settling chamber is to be upgraded with a compressor, the septic tank is supplemented with an aeration tank. To do this you will need:

Important! Such a pipe can be made from any suitable length. Drill holes, spacing them evenly and observe the appearance of air bubbles on the surface during startup - this means that the compressor installed for septic tanks is working normally.

By adding a mixing structure to the entire installation, it is possible to improve the distribution of masses so that the air flow flows evenly, this will improve the process of decomposition and recycling of accumulations. As a means of post-treatment, it would be a good idea to install an additional chamber where the wastewater will settle and be clarified.

Homemade aeration devices

For septic tanks with small tank volumes, a low-performance blower (up to 20 l/min) is suitable. Craftsmen have learned to use compressors from refrigerators and cars to aerate such structures. Cheap, accessible, simple.

A perforated hose is easy to make from a plastic pipe. One end of the homemade aerator is put on the outlet pipe of the supercharger, the other is sealed or hermetically sealed with a plug. Enough holes are made in the body of the pipe to work correctly with the used aggregate model.

The disadvantage of such devices is their small working resource. They are not designed for continuous operation. With the air flow, lubricant quickly leaves the device; installing oil traps has little effect on the situation. When using a homemade device, you need to be prepared for its failure, be able to fix common breakdowns, and perform the necessary maintenance. And in case of critical breakdowns, it is advisable to have a serial model with the necessary parameters in mind.

How does the cleaning proceed?

To understand the loan you need an aerator, you need to familiarize yourself with how wastewater treatment occurs in a septic tank. Organic compounds are decomposed by bacteria, which are of two types:

In conventional septic tanks, ventilation pipes are installed to remove gases formed during the decomposition of organic matter. However, such a system cannot ensure that a sufficient amount of oxygen enters the tank.

Therefore, to ensure aerobic cleaning, it is necessary to install an aerator. These devices are installed at the bottom of the tank; they provide ventilation inside the septic tank body, thereby ensuring the flow of oxygen into the environment. Exhaust air is removed through a conventional ventilation system.

Principle of operation

The aeration element in the septic tank is necessary for uniform distribution of air in the cleaned environment. The most effective way to ensure high-quality wastewater treatment is fine aeration, that is, air should enter the liquid in the form of small bubbles. Principle of operation:

Advice! If the septic tank uses the principle of intermittent aeration, then while air is not supplied, the holes must be closed. Otherwise, sludge particles will get inside the device.

There are two types of aerators used in septic tanks:

Compressors: types, performance, the right choice

In the device, gases are compressed and supplied under pressure. The process takes place in a special chamber where the air is retained and then released outside.

Recommended reading: What is a septic tank?

operating principle of an aeration compressor

Some installations also provide additional devices, such as an intercooler-cooler or an air dryer. Purchasing them for the purpose of modernization, however, will be a waste of money.

There are volumetric units that increase gas pressure, reducing its volume. These include piston and rotary mechanisms, which differ from each other in the principle of gas injection into the chamber. In the first case, the pressure arises due to the piston movement, and in the second - due to the screw block.

Among piston compressors, the membrane type stands out. Its main advantage is the ability to pump pressure even at low productivity. The piston supplies air directly to the diaphragm or crank mechanism. In this case, the membrane is progressively displaced, and the air in the chamber of the device is compressed.

The dynamic type involves pumping air by increasing speed and converting to higher pressure. Such devices are represented in most cases by centrifugal options, among which there are axial and radial ones. However, they are too big, noisy and expensive. Therefore, they are almost never used for septic tanks.

For autonomous cleaning or a post-treatment system, the best option is a membrane-type device, a mini-compressor. It is inexpensive and works quietly. You can also choose screw compressors, but not dry compression ones, as they are too large and require special care.

The performance of the unit depends on its type. For septic tanks with a volume of two to three cubic meters, a compressor with a capacity of sixty liters per minute is suitable:

- for devices with a volume of four cubic meters - a capacity of eighty liters per minute;

- for six cubic meters - one hundred and twenty liters per minute.

Septic tanks with biofilter: design, types, principle of operation

Such devices, as a rule, are most suitable for small areas where it is not possible to allocate space for filtration fields.

septic tank design with pre-installed biofilter

A septic tank with a biofilter consists of:

- a septic chamber where waste enters;

- a secondary settling tank or intermediate chamber, where the wastewater is cleared of small inclusions;

- the third chamber, where a biofilter is installed, thanks to which entire colonies of special microorganisms multiply.