The machine gives the metal a stable relief shape. The main functions are cutting and rolling. As a result of processing, a profiled sheet is obtained. It is used for roofing, wall cladding, construction of fences, cabins, and garages. The great popularity and high demand for corrugated sheets are explained by the versatility of application, ease of installation and affordable price. Such factors serve as a serious basis for starting a profitable business. You need to find a small work site and purchase specialized equipment.

Properties of corrugated sheets

The raw materials are:

- steel with aluminum or zinc coating;

- aluminum with or without aluminum-silicon coating.

The use of materials of different properties determines the use of universal equipment. The main requirement for machines for the production of corrugated sheets is careful handling of the coating. The purpose of the compositions used to paint the surface is to protect against corrosion and increase service life.

Quality largely depends on manufacturing conditions. Equipment for rolling and cutting metal should be located in dry, heated workshops with a stable temperature regime. The same requirements apply to the storage room for raw materials - sheet metal rolls.

What is corrugated sheeting used for?

Due to its high performance properties, corrugated sheets are actively used in construction and facing works. It is excellent for cladding the facades of buildings and structures, and is used for constructing fences, fences and even roofs. It is used not only for private and civil houses, but also for industrial buildings, garages, warehouses, and utility rooms. In some cases, in production, corrugated sheets are used for interior decoration.

The material has earned such demand and popularity not only due to its properties and characteristics, but also to other factors. For example, a wide range of colors, which allows you to choose the right color to suit the landscape design or customer preferences. In addition, corrugated sheeting is easily mounted on the surface and does not require special care during operation. You can repaint it yourself and cut it.

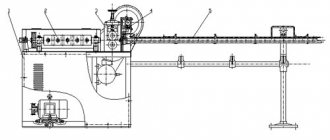

Preparing supports and table for feeding workpieces

Self-production of a rolling machine begins with assembling a frame to accommodate all equipment components. In this case, it is enough to install reliable supports, securing them to the base: preferably a concrete floor.

Machine base

Next, a table is assembled, along the surface of which the workpiece will be fed into the machine. Its length should be several times greater than the length of the finished product, since there will need to be free space on the surface to accept the finished product. The optimal table surface material is aluminum sheet.

There should be a special bar on the table that can secure the workpiece to the table using bolts. In the same way, a manual lever is secured, which feeds sheets of material along the table into the machine for corrugated sheeting, setting the required feed angle.

Types of machines

There are several types of machines for the production of corrugated sheets. Let's look at the most basic ones:

- manual;

- mechanized.

Manual machines do not have an electric motor and operate using human physical strength. You don’t have to buy such units - you can assemble them yourself. However, manual machines are definitely not suitable for large-scale production. With their help, it is almost impossible to obtain high-quality corrugated sheets without defects and defects. Such devices are usually used at home or in small businesses. In addition, manual units cannot boast of high productivity. The number of products produced per hour is minimal.

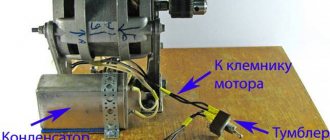

Mechanized machines are equipped with a hydraulic electric motor. This type of equipment is used in factories with regular large turnover of finished products. They are equipped by the manufacturer at the buyer’s request, so they can have a wide variety of additional functions that simplify the work of the enterprise and speed up the production process hundreds of times. In addition, most of them have software control, which frees employees from control over the installation. Some units may not require an operator at all, saving on labor costs.

Features of semi-automatic production lines

Semi-automatic lines are more professional than manual machines. They produce high-quality products and can compete with industrial equipment. Semi-automatic installations are equipped with an electric drive, which eliminates the need for manual labor. Such machines are mobile because they can be moved to the desired location (for example, directly to the construction site).

The quality of the resulting profiled metal sheet will be high. In terms of its main characteristics, it is almost as good as products produced on professional lines.

Tips for choosing equipment

Many novice entrepreneurs cannot quickly choose equipment for the production of corrugated sheets. That is why it is recommended to familiarize yourself with the advice of professionals who will help you choose a specific model:

- specify the production volume according to the business plan (large-sized machines should be purchased only for large-scale enterprises);

- to produce corrugated sheets of different brands, it is necessary to choose installations with replaceable rollers;

- many units have a number of additional functions, including cutting with scissors, unwinding of rolled materials and many others;

- The thickness of the material you will be working with is indicated in the machine specifications.

Of course, when choosing equipment, it is important to pay attention to the quality of assembly and component materials. The rollers must be made of stainless tool steel, which increases the service life of the machine and makes it more practical to use.

Overview of machines for making corrugated sheets

Today, the variety of equipment for the production of corrugated sheets never ceases to amaze. Modern technology allows you to perform many operations, ensuring continuous operation of the enterprise and the production of high-quality finished products.

However, you shouldn’t immediately “rush” to the first model you come across. You should weigh all the pros and cons, choose the ideal equipment for yourself, which will simplify the production technology and save money on hiring employees. So, let's look at the most popular machines for making corrugated sheets, which are popular with manufacturers.

Machine S10

The C10 machine is a horizontal equipment for the production of corrugated sheets using the cold-rolled method. Works with galvanized rolled steel or galvanized steel with a polymer coating on the surface. It has software control and a touch screen with a user-friendly interface, which makes the production process easier.

Equipment characteristics include the following:

- presence of an electric motor;

- material thickness range – from 0.5 to 0.8 mm;

- maximum workpiece width – 1250 mm;

- unit dimensions – 4600 x 1800 x 1100 mm;

- machine weight – 2.15 tons.

The model includes a rolling mill, a mechanism responsible for unwinding rolled material, guillotine shears for cutting workpieces, and a disc cutter.

Machine S20

The C20 machine is a horizontal equipment for the production of high-quality corrugated sheets. Has a high level of safety and durability. Works not only with galvanized steel, but also galvanized rolled steel. Equipped with a mechanism for unwinding rolled materials, which speeds up the production process.

Among the characteristics are the following:

- equipped with an electric motor for automatic operation;

- rolling mill width – 1250 mm;

- processing of materials with a thickness of 0.4 to 0.7 mm;

- operating speed – 32 m per minute;

- power – no more than 11 kW.

The equipment includes an unwinding station, a rolling mill, a vertical cutter, and guillotine shears. It differs from other similar models in the presence of a stamping press with punches, which increases the functionality of the unit. Also included is a logic control system that frees operators from regularly monitoring the work process.

Machine S21

The C 21 machine is a horizontal equipment with an electro-hydraulic motor, designed for the production of corrugated sheets in large quantities. It is distinguished by continuous operation, high efficiency, high-quality finished products without defects and defects. It works using cold-rolled technology with galvanized steel and galvanized rolled products.

The characteristics include the following:

- power no more than 18 kW;

- equipment dimensions – 2900 x 2500 x 1600 mm;

- thickness of the processed sheet – from 0.37 to 0.7 mm;

- operating speed – 35 m per minute;

- workpiece width – 1250 mm with an error of 5 mm.

The unit includes a rolling mill, a mechanism for unwinding rolled material, a logical equipment control system, guillotine shears, and a receiving and loading point. The C21 machine is absolutely safe to operate, install and dismantle. It is durable, wear-resistant and easy and inexpensive to repair.

Machine S44

The C44 machine is a large-scale production equipment for the production of corrugated sheets, which has high precision, safety and durability. Allows processing of rolled galvanized steel, both without polymer coating and with it. Refers to a continuous flow unit, has a horizontal arrangement.

The equipment has the following characteristics:

- unit dimensions – 2500 x 2250 x 1460 mm;

- the maximum width of manufactured products is 1000 mm;

- thickness of the processed material – from 0.3 to 1 mm;

- maximum production speed – up to 17 m per minute;

- unit weight – 5 tons;

- power – no more than 9.5 kW.

The C44 machine for the production of corrugated sheets includes an unwinder with a load capacity of no more than 7 tons, a rolling mill, an automatic cutter, a hydraulic press, and a receiving mechanism. The equipment is also equipped with an automatic control system, which frees production employees from constant monitoring.

Machine S15

The C15 machine is a horizontal equipment for the production of corrugated sheets from galvanized steel or galvanized rolled products. Allows you to produce corrugated sheets at a speed of 6-8 meters per minute. It is characterized by safety, long service life, and easy maintenance. It has a built-in automatic control system, which allows you to program the unit and not carry out regular monitoring. This saves money on hiring employees.

Technical characteristics include the following:

- maximum power – 22.7 kW;

- equipment dimensions – 20600 x 2600 x 1700 mm;

- machine weight – 14.8 tons;

- width range of the processed material – from 0.35 to 0.7 mm;

- rolling mill width – up to 1250 mm.

The unit includes a rolling mill, a mechanism responsible for unwinding rolled material, electromechanical shears, and automatic control. The C15 machine allows you to produce a large batch of products in a short period of time. So in 1 minute the installation can produce up to 40 meters of finished corrugated sheeting.

Machine S25

Horizontal production equipment for the production of corrugated sheets with a width of 1080 mm. The C25 machine is distinguished by safety, autonomy, production accuracy, and continuous operation even at maximum power. Works using the cold-rolled method with galvanized steel.

Technical characteristics include the following:

- device power no more than 7 kW;

- thickness of the roll material – from 0.4 to 0.7 mm;

- maximum width of sheet material – 1250 mm;

- unit dimensions – 8000 x 1500 x 1300 mm;

- The load capacity of the unwinder mechanism is up to 5 tons.

The equipment for the production of corrugated sheets is equipped with a rolling mill, an unwinding mechanism, an automatic control system and a touch screen, a guillotine located in a vertical position, and a receiving stacker. This configuration allows you to simplify and speed up the production process and save on employees.

Cantilever roll unwinder (load capacity - 10 tons)

The first element of the production line is the roll unwinder. As you can see, LZPO offers two types of unwinder: cantilever or two-support. The main difference between them is ease of use. So, the roll is placed on the cantilever unwinder using a crane beam. On a two-support unwinder, it is necessary to remove the reel, insert it into the roll and, together with the roll, place it on the supports. The unwinder synchronizes the operating speed with the rolling speed using its own automation.

We especially note that the unwinder has its own control system (controller and frequency converter). This allows smooth synchronization of the operating speeds of the unwinder and the rolling mill.

| Roll weight, kg | 10 000 | |

| Max. roll width, mm | 1300 | |

| Internal diameter of the roll, mm | min | 470 |

| max | 625 | |

| External diameter of roll max, mm | up to 1200 | |