Spread the love

Everyone wants to choose the best quality CNC machine that will work well, be easy to maintain and, of course, not break. Today, there are a lot of manufacturers that offer not very high-quality services and products. There are especially many “Chinese” who take the price and insist that “all spare parts are from Europe and only the assembly is Chinese.” As a rule, the owners of such machines are not satisfied with the purchase and sooner or later come to trusted brands, if only because, in the end, it is easier and cheaper to buy spare parts, equipment and additional modules. And even under force majeure circumstances, it is much easier to contact old companies that value their reputation. Of course, there are little-known, but very worthy manufacturers who create machines that are superior to popular machines both in quality and cost; we will talk about them in a separate article. Today we will look at the best-selling and popular manufacturers of CNC machines, but this does not mean that they are the best. Rather, this is a list of companies whose products you definitely won’t regret buying.

Best Selling CNC Machine Brand

The CNC machine brands presented here are just a selection of brands with world-renowned sales. American and Japanese brands are selling very well, ranking first in the world, but why are they not the best CNC machine brands in the world? Because the machines are very precise, mass production can ensure maximum supply, mass production cannot guarantee high quality, this does not mean that they are not good, on the contrary, they are also very good!

The top selling brands of CNC machines are the following, not sorted by sales volume:

- DMG Mori

- Spinner

- STAMA

- MoriSeiki

- Okuma

- Yamazaki Mazak

- Makino

- Toyoda

- MAG

- Hardinge

- FIDIA

- Danobat

- Haas

Have you heard of these brands? In fact, there are many well-selling CNC machine brands . There are also many well-selling CNC machine brands in China. China should be the country with the highest demand for CNC machines in the world. For example, TAICNC produces about 1000 CNC machines per month, more than 90%.

Modern innovations in individual production

In the home workshop, modern craftsmen, commissioned for large enterprises, process parts according to the attached drawings. Such part-time work is also beneficial for enterprises: there is no need to use additional technological equipment in the workshop to perform routine operations.

The home craftsman carries out work under a contract with the customer; he solves problems of delivery of blanks and parts independently. As a result, the overhead costs of the main production are reduced. The workplace is created by the contractor himself.

To organize the production of income, it is enough to create an individual enterprise (IE) in order to have official status (financial calculations are simplified). Currently, there are enough such organizations; they carry out significant volumes of orders.

Popular manufacturers of CNC machines. German-Japanese DMG Mori

DMG was originally a German manufacturer of CNC machine tools and has now been acquired by the Japanese company MORI SEIKI. It is an international brand with a global presence. With a presence on six continents, a 24-hour service hotline and warehouses stocked with spare parts, they are one of the world's premier machining companies. But don't think that their good name is entirely dependent on customer service. Their CMX series in particular is known for its accuracy and ease of use. For the machinist on a budget, guaranteed 24-hour delivery of all spare parts makes a used Mori Seiki a particularly good investment. They provide the following services:

- CNC machines

- Automation system

- Comprehensive digitization

- Production of additional equipment

Review of manufacturers

Domestic

The main advantage of domestic machines is their availability. In addition, many years of experience of some companies allows them to provide high-quality products on the market, no worse than those produced in Germany and Japan.

Home master

The machines from this manufacturer are of high quality and have been on the market for quite a long time. Equipment of this brand is often used in school classrooms and small workshops. Such equipment can completely replace several highly targeted units, thereby saving money and preserving free space inside the workshop.

Craftsman

This lathe can be used to perform various types of processing of products made from metal, plastic or wood. The device is available in two versions:

- With feed drive, milling device and wood processing unit.

- With manual longitudinal recoil of the caliper.

The first option makes it possible to perform turning and drilling, and the second - turning, milling, planing, sawing and drilling work. You can improve and expand the functionality of the machine using additional elements.

Caliber

This company has been selling tools since 2001. A wide range of models allows you to choose the model you need. In the event of a breakdown, the company’s specialists will promptly diagnose and identify faults, and subsequently correct them. The machines are offered at reasonable prices and many products come with a guarantee.

China and other countries

China's bad reputation as a manufacturer of low-quality goods and rip-offs is long gone. Now it is a supplier and manufacturer of the best performance and quality products in the world.

Optimum

Machines of this brand are produced in Germany. This brand produces not only large lathes, but also miniature ones, which are known and highly valued by many specialists throughout Europe. The most famous models are D140x250, D210x400, D250x550. They are equipped with a CNC system.

Corvette

This company provides products at low prices. Many customers note the good quality of the goods provided. Since 2009, we have been selling machines. Machines are available, both large-sized and small-sized. When selling wholesale for an enterprise, a large discount is given.

JET

Tabletop lathes of this brand have been on the market for more than 50 years. They are produced by the Swiss company JET, which has become very popular among home craftsmen and craftsmen. Despite the fact that at the moment some components are manufactured in China, their quality does not deteriorate.

These units have earned the trust of several generations of users due to their high quality, precision and processing efficiency. There are no problems with them when working, their maintenance is simple. The most popular and best-selling models are: BD-3, BD-7, BD-8A.

Proma

The company has been on the market for 20 years. All types of machines are sold, including custom ones. The company's products are constantly being improved and modernized, taking into account the needs and demands of consumers.

DIY

The tabletop unit of this company is a compact turning device, which is produced according to uniform technical documentation by several Chinese manufacturers.

Stalex

The company focuses on the sale and service of metalworking equipment. All goods are always in stock, which is noted by numerous buyers.

Zenitech

The company sells mainly large-sized machines, but there are also several models of small-sized machines. There is always a hotline, by calling which you can ask questions and clarify all the nuances.

FDB MASCHINEN TURNER

Many buyers are put off by the somewhat inflated price of the product presented by this company. But all lathes are of high quality and come with a guarantee. Several times a year there is a promotion where the discount can be 30,40 or even 50 percent.

METALMASTER

METALMASTER equipment is developed and constantly improved in cooperation with German engineering technicians. The production of machines is carried out at world-famous factories.

Popular manufacturers of CNC machines. German Spinner Precision Machine

Spinner precision machines operate successfully around the world with many renowned customers in more than 60 countries on 6 continents. They have been developing and producing state-of-the-art machines since 1950. More than 20,000 delivered machines demonstrate their high efficiency, precision and reliability.

German Spinner Precision Machine

Although Spinner is a medium-sized company, they produce and sell over 1,000 CNC machines per year. And every year their number increases. The company combines the know-how of a global player with the flexibility and cost-effectiveness of a family business structure. They provide the following services:

- CNC milling machine

- CNC turning center

- CNC grinding machine

- Automation

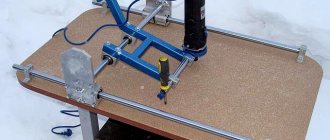

DIY metal milling cutter: option No. 2

If it is necessary to form holes or recesses of small depth, it is recommended to use a different manufacturing scheme. Structurally, the machine will be similar to an engraving machine. The difference is an increase in the power of the milling head.

The structure will consist of a fixed frame that serves as a desktop. A movable carriage is installed on the side guides. It is recommended to use a factory router. At the place of its installation it is necessary to provide a raising/lowering mechanism.

Specifics of self-production:

- the size and design of the work table and carriage depend on the maximum dimensions of the workpiece; It is best to purchase a factory base for the machine; use stepper motors; It is necessary to have a CNC to automate the work.

Using this milling machine, you can perform artistic metal processing and make complex grooves and holes. The disadvantage is the maximum processing depth - up to 1.2 mm.

Popular manufacturers of CNC machines. German STAMA

Popular manufacturers of CNC machines. German STAMA

STAMA is a brand of the German CHIRON group, active for almost a century, and produces multi-spindle machining centers in the spirit of innovation, highest quality and flexibility. The company specializes in complex, unique milling and turning processes, making it one of the leading providers of process solutions for specific customers and industries around the world. They provide the following services:

- CNC Machining Center

- CNC turning center

- Dual Spindle CNC Machining Center

- Ready solutions

Organize by base size

Standards regulate the basic parameters of equipment characteristic of this type. For a group of turning and cylindrical grinding machines, this is the maximum size of the part for processing.

For milling machines, the main consideration is the size of the work table for installing workpieces and equipment. For cross-planing machines, the basic value is the stroke of the slider.

A set of machines for one type of processing, with similar kinematics and structure, but differing in main dimensions, is called a size range. For example, according to the standards, gear hobbing machines have 12 standard sizes with a maximum workpiece diameter for processing from 80 mm to 12.5 thousand mm.

Popular manufacturers of CNC machines. Japanese Mori Seiki

Popular manufacturers of CNC machines. Japanese Mori Seiki

Mori Seiki was founded in 1948 and has grown to become a leading manufacturer of CNC equipment such as lathes and machining centers. They have over 160,000 installations worldwide and are a key player in the CNC market. They are constantly working to improve the software and provide updates to keep their machines up to date. They provide the following services:

- CNC lathes (2-axis and multi-axis)

- Vertical CNC Machining Center

- Horizontal CNC Machining Center

- CNC flat lathes

Types of metal milling machines

- Widely versatile: an additional spindle head is installed on the movable trunk, allowing you to manipulate the cutting tool. It is possible to carry out cutting, countersinking, drilling and boring of metal with two spindles at once. Typically, instead of a console, a carriage moves along the guides, allowing you to secure either a table or auxiliary equipment.

- Horizontal: very easy to operate and maintain. They consist of a bed with a horizontal spindle without frills. Such simplicity increases the reliability indicator.

- Machining centers: milling + lathes.

- Vertical: the milling process is carried out not only by raising the table, but also thanks to a controlled cutting tool. Additional modifications are equipped with axial displacement of the spindle.

- Carousel: designed for continuous mass processing of open horizontal surfaces.

- Consoleless: open type, increasing the maximum possible size of the workpiece being processed. There is no console, so the table moves along the guides of the frame fixed to the foundation. They have high rigidity, which increases the precision of metal processing.

- Keyed: as the name suggests, they are designed for milling keyways.

- Longitudinal: equipped with a pair of vertical or horizontal cutters. The movement of the table is only longitudinal, and the spindle is either vertical or longitudinal.

- Universal: any cutter for small workpieces can be used. Processing occurs in two planes. The rotating mechanism rotates the table 45 degrees around its axis, which allows you to pick up any coal, and additional equipment increases functionality.

Japanese Okuma

Popular manufacturers of CNC machines. Japanese Okuma

With over a century of experience and the largest distribution network in America, it's safe to say that Okuma is one of the largest players in the engineering industry. Notably, the company is the only supplier in the industry that has CNC machines, drives, motors, encoders, spindles and CNC systems that are manufactured in-house. Okuma has always been an innovator, remaining at the forefront of development of all technologies, including CNC routers.

They provide the following services:

- CNC lathe

- CNC Machining Center

- CNC grinding machine

- CNC Laser Machine

- Double Column CNC Router

Summary

Of course, as they say, you should always buy the best when it comes to clothes and furniture! And among the Cad/Cam milling machines,

the choice is very wide, as is the price range. The number of improvements and the level of automation of physical work is constantly growing. However, all the convenient additions and improvements increase the cost. Therefore, it is necessary to accurately determine the future production load of the milling machine.

And here it is necessary, first of all, to understand what materials and to what extent you are supposed to work with, and based on these conditions, select a router. For ordinary dental clinics, with a small volume, where the laboratory works for the needs of the clinic, low-capacity, desktop, small-sized machines, etc.

For large dental laboratories serving other clinics with a large volume of orders, large, high-performance milling machines can be recommended. Firstly, by automating physical labor you will receive guaranteed quality, reduce production costs and be able to plan your workload during peak periods.

Remember, soft raw materials are processed dry, but metals require liquid cooling and lubrication. Pay attention to the spindle speed and the location of the controls. The presence of automatic systems for changing working tools can be very convenient.

Japanese Yamazaki Mazak

Popular manufacturers of CNC machines. Japanese Yamazaki Mazak

Yamazaki Mazak was founded in 1919 and has contributed to the development of the machine tool industry as a leading global company. Yamazaki Mazak not only produces advanced machine tools such as multi-task centers, CNC turning centers, machining centers and laser machines, but also automation systems with a DONE IN ONE concept to support global production, providing exceptional productivity and versatility. They will continue to develop advanced machines to advance both manufacturing and society.

Mazak has several factories around the world, including Japan, China, USA, UK and Singapore, which provide the following services:

- Multitasking machines

- CNC turning centers

- Vertical machining centers

- Double Column Machining Centers

- Horizontal machining centers

- CNC laser processing machines

- FMS (Flexible Manufacturing System)

- CNC systems

- CAD/CAM system

- Manufacturing Support Software

Popular models of narrow specialization

Milling cutters designed to perform a narrow range of tasks and have a limited set of functions to optimize a certain type of material processing.

Makita MT M3700

Characteristics:

- type – edge;

- speed – 35 thousand rpm;

- power – 530 W;

- cutter stroke depth – 42 mm;

- collet size – 6 mm;

- cable – 2 m;

- weight – 1.4 kg;

- cost – 5349 rub.

A tool with easy milling depth adjustment, good performance and low cost. Equipped with a comfortable rubber-coated handle, it can perform up to 35 thousand rpm.

Advantages:

- price;

- build quality;

- light weight;

- ergonomics.

Flaws:

- no spindle lock;

- low power.

BOSCH GKF 550 Professional

Characteristics:

- type – edge;

- power – 550 W;

- collets included – 6 mm;

- speed – 33 thousand rpm;

- weight – 1.4 kg;

- price – 5290 rub.

A unit with stable support for milling depth. The 550 W motor helps you cope with many types of finishing and carpentry work. The ergonomic body ensures ease of use. Optimized ventilation reduces device heating.

Advantages:

- ease of use;

- ease.

Flaws:

- no cutters included;

- there is no protection against accidental activation.

Makita 3709

Characteristics:

- type – edge;

- speed – 30 thousand rpm;

- power – 530 W;

- cutter stroke – 40 mm;

- collets in the set – 6 mm;

- cord – 2.5 m;

- weight – 1.5 kg;

- cost – 5931 rub.

Edge router for forming grooves and holes of various shapes in composite, wood, plasterboard, and ceramic products. High speed of rotation makes it possible to interact with compacted materials. The transparent plastic platform allows you to clearly see the element being processed.

Advantages:

- convenient depth regulator;

- good equipment with limiters and stops;

- high power and speed.

Flaws:

- there is no stopper on the shaft;

- there is no depth limiter;

- no soft start.

Japanese Makino

Popular manufacturers of CNC machines. Japanese Makino

More than 80 years ago, founder Tsunezo Makino invented the horizontal machining center. Today Makino is sold in 41 countries around the world and is widely known as the most advanced machining center. As an industry leader in hardware design and digital innovation, Makino delivers revolutionary solutions to deliver superior performance. They manufacture the most accurate and high quality metalworking and EDM machines in the world - horizontal machining centers, vertical machining centers, 5-axis machining centers, graphite machining centers, and wire and sinker EDMs.

Safety precautions

Although all modern machines are necessarily equipped with protection, divided into a number of elements, compliance with basic labor protection instructions is still mandatory. The protective parts themselves must certainly be placed in the correct positions. Their serviceability is checked in any case before starting work and after any long break. Do not work in poor visibility or during any sudden deterioration in health.

A milling machine is serious equipment, and you shouldn’t allow just anyone into it. You must be of legal age and be willing to obtain a 2nd level in electrical safety (this is the minimum). A first aid kit and a fire extinguisher must be available at the workplace. You need to master each machine model very carefully from scratch. If we are talking not about home conditions, but about an enterprise, then additional instruction is certainly required.

Wood shavings must be removed regularly. Its excessive accumulation threatens a fire. The milling machine must be grounded, as well as all the wires feeding it. You can work with workpieces only after checking their fastening. Cutting parts with chips and deformations, with cracks and burrs must be replaced.

Japanese Toyoda

Clever engineering has been the cornerstone of Toyoda machines since the company was founded in 1941 as Toyoda Machine Works. Originally produced for the production lines of a major Japanese automobile company, Toyoda grinding machines were designed to operate in high-productivity environments.

Over the years, Toyoda has maintained this level of craftsmanship to ensure that its production is of the highest quality standards. In 1968, Toyoda expanded its product line to horizontal machining centers and later included automation systems, vertical machining centers and lathes, TOP centers, bridge machines and boring machines in Toyoda Americas Corporation's JTEKT product line.

Popular manufacturers of CNC machines. Japanese Toyoda

Toyoda understands tight tolerances, superior speed and maximum productivity. Every detail is carefully considered - from the durable cast iron base to the operator-friendly ergonomic design - to help maximize productivity in the metalworking industries.

Task

Generally speaking, sandwiches and salads are made “in a hurry”; a romantic dinner can be whipped up in a hurry, but not a machine. However, I included this phrase in the title of the article. Why? I'll try to explain.

“In a hurry” this means technologically for home production. Those. the machine must be designed so that it can be manufactured using a minimum set of the most common metalworking tools. Literally, if you have in your arsenal a jigsaw with a metal file, a drilling machine, tap dies and a file, then this should be enough. At worst, a simple hacksaw and a drill will do.

Some people will say: “Well, you’ve gone too far, comrade!” This doesn’t happen,” and he will be right. That really doesn't happen. Because if milling work can be eliminated completely, then we cannot do without basic turning work, which means there should be very little of this work, everything else should be done by hand, in the kitchen.

When setting yourself such a task, you need to understand well that your plans can only be achieved if you widely use purchased components and standard aluminum profiles. Guides - the cornerstones of a portal engraving and milling machine - will also have to be purchased, and they are expensive. So, “quickly” does not mean cheap!

One final thought. “In a hurry” is associated with the concepts of simple and fast. If you can agree with the definition of “simple,” then it’s unlikely to work quickly. The production of even simple parts can take an indefinite period, but as they say, “patience and labor will grind everything down.”

Let's summarize:

- For milling balsa, plywood, wood, plastics and thin (up to 2 mm) aluminum alloys.

- On linear ball guides and timing belts.

- The working field is at least 1000x300x90.

- Positioning resolution is no worse than 0.1 mm.

- Positioning speed no less than 2 m/min.

Germany MAG

MAG is a leading manufacturing technology group for milling and turning for production systems and turnkey machines with customized application technologies. The firm has become a global player since its founding in 2005. MAG serves the automotive and trucking industries and their suppliers. unrivaled technology and experience.

Popular manufacturers of CNC machines. German MAG

MAG offers machines, production systems and services including turning, milling, honing, system integration, automation, software, maintenance, upgrades, e-learning and core components for machine tools. As a full-scale supplier, MAG's manufacturing solutions include processing technology, process capabilities, systems engineering and turnkey systems.

Spindle (cutter) rotation speed.

It is selected automatically based on the material being processed. Soft and plastic materials are processed at low speed, brittle ones, respectively, at high speed. For example, speed in the range of 10÷60,000 rpm. /min allows you to process almost the entire range of standard materials.

The set of tools in modern milling cutters usually contains from 5 to 20 items. There are plenty to choose from. As another auxiliary function, an automatic cutter replacement function has appeared. This is convenient and allows you not to stop the machine.

American Hardinge

Hardinge is a multinational machine tool manufacturer headquartered in Elmira, New York, USA. He started work in 1890. Hardinge is best known for its lathes, both non-NC and CNC.

Popular manufacturers of CNC machines. American Hardinge

The machine tool industry has been globalized since the 19th century, but in recent decades it has witnessed greater globalization and reorganization. Hardinge acquired machine tool manufacturers and its brands now include Hardinge, Bridgeport, Kellenberger, Hauser, Tripet, Jones & Shipman Hardinge Ltd and Tschudin. It has subsidiaries in England, Germany, Switzerland, China and Taiwan, China. The company employs 1,500 employees. They provide the following services:

- CNC grinding machine

- CNC turning center

- CNC milling machine

- Ready-made solutions and integration solutions

Specifications.

Pay attention to some more nuances of the technical characteristics of milling machines. The number of axes in which the cutter and workpiece move. Milling machines have from 3 to 6 axes. 3-axis machines are usually used for the manufacture of simple products. The more axes a machine has, the more capabilities it has for manufacturing complex products. The level of accuracy of workpiece processing depends on the specific equipment model and can range from 5 microns to 50 microns. For most models, this value is 15-20 microns.

Italian FIDIA

Fidia was founded in 1974 to design and build sophisticated numerical control systems: an advanced technological solution for processing complex shapes for the mold and die industry.

Popular manufacturers of CNC machines. Italian FIDIA

By gradually expanding its know-how in this business segment and constantly updating its products, Fidia has anticipated the demands of the market. In the 1980s, a new series of numerical control based on the use of microprocessors was developed; high-speed milling systems were introduced in 1990 with the launch of the first DIGIT 165; In the mid-1990s, Fidia's own CAM programs were developed and manufactured: HI-MILL®. They provide the following services:

- HSM machines

- Numerical control

- Milling heads

- Accessories for CNC

- CNC software

Spanish Danobat

Danobat was founded in 1954 with a history of more than 60 years. The offer includes advanced machines that provide high precision, reliability and productivity, designed to handle the most complex machining processes. Advanced solutions for the production of high added value components, which are developed in close cooperation with leading companies in their sector, resulting in fully automated solutions and turnkey lines; and advanced services based on the latest information and communication technologies.

Popular manufacturers of CNC machines. Spanish Danobat

Reference manufacturer of high added value solutions in the areas of grinding, turning, cutting, stamping, bending and automated production systems for composite structural components.

Processed materials

Wood processing devices have average power (1-1.5 kW) and a reinforced design. Since there is a risk of the cutter jamming during operation, the machines are equipped with a device for supplying coolant to the contact point. This is water or machine oil. The units are used for the manufacture of furniture legs, slotted decor, picture and photo frames, facades, and figured consoles.

Metal cutting machines look and operate somewhat differently. Their features:

- more complicated design compared to wood routers;

- high price;

- lack of a cutter cooling function in a number of models (since the risk of fire due to friction of the cutter on the workpiece is minimal);

- Possibility of equipping with an industrial vacuum cleaner socket (for removing chips).

Automatic waste collection is almost never carried out, since contact with skin, eyes or respiratory organs will cause harm to health. Typically the task is performed manually by the operator.

In machines for processing plastic and plexiglass, cutters with a diamond or corundum working surface are used. The coating can be sprayed or all-sintered. Diamond chips are baked on the surface of the router at high temperature, resulting in a strong and durable connection.

The liquid must be supplied to the area of contact with plastic/glass. Otherwise, waste getting under the cutter can lead to damage to the entire workpiece (due to the plasticity of the material).

Units of the 3000, 3200, 4000, 4400, 5000 series are suitable for processing PVC, acrylic glass, polycarbonate, and fiberglass.

Multicut-4000 machine

American HAAS

Popular manufacturers of CNC machines. American HAAS

Haas has only been around since the 80s, but they've made quite a splash in that time. In addition to having all of its manufacturing in the USA, Haas boasts extensive machining expertise at all levels. For beginners, Haas offers relatively affordable prices as well as comprehensive training programs on every aspect of operating their plants. For more experienced production owners, they offer quality that can easily compete with their Korean and Japanese counterparts (especially in their exemplary VMCs), as well as a variety of machine accessories. Haas machining centers are probably the most versatile CNC milling machines available.

Types, structure and design features

Tabletop milling machines have several varieties, which differ in design features and functionality. Tabletop machines are compact, easy to operate, low noise, and affordable.

Compact models consist of the same basic components as industrial equipment: bed, spindle, guides and work table. Fastening elements, a control system, and wires are installed on the frame.

Console

Console machines have a similar principle of operation with vertical milling equipment. The spindle in them moves along vertical guides.

Portal

In this case, movement occurs along three axes. The portal machine is mounted on a special guide, which is mounted transversely to the table.