Explanation of the designations of the electrodes used for welding

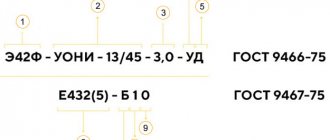

The markings on the electrode pack are very important. This determines whether the selected welding materials are suitable. Let's look at the decoding of the notation. Designations are applied in accordance with GOST 9466. The marking has the form of a simple fraction, with a numerator and denominator.

E50A - This is a type of electrodes used for manual arc welding. It is determined depending on the material that needs to be boiled. For ordinary black, heat-resistant and structural steels, the type is taken from GOST 9467.

The number in the index that follows “E” indicates temporary resistance (σпч). For a weld seam welded with E50 type electrodes, the temporary resistance is 50 kgf/mm2.

Next comes the stamp - “UONII 13/55”. The brand carries information about the metal from which the electrode core is made. The brand is selected based on the metal being welded. You can familiarize yourself with the list of main brands and their areas of application.

Let's go back to the labeling. After the mark comes the diameter of the electrode, indicated in millimeters - “4.0”. After the diameter comes the letter “U” - this place indicates the purpose of the selected electrodes.

What is the electrode coating made of?

Therefore, according to purpose, the electrode coating can be distinguished:

Gas-forming components

, which when heated, decompose into gases that displace air. These include some minerals (marble, magnesite) or organic substances (flour, starch, dextrin).

-Slag-forming components

, which protect the crystallizing metal from the effects of oxygen from the air. At high temperatures they form slag that floats to the surface of the weld. These include oxides of silicon, titanium, aluminum, calcium, manganese, etc. They are found in marble, granite, hematite, quartz sand, ores, ilmenite and rutile concentrate.

-Deoxidizing components

, which can restore some of the oxides to full metal. Deoxidizers include iron-containing compounds - ferromanganese, ferrotitanium and ferrosilicon.

-Stabilizing components

, which facilitate the burning of a voltaic arc. They are found in marble, chalk, feldspar, soda ash, and potash.

-Alloying components

, which give the seam additional strength and resistance to corrosion. In the electrode coating they are present in the form of alloys - ferrochrome, ferrotitanium, ferrovanadium.

All these elements are crushed into powder and bound into a homogeneous mass using sodium or potassium liquid glass.

Some coating materials serve multiple functions. For example, marble is a gas-forming, slag-forming and stabilizing mineral.

Therefore, the types of welding electrodes are distinguished by coating thickness:

| Coated Diameter Ratio (D) to electrode diameter uncoated (d) | Letter designation according to GOST 9466-75 | International designation | |

| Thin coating | less than 1.2 | A | A |

| Medium Coverage | from 1.2 to 1.45 | WITH | IN |

| Thick coating | from 1.45 to 1.8 | D | R |

| Extra thick coating | more than 1.8 | G | WITH |

What is the purpose of electrodes?

Differences in the coating and core material of the electrodes are determined by their purpose. Some are used for welding carbon, low-carbon, and low-alloy steels whose tensile strength does not exceed 600 MPa. This group is conventionally designated by the letter – U.

The second group are materials used for medium-alloy steels whose tensile strength exceeds 600 MPa. Symbol – L.

The third group includes welding materials used for welding work with high-alloy steels. The properties of which are aimed at solving certain problems. They are designated V.

The next group is used when welding heat-resistant alloy steels. Denoted by T.

And the group closes, which also includes highly specialized welding materials, namely those used for surfacing metal products with special characteristics. Designated - N.

The last designation is “D”.

The thickness of the coating is indicated here. They come in 4 types:

- “M” – with thin.

- "C" - with average.

- "D" - with thick.

- “G” – especially thick.

Each type includes electrodes in which the ratio of the diameters of the rod and coating corresponds to the following conditions:

- For thin – D/d ≤1.2

- For medium D/d ≤1.45

- For thick D/d ≤1.8

- For particularly thick D/d ≥1.8

Now let's go down. We see “E 43 2(5)” - this is the index of the weld metal (welded metal). Most often it is taken from GOST 9467, 10051 or 10052. According to the index in GOST, you can see what minimum properties the seam will have. Next we see the letter “B”. It indicates the type of electrode coating.

Types of coverage: how to determine which one to choose?

Coating of electrodes is possible in the following options:

- Acid coating - A

- Basic coating - B

- Rutile coating - R

- Cellulose coating - C

In this regard, it is impossible to say which one is better and which one is worse: they are all designed for different types of work, as well as conditions of use. Therefore, it is impossible to unambiguously answer the question which electrodes for welding will be better. As a rule, it is necessary to use them to form a strong weld seam in critical structures.

Next we see the number “1”.

This is a designation for the positions in which you can cook.

“1” – for any provisions;

“2” - for any, except top-down;

“3” - vertical from top to bottom, horizontal, bottom;

“4” - lower position and boat position.

And the number “0” ends.

This is the type of current and polarity. This figure is taken from the table below. Indicates “0” that welding must be performed on direct current with reverse polarity connected. Having analyzed the transcript, we will dwell in more detail on each point.

What are welding electrodes coated with and what is this coating?

Coating is a special coating that is designed to protect molten metal from the negative effects of oxygen. It creates a gas shell while the core melts.

Coatings are divided according to the functions they perform: gas-forming and slag-forming functions.

Gaseous components create protective gases and an ionizing atmosphere.

Slag-forming agents include elements that promote deoxidation, refining, alloying of the seam and the base metal, increasing the bonding and plastic properties of the seam. During welding, a layer of slag is formed in the weld pool for protection.

Types of coverage: how to determine which one to choose

There are 4 main types of electrode coatings used in manual arc welding. Let's deal with each of them one by one.

Let's talk about the main component. Rutile is a natural mineral that, forming a protective gas shell, creates a weld pool. Welding with materials such as rutile is characterized by high stability.

Ignition of the arc occurs without problems even for beginners. That is why they are often used in installation. The seam is obtained with small scales, with a uniform casting structure over the cross-section.

The following advantages of working with this coating can be highlighted:

- It is permissible to use both alternating current (AC) and direct current (DC);

- Easy to ignite using both new and secondary arc ignition;

- Not demanding on the cleanliness of the product surface. Can be used on rust, undried edges of the product, scale and even paint;

- The metal practically does not splash.

The disadvantages include:

- There is not a large range of materials that can be used with;

- In the weld pool there is active mixing of slag and metal, which makes it difficult to distinguish where the slag is and where the metal is. This leads to slag inclusions;

- The presence of moisture in the coating leads to a defect in the form of pores. This is an important point that is worth paying attention to. Proper storage and calcination before welding is necessary.

Acid coating: application features

Good to use, but in an open space, otherwise it will not be safe for the welder. The advantage is definitely that the slag is easily separated.

Acid coating requires low idle voltage. Currently they are rarely used.

Basic coating

They have become very widespread, one might even say ubiquitous, due to their versatility. Their coating contains fluorine and calcium. During welding, the coating elements evaporate, protecting the molten metal. The bath's gas shield actually consists of carbon dioxide.

They are used when using direct current; as a rule, the polarity is reversed.

When melted, the coating removes harmful impurities from the weld such as sulfur (S), phosphorus (P) into the slag. This helps to increase strength, increase ductility, and reduce fragility. As a result, there are no cracks.

Arc ignition is worse than that of rutile ones, but their range of application is wider. The arc burns less stably compared to rutile. This is due to the content of fluoride compounds that reduce ionization.

Welding should be carried out only on a well-prepared surface. There should be no moisture or dirt. Otherwise, we will get a large number of pores in the weld metal. Another reason for pores is an increase in the length of the arc. The protection dissipates and gas from the atmosphere enters the weld pool.

Cellulose coated electrodes

The use of welding materials with this type of protection is less and less. This is due to the fact that welding with them hydrogenates the weld seam. The strength of the connection decreases and pores appear.

More than half of the coating consists of organic substances and during welding provides strong gas formation. They cook in all positions; it is even possible to carry out the process from top to bottom.

The surfaces may not be well prepared; this will not actually affect the quality of welding. This has something in common with rutile coating.

Electrode selection criteria

Knowing the basic selection criteria will help you select suitable electrodes. The factors presented below influence the choice of a particular brand to varying degrees, but together they form a complete picture. So, the choice of welding materials is influenced by:

- the metal being welded - its type, type, thickness and the resulting requirements for the characteristics of the welded joint.

- the conditions in which the work is carried out and the further operation of structures and structures will take place.

- The experience and skill of the welder will affect the usability of certain grades.

- the quality of electrodes capable of providing the necessary characteristics of the weld metal.

Let's dwell on some factors and consider them in more detail.

Today there are a large number of metals and alloys, differing in their characteristics and areas of application. Therefore, it is important to select electrodes that ensure the production of weld metal similar in characteristics, mechanical properties and chemical composition to the base metal. This is achieved through the use of a special wire (core) and coating composition.

Among the main characteristics of metals are: strength, hardness, elasticity, ductility and toughness. For steels used in some industries, heat resistance, wear resistance and fatigue are also important. As a rule, on the packaging of products there is a brief description of what steels this or that brand is intended for.

Electrodes are distinguished according to their intended purpose: for manual arc welding of carbon and low-alloy steels, alloyed heat-resistant steels, high-alloy steels with special properties, cast iron, copper and alloys based on it; for manual electric arc surfacing of surface layers with special properties; for electric arc cutting.

The conditions of welding and operation of the connected structure also influence the choice. For welding in northern conditions, there are certain requirements for products. For example, GOODEL-52U electrodes are capable of operating at temperatures down to -50 degrees Celsius.

The thickness of the metal being welded affects the choice of product diameter. To connect parts of small thickness, small electrode diameters are used. This allows you to avoid burning and damage to the part. Accordingly, as the thickness of the workpiece increases, the diameter of the electrode also increases. And this in turn leads to an increase in the strength of the welding current, to ensure a greater depth of penetration. Today, electrodes of various diameters are produced, mainly from 2 to 6 mm. We will talk in more detail about how to choose the diameter of the electrode and the strength of the welding current depending on the thickness of the metal below.

Tip: if you don’t know or have forgotten how to choose the welding current, you can look at the manufacturer’s recommendations on the packaging with the materials. As a rule, acceptable welding modes are indicated there.

The experience and skills of the welder also influence the choice of brand. There are a number of different classifications other than ranks. For example, certification by NAKS for access to certain types of welding work. The more experienced the welder, the easier it is for him to weld with different types of electrodes. Beginners are recommended to start with rutile-type consumables and, after mastering them, begin practice with products of the basic type. This is due to the fact that basic electrodes require certain skills and dexterity, but once mastered they give excellent results. High weld quality and resistance to the formation of crystallization cracks; such electrodes also have a low hydrogen content.

The quality of welding materials directly affects the characteristics of the welded joint and the welding process itself. It is necessary to choose electrodes from reliable manufacturers who guarantee the quality of their products. You should also beware of counterfeits of some popular brands. As a rule, you can distinguish the original from the counterfeit by carefully examining the pack. Real packaging will always be of better quality: denser, more airtight, without obvious violations of integrity and traces of “crooked” gluing. You can also check the electrode itself. If the coating is not of a uniform color or has an uneven application, with a lot of chips, then you should think about it before buying such a pack. In any case, before purchasing, you should read several articles on this topic.

Things to keep in mind when getting ready to start welding

Before you begin, you should carefully inspect your home welding electrodes and determine:

Is there any mechanical damage? If they exist, then this is an obstacle to further actions, the welding arc will not be stable, and the protection of the molten metal of the bath will not be of high quality.

Humidity: Should be minimal. The electrodes will only be dry if they have been stored correctly. Don’t worry if this point has become an obstacle to further action – it can still be fixed.

To do this, you need to dry them in a special oven or, if you are at home, in a regular oven.

Another option, which will be more time-consuming, is to leave them in a warm, non-humid place. So, dry welding materials will provide you with a strong weld and reduce the risk of such a defect as gas pores.

The shelf life of electrodes used for manual arc welding is determined by the manufacturer, but as a rule it is without restrictions. The main thing is the storage conditions, which are also given by the manufacturer. In a closed package sealed in plastic film, the electrodes will be nothing even after 10 years.

And now more about polarity

If work is carried out on direct current (which most often happens), then the question may arise: what polarity should be connected - reverse or direct? How to do it?

We partially paid attention to the first question when we considered the types of coatings and types of electrodes. So be sure to check this when you get started.

Direct polarity connection diagram: ground is connected to the “plus” of the inverter, and the electrode holder is connected to the “minus”.

When the connection is made according to the reverse polarity scheme, as you understand, everything is the other way around: the ground cable is connected to the “minus” of the device, the “plus” is connected to the holder.

The question arises, what is the difference between these two connection schemes?

The difference when connecting is that with reverse polarity, more heat goes into the electrode metal. This reduces the heat input into the base metal and the structure is less deformed. When using direct polarity, on the contrary, heat input increases in the metal of the product.

It is often used for welding thick metal or TIG welding. You can read more in this article.

Main types of electrodes

According to their intended purpose, consumables used in electric welding are divided into the following groups:

- welding of workpieces made of carbon and low-alloy steels;

- connection of structures made of high-strength and heat-resistant steel grades;

- work on stainless steel;

- electric welding of aluminum and its alloys;

- connection of copper elements;

- welding of cast iron parts;

- performing surfacing and various repair work.

A separate category includes products used for alloys whose composition is unknown and difficult-to-weld grades of steel.

What electrode diameter to choose

This is another question you may encounter. Everything here is quite simple: the diameter will be selected according to the thickness of your welded metal.

Moreover, if the metal is very thin (less than one and a half millimeters), then manual welding (RMW) is most often unacceptable (here we use tungsten electrode welding, semi-automatic or automatic).

In other situations, you can select an electrode. You can see the ratio in the following table:

Welding position

The spatial position of the electrode is also included in its marking. The number 1 denotes electrodes that are used for welding only in the lower position of the part (electrode on top).

The number 2 marks products used with a horizontal or vertical seam (ceiling is excluded).

Number 3 is used for ceiling electrodes (the electrode rests on the part from below). The welder must take these markings into account to avoid a poor-quality weld or injury.