For the installation of various types of utilities in the form of ventilation systems, gas supply, pipelines and cable lines, various types of clamps are used. Let's look at what they are made of and the design features. Let's get acquainted with the methods of using universal and specialized fasteners. Read to the end and you will learn about the standard sizes of fasteners commonly used in the private sector.

Worm-type metal crimp clamp Source chkalovskmarket.ru

What types of clamps are there? Characteristics and application of all types

A clamp is a connecting element that looks like such a device - a rod.

The ends of this product can be pulled together, creating a circle. This product is needed to reliably fasten and seal hoses, pipes, parts of pipelines, cables, and pipes. There are types of clamps with temperature ranges and technical documents, which we have presented in the table.

Technical document

GOST R IEC 62275-2015

Next, we will consider all types of clamps with their characteristics and applications.

Repair clamps for pipelines: operating rules and appearance

To eliminate the dangerous consequences of accidents on pipe lines, repair-type clamps are used. For example, if there is a break in the plumbing or heating system, it is enough to simply fix the location of the problem without releasing the pressure. This type of repair can be temporary or permanent.

The repair clamp may consist of several sections

Technical Specifications for Repair Fasteners

From a technical point of view, a stainless steel or galvanized pipe clamp is a bracket with a rubber insert that makes the connection watertight. However, these models of devices are intended exclusively for damage on straight sections of the pipeline. On bends or branches, it is impossible to repair burst structures in this way.

Devices for repairing pipelines must have the following characteristics:

- presence of bolt clamps;

- the presence of rubber sealant of different thicknesses;

- the ability to space crimp parts together;

- durable metal that cannot be deformed.

Pipe clamps typically use a cut seal

On a note! Temporary protection against flooding when a water or sewer pipe breaks is guaranteed when using galvanized repair clamps.

What types of repair clamps are there?

Depending on the complexity of the pipeline fastening work, it is necessary to select the model of the repair clamp. Let's look at the existing varieties:

- unilateral. Most often, this is a U-shaped fastener model, which has one axle shaft with threads at the ends and a jumper, which subsequently secures the pipe with bolts. However, this type of device is only convenient for preventing various leaks;

- double-sided - this is a structure that has two metal semicircles that are connected to each other using bolts, which on this structure can be from 2 to 4 pieces;

- multi- component This clamp is a more complex type of fastening. Typically this option is intended for fixing several pipelines at the same time.

Power fasteners may taper towards the point of attachment

What is the difference between fastening models and repair models?

Clamps manufactured by our industry are classified according to their purpose as fastening and repair, and the name itself defines their purpose, which is their main difference. Fastening models are designed to fix pipelines in a given location for further operation.

Their main functions are:

- strength and reliability of fixation of installed pipes;

- ease of installation and long service life;

- preventing transverse displacement of the pipeline system with the possibility of longitudinal movement during use.

Fasteners must ensure reliable fixation of pipelines in places where they are laid

Repair clamps are used to repair pipes in cases where it is impossible to repair the damage in any other way, or this must be done quickly, without stopping the circulation of liquid in the damaged pipeline. The main requirements for repair models that determine their purpose are:

- ease of use and the ability to quickly perform installation work;

- reliability and long service life.

Using repair models, you can repair pipes made of various materials: steel and plastic, asbestos cement or cast iron for various types of damage: fistulas and fractures, cracks, mechanical damage and other faults.

Repair models made of stainless steel will ensure quick completion of repair work and will not spoil the visual perception of the room where they will be installed

Varieties

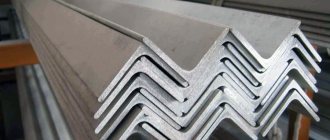

A metal worm clamp is made exclusively from steel, but steel can have different properties.

Based on this feature, the following types of clamps are distinguished:

- Galvanized steel. They are characterized by increased resistance to aggressive chemically active substances. The advantages include low cost and high reliability of the connection. Scope of application: installation of water supply, cooling and gas supply systems.

- Made from stainless steel. They use steel: easily magnetized, poorly magnetized, and also steel with antimagnetic properties. Stainless steel fasteners are highly resistant to corrosion and sudden temperature changes, and are used in damp rooms and for open-air work. Disadvantages include a higher price.

- Combined. Carbon steel is used to make the screw, and stainless steel is used for the band and lock. Thanks to this combination, it is possible to achieve the optimal price-quality ratio.

The worm clamp has different screw sizes, depending on the shape of the head. And it comes in various configurations: hexagonal, with a straight or cross-shaped groove, with a collar. In accordance with the shape of the head, you should select a screwdriver for the job. They are also available with a plastic thumbscrew, allowing you to do without a screwdriver.

In addition, the clamps are different:

- The length of the tape and, accordingly, the possible diameter. The sizes of the worm metal clamp are distinguished, used for pipes with a cross section from 0.8 to 1.6 cm, from 1.2 to 2.0 cm, from 1.6 to 16 cm, over 16 cm.

- Tape width. As a rule, narrow ones are used when the elements being connected will experience strong vibration. The area of application for wide ones is sleeves for which too much compression is contraindicated.

- The ability to withstand loads of a certain intensity: in accordance with this criterion, light and heavy series clamps are distinguished.

As already mentioned, the fastening tape may have teeth or notches. The best are considered to be clamps with teeth made by corrugation and located at a certain angle. In a clamp with such teeth, the screw never comes off the tape, even if you have to work in extreme conditions. If there are perforated holes on the tape - notches, the clamp is less resistant to mechanical stress.

Equipment

Clamps can be sold with or without rubber seals. Microporous types of rubber are used as gaskets, ensuring almost complete damping of vibration waves arising from the movement of water inside the system. In addition, the gasket significantly reduces noise and makes the joint more airtight. The use of clamps with rubber seals is advisable when installing water supply systems in residential premises, carrying out repair work, as well as when working with systems into which coolant is supplied under high pressure.

If the pipeline is installed in rooms that have special sanitary and hygienic requirements, food-grade rubber gaskets are used as a seal.

Clamps are presented in a wide variety of standard sizes, which greatly simplifies their selection and allows you to purchase a model for pipes of any cross-section. Models are produced in the range of 14-540 mm and cover almost the entire range of pipe sizes, including large-diameter products.

Types of clamps

Clamps can be used to perform a variety of tasks. For ease of use, manufacturers have developed several varieties, each of which has individual characteristics.

They are presented on the market in the following types:

Spiral - is a kind of crimping tape in which there are holes for bolts. They are widely used in work on pipelines (where there is high operating pressure), hydraulic systems, etc.

Wire - visually represents one or more metal rings and has a tightening element in its design. The main area of purpose is working with corrugated pipes.

A screw worm is a strip with a toothed ring and is equipped with screws for tightening. Often used in heating systems. Worm-worm clamps are also used as a locking mechanism for piping systems that are particularly susceptible to vibration.

Pipe - this type consists of rings with staples. They are installed when there is a need to reduce the internal voltage of the system.

Spring - highly specialized devices. They are used for requirements that are characterized by linear expansion.

Options for the mechanical part of the ties

Any model of fastening screw is equipped with a fixation unit. There are models with fastening at one point and those that are fixed in two or more places.

Products with fixation at several points are solid parts in which holes are made for installing bolts or self-tapping screws

Devices with fastening at one point can be equipped with a pin with a pointed end and threaded threads, or have a hole for mounting self-tapping screws. Fastening of such clamps is carried out using polymer dowels.

Clamps for flexible hoses

For flexible hoses, 2 types of clamping elements are mainly used. We have already talked about worm-type clamps, but it’s worth taking a closer look at power clamps for high-pressure hoses.

Power clamp for high pressure hoses

Several types of products are used for crimping high-pressure hoses:

- cast universal, having 2 bolted connections (one on each side);

- galvanized wire with a tightening bolt mechanism;

- galvanized belts with the same tightening mechanism;

- power - here the crimping is done using a kind of tape, but bolt clamping mechanisms are located on both sides.

Power Stainless Steel Plumbing Product

Types of clamps

By design

Structurally, clamps are divided into 3 types:

- A ring that opens on one side and a movable detachable connection on the other side. The connection is secured with a bolt.

- Two half rings, which are fastened together with bolts.

- The bracket is shaped like the letter U. This type of fastener can have a rubberized gasket or surface inside, or be completely metal.

By task

Clamps are divided based on the tasks performed:

- Spiral

- Power

- Reinforced

- Wire

- Worm

- Pipe mortise

Details

SPIRAL

Spiral clamps are divided into two types, the difference between them is only in the rotary tightening mechanism, left or right tightening direction. Main lines made of reinforced pipes are used.

POWER

The part is a tape with a tightening mechanism. Direct purpose: fastening pipes under pressure. It is especially convenient to use for rectangular pipes, for rigid hoses, for hydraulic pneumatic drive systems, for hoses with rigid walls and reinforcement.

REINFORCED

Fix pipes with stronger pressure. Used for rigid or reinforced hoses. The limited length of the hinge screws ensures fixation with a small difference in the internal cross-section. Withstand pressure up to 30 atm. And they have decent strength.

WIRE

The design of the product is one or several rings of zinc-coated steel wire. They do not deform during long-term use. The optimal operating option for corrugated products, for pipes with thin soft walls and for systems with increased vibration.

According to the tightening method, wire clamps are divided into two types:

- Screw fastening. For connecting spiral hoses.

- With spring-type fasteners. For its fastening there are special “ears”, which are clamped/pressed with fingers to increase/decrease the diameter of the product, without requiring any additional tools.

WORM

Externally, the clamp looks like a monolithic gear track made of metal, with a tightening screw. A clamp with this design has uniform tightening. Used for durable installation of hoses and pipes that are subject to vibration, as well as in heating systems and plumbing systems.

TUBE

The design is a round ring made of a metal plate with a rubber liner inside. Clamping is carried out on one or both sides using a bolt. This type of product is used for fastening open pipes in a certain area to reduce system stress and high-quality fixation of the pipe position.

ALL CLAMPS WITH A SEALING IN THE FORM OF A RUBBER GASKET ARE USED FOR SPECIFIC PURPOSES: TO REDUCE PIPES VIBRATION, TO REDUCED SHIMM, TO INCREASE THE TIGHTNESS OF THE CONNECTION.

THE COST OF CLAMPS WITH RUBBER INSERTS IS ALWAYS HIGHER.

SPRING

Tinder SHV and SGV are used for fastening due to exposure to high temperatures, which lead to expansion and various kinds of deformations.

Fastener placement rules

There are the following distance standards given in the construction standards SN 408 (instructions for the design and installation of water supply and sewerage networks made of polymer pipes). Some of its and other provisions for the most commonly used household communications:

- If pipes made of PP polypropylene or low-density polyethylene (HDPE, HDPE) are used to supply cold water, the distance between them when installed horizontally should not exceed 550, 650 and 750 mm, respectively, for 20, 25 and 32 mm diameters.

- For polypropylene 25 mm and 32 mm pipelines, most often used in heating lines, the distance between supports for horizontal installation should be on average 600 or 700 mm, respectively, in the temperature range from 60 to 80 ° C.

- For medium-heavy PVC pipes with a diameter of 50 mm when laid horizontally, the approximate distance between fastening points should be 600 mm.

- When hanging a horizontal 110 mm medium-heavy pipeline, the approximate distance between the supports is taken to be 1100 mm.

- With a vertical arrangement of pipes made of PP polypropylene, PVC polyvinyl chloride and HDPE low-pressure polyethylene, the following standards for distances between supports for a working environment with a temperature of 30 ° C are accepted: - for the 32nd pipe - 1000 mm; — for the 50th — 1500 mm; — for the 110th — 3500 mm.

- Additional fastening of pipes should be done at their bends, that is, at the points where the curved section has the least rigidity.

- All supports should be placed at the sockets of horizontal pipelines and under them when they are laid vertically.

Types and features of worm clamps

A worm clamp is a type of fastener designed for fastening, connecting and sealing hoses, pipes of various sizes, pneumatic hoses and pipes. Such a clamp has in its design a tape, a screw and a worm joint lock. The body is made by pressing, so the structure is very strong and resistant, which allows you to reliably connect a pipe or hose. Particular attention is paid to the manufacture of the tape; there should be no sharp edges on it, so as not to damage pipes and hoses.

Types of Worm Clamps

Worm-worm clamps vary in size, which are selected according to the diameter of pipes, hoses or pipes. They are widely used in the automotive industry, industry, air ducts and ventilation systems, etc.

There are worm-drive butterfly clamps that have a special screw. These clamps are used when the hose needs to be removed and connected repeatedly. Another type of such a clamp is a worm-type clamp with a wing, the diameter range of which ranges from 16 to 60 mm.

The screw itself can have different types of heads:

- Hexagonal;

- With splined groove;

- With cross groove;

- With collar.

Worm-worm clamps are made of galvanized or stainless steel, which makes them resistant to aggressive environments and non-corrosive.

Design features according to GOST

The main areas of use for worm-drive clamps are pneumatic and hydraulic systems. Parameters such as design features and dimensions are determined by GOST 28191-89. They vary in types and series.

Worm worm clamps are divided into light and heavy series clamps. Light series clamps have diameters from 8 to 16 mm, from 12 to 20 mm, from 16 to 160 mm and over 160 mm. Heavy - from 16 to 160 mm and over 160 mm.

Self-production

If it is impossible to purchase a factory clamp, making fasteners yourself will not be difficult. The crimping element can be made from a galvanized tin plate 1 mm thick. To do this, you need to cut a strip, the width of which can be 4-8 cm. To determine the length, measure the diameter of the pipe and multiply by 3.14. The resulting numerical value will be the length of the strip. To this value you need to add another 3-4 cm, necessary to form the mounting ears, and then cut out the workpiece.

Two holes should be drilled on the sides of the strip at a distance of 5-7 mm from the edge. If you plan to make a wide clamp, the number of holes should be increased. So, for products up to 6 cm wide, two fasteners are sufficient, while for a model 8 cm wide, 3 bolts will be required. After checking that the holes made match, insert the gasket into the clamp and tighten the bolt.

To ensure a more airtight connection, it is recommended to pre-glue the rubber strip to the metal. Next, using the finished bracket, you should tie the pipe, then connect the ears to each other and tighten with a bolt.

A simple device, low cost and easy installation significantly expand the scope of application of clamps, distinguish them favorably from other fastening devices and allow you to install them yourself.

For information on a stainless steel pipe clamp, see the following video.

Classification

Spring hose clamps come in several types. Parts can be made from:

- round wire – used in cooling systems (low pressure only);

Wire clamps

- spring steel - necessary for devices operating under high loads (internal combustion engine hoses, internal combustion engine, radiator pipes);

Spring clamp

- flat tape - suitable for lightly loaded units (household appliances).

Band clamp

When installing the equipment, there is no need to use special tools. The clamp has two teeth, through which the dimensions of the fixing ring are increased. The name of the part is explained by the spring properties of the source material. Spring clamps are rarely used in high pressure systems.

To achieve reliable fixation, use worm-type clamps. Both ends of the part are combined through a unique element.

Power clamps are used to secure reinforced hoses. The list of the most common ones includes universal clamping elements. They are able to function at different temperature conditions.

Tapes may have:

- through holes - such products are made of rubber, which explains their low strength;

- two protrusions (no holes) - they are directed in two different directions;

- convexities located on the outside (no holes) are considered the most durable.

Crimping products are also classified based on design and purpose. Clamps are also available in spiral, wire, power and pipe. Parts equipped with reinforced fasteners and rubber seals are often called power hinge devices.

The main feature of crimp clamps is the presence of a bandage characterized by a certain thickness. The cuff is made of corrugated rubber. It prevents damage of various types when tightening parts. This results in a reduction in noise and vibration levels during pipeline use.