The cutters are sharpened on special machines by sharpening workers. But the planer often has to sharpen the cutters himself on a sharpening machine. In this case, the cutter surfaces must be sharpened in the following sequence:

main rear; auxiliary rear; front; transitional (rounded or chamfered). This sequence makes it easy to measure the angles obtained during sharpening.

Sharpening of high-speed steel cutters is carried out in two stages: preliminary, in which the shape with the required sharpening angles is given, and final, in which the specified cutter geometry with a high surface finish is obtained. Pre-sharpening is always performed before hardening on an electrocorundum coarse-grained grinding wheel with a grain size of 80-50 and a hardness of C1-CT1. The final sharpening of the cutters is carried out after hardening on a fine-grained grinding wheel with grit 25 and hardness C1-C2 or on a wheel with grit 16 and hardness CM1-CM2.

Sharpening of metal-ceramic cutters , i.e. cutters with plates made of hard alloys, is carried out after soldering the plate to the holder. Using an electrocorundum wheel with a grain size of 50-40 and a hardness of CM1-CM2, the parts of the holder protruding under the plate are removed. Sharpening of metal-ceramic cutters, just like sharpening of high-speed steel cutters, consists of preliminary and final sharpening.

Preliminary sharpening is carried out on a grinding wheel with a hardness of M3-SM1 made of green or black silicon carbide on a ceramic bond with a grain size of 25. Grinding wheels with a hardness of M3 are used for sharpening cutters made of alloys T15K6, VK3M and T30K4, and wheels with a hardness of SM1 are used for sharpening cutters made of alloys VK8, VK6 and T5K10.

For final sharpening, wheels made of the same material on the same bond are used, but with a grain size of 16-10 and a hardness of CM1. The peripheral speed of the wheel during manual sharpening should be 15 m/sec, and during automatic sharpening 10-12 m/sec. Sharpening is carried out by lightly pressing the cutter on the grinding wheel and simultaneously moving it relative to the wheel at a speed of 1 m/min.

To prevent the cutting blade from overheating during sharpening, either very light pressure of the cutter on the grinding wheel, or abundant cooling of the sharpened cutter is necessary. Coolants must have sufficient heat capacity, not cause corrosion of machine parts, and be transparent.

When cooling the cutter during sharpening, sulfurized oil of the following composition (%) is recommended: technical vegetable oil (sunflower, linseed) 19, mineral oil (vaseline, industrial, velocite) 78, sulfur 3.

Uneven, intermittent cooling is especially harmful for cutters with carbide inserts, as it causes invisible cracks on the surface of the inserts and leads to chipping of the cutting edge during operation. The runout of the grinding wheel also leads to the appearance of cracks on the cermet plates during sharpening, so such grinding wheels cannot be used. Wheel runout, clogging, poor supply of coolant are the main reasons for damage to cutters during sharpening.

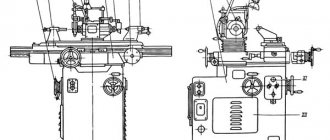

When sharpening, the angles of the cutter are checked with templates, universal inclinometers and a table goniometer. A table goniometer for checking cutter angles (Fig. 119) consists of a plate 7, a stand 1, a slider 2, a plate 3 with a scale of up to 90° and a square consisting of a lever 4, and faces 5 and 6 located at an angle of 90° to each other If the marks of the lever 4 with zero division on the plate coincide, the edges of the square are located: one perpendicular to the plane of the plate, the second parallel to it.

To measure the front angle with a protractor, the cutter is applied to face 5 with the front surface and the angle value is read on the degree scale. To determine the rear angle, the cutter is applied to face 6 with its rear surface and the value of the rear angle is determined using a scale.

Finishing of cutters. If the cleanliness of the processing of the front and rear surfaces of the cutter is of a high class, then the duration of work, and therefore the productivity of the cutter, increases significantly, while the processed surface is also of high cleanliness. Therefore, the front and main rear surfaces are processed to grade 9-10 cleanliness. Since such classes of cleanliness cannot be achieved by sharpening, a special sharpening is performed, called finishing.

Finishing is carried out on finishing discs made of medium-hard cast iron. The diameter of the finishing disk is 200-250 mm, it rotates from the cutter clockwise, the rotation speed of the working surface is 0.8-2 m/sec. The disc is coated with a paste containing boron carbide powder with a grain size of 4-3 or green silicon carbide of the same grain size. To hold the paste on the finishing disk, iron oxide is added to the paste in an amount of 5-10% of the total weight of the paste.

Rice. 119. Table goniometer for measuring cutter sharpening angles

The front and main rear surfaces are not adjusted to their entire width, but only on a strip 2-3 mm wide, for which the indicated angles are sharpened 3-4° more than the required values. The quality of the finished surfaces must be within the above cleanliness classes.

Sharpening cutters with diamond wheels. Rough sharpening of hard alloy plates is carried out with the end of a cup diamond wheel with a grain size of AC 12 on a ceramic bond, finishing sharpening is done with diamond wheels with a grain size of AC8 - AC5, which makes it possible to obtain surfaces of the 9th and 10th classes of cleanliness. To obtain grades 10 and 11 of purity, diamond wheels with grain sizes AC4, AC3 and ASM40 are used. The rotation speed of the diamond wheel is 25-30 m/sec. When rough sharpening a cutter, the feed is 0.01–0.015 mm per pass, and when finishing it is 0.005–0.008 mm. Sharpening cutters with diamond wheels eliminates the need for finishing.

When sharpening cutters, the following rules must be observed:

do not use a grinding wheel that causes runout;

the support (support) must be securely fastened as close as possible to the grinding wheel at the required angle;

The cutter cannot be held suspended; it must be supported by a tool rest;

to avoid uneven wear of the grinding wheel, the sharpened cutter should be moved over the entire working surface of the wheel;

The sharpened cutter should not be pressed tightly against the wheel, since the cutter heats up unevenly and cracks form on it, and the grinding wheel quickly deteriorates and becomes uneven;

It is strictly forbidden to sharpen on a machine that is not equipped with a protective casing;

be sure to wear safety glasses;

Read also: Universal template for a router

When centralized sharpening and finishing of cutters, the sharpener's workplace must be equipped with local ventilation.

The effectiveness of a cutting device depends on the quality and timeliness of sharpening. The latter is due to the fact that with constant use, functional resources are lost over time. Experience over the past decade has shown that the best abrasive tool for this job is diamond sharpening wheels. They process all known types of materials, and product wear is ten times less.

Diamond wheels, design, advantage

Thanks to the physical and chemical properties of diamond and its functional potential, it successfully restores the cutting capabilities of the tool and quickly returns it to working condition. Products of this type are distinguished by cost-effective cutting capabilities and productive dimensional accuracy. These qualities have found worthy use in various spheres of life (industry, everyday life, etc.).

Moreover, diamond wheels, as an abrasive sharpening material, are used for sharpening and finishing cutters, drills, saws, etc. In addition, they are used to process and polish various types of surfaces. The main advantage in their use is simplicity, accuracy, speed and cleanliness of processing. And what is also important, it has little wear and tear - it is durable.

By their design, diamond discs are presented in the form of a body and an applied diamond-bearing layer, which consists of an appropriate powder, a binder and a filling material. The body of the product can be made of black or non-ferrous alloy. polymer. In such circles, two types of diamonds are used: artificial and technical (natural).

Moreover, they are presented in the form of individual crystals or powder. It is known that about 2/3 of the diamonds used in the industry in the form of powder are used for the manufacture of disks, bars and other tools. To hold the diamond powder on the disk, special binders are used that firmly hold the individual granules together.

The manufacturer currently offers the consumer three options for discs on organic, ceramic and metal bonds. The first type of wheel is used for grinding cutting plates and other blanks made of hard materials. They wear out quickly during operation. Discs of the second type are used for finishing tools (cutters, knives, etc.).

Products with metal bonds have sufficient heat resistance, strength and a long service life, but occasional salting is considered a disadvantage; as a result, editing is required.

What are diamond wheels for metal used for?

Diamond grinding wheels are one of the types of diamond tools. These devices are used to equip machines and electrical equipment. Diamond wheels are rarely used for manual operations.

Photo No. 1: diamond grinding wheels for metal

The main areas of application of these devices are machine tool and mechanical engineering. More highly specialized areas of use include:

- medicine;

- instrument making;

- production of porcelain, glass and crystal products;

- dentistry (dental prosthetics).

The following basic operations are performed using diamond wheels for metal.

- Sharpening of parts and tools (incisors, scalpels, knives, etc.).

- Honing.

- Finishing.

- Grinding.

- Polishing.

- Rip-off.

- Rough finish.

Most often, diamond wheels are used for processing workpieces and products from:

- hard alloys and other difficult-to-process materials;

- glass;

- ceramics.

In addition, semi-precious, semi-precious and precious stones are processed with diamond wheels.

Scope of consumption of diamond wheels and classification

Diamond sharpening wheels are intended for sharpening saws made of hard alloys, they are used to refine soldering, they are indispensable for sharpening turning tools, etc. They have a fine structure that allows finishing of the workpiece, which cannot be done using an ordinary standard one. abrasive sandpaper. Grinding discs of different types, types of diamond and grain size on mechanical and organic bonds are used for refining and sharpening turning tools, milling cutters and other devices made from hard raw materials. The Russian market for diamond wheels is represented by products of various shapes:

Which disk to use in each specific case must be determined individually, based on the proposed workpiece, surface, area and manufacturability. If a circular saw requires a circle plate, which, thanks to its sharp edge, can work between the teeth, then a straight profile or cup would be more suitable for a knife. To restore the original quality of turning cutters, drills and other devices, it is necessary to use reliable sharpeners.

Diamond blade shapes

Grinding wheels are also distinguished by grain size:

- 100/80 – fine fraction;

- 125/100 – average;

- 160/125 - large;

- 200/160 – larger;

Products with fine grain are used for final finishing of turning tools, knives, blades, etc. Using products with a medium grain, you can achieve the required sharpness of the cutting part of the device. The coarse grain structure allows, for example, to remove part of the metal and align the cutting part of the part. Products with fine and medium grains are the most common; they are also used in everyday life.

The sharpening disc is distinguished by diameter (125–300 mm). Therefore, you need to select it based on the size of the existing sharpener. The thickness and width of the diamond layer is considered important in such products. A wide layer will allow you to conveniently process a part of a decent area or a large diameter with a drill; in addition, the wear of the diamond coating will be prolonged.

Diamond sharpening wheels are universal; they can restore the cutting capabilities of a product that has failed, and after completing this procedure, return it to the technological process. It is used for sharpening end and disk mills, cutters, drills of different diameters; such a tool, after processing, is distinguished by decent cutting abilities and accuracy.

A distinctive feature of such a grinding wheel is the presence of a fine fraction of diamond grain on the working part; it has been proven in practice that it is capable of performing precise finishing of the cutting part of a cutter, plate, knife and other tools. Depending on the purpose of use, the choice of diamond wheel for sharpening is made. For finishing, they use a straight profile sharpener.

Design feature

The cutting elements themselves are prepared using cold pressure on presses, from a mixture of diamond powder/crystals and a binder substance. Separate molds are prepared for each type of segment. The formulas or composition of the binder component are developed according to user needs. A diamond sharpening wheel will not effectively sharpen CBN cutters.

The connection of the cutting edge to the base of the disk can be done using two methods:

The fastening of the abrasive or its segments to the steel base is carried out in presses at high temperatures and pressures, in accordance with the technological map. Silver solder is often used as a binder. The soldering method is the same for making disks with a segmented edge and a solid one.- Laser welding of base and abrasive at the molecular level. Suitable for segmented tools only. Considered more reliable.

In both cases, the joints require machining of the weld, initial sharpening and grinding with a ceramic sharpener.

During this mechanical process, diamond crystals are released, giving the instrument the declared physical, technical and quality characteristics.

A Brief Overview of Diamond Sharpening Wheels

When processing the desired product, a specific abrasive tool is selected, taking into account the shape and material of the workpiece, as well as other features. The work is performed wet using coolant or dry. Such a disk, using cooling, can perform work on both surfaces of cutters, reamers, broaches, etc.

Carbide tools, after sharpening with diamond discs, contribute to increased equipment productivity due to accurate and high-quality work.

Sharpening with a cup diamond wheel

The diamond cup wheel is a device that is suitable for sharpening and finishing products made of hard alloys. Used for grinding parts made of materials that are difficult to machine. Among other things, they are used when working with hard non-metallic surfaces (ceramics, stone, glass). A sharpening wheel, made in the form of a cup, is used for sharpening cutters, knives and soldering tips.

A diamond disk disc is often used to remove paint and varnish from parts; in addition, it is used for processing metal (cast iron, steel); it has proven itself well when working with art glass products. The use of this type of diamond wheel for sharpening can reduce labor intensity by half compared to using a conventional grinding product.

This product, made in the form of a plate (due to its shallow depth), is successfully used for sharpening saws with carbide tips.

A straight profile is a sharpening wheel made in the shape of a flat disk with a diamond abrasive layer at the end. Used for processing metal surfaces where a consistent plane is required.

Read also: What does c16 mean on a circuit breaker?

The diamond grinding wheel, as a tool, is used not only for sharpening; it is also used for refining materials that are difficult to process. They perform work on grinding carbide parts. The practical use of such a product is economically beneficial because it reduces labor intensity and significantly increases productivity.

For example, a 12a2 45 wheel with a diamond layer is made in a cup or disc shape and is used for metal processing of multi-edge carbide tools with straight and spiral teeth, cutters, broaches, drills, etc. The same product is used for grinding surfaces in the automotive industry, construction, electronics and others industries.

And the product 1a1 is made in the form of a straight profile, the scope of application is quite wide, it is needed where processing of cylindrical, flat and conical surfaces is needed. It is indispensable for finishing conical and cylindrical holes. They are used in dies made of hard alloys when processing splines and grooves. And, of course, they are used for sharpening and finishing cutters, drills, cutters, etc.

Like any industrially manufactured abrasive product, a diamond sharpening disc is marked by the manufacturer. This designation contains a number of numbers, each of which corresponds to a specific value: diameter, fit, depth, thickness of the diamond-bearing layer or grain size.

If you find an error, please select a piece of text and press Ctrl+Enter.

A diamond grinding wheel is a type of diamond consumable tool. Used in manual and automatic (including angle) grinders for finishing, sharpening, honing and grinding. It is used for processing difficult-to-cut and hard-alloy materials, ceramic surfaces, glass, precious, semi-precious and semi-precious stones. It has an optimal balance of strength and fragility, is characterized by increased efficiency, a large working reserve and self-sharpening.

Features of selecting wheels by grain size

The smaller the grain size, the higher the quality of the processed surface, the lower the roughness value. But it should be taken into account that fine abrasive reduces productivity and leads to clogging of the wheel surface. Therefore, fine-grained diamond discs are used at the final stage, when finishing the surfaces of parts, as well as when sharpening cutters, knives and other cutting tools. Medium-grained wheels are used for semi-finishing of metal products. Coarse-grained – for roughing and peeling of workpieces.

When selecting the grain size of the wheel, it is necessary to take into account the properties of the material of the workpiece. The size of the abrasive should increase as the viscosity or hardness of the material being processed increases. The choice of grinding depth also depends on the grain size. The larger the abrasive grain, the greater the cross feed of the tool can be. It is also possible to increase the depth of metal layer removal when using coolant.

Scope of application of diamond grinding tools

Thanks to the capabilities of diamond tools, the areas of their use are very wide. The labor intensity of processing hard alloys is reduced several times compared to working with other abrasive materials. Tools sharpened with diamonds work more efficiently and do not require processing for longer. For single-edged parts with a cutting part made of carbide material, such sharpening increases wear resistance by one and a half times, and for multi-edged tools this figure is even higher.

The surface treated with a diamond grinding wheel does not crack, chips or other defects do not form on it. This makes it possible to process glass and ceramic products: car windows, mirrors and much more.

This tool is indispensable when grinding glass for optical instruments, at enterprises producing porcelain, crystal and glassware, and when grinding screens. Diamond grinding is widely used in medicine for sharpening microtome knives, scalpels and injection needles, for dental treatment and prosthetics in dentistry.

In addition, diamond grinding wheels are also used for dressing wheels made from other materials.

However, in order for the beneficial properties of diamond wheels to be fully used, and the result of the work to meet expectations, the correct choice of product among many varieties is required.

Design of diamond grinding wheels

The circles represent a body on which a layer of diamonds with different structures is applied. In addition to the diamond elements, the spraying includes a filler and a binder.

All products have different characteristics and differ in:

- the type and shape of the circle;

- case size;

- degree of grain size;

- type of ligament;

- diamond concentrations;

- imbalance class;

- accuracy class;

In addition, they are characterized by strength, hardness, and wear resistance.

Frame

For the manufacture of diamond wheel bodies, steel grades St3, 30, 25 and 20, aluminum alloys grades D16 and AK6 or polymers are used.

For grinding wheels shaped like AGC or A1PP, shanks made of U8 or U7 steel are required.

Diamond concentration

The concentration of the diamond-bearing layer, which is expressed as a percentage, is the number of grains in 1 cubic millimeter of powder used in the abrasive layer. This characteristic affects the efficiency and economy of the tool. The concentration depends on the grit - the higher the grit and the harder the material being processed, the greater the percentage of diamond concentration required for the job.

Diamond grinding wheels are available in 150, 100, 75, 50 and 25 percent concentrations. 100% is taken to be 4.39 carats (1 carat equals 0.2 g) contained in 1 cm3, which corresponds to 0.878 mg/mm³.

This indicator determines the productivity, cutting ability, service life and price of the tool. Optimal performance depends on the area and shape of the material being processed, the type of tool used, bond quality, diamond grain size, and processing conditions.

The choice of circle concentration is based on the following requirements:

- a high concentration is necessary if the contact surface between the workpiece and the grinding wheel is small (for example, during cylindrical grinding), this guarantees a long service life of the tool and increases its wear resistance;

- low concentration is selected for treating large area contact surfaces.

Grain

Grit is the size of a diamond grain or crystal intergrowth (this indicator is determined by thickness, width and height, but usually only width is taken into account). The degree of grain size determines the cleanliness of the surface after processing, work productivity, the amount of material removed per single pass of the wheel, tool wear and other indicators.

The grain size is indicated in accordance with GOST 3647-80 and is indicated in microns by a fraction in which the numerator in microns indicates the size of the upper sieve, and the denominator - the lower one. According to international standards FEPA (and GOST R52381-2005), the characteristic is indicated by the letter F with the corresponding number - the higher it is, the smaller the grain size.

The grain size is selected depending on the required surface roughness after processing, the type of material, the amount of allowance removed when passing the tool, etc.

The smaller the grain size used, the cleaner the treated surface is. But fine grain size is not always preferable - it gives high cleanliness, but at the same time leads to clogging of the tool and burning of the surface being processed. Using a fine-grained wheel also reduces productivity.

The grain size differs by fraction as follows:

- fine 100/80;

- average 125/100;

- large 160/125;

- larger 200/160.

Wheels with a lower index are used for final finishing of blades, knives, cutters and other products, for final grinding. The middle link allows you to achieve the necessary sharpness of the cutting parts, and coarse grains are used to level and remove part of the surface being processed.

Read also: How to use a tester to determine phase zero and ground

It is advisable to use low-grain wheels to reduce surface roughness, and larger grains when it is required to increase productivity and with large allowances. The less viscous and harder the material, the higher the grain size index can be.

Features of the diamond cutting process

After numerous conversations with beginning stone cutters - buyers of our SNO-3 cutting machines, it seemed useful to delve into the essence of diamond cutting in order to simplify the self-learning process for them or, at least, protect them from gross operational errors, and the machines from meaningless alterations.

Let's look at all aspects of diamond cutting in detail.

Physical principles of the stone cutting process.

First, let's look at what we're going to cut. Stones in nature are:

- natural solid chemical elements or their compounds with a crystalline structure in the form of mineral individuals (regular polyhedra - crystals or mineral grains)

- compounds of mineral individuals called mineral aggregates or rocks .

Examples of mineral individuals include single crystals of diamond, quartz, garnet, or a single grain of sand from the beach. Within one mineral individual, its properties are theoretically the same and are determined by the chemical composition and characteristics of the crystal structure of this mineral species. There are more than 5,300 mineral species in nature, but about 100 are widely distributed. The ability to mechanically process a mineral species depends on its specific properties: hardness, brittleness (or plasticity), flexibility and, very importantly, the ability to chip along certain directions of its crystalline structure (called “cleavage” and “separateness”). From one mineral species to another, all these properties vary significantly. For example, the hardness of the softest mineral, talc, in absolute values differs from the hardness of the hardest mineral, diamond, by more than 4000 times. Pyrite, being hard as steel, is fragile and cracks even under insignificant loads, but on native copper, which is soft compared to pyrite, cracks do not occur even under gigantic loads, due to its ductility (malleability).

Typical mineral aggregates (or rocks) are, for example, granite, marble, charoite or lapis lazuli. The properties of rocks depend on what (or what) minerals they consist of, what size and shape the individuals of these minerals are in a given aggregate, how these individuals are located relative to each other, how homogeneous the rock is in composition and structure, and to what extent it was subject to natural geological processes after its formation. Due to the presence of such a large number of heterogeneous factors, the range of strength properties of rocks is also very wide. For example, talkite, which consists mainly of talc, can be cut with a knife, malachite can be sawed with a hacksaw, but for any rock containing the most common minerals on Earth, quartz and feldspars (granite, gneiss, gabbro, etc.), cutting will have to use a diamond blade. As for mineral individuals, the leading property for rocks in terms of their ability to be machined is the hardness of the minerals composing them. However, other factors discussed can sometimes make a mineral aggregate consisting of not very hard minerals difficult to cut, “sticky”. This is observed when processing jade, jadeite, rhodonite, etc.).

So, stones are incredibly diverse in their mechanical properties, which, of course, should be taken into account when sawing.

How does a seemingly smooth diamond blade cut a stone? Any stone processing process - cutting, drilling, grinding or polishing - is essentially scraping, tearing, chipping or removing chips from the surface of the stone using a harder substance - an abrasive. This term comes from the Latin “abrasio” - scraping. The greater the difference between the hardness of the sawn stone and the abrasive, the higher the productivity of stone processing. Therefore, natural or synthetic diamonds are used in stone processing tools, including cutting discs, which can destroy all known stones.

Upon closer inspection, the cutting edge of a diamond blade, composed of a tin-copper alloy (80% copper), contains small embedded diamond grains. Their size, depending on the purpose of the disk, ranges from a few hundredths to 0.5 mm. Large diamonds can cut faster (let us remember and compare a hacksaw with large teeth to a “fine-toothed” one), but they mercilessly chip away at fragile stones, since their main effect on the stone is not scratching, but chipping. This significantly limits their use. The amount of diamonds in a metal binder, depending on the purpose, can vary widely: from 25 to 200%, where 0.878 mg of abrasive per 1 mm3 of the cutting edge is taken as 100% concentration. The highest contents (100% or more) are used for cutting particularly hard materials, such as hard alloys, while in stone cutting a lower saturation (25 - 100%) is quite sufficient.

Having considered what we cut and with what, let’s focus on the cutting mode. It is specified and provided:

- feed force,

- disk rotation speed,

- maximum permissible depth of cut for a disc of a given diameter,

- engine power,

- cutting geometry,

- coolant supply,

- sharpening the disc.

Feeding power.

When the disc rotates, diamonds scratch the material being processed. To do this, it is necessary to apply some force to the stone (or disk, depending on the type of stone-cutting machine), pressing the diamond grains to the stone. This force is called pitching force . Obviously, for maximum effective cutting, this force must ensure maximum immersion of the protruding part of the diamond grain into the material being cut for a given stone. If we draw an analogy with sawing wood, the maximum cutting speed is achieved when the saw teeth are deepened to their full height. From this it is easy to conclude: the larger the diamond grain, the greater the feed force must be for maximum cutting efficiency. The process is shown schematically in Fig. 1

Some inexperienced stone cutters believe that the greater the feed force, the faster the cutting. They press as hard as they can on the stone, and the cutting speed actually increases to a certain limit, and then does not increase, but the cutting disc soon becomes unusable. A disappointed master believes that the disk is of poor quality, or the machine does not rotate the disk fast enough, or it does not have enough power. Let's figure out what's going on.

The depth of diamond immersion in a stone is limited by the metal band of the disc, which holds the diamond grains. An attempt to unreasonably increase the feed force leads to the fact that the stone being cut begins to wear out the metal bond, and the diamonds fall out of the cutting edge. The disc quickly becomes dull (“greasy”).

Another negative effect of excessive feed force is distortion of the cutting wheel. The metal of the disk is quite thin and becomes deformed if too much force is applied. A curved disk leads the cut to the side, and it certainly gets jammed inside the uneven cut. No further cutting is possible in this cut.

It is especially important to minimize the feed force at the very beginning of the cut, when the cutting disc has not yet penetrated into the stone. You must also be extremely careful when the edge of the stone is beveled and not perpendicular to the plane of the disk. At the same time, at the beginning of the cut, the probability of the disc moving to the side increases. The feed force should also be reduced at the end of the cut, since excessive pressure can break off the thin edge of the stone, forming a chip and a burr.

Let us formulate the basic principles for determining the feed force. An increase in feed force is allowed:

- for harder stones compared to soft ones,

- when the diamond grains in the disk are larger in size compared to small ones,

- at a higher concentration of diamonds in the disk,

- with a large cross-section of the stone being cut (to overcome excess friction in cutting a large area).

Limitations on the feed force are imposed by:

- small thickness, and, consequently, rigidity of the cutting disc. Thin disks (for example, 0.2 - 0.4 mm thick with a diameter of 100 - 150 mm or 1.0 - 1.2 mm with a diameter of 230 - 250 mm) easily bend with excessive force and are “pushed” to the side.

- initial and final cutting phases.

It can be summarized that the choice of longitudinal feed force, as well as the choice of a suitable diamond blade, seem to be the basis of the stone cutter's skill when cutting stone. It is done depending on the type of stone being cut, the machine used, the method of supplying coolant to the cutting zone, and the parameters of the diamond blade.

For example, it recommends for disks with a diameter of 125 - 350 mm with a diamond layer thickness of 0.8 - 1.5 mm a feed rate of 0.25 - 0.4 mm/s, and for disks with a diameter of 200 - 500 mm with a diamond layer thickness of 1, 9 – 2.4 mm feed rate 0.2 – 0.3 mm/s. These numbers can serve as a guide for a beginning stone cutter.

Cutting force.

In addition to the feed force, the cutting disc is acted upon by the cutting force that occurs when the disc is rotated by an electric motor. The vector of this force is directed tangentially to the circumference of the cutting disc at each cut point (Fig. 2).

Obviously, the longer the cutting edge travels along the stone per unit time, the faster (at a constant feed force) the cutting will occur. However, the speed of rotation of the disk is limited by its structural strength. The maximum permissible speed must not be exceeded, as this may cause the disc to break and cause injury to the operator . The maximum permissible revolutions are indicated on the disk itself or in its passport in rpm or m/s. convert the peripheral speed V (m/s) into rotation speed n (rpm) and vice versa using the formulas:

n = 19.1×V/D

and V= 0.0523×D×n,

where n is the number of revolutions, in min., V is the peripheral speed of the disk, in m/s, D is the diameter of the disk, in m.

Discs with a diameter of more than 200 mm have a maximum peripheral speed of 35 m/s. This means that the permissible rotation speeds in rpm are: for D = 230 mm - 2906 rpm, and for D = 250 mm - 2674 rpm. It is clear that for safety reasons it is advisable to use slightly lower disk rotation speeds.

Maximum permissible cutting depth

Manufacturers of diamond blades recommend limiting the cutting depth for proper operation. Thus, Distar recommends for the most popular disc diameters:

| Disc diameter, mm | Maximum cutting depth, mm |

| 200 | 45 |

| 230 | 60 |

| 250 | 70 |

Engine power.

The engine power must provide a torque sufficient to ensure constant specified rotation speeds of the cutting disc over the entire range of permissible feed forces. In other words, if, with a stone cross-section acceptable for a given disk diameter, a full supply of coolant, a “non-greased” disk, no curvature of the cut and longitudinal feed at the above speed, there is no drop in the disk rotation speed, this means that the engine power is sufficient for normal work.

Increasing the machine engine power above the required is inappropriate because:

- increases energy consumption;

- leads to an increase in the cost of the machine,

- is potentially dangerous because if the cutting disc jams, it, like the stone, is more likely to break and cause injury to the operator.

Cutting geometry.

The cutting disc has different thicknesses of cutting diamond edge and steel base. As a rule, this difference varies in the range of 0.1-0.4 mm. It is analogous to the “setting” of saw teeth on wood and prevents the disc from jamming in the slot. At the end of the blade's life, due to wear on the cutting edge, this difference decreases and the risk of jamming increases.

In this regard, the instructions for cutting discs from reputable companies indicate that using the side surfaces of the diamond edges of cutting discs for roughing or grinding stone is strictly prohibited. Failure to comply with this rule leads to the fact that a disk that seems little worn at first glance, on the side of which they spent a couple of days shaping samples, with a cutting edge 9 mm high (out of 10 mm for a new disk) begins to clamp even in a shallow slot. Many operators perceive this as a signal of insufficient engine power, however, when replacing the disk with a new one, this phenomenon completely disappears!

An important factor determining the ease of cutting when using a stone clamping device (and a device for sawing thin plates in SNO-3) is the adjustment of the stone feed strictly parallel to the plane of the diamond blade. The permissible deviation from parallelism when using a clamping vice should be no more than 0.1 mm per 250 mm length. The SNO-3 machines provide the ability to adjust the parallelism of the direction of movement of the vice and the supporting plane of the device for sawing thin plates relative to the plane of the disk.

Use of coolant.

Proper use of coolant is important. Its main purpose is to cool the disk, which heats up both directly at the cutting point and during friction against the walls of the cut. In the first case, if the cooling is insufficient, the disk can heat up to such an extent that the metal bond of the diamond layer becomes plastic and breaks. In addition, the coolant washes away cutting products (“sludge”), reducing friction in the cut, and cleans the diamond grains of the blade. If there is a lack of fluid in the cut, the cutting speed drops; in addition, due to the heating of the steel base, the disc can become plate-shaped. Sometimes, when it cools, it takes on its previous shape, but often cannot be used further, as it tends to bend the cut.

Pure water is mainly used as a coolant. A good result is obtained by adding a small amount (about 1-2 cm cubic per 30 - 40 liters) of washing powder to the water (optimally for children's clothes - it is less allergenic) with low foaming (that is, for automatic washing machines). At the same time, the friction between the disk and the walls of the cut is noticeably reduced and the washability of cutting products (sludge) is improved.

Sharpening the cutting disc.

Cutting stone, especially chalcedony, agate, chrysoprase, quartzite, jasper, jade and some other stones causes gradual chipping of diamonds from the metal base of the disc, which significantly reduces the cutting speed. In this case, you should sharpen the disc by removing a thin layer of the metal base and thereby exposing new diamond grains, until now hidden in the depths of the cutting edge. To do this, it is necessary to cut with this disk a piece of an abrasive wheel or a block of silicon carbide (grade 63C) with a grain size of 16 - 25 microns, hardness CM1 - CM2, thickness 15 - 25 mm. It is enough to make 2 - 3 cuts 2 - 3 cm long with normal irrigation with coolant. The grain size of the sharpening stone is important because it must be smaller than the size of the diamond grains of the disc to prevent them from being knocked out of the copper matrix. It is clear that excessively frequent sharpening leads to premature wear of the working diamond edge of the disc.

After acquiring some skill, a stone cutter, especially when working with the same type of raw material, easily notices a drop in cutting speed due to the “clogging” of the disk. At first, you can follow the recommendations of disc manufacturers, who advise sharpening them every 15 square meters. cm of cut - for discs with a diameter of 100 - 160 mm, and every 90 sq. cm of cut for discs with a diameter of 200 - 250 mm. However, if you acquire such a skill and focus not on the work performed by the disk, but on the real drop in cutting speed, you can significantly increase the service life of the disk.

We wish everyone pleasant work and numerous delights from opening new stones!

L.V. Kulachkov, K.L. Kulachkov 2022. All rights reserved. Reproduction is permitted with reference to the original source.

Bundles for diamond grinding wheels

Diamond grinding wheels are produced with three types of bonds: metal, designated by the letter M (the base is compositions of tin, zinc, copper, aluminum), ceramic, designated by the letter K (with a base of glass or fireclay and the addition of aluminum) and organic, marked with the letters KB or K (made of carbolite or pulverbakelite). If a filler is used, its role is played by powder made of graphite, copper, alumina, electrocorundum or boron carbide.

Diamond wheels, which use a metal bond in their construction, are characterized by increased heat resistance and strength, retain their geometric shape for a long time and have a long service life, but quickly become greasy. They are used for grinding large volumes of material and pre-processing them. The result is a surface with an eighth to ninth roughness class. Filler is not used in such circles, and the working layer can be fixed to a transition steel ring, which is attached to the body.

Properties of circles with metal bond:

- high hardness;

- high speed and productivity;

- good heat resistance and thermal conductivity;

- high removal productivity.

An organic binder requires the use of filler. It has low hardness, heat resistance and thermal conductivity, but fairly high productivity and processing speed.

Wheels with an organic bond are used for finishing and finishing work, for finishing and finishing sharpening of products made of superhard materials and hard alloys, for processing medical and measuring instruments. Allows you to obtain a surface of the eleventh and twelfth roughness classes. Unlike wheels with a metal bond, they are less greasy, but they consume diamonds three times more.

Tools with a ceramic bond are characterized by a diamond-nickel coating, which can be applied in one or several layers. The thickness of the bond is two-thirds the size of the diamond grains. Thanks to this, the crystals protrude above the surface of the ligament, but are securely fixed. As a result, the resulting chips are easily removed from the treated area.

Properties of ceramic bonded wheels:

- high cutting ability;

- affordable price;

- any geometry;

- high thermal conductivity.

Used for grinding and cutting germanium, silicon, sital, other semiconductor materials, technical glass and ceramics, and stone processing. It is also used for finishing products made of alloy steels, hard alloys, and in the manufacture of hand tools.

Diamond wheels with a metal bond are used only with water cooling; those with an organic bond can be used both with and without cooling, and the use of alkaline solutions is not allowed.

Rules for using diamond wheels for metal

In order for diamond wheels for metal to last as long as possible, you need to follow the recommendations of specialists and the rules for using tools.

How to properly install diamond wheels on spindles

- It is prohibited to install diamond wheels for metal on full-size, small-size or oval spindles. Here are the recommended differences between the diameters of the spindles and the diameters of the mounting holes in the tools.

| Diameter of diamond wheel for metal | Recommended difference between spindle diameter and bore diameter |

| Up to 100 mm | 0.1–1 mm |

| From 101 to 250 mm | 0.2–1 mm |

| More than 250 mm | 0.3–1.5 mm |

Table No. 3: recommended differences between the diameters of the spindles and the diameters of the mounting holes of diamond wheels

- If the difference is less than acceptable, then the hole should be bored. Otherwise, there are two options. Most often, bushings of suitable sizes are used. The hole in the circle can also be narrowed by pouring a special mass.

- The circles are secured using clamping washers. Gaskets are placed between them and the tools. It is not recommended to clamp the circles too tightly. High pressure can cause the device to break.

Rules for using diamond wheels for metal

1. When processing workpieces with diamond wheels on ceramic or metal bonds, it is imperative to use coolant. When working with wheels with organic bonds, the use of coolant is recommended.

2. After installing the tool, you need to check it. To do this, the equipment is started idle at the operating speed. In this case, a protective casing must be installed. You can start working only after the disk has passed the strength test. The runout should also not exceed the established norm.

3. When processing, it is prohibited to use levers that increase the load on the tools.

4. Cooling fluid must be supplied and discharged evenly and in a timely manner. Constant immersion of the circle in the composition is not allowed.

5. Diamond wheels for metal are cleaned in different ways.

- Pumice stones are used to remove dirt from instruments with organic bonds.

- Circles on metal bonds are cleaned using silicon carbide bars. The grit of the device should be 1–2 numbers coarser than the grit of a diamond wheel for metal.

6. To restore the cutting ability of diamond tools, dressing is used. It involves treating the working surface with diamonds, diamond substitutes or cutters.

How to properly store abrasive tools

- It is recommended to store diamond wheels for metal on racks.

- The room should be bright and heated.

- The storage temperature for ceramic bonded circles is not lower than +5 °C.

- The storage temperature for bakelite bonded wheels is not lower than +10 °C.

- It is recommended to place tools on racks in groups. For example, depending on the form.

Photo No. 3: an example of organizing the storage of abrasive tools

Hardness of grinding wheels

The hardness of the wheel does not depend on the hardness of the diamond coating. This characteristic means the ability to hold diamond grains in a binder in contact with the surface being processed. Hardness depends on the technology used in manufacturing, the shape and grain size of the grain, and the quality of the binder.

The self-sharpening ability of a wheel – its ability to restore cutting characteristics after removal or destruction of diamond elements – largely depends on hardness. During operation, the cutting grains split and fall out, and new diamonds begin to act, which prevents the appearance of cracks and burns on the surface being processed. The possibility of self-sharpening decreases with increasing wheel hardness.

The wheels are divided according to hardness into 8 groups, designated according to GOST 19202-80 and R 52587-2006 with the following signs:

- VM1, VM2 F, G – very soft;

- H, I, J, M1, M2, M3 – soft;

- K, L, SM1, SM2 – medium soft;

- M, N, C1, C2 – medium;

- O, P, Q, ST1, ST2, ST3 – medium-hard;

- R, S, T1, T2 – solid;

- T, U, VT – very hard;

- X, Y, Z, V, W, CT – extremely hard.

The choice of hardness is determined by the shape of the part and the required grinding accuracy, the type of processing, the type of tool used, and the properties of the material. Deviations from the optimal characteristics can lead to the appearance of cracks and burns (if the hardness is higher than necessary) or to changes in the geometry of the wheel and its wear (if the hardness is insufficient). It is especially important to follow the rules for selecting a wheel based on hardness when working with products made of hard alloys.

Increased hardness of the wheel will be required if high precision of dimensions and shapes is required. If cutting fluids are used during operation, the hardness may be higher than when grinding dry.

Accuracy class

The accuracy of the geometric shapes and sizes of diamond wheels corresponds to three classes and is designated as: B, A or AA. Less critical operations are carried out with tools of class B, class A refers to higher quality and precision. And high-precision AA wheels are intended for use on multi-circuit and high-precision machines or automatic lines. It corresponds to wheels characterized by uniformity of grain composition, accuracy of geometric parameters and high balance of diamond composition, in the manufacture of which the best grades of materials are used.

Types of work: with and without cooling

Water-cooled grinding is preferable because stronger machining conditions can be applied and the wheel wears less. This also reduces the possibility of burns and other thermal damage to the treated surface. Not water, but 1-5% emulsion is used as a coolant for grinding wheels.

For wheels with a metal binder, it is recommended to use BV lubricant, a 1.5-3% emulsion obtained from the NGL-205 emulsion, or from the “Akvol 10” emulsion. For wheels with an organic binder, use a 3% emulsion from industrial oil, soda ash in the form of a 0.5:1.0% solution, 0.1% wetting agent OP10 or OP7, or an emulsion obtained from borax, sodium nitrate, triethanolamine and trisodium phosphate.