From compressed air | 08/04/2017

Autumn is just around the corner. And, if your dacha is heated by a solid fuel boiler, it’s time to think about collecting firewood. With a large volume of heated premises, mechanized harvesting is clearly preferable in terms of productivity than a conventional ax. A hydraulic wood splitter (or, otherwise, a hydraulic splitter) is a good solution to the problem.

Why do we need firewood - improving fuel quality

There are quite a lot of energy sources in the modern world:

- Natural gas is available over large areas. It is enough to open the burner and light it, and a bluish light appears, which releases a significant heat flux.

- The liquid fuel supplied through the injectors burns with a bright red or yellowish flame. Even heat engines use different types of liquid energy carriers.

- Coal and its processed products have a long combustion cycle. The reddish flame gives off heat for a long time not only by convection; a powerful flow of thermal radiation reaches all surrounding objects.

- Firewood was the first available source of heat. They remain relevant today.

Many homes use stove heating. Baths and saunas, when advertising their services, indicate that they use wood of certain tree species as a heat source. Outdoor cooking traditionally involves the use of wood in the technology of cooking food.

Using other methods

The question may arise: “why not just cut the wood with a chainsaw.” Although this is an option, the chainsaw is designed for something else. Its design does not imply precise and high-quality processing of wooden boulders. The essence of the question is that with the help of a chainsaw they perform transverse cutting of wood , and hard and heavy logs are from a different area.

The question of whether it is good to use heavy hammers and thick wedges falls under the same category of answer. The productivity of such an action is, in principle, much higher than that of working with a chainsaw, but nevertheless, the effectiveness of this method is not so great and your tasks that you want to do besides chopping wood will have to be postponed until later. Because doing splitting work using a hammer and wedges will take too much of your time.

Recent Entries

Chainsaw or electric saw - what to choose for the garden? 4 mistakes when growing tomatoes in pots that almost all housewives make Secrets of growing seedlings from the Japanese, who are very sensitive to the soil

Theoretical foundations of heat engineering - solid fuel combustion

To make it easier to set fire to wood, it needs to be split into relatively small fragments. After splitting the logs into separate logs, the surface of contact of the combustible material with the air is increased. As a result, instantaneous heat transfer inside the firebox increases in proportion to the combustion area. Therefore, the procedure of chopping wood is a technique that allows you to increase the efficiency of fuel use.

Attention! Firewood chopped into logs is placed in woodpiles. They dry out in them. The moisture inside the wood evaporates rapidly. The apparent heat of combustion increases, since there is no need to waste energy on evaporating the liquid located in the intercellular space.

In thermal engineering, the following concepts have been introduced to characterize fuel:

- The highest calorific value, implying the total heat released during the combustion of a specific type of combustible substance.

- The lower calorific value is the actual amount of heat, which takes into account the energy costs for heating the fuel and the removal of ingredients from it during the combustion process that are not involved in the process itself.

Therefore, drying firewood is a technique that improves the performance of a fuel cell. Pre-grinding increases the efficiency of drying firewood, and subsequently burning it in a stove or other device for burning solid fuel.

Product Features

A wood splitter is always useful on the farm; you can either buy it ready-made or make it yourself using available materials. Ready-made options have been improved; there are a number of additional functions that allow you to chop maximum firewood in a short time.

There are many installations operating in an automated format. This is good, because you can not waste time on work, but start a machine that will do everything itself. Experts identify several characteristics that can be used to classify mechanisms into categories:

- Depending on the method of stacking logs, machines can be vertical or horizontal. Sheer structures are considered more powerful and durable, since they can process even a thick deck in a short period of time. If the logs are crooked or have many irregularities, then it is better to give preference to the horizontal mechanism.

- Maximum amount of stacked firewood. Depending on this criterion, equipment can be divided into equipment for home use and for industrial use.

- Drive types. For home use, a machine with a low power electric type is suitable.

In this video we will look at a hydraulic wood splitter:

Wood splitting process

There are different ways to chop wood. Traditionally, it is customary to strike with an ax, trying to split a sawn fragment of a log, striking the end part.

A heavy wedge (the ax is wedge-shaped) is inserted into the body of the log. If you come across wood without knots and with a loose structure, then even with relatively little physical effort, the wedge will be inserted inside. Tangential forces will push the fibers apart, causing the body to split into two components.

If the apex angle is made small, then the wedge-shaped body will penetrate deeply inside, but the magnitude of the tangential forces will be small. The destructive force will not be enough. The ax will jam in the resulting gap.

When a less acute angle is formed, the tangential forces will be more significant. They can split wood.

The rheological properties of different types of wood are studied in laboratories. Viscosity depends on many factors. It has been established that for most types of wood it is desirable to have a wedge with an apex angle of 25...30 °. Such a cutting tool has the best chopping properties in terms of splitting properties.

With slow penetration of the wedge, the kinetic energy not accumulated as a result of the swing and subsequent impact becomes decisive. The process occurs by introduction into a plastic body, where, when certain values are reached, the bonds between the fibers are broken.

Research has shown that for wood splitters the apex angle should be 30...38 °. Then the penetration of the wedge will be accompanied by the breaking of bonds with less effort. Only some species will resist: elm, maple, apple, cherry.

For pine, oak, ash and a number of other species, a small penetration into the body is sufficient. Breaking ties is quite easy.

The length of the block also influences the magnitude of the forces. The shorter it is, the less resistance the tree has when splitting. Usually the length is determined by the depth of the firebox - the firewood must be placed inside the stove so that the door can be closed.

Mechanical assistants for splitting wood

A number of metalworking enterprises produce wood splitters. Based on their operating principle, they are divided into several types:

- Cleavers are installations for chopping action. The logs are placed on special supports, and then blows are applied with a weighted chisel.

- The chopping wedge is placed motionless, and the objects to be split are supported on them. The blows are applied with heavy sledgehammers, the splitting is carried out when passing through a passive working element.

- Pressers are installations with a mechanical pusher drive. The log is laid on a bed, and then it is pushed through a flat or cross-shaped knife.

- Screw destroyers are embedded inside the layered material. Penetrating deeper, they split even strong and twisted wood.

Safety instructions

When working with mechanical devices of any type, there is always a risk of injury. When using homemade wood splitters, this risk often increases rather than decreases. Always and under any conditions, do not forget about safety precautions. When using a mechanical log splitter:

- in order to protect yourself as much as possible from all kinds of injuries, sawdust or chips getting into your eyes, you need to work in protective clothing, shoes, glasses and a hard hat;

- wood involved in processing must be firmly installed and secured in gutters or special recesses;

- Do not work in poor visibility conditions or on slippery surfaces;

- all elements of a mechanical wood splitter must be firmly welded and secured to each other;

- the cleaver or cutter should not have chips or cracks;

- You should not collect firewood in close proximity to other people;

- It is important to carefully monitor the condition of the tool used.

When using electrically driven mechanisms, first of all, attention should be paid to the electrical part, as well as:

- the wiring must correspond to the required cable cross-section and not get hot when using the tool;

- all used parts - sockets, electrical plugs, starting equipment - must not have visible damage and be powered into the electrical network according to the standard;

- all moving elements of the mechanism must be fenced with a protective casing and grille to prevent work clothes, hair, etc. from getting into them;

- work clothes must be tight, tucked in, intact and free from sagging;

- when using a belt, it is best to tuck in the free remainder;

- glasses and gloves must be intact, glasses must have good visibility.

Wood splitters have become indispensable assistants when preparing large quantities of firewood. They save many times a person’s time and effort, and do not require the expenditure of significant funds when produced by hand, unlike factory samples. But we should not forget that in reasonable amounts, physical labor ennobles and develops the will of a person. Therefore, sometimes it is more pleasant and useful to perform a small part of the preparation of firewood with a regular ax.

Cutting wood with wedge devices

Wedges are the simplest devices for cutting wood. In them, the level of labor mechanization is minimal. The main task of the device is the oriented fixation of the block relative to the cutting edges. The blows are delivered by the user himself, swinging a heavy hammer or sledgehammer.

In cleavers, the movement of the wedge ax is performed along a constant trajectory. The processing object is placed on a stationary platform. To maximize the impact force, the mass of the actuator is increased.

To soften the operation of the device, it is equipped with powerful springs. They soften the impact at the end point, preventing the wedge from touching the supports (preventing the wedge from dulling). Along the way, the springs help the user lift the heavy knife to strike again.

In a stable position, the entire system is in a balanced state. The moment created by the weight of the load G located on the arm L₁ is balanced by the force of the spring F on the arm L₂.

G·L₁ = F·L₂

It is most convenient to use springs from a car. For standard cars, the initial compression value is F = 8 kN (800 kg). Shoulder L₁ = 2.0 m. Taking arm L₂ = 0.3 m, the weight of the load G = 300 kN (30 kg) is obtained. The spring mechanism works quite softly, although the action of the wood splitter is based on striking the logs being cut.

The person lifts the load from the waist level by 0.5...0.6 m. Then the wedge is released. He falls and breaks the log. If complete destruction has not occurred, then you have to lift the cleaver and the block. With subsequent impacts, the weight of the entire system acts, and the impact is stronger. Even knotty scraps break when struck repeatedly.

Mechanisms for feeding logs for splitting

Wood splitters, which implement the principle of pressing through fixed knives, mechanize the main technological process: splitting logs into separate fragments. Based on the type of pusher drive, it is customary to determine:

- Hydraulic, in which the pushers are connected to the rods of hydraulic cylinders. The pump creates pressure in the oil, which is transmitted inside the mechanism. These are the simplest designs, since hydraulic drive devices do not have additional energy converters.

- Inertial ones use rotating masses. The energy accumulated by the flywheels is converted into forward movement of the pusher. The devices use special clutches that are engaged by the operator after installing a piece of log on the bed.

- Rack and pinion mechanisms use a converter from rotational to translational motion using a gear and a rack with teeth. At the right moment, the gear rotates until it engages the teeth of the actuator. The pusher moves the block onto the stationary knives. It splits into smaller elements.

- The crank mechanism receives torque from the gearbox. It is converted into translational movement of the pusher. Switching on (off) is regulated by a constantly open clutch. At the right moment, the operator engages the clutch, the crank begins to rotate, causing the connecting rod to move forward. The cycle ends with the return of the crank and connecting rod to their original position.

- Split nut and lead screw. The engine turns on, the rotation of the shaft is transmitted to the lead screw. At the right moment, the split nut is connected, the rotating shaft moves it, acting on the pusher. To return, the direction of rotation of the shaft is changed (a reverse rotation gear is used).

Advantages

A device for splitting firewood of this type, even if made manually in compliance with all technical and operational standards, has the following advantages:

- simple and reliable in operation;

- durable;

- can operate with a drive of both 220 V and 380 V and higher;

- for combined structures any operating conditions are acceptable;

- the type of wood does not matter, the splitting force is up to 14 tons;

- has a double degree of protection, safety clutch and thermal relay;

- consumes little energy - no more than 1.5 kW per hour, while gasoline consumption is 500 g;

- splitting a log 60-70 cm long is carried out on average in 1.5 minutes;

- The performance is not inferior to industrial hydraulic equipment.

Screw splitter

Such devices do not have high performance, but they take up relatively little space. They are installed in woodsheds (rooms for storing firewood). There they also split the bars into small logs and wood chips.

The machine includes:

- An electric motor transmits torque from it to the actuator.

- Drive and driven pulleys with a V-belt, a reduction V-belt transmission helps to increase torque and also reduce the rotation speed on the main part of the device.

- The cone is the main working body. A persistent conical thread is cut on the conical surface. When rotating inside the body being destroyed, the conical screw part cuts deeper, pulling the log towards the support.

- A wedge is an auxiliary device that helps destroy a drawn part.

The mechanism is simple, it is controlled by one person. During the work, you have to feed the block of wood onto the cone. Its design is more complex. The thrust thread is cut with a pitch of 7 mm.

Pros and cons of homemade models

Let's look at several of the most successful models of mechanical wood splitters, which are easy to manufacture, easy to use, safe and can simplify the process of processing wood into firewood as much as possible. Mechanical wood splitters are divided into several types. Let's look at their positive aspects and disadvantages.

Mechanized wood splitter

A simple version of a homemade wood splitter with a simple drive, which is the easiest to make, since it does not require large financial outlays. Even if the necessary parts are not available, acquiring them will not be particularly difficult. However, such a device will bring the greatest benefit only if the need for firewood is minimal. The disadvantages of such a wood splitter are the long handle on which the cutter is attached, and considerable effort. But even such a primitive mechanical wood splitter can significantly facilitate the work of preparing firewood.

Spring pressure wood splitter

A pressure or spring wood splitter implies certain costs for materials for manufacturing, but will significantly reduce the load on the worker’s muscles. The mechanics remain the same, but a spring shelf is added to the strut. The spring should not deform during compression and have a certain elasticity (Fig. 2). The height of the frame of such a wood splitter is usually 65-80 cm. The design is simple, takes up little space, but has its drawbacks:

- such a wood splitter requires complex work with an impact tool, which increases the risk of injury;

- it makes it much easier, but does not reduce the effort when preparing firewood to a minimum.

Vertical inertia wood splitter

Another simple version of a mechanical wood splitter. The advantages of such a wood splitter are ease of manufacture and low cost of material. This wood splitter will also make working with soft wood much easier. There are few disadvantages to such a wood splitter - it is useless for working with sticky varieties of wood, since the cleaver will get stuck in the log and getting it out, given the small size of the wood splitter, will be problematic.

Electromechanical wood splitter

In order to make your work as easy as possible in the process of converting wood into solid fuel through the use of a mechanical wood splitter, it is possible to install an electric drive on it, as shown in the photo (Fig. 4). However, the manufacture of such a wood splitter requires certain costs, knowledge in electromechanics, the ability to read drawings and the use of electric welding.

Step-by-step guide to making a spring log splitter

To complete the work you will need the following tools:

- Angle grinder (grinder) with a set of cutting discs and cleaning flap wheels.

- Welding machines and modern inverter-type household devices for welding steel structures are relatively small in weight. The process is carried out using direct current, so the welds are neat, and the molten metal of the electrode completely fills the joints between the parts.

- Clamps will help connect the parts to be welded.

- Measuring and marking tools will help produce blanks for future designs.

Materials needed:

- Channel No. 10...16 (the number determines the height expressed in centimeters).

- Profile pipe 40·60 mm (30·60 mm).

- Rail 300…400 mm long.

- I-beam No. 12...16.

- Corner No. 30...50.

- Bushing from the car suspension (it may have wear).

- Pipes with a diameter of 40...70 mm.

- A suspension spring for a passenger car, for example, from a VAZ.

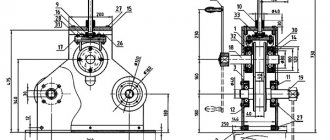

Before starting work, a preliminary design is drawn. Some craftsmen have mastered engineering design programs, with the help of which they can work out the details of a future product. Manufacturing details are shown below.

An approximate diagram will help you navigate the process of manufacturing the installation.

The support is made from the channel. A stand is welded to it. It is best to use an I-beam for the rack. This type of rolled product has high rigidity. Under prolonged loads, it is quite difficult to bend such an element.

To ensure stability of the base, jibs are welded to it. Additionally, stops are created from the existing pipes; they will prevent a possible fall of the entire product.

A support for the spring is cut from the channel. A square hole is sawn through it. This will allow you to securely fix the element on the rack in the future.

The installation height of the support is determined by the length of the existing spring. At the same time, they focus on the height of the entire wood splitter, as well as its ease of use for humans. It is convenient to lift a load located at waist height. You will have to lift it slightly above chest level.

All these considerations will allow you to choose the height of installation of the spring support on the strut.

The corners are used to make jibs. They will hold the support. Then, when the wood splitter is dynamically loaded, there will be no displacement of the supporting surface.

To fix the lower end of the spring, you need to make a cylindrical clamp. A small piece of pipe is used to make it. It is advisable to select a pipe according to the inner diameter of the spring. Then it will not move during operation.

There is a slot in the top of the rack. A bushing is installed in it. Then it is boiled. When installing, you must maintain perpendicularity to the rack. The hub axis must be parallel to the ground. For welding, a conductor is used that will allow the specified conditions to be met.

The shaft is installed in the sleeve. A rocker arm is welded to it (a channel is used). A small piece of pipe is mounted on the lower part of the rocker. The upper part of the spring will be fixed in it.

In order for the rocker to move freely, a window is cut in it; its dimensions depend on the parameters of the rack.

A profile pipe is welded to the rocker arm. A chisel is installed at its end. These tools are made from carbon steel U9...U10. The hardness of this metal is HRC 60...63. This tool will last a long time. During operation, it is easy to sharpen it using an angle grinder and a grinding wheel.

The wood splitter becomes operational. A load (part of the rail) is welded above the chisel. For ease of use, the handle is welded. To reduce damage to your hands, wear rubber elements. They will dampen vibration upon impact.

To work, you will need to install a large piece of log. Logs will be placed on it, which will have to be cut.

The log is held with one hand. They raise the cleaver and then strike.

The cleaver goes down. The fragment located below splits. The chisel goes lower. If a complete split occurs, the point hits the wood support and does not become dull.

History of the woodcutter. A few words about the evolution of the instrument

The most labor-intensive stage of the entire firewood preparation process is splitting the logs. And for this purpose a tool such as a wood splitter is used. In Rus', a woodcutter was a person who chops wood for a stove with a cleaver or an ax. Of course, at the age of 20, 30 or 40, a man can easily cope with this. Take a good swing, hit hard - and that's it! But by the age of 50, even for a person accustomed to physical labor since childhood, it is no longer easy to swing a cleaver, and therefore the need arose for a device for chopping wood that could make the work easier.

Today it is easy to acquire a wood splitter. It can be bought in a store (similar tools are produced by many companies), but the average rural resident does not always have the means to purchase it.

In this case, there is only one way out - to make this most useful device with your own hands; fortunately, you can find a great many photographs of a homemade wood splitter on the Internet.

Note! Mechanical wood splitters come in various types - manual, spring, cone. However, they all make work much easier (to a greater or lesser extent).

Organization of the production process

After making the wood splitter, you will have to start chopping firewood. In order for the job to be done easily, it is necessary to properly organize the production process.

The sawn fragments should be placed on one side. To get less tired, the distance should be only two or three steps.

It is advisable to place the chopped logs on a cart. The volume of the cart is small; no more than 30...40 kg of firewood will fit into it.

After filling, they need to be transported and placed on a woodpile. While the chopped firewood is being transported to the storage location, you can take a break from your main work. Changing activities is also a vacation.

Video: do-it-yourself mechanical wood splitter or how to assemble a wood splitter.

Advantages and disadvantages of using a wood splitter

Before making any unit with your own hands, you should ask yourself whether it is necessary on the farm. Buying or making a device yourself will require a lot of financial costs and effort; you need to weigh all the advantages and disadvantages. The advantages of the device include:

- Physical activity on a person. The machine operator only loads and controls the process; the main physical work is performed by the wood splitter mechanism.

- A device that includes an electric drive will cope with the tasks faster than doing the work manually.

- Convenient use preserves health and physical strength.

- Ease of operation and the absence of the use of physical force make it possible for all types of people to use the mechanism.

Application of a wood splitter

There are noticeably fewer disadvantages during operation, but they are still present, as with every device.

- Complex design of some models. For a more uniform log, the final result is a hydraulic splitter. Making such a mechanism at home with your own hands is expensive and will take a lot of time.

- High cost of finished structures. Buying a ready-made wood splitter will save time on manufacturing, but the cost of some models is so high that it does not justify itself during use.

It is necessary to understand that for a small area purchasing equipment is not advisable. Having a clear purpose and constant sale of firewood, you should think about buying or making your own wood splitter.