One of the most common metals around the world is tin. It has been used by blacksmiths for many centuries to make a wide variety of things. Even before the advent of the metallurgical industry, blacksmiths knew at what temperature tin melts and what physical and chemical properties it has. An important point is that the alloy of tin and copper can be considered the first manifestation of the development of metallurgy as a separate industry. The first artificial connection created by man largely depended on the fairly low melting point of the metals being joined.

Receipt and use

The element in question is not found in its pure form. It is part of cassiterite in the form of oxide. Many centuries ago, this metal was mined in open mines, but today such deposits are practically not developed. To obtain tin, the ore is purified. The concentration of the element is 1%. To obtain 1 kilogram of the metal in question, it is necessary to process about a hundredweight of ore.

The melting point of lead and tin is relatively low , which determines the possibility of using these materials at home at the time of soldering. Metals are sold in the form of a small rod.

The fact that the melting points of tin and lead are approximately the same determines the mixing of these elements to obtain an alloy with more attractive performance properties. In addition, silver, copper and other elements can be added to tin.

Tin and Lead (page 1)

TIN AND LEAD

Tin and lead are in the main subgroup of Group IV of the Periodic Table, which also includes carbon C, silicon Si and germanium Ge. The first two elements are non-metals, germanium belongs to the transition elements, and tin and lead are typical metals. Therefore, in this section, tin and lead will be considered separately from the other elements of the main subgroup of group IV.

Historical information.

Tin and lead are among the seven metals known to mankind since ancient times, so the exact date of their discovery is not known. It should be noted that until the advent of AD. e. tin and lead were often confused with each other, since both metals have similar properties. Echoes of this misconception have survived to this day: for example, in some Slavic languages (Bulgarian, Serbian, Czech, Polish) the metal lead is called the word tin.

The first mention of pure tin dates back to the 2nd millennium BC. e. The metal was obviously inaccessible and expensive, since tin objects are rare among Roman and Greek antiquities. The discovery of tin was most likely due to the accidental recovery of cassiterite (tin stone), the alluvial deposits of which occur at or close to the earth's surface. Another factor that contributed to the discovery of the metal was that tin ores are much easier to reduce than ores of other metals. But long before they learned to extract tin in its pure form, mankind widely used an alloy of tin and copper (bronze), which was obtained already in the 4th millennium BC. e. Throughout the Bronze Age, this alloy was, in modern terms, a strategic material: tools, weapons, household items, etc. were made from it.

The first lead products date back to the 3rd millennium BC. e. (Mesopotamia, Ancient Egypt). The metal was discovered due to the widespread availability of its ores and the ease with which it could be smelted - it was enough to put lead ore in a fire with a large amount of charcoal and create draft (constant access of fresh air).

The origin of the Latin and Russian names of both metals has not been established for certain. One version sounds like this: the Latin word stannum

(resistant) originally referred to an alloy of lead and silver, later to another alloy imitating it, containing about 67% tin, and only from the 4th century AD. e. this word began to be called tin.

Distribution in nature

. Tin and lead do not belong to the group of the most common elements in the earth's crust, but they are not rare metals either.

Both metals are found in nature mainly in the form of oxygen or sulfur compounds, among which cassiterite (tin stone) SnO2, stannite (tin pyrite) Cu2S∙FeS∙SnS2, galena (lead luster) PbS, anglesite PbSO4 and cerussite PbCO3 are of industrial importance. In total, about 25 tin and more than 100 lead minerals are known. Tin and lead are extremely rarely found in a native state.

Physical properties

. Tin has two allotropic modifications. Under normal conditions, the β-form (white tin) is stable - a shiny silvery-white metal. Gradually, the shine disappears as an oxide film forms on the metal surface. At temperatures below –13°C, white tin transforms into the α-form (gray tin); this transition occurs especially quickly at temperatures below –30°C. α-Tin is a gray metal similar in appearance to lead. In addition to color, the two modifications of tin differ in density and ductility. White tin, with a density of 7.29 g/cm3, is slightly heavier than gray tin, whose density is 5.85 g/cm3. β-Tin is a soft and ductile metal, it is easily rolled into thin foil (staniol), while gray tin does not have ductility and easily crumbles into powder.

There are many cases where products made of white tin turned gray in the cold and were destroyed. This phenomenon is called the “tin plague.” The reason for the destruction is a sharp increase in the volume of the metal, because the density of white tin is greater than that of gray tin, and therefore, with equal mass, α-tin will occupy 25-26% more volume compared to the β-form. The transition from one form of tin to another is facilitated by the contact of white tin with particles of the gray form, and it spreads like a “disease.” This “disease” is one of the reasons for the death of Scott’s expedition to the South Pole in 1912. On the way back, the participants were left without fuel due to the fact that it leaked through the tin-sealed tanks affected by the “plague”.

Lead is a dirty gray metal, but when cut fresh it has a bluish tint and shines. However, the shine quickly disappears as the metal is covered with a protective film of oxide. Lead is one of the heaviest metals: its density is 11.34 g/cm3, which is about one and a half times more than iron, or four times more than aluminum. It is not for nothing that in Russian the word “lead” is synonymous with “heavy”. In addition, lead is one of the softest metals and can be easily scratched with a fingernail or cut with a knife.

Both tin and lead belong to the group of fusible metals. Their melting points are 232°C and 327°C, respectively. Boiling points: for tin 2270°C, for lead 1750°C. But long before the boiling point is reached, tin and lead begin to evaporate. For tin, volatility begins at approximately 1200°C, for lead – at 700°C. The latter must be remembered by those who work with lead at elevated temperatures, since the metal itself, as well as its compounds, are toxic. Once in the body, lead accumulates in the bones, causing their further destruction.

The electrical conductivity of tin and lead is low for metals. If we compare both metals with copper, they are about 10 times worse at conducting electric current.

Chemical properties

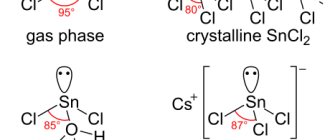

. The electronic configuration of tin and lead atoms ends at ns2np2, where n is the number of the last (outer) electron layer. Therefore, both metals can exhibit valences II or IV. Tin exhibits both valences equally, but tetravalent tin compounds are more stable. In lead, the divalent state predominates over the tetravalent state, so in most compounds it exhibits valency II. In addition, the atoms of both metals contain unfilled p and d orbitals, which affects the ability of tin and lead to form complexes.

Since tin and lead are located immediately before hydrogen in the electrochemical voltage series of metals, they can be classified as low-active metals. Moreover, the presence of an oxide layer on the metal surface affects the decrease in their reactivity.

At room temperature, tin and lead are resistant to most non-metals and combine only with chlorine and bromine, while tin exhibits valency IV, and lead exhibits valency II:

But if you select certain conditions, you can get tetravalent lead chloride (lead (IV) bromide and iodide do not exist, since tetravalent lead is a strong oxidizing agent and it would oxidize bromide and iodide ions to free halogens):

However, lead(IV) compounds are generally unstable and are easily converted to divalent lead compounds:

At elevated temperatures, the chemical activity of metals increases significantly, and they react with oxygen, fluorine, iodine, sulfur, selenium and tellurium. In addition, when heated, tin reacts with phosphorus and nitrogen. And again there is a difference in valence: tin, as a rule, exhibits valency IV, while lead exhibits valency II:

Only when reacting with sulfur are both metals divalent:

There is also tetravalent tin sulfide SnS2, which is obtained by indirect methods, for example, by passing hydrogen sulfide through acidified solutions of tin (IV) salts. Lead(IV) sulfide does not exist for the same reason that lead(IV) bromide and iodide are never formed.

Both metals do not interact with cold or boiling water, but at elevated temperatures they are able to decompose water vapor:

It is the inertness of tin in relation to water and oxygen under normal conditions that explains the use of this metal in the coating of tin containers for food products. In addition, metal tin and its corrosion products are relatively harmless to the human body. Lead was used for some time for these purposes, but after it became known about its toxicity, it was abandoned.

Since tin and lead are located in the series of metals to the left of hydrogen, they are able to react with acids. In this case, both metals exhibit valence II, with the exception of concentrated sulfuric and nitric acids - with them tin is already tetravalent. Due to the low chemical activity of metals, their dissolution in acids occurs extremely slowly. For example, dilute hydrochloric and sulfuric acids begin to have a noticeable effect on tin only when heated. At room temperature, the reaction occurs at a very low speed, making it almost impossible to notice the bubbles of the gas being released:

| Due to its large volume, this material is placed on several pages: 1 |

Metal melting

For tin, the melting point largely depends on whether there are impurities. The temperature at which the metal becomes plastic or liquid can vary from 145 to 250 degrees Celsius, depending on the composition. If necessary, you can melt a large amount of metal to fill it into a mold.

When choosing a material to create a mold, the following points are taken into account:

- The structure should not be wetted by liquid tin. Otherwise, the form may change its size.

- The material used must withstand temperatures of at least 250 degrees Celsius. Otherwise, after filling, the mold will lose its basic performance qualities.

It is worth considering that in liquid form the metal in question can oxidize upon contact with air. The solid substance, on the contrary, has increased resistance to oxygen corrosion.

A three-component alloy based on lead has become quite widespread in electrical engineering. Tin and silver can be used as additional components. When producing such an alloy, attention is paid to the fact that the metal concentration should not be less than 95%. With this option, the combination of substances has a melting point of about 220 degrees Celsius.

Technical Parameters of Tin

Tin - from spoon to radiator

This chemical element has been known for more than 3,500 years and was originally intended for the manufacture of tableware. Modern consumption of tin is associated with the canning industry.

A patent for a method of storing food in tins belongs to a chef from France. Since 1810, humanity has been able to store food for a long time.

Tin is the main component of solders used for soldering and tinning of heat exchangers, radiators of automobile engines, and tinning of medical and food equipment.

The material is used for the production of tin bronze, which has excellent mechanical, casting, and anti-corrosion properties. Such alloys are used in parts intended for use in special conditions and under special loads.

An alloy with a low coefficient of friction is babbitt. It contains 83% tin, antimony and copper. It is used in the production of bearings. Thanks to the stable compound of antimony and copper, the alloy has high hardness.

The bearing operating mechanism and composition components eliminate the occurrence of mechanical damage on the surface of the part.

Tin has specific physical properties:

- Its deformation is accompanied by a sound generated as a result of shear under the influence of force.

- At temperatures of -39 °C and + 161 °C, tin turns into powder.

History knows cases of such transformations. Buttons made from pure material lost their shape in the cold, and the “tin plague” destroyed metal ingots.

Solder making

In order to improve the performance characteristics of the solder, a small amount of antimony is added to its composition. This type of solder is used for soldering various radio components, especially critical areas.

When choosing a solder, you should pay attention to the alloy containing silver . Its performance qualities can be called:

- The service life is significantly increased. Due to silver, the structure becomes more resistant to the oxidation process.

- By increasing the concentration of silver, it becomes possible to use solder in the manufacture of various parts of industrial equipment. However, silver significantly increases the cost of the alloy, as well as the manufactured product. This is why alloys with high concentrations of silver are used to make important parts.

Zinc is being added to the composition , but such alloys are less popular. This is due to the fairly high chemical activity of zinc. Due to interaction with the environment, such an alloy quickly deteriorates. Solder pastes are produced based on a zinc-containing mixture, which have a relatively short service life. The melting point in this case is 200 degrees Celsius.

Pure tin has also been used as a semiconductor solder for many years. The melting point of this element in its pure form is 240 degrees Celsius. They are used exclusively in industry, which is associated with high cost. In its pure form, due to a significant increase in temperature, the structure of tin is reconstructed, black spots appear on the surface, which indicate a significant deterioration in its basic qualities.

Characteristics of individual brands

All representatives of the category belong to low-melting solders. Tin-lead alloys, regardless of the ratio of the starting metals, melt at temperatures up to 450 °C. The characteristics of POS solders are regulated by GOST.

Manufacturers supply solder products:

- in cast ingots;

- in the form of wire products;

- ribbon-shaped foil;

- tubular products with fluxes inside;

- powders or paste.

In general, there is a clear pattern. The lower the mass fraction of tin in tin-lead solder, the higher its melting point and the lower its strength properties.

More than half tin

In an alloy containing 90% tin, the rest of the mass is lead. POS-90 solder has a melting point of 220 ℃.

It is used for soldering products that will subsequently be subjected to galvanic treatment with gold or silver.

Tin-lead solder with 61% tin has a more accessible melting point of 191 ° C. POS-61 is used for the manufacture of thin contacts for parts made of copper and steel alloys in various measuring instruments. The areas where the alloy is applied should not be exposed to strong heat.

Solder can be used for soldering wires up to 0.08 mm thick in a winding. It may be exposed to high frequency currents.

Read also: Gear tooth module table based on diameter

Solder is used in all situations that require great strength and reliability of the connection of radioelements and microcircuit components. They can be used to solder wires protected by a polyvinyl chloride sheath.

Tin-lead solder containing equal shares of two metals is designated as POS-50. It melts at 222℃. Applicable in all situations where POS-61 can be used.

The difference is that this solder has a higher melting point. If the contact can heat up this quality will be useful.

Less than half a tin

Seams for which there is a high probability of heating to even higher temperatures should be soldered using POS-40 solder. The melting point of a tin-lead alloy containing from 39% to 41% tin is 238 °C.

Please note that the presented indicators are typical for the final melting of the alloy. The process begins at slightly lower temperatures.

The alloy is designed to work with wires and parts made of different metals. The resulting seam has a smaller margin of safety than joints made with alloys with a higher mass fraction of tin. Solder is used to make connections that are not subject to heavy mechanical stress.

The POS-30 alloy has an even higher final melting temperature. It is equal to 256 ℃.

This tin-lead solder is used for soldering non-stress joints in copper and steel materials.

POS-18 solder finally melts at 277 ℃. The resulting seam has little mechanical stability.

The presented tin-lead alloy can be used for tinning, soldering unloaded copper parts, and galvanized iron products.

The tin-lead alloy, containing only 10% tin, has the maximum melting point in this series, equal to 299 ℃, and the minimum strength.

POS-10 can be used for soldering and tinning contacts on the surface of relay devices. GOST allows the use of the composition for processing control points in the furnaces of steam locomotives. Currently, steam locomotives remain only in museums; sometimes they have to be repaired and restored.

Solders marked POS are antimony-free consumables.

Features of production and processing

Consumable raw materials are obtained from ore. For example, to obtain 1 kilogram of pure material, it is necessary to process 100 kg of ore. Both materials melt at low temperatures. To manufacture the alloy, the following features must be taken into account:

- When making a casting mold, you must use a material that is not susceptible to wetting by molten consumable metals.

- The mold must withstand heating at temperatures above 250 degrees.

- Molten metals quickly oxidize when exposed to the environment. Solid metal is protected from oxidation.

When it comes to making solder, antimony is added to the compound. Some craftsmen add silver. It has the following features:

- Silver protects the material from rust formation.

- Due to the addition of noble metal, the price tag for finished solder increases, but its functionality expands.

There are solders with added zinc. However, they are rarely used. Zinc actively reacts to environmental factors. It begins to collapse, which leads to a violation of the integrity of the product. It is better to use a mixture of antimony, tin and lead. This solder is used to solder radio components, contacts, and wires. By changing components, craftsmen achieve the desired characteristics from a consumable. We must not forget about the use of flux.

The alloy of tin and lead has special characteristics. They change after adding alloying components. Ready-made compounds are used for the manufacture of solders, wear-resistant parts, dishes, cutlery, and cans.

How to distinguish lead and silver?

Silver jewelry has been popular since ancient times, being a more affordable alternative to gold. Therefore, many try to pass off other metals as silver, including lead. In most cases there is no particular problem in distinguishing them from each other, but beginners in this matter may have difficulties. So here are a few obvious differences you need to know.

Silver has a silvery-white color, with almost 100% light reflectance. Over time, this metal can darken, which is a natural reaction (silver becomes coated with sulfide). If it is real silver, then you can clean it with a special cream or toothpaste - you won’t be able to do this with lead, which also darkens.

It looks like silver, but has a bluish tint. Another simple way to check is with boiling water. You need to immerse the silver and lead product in boiling water for a few seconds and then remove it. Silver will get quite hot, but lead will not because it has low thermal conductivity.

Lead itself is a soft metal, so it can be easily bent (silver is used to make jewelry, so it has a higher density). At the same time, silver does not leave dark marks on the paper, unlike this metal.

We have experienced employees who can easily distinguish one non-ferrous metal from another. If additional analysis is needed, the scrap is sent to the laboratory. Therefore, if you have accumulated a certain amount of non-ferrous scrap metal and you cannot determine its type, then contact our collection points, where they will help you with this issue. We always adequately assess the amount of impurities in scrap, so we offer high prices when purchasing.

Tinning process.

Tinning (tin plating) is the process of applying a thin layer of tin or an alloy of tin with lead, bismuth, antimony, zinc, copper, nickel, as well as more exotic indium and gallium, to the surface of products.

You can tin copper, brass, bronze, carbon and stainless steel, aluminum and its alloys, titanium, ZAM.

Potential Sn0/Sn2+ = -0.136 V, Sn0/Sn4+ = +0.015 V, therefore, tin is more electronegative than copper and more electropositive than all other traditional bases. For this reason, tin-based coatings can electrochemically (anodically) protect only copper from corrosion. For other materials, tin will be the cathode and will provide protection only if there are no pores, chips or through scratches.

In general, tin coatings provide good screwability of threaded connections, solderability, and tightness of assemblies. Tin coating is a preparatory operation before filling bearings.

Tin coatings are characterized by good adhesion to the base metal, high elasticity, resistance to sulfur compounds and to tropical climates.

2.1 Tinning with pure tin.

The main area of application for pure tin coatings is the food industry. Tin forms complexes with organic acids in a sealed environment, as a result of which its potential shifts to the positive region and it becomes an anode with respect to iron. This property, as well as the almost complete harmlessness of simple tin compounds, made it possible to use it to protect the internal surfaces of cans. In the 20th century, about 50% of the mined tin was used for the production of white (tinned) tin. These same properties of tin have made it possible to use coatings based on it for anti-corrosion protection of a wide range of food equipment.

In electrical engineering, tin coatings are used to protect copper cables from the destructive effects of sulfur contained in rubber insulation; for soldering contacts; to create an easily break-in electrically conductive layer between the rubbing surfaces. Tin coatings are plastic and withstand mechanical loads (rolling, stamping, drawing).

Electrochemical tin coatings are easy to obtain, which is ensured, in particular, by the high current efficiency of tinning electrolytes, but they have a number of problematic properties:

• In the case of long-term storage, the growth of thread-like crystalline formations is observed on their surface, which grow in length up to 3-5 mm with a thickness of several microns. These formations, called “whiskers,” can cause a short circuit inside electrical and radio equipment, and, accordingly, lead to its failure. The exact cause of such phenomena has not yet been established. It has been observed that the material on which the coating is deposited influences the rate of whisker formation. So, in particular, on a tin coating applied directly to brass, without a technological sublayer, thread-like crystals appear more often and grow faster than on a steel base.

• There is a theory that under the influence of impurities in the coating, internal compressive stresses of a specific nature arise, which is the main reason for the growth of threadlike whiskers. Impurities in the coating can be mechanical inclusions (particles of a foreign solid phase), have a diffusion nature (diffusion from the base metal into the coating), and can also be included in the deposit during coprecipitation with the base coating. Also, the cause of whisker growth is considered to be the presence of stress in the base metal.

• “Tin plague” - transition from a compact allotropic modification to amorphous tin. When the temperature drops below +13.2ºС, a phase transition occurs from compact white tin to powdery gray tin. The process proceeds intensively at temperatures below -30 °C and is accompanied by an increase in the specific volume of the metal, as a result of which the coating is completely destroyed.

• One of the main problems with pure tin is that it has a very short life as a solder plating. Theoretically, this period is two weeks. In production practice, it has been established that after 2-3 days of storage, soldering becomes almost impossible. This is due to the fact that pure tin coating is very porous and contains a large number of impurities. The solderability of a tinned surface may also decrease due to the formation of intermetallic compounds such as Cu3Sn, Cu6Sn5 at the copper-tin interface, which lose their ductility even at a small thickness (3 µm).

To preserve the solderability properties and reduce the porosity of the coating, the tinned surface must be melted. Melting is carried out by immersion in glycerin at 230 ºС, which is very energy-consuming and increases the final cost of the coating.

2.2 Tin plating with tin-copper alloy (bronzing).

Features of the functional properties and appearance of the tin-copper alloy are determined by the percentage of components. With a content of 2 to 3% tin, the coating has a copper-red color; when the percentage of tin increases to 15-20, the coating becomes golden yellow (yellow bronze), and at 35% tin it acquires a silver-white color, close to tin ( white bronze).

Yellow bronze coatings on steel exhibit high corrosion resistance in cold and boiling tap water. Yellow bronze has low porosity and can be used both as an independent coating and as a sublayer, for example, before chrome plating.

Coatings with a high tin content (more than 35%) have high porosity and cannot be used for protection in aggressive corrosive environments. White bronze has a very decorative appearance and is used as a replacement for nickel plating. Also interesting are coatings with a tin content of 45% or more - they can be painted black by anodic oxidation.

The electrical properties of the coating play a major role: the resistivity of electrolytic bronze containing 25% Cu and 75% Sn is 0.189 Ohm*mm2 /m, and that of 60% Cu and 40% Sn is 0.248 Ohm*mm2 /m. As is known, the resistivity of silver is 0.015 Ohm*mm2 /m, Cu is 0.017 Ohm*mm2 /m, and Sn is 0.143 Ohm*mm2 /m. The data presented indicate that white bronze coating is inferior in electrical properties to silver and copper coatings. However, when working in an environment containing sulfur compounds, the transient resistance of bronze coatings is more stable than silver ones. The value of the electrical resistance of the alloy increases synchronously with the increase in its hardness, the maximum corresponds to a Sn content of 40-45%.

2.3 Tin plating with tin-lead alloy.

Due to its chemical resistance, the Sn-Pb alloy is actively used as a protective anti-corrosion coating.

The alloy is low-melting, has a high density and low mechanical strength, and can be used to ensure sintering and as an anti-friction coating.

The coating ensures the uniformity of the soldered seam, eliminating the formation of heterogeneous systems with a complex structure that cause brittleness of the joint.

The average electrical conductivity of tin-lead coatings is comparable to that of gold coatings.

A positive property of the alloy should also be considered to ensure the constancy of the contact resistance when changing contact pressures.

Lead-tin alloy coatings containing only 5% tin have been found to provide significantly better corrosion protection than lead coatings in marine environments. Alloys with a 50/50 Sn-Pb content exhibit the greatest chemical resistance. The best antifriction properties are provided by an alloy with a composition of 8-12% Sn. Such coatings also act as a lubricant when stamping parts from sheet steel.

The use of POS-60 coating (tin 60%, lead 40%) allows you to intensify the soldering process by reducing the melting temperature of the alloy to 183 ºС

2.4 Tin plating with tin-zinc alloy.

Sn-Zn alloys have higher protective properties under atmospheric corrosion conditions compared to pure zinc. Its operation is allowed at high humidity and significant temperature fluctuations. An alloy containing 20-25% zinc has the best corrosion resistance. It is electrochemically anodic in relation to steel, and its porosity, compared to pure tin, is significantly lower. When the zinc content in the alloy increases to 50%, the corrosion resistance approaches that of pure zinc coating. When the alloy contains 10% zinc or less, the coating becomes cathodic in nature with respect to steel and ceases to protect it electrochemically.

An alloy containing 20% zinc is easy to solder and is solderable longer than zinc. It is also easy to polish.

2.5 Tin plating with tin-nickel alloy.

Coating with tin-nickel alloys is recommended to impart solderability to the surface of copper and steel parts with acid fluxes while protecting them from corrosion. Also, coating with an alloy containing 35-40% nickel can be used instead of chrome coatings. The microhardness of the alloy deposits is in the range of 4000-6000 MPa, the wear resistance is several times higher than the wear resistance of nickel coating.

The coating has high decorative characteristics and, due to its low porosity, can be used with one copper sublayer, without intermediate nickel plating. Subject to certain electrolysis conditions, the coating can be obtained shiny directly from the bath, without the use of shine-forming additives. The alloy can be used instead of tinning when higher mechanical properties than tin plating are required.

It is very advisable to use a tin-nickel alloy for parts to be pressed into plastics.

Electrolytic alloy Sn-Ni (65% Sn) is an intermetallic compound, stable up to 300 ºС. This coating is not recommended for use on parts that are subject to repeated bending or act as springs, as it is prone to peeling and cracking due to high internal stresses.

Porosity tests have shown that steel samples coated with a Sn-Ni alloy 15 µm thick with a copper sublayer 20 µm thick have virtually no pores and have high corrosion resistance in a salt fog environment with alternating heating. In addition, it was found that the coating retains solderability for several months, corresponding to a freshly deposited coating. After two years of storage, the solder strength of the tin-nickel coating decreased by 20%, and that of fused tin by 60%

2.6 Tin plating with tin-bismuth alloy.

Tin-bismuth coating has all the advantages of pure tin, but also has a number of advantages over it. Bismuth in the coating prevents the allotropic transition of tin from white to gray, allows you to maintain solderability for up to a year, eliminates the growth of “whiskers,” and increases corrosion resistance. The coating exhibits the best solderability with a low bismuth content in the alloy - from 0.5 to 2%. Alloys of tin and bismuth form eutectic-type systems, and with a bismuth content of up to 5%, the formation of a stable solid solution is expected at temperatures up to 231.8 °C.

2.7 Tin plating with tin-antimony alloy.

The tin-antimony alloy (5-10% Sb) is identical in properties to tin-bismuth. Tin-antimony thermal alloys with an antimony content of up to 0.5% are not susceptible to the “tin plague”. The main advantage of the tin-antimony alloy is that it does not contain highly toxic elements such as bismuth or lead, but this does not impair its performance properties.

2.8 Tin alloys, rarely used in electroplating.

2.8.1 Cadmium-tin alloy.

Cadmium-tin alloys are a simple eutectic mixture.

Alloys containing 25% tin and 75% cadmium exhibit high protective properties in salt fog environments. There is evidence that cadmium-tin coatings (40-60% cadmium) can be passivated in a chromate solution with increased resistance to corrosion. Tests have shown that cadmium-tin coatings in an environment of heat and moisture are not inferior in corrosion resistance to coatings with Cd-Zn and Sn-Zn alloys. During tests, dense, non-erasing films of corrosion products are formed on the surface of the Cd-Sn coating, increasing their protective properties.

Of particular interest is the use of cadmium-tin alloy for corrosion protection of steel parts of aircraft equipment. The corrosive environment, in this case, is especially aggressive due to sudden temperature changes, moisture condensation on the surface of parts, as well as exposure to volatile plastic products, insulating materials, lubricating oils and fuels.

2.8.2 Copper-zinc-tin alloy.

In practice, Cu-Zn-Sn electrolytic alloy is difficult to control by percentage of components. The alloy can be obtained in various colors: from silver-steel to golden. The color of the precipitate can be varied by the temperature of the solution and by adjusting the current density.

Alloys of this composition retain their ability to be soldered for a long time and have fairly high hardness and wear resistance. In industry they can be used to protect threaded and precision parts from corrosion, for which a large coating thickness is not allowed. Golden-colored coatings can be used to decoratively imitate gold. During the study, copper-zinc-tin and copper-cadmium-tin alloys were tested in a tropical humid climate. Tests have shown that these three-component alloys protect steel less well than coatings with Zn-Cd, Sn-Zn and Sn-Cd dual alloys with appropriate passivation.

2.8.3 Lead-tin-zinc alloy.

The introduction of a third component into the lead-tin alloy makes it possible to further improve the protective, antifriction and other functional properties of coatings. To reduce tin consumption when coating parts of internal combustion engines, it is proposed to use a three-component alloy: 91-93% lead; 6-8% tin; 0.5-5% zinc. The use of lead and zinc coatings for such parts is not effective due to their low corrosion resistance to organic compounds and elevated temperatures. Under these conditions, tin and cadmium coatings reliably protect parts from corrosion, but Sn and Cd are among the scarce and expensive metals.

The Pb-Sn-Zn coating has the highest corrosion resistance with a zinc content of no more than 1%. In this case, the protective properties of the coating in high temperature environments and organic compounds are much higher than those of tin and cadmium coatings. In addition, the pronounced protective properties of the three-component alloy allow the use of coatings of small thickness (3-5 microns).

2.8.4 Lead-tin-copper alloy.

The precipitated alloy contains about 90-93% lead; 6-9% tin and 0.75-2% copper. The alloy is recommended for coating bearings and for ensuring run-in, as it exhibits excellent anti-friction properties and resistance in an environment of organic compounds.

2.8.5 Lead-tin-antimony alloy.

Additions of antimony to a lead-tin alloy have an effect similar to the addition of copper: improving the antifriction properties of the coating, resistance to erosion and abrasion. The precipitated alloy contains 82% lead, 11% tin, 7% antimony. An alloy containing 93-97% lead, 0.5-1% tin and 5-6% antimony has also been used in industry.

It is advisable to use it to improve the antifriction properties of bearing shells with a porous chrome coating. Coating with a three-component alloy with a thickness of 20-30 microns significantly improves the run-in properties of chrome liners and increases their corrosion resistance.

2.8.6 Lead-tin-indium alloy.

For bearing shells operating at high specific pressures and high sliding speeds, coatings with alloys containing indium are recommended. It is possible to use a coating containing 42% lead, 42% tin and 16% indium for these purposes.