Our world is full of amazing facts that are interesting to many people. The properties of various metals are no exception. Among these elements, of which there are 94 in the world, there are the most ductile and malleable, and there are also those with high electrical conductivity or a high resistance coefficient. This article will talk about the hardest metals, as well as their unique properties.

Iridium

Iridium ranks first in the list of metals that are distinguished by the greatest hardness. It was discovered at the beginning of the 19th century by the English chemist Smithson Tennant. Iridium has the following physical properties:

- has a silvery-white color;

- its melting point is 2466 °C;

- boiling point – 4428 oC;

- resistance – 5.3·10−8Ohm·m.

Because iridium is the hardest metal on the planet, it is difficult to process. But it is still used in various industrial fields. For example, it is used to make small balls that are used in pen nibs. Iridium is used to make components for space rockets, some parts for cars, and more.

Iridium

Very little iridium occurs in nature. Findings of this metal are a kind of evidence that meteorites fell in the place where it was discovered. These cosmic bodies contain significant amounts of metal. Scientists believe that our planet is also rich in iridium, but its deposits are closer to the Earth's core.

Ruthenium

The second position on our list goes to ruthenium. The discovery of this inert silvery metal belongs to the Russian chemist Karl Klaus, which was made in 1844. This element belongs to the platinum group. It is a rare metal. Scientists have been able to establish that there is approximately 5 thousand tons of ruthenium on the planet. It is possible to extract approximately 18 tons of metal per year.

Ruthenium

Due to its limited quantity and high cost, ruthenium is rarely used in industry. It is used in the following cases:

- a small amount of it is added to titanium to improve corrosion properties;

- its alloy with platinum is used to make electrical contacts that are highly resistant;

- ruthenium is often used as a catalyst for chemical reactions.

Tantalum

A metal called tantalum, discovered in 1802, takes third place on our list. It was discovered by the Swedish chemist A. G. Ekeberg. For a long time it was believed that tantalum is identical to niobium. But the German chemist Heinrich Rose managed to prove that these are two different elements. Scientist Werner Bolton from Germany was able to isolate tantalum in its pure form in 1922. This is a very rare metal. The largest deposits of tantalum ore were discovered in Western Australia.

Tantalum

Due to its unique properties, tantalum is a highly sought-after metal. It is used in various fields:

- in medicine, tantalum is used to make wire and other elements that can hold tissue together and even act as a bone substitute;

- alloys with this metal are resistant to aggressive environments, which is why they are used in the manufacture of aerospace equipment and electronics;

- tantalum is also used to create energy in nuclear reactors;

- the element is widely used in the chemical industry.

Chromium

Chromium is one of the hardest metals. It was discovered in Russia in 1763 in a deposit in the Northern Urals. It has a bluish-white color, although there are cases where it is considered a black metal. Chrome cannot be called a rare metal. The following countries are rich in its deposits:

- Kazakhstan;

- Russia;

- Madagascar;

- Zimbabwe.

Chromium

There are chromium deposits in other countries as well. This metal is widely used in various branches of metallurgy, science, mechanical engineering and others.

Beryllium

The fifth position in the list of the hardest metals goes to beryllium. Its discovery belongs to the chemist Louis Nicolas Vauquelin from France, which was made in 1798. This metal has a silvery-white color. Despite its hardness, beryllium is a brittle material, which makes it very difficult to process. It is used to create high-quality loudspeakers. It is used to create jet fuel and refractory materials. The metal is widely used in the creation of aerospace technology and laser systems. It is also used in nuclear energy and in the manufacture of X-ray equipment.

Beryllium

Who is for them?

But a person would not be himself if he had not found a replacement for iridium with osmium. Since it is inappropriate and too expensive to use them, then attention was not without success turned to other metals that have found their application in different situations and industries for the creation of new alloys, composite materials, production of equipment, machines and mechanisms for both civil and military use:

- Titanium. It is with the beginning of the use of this lightweight, but at the same time very hard, durable, ductile, refractory metal that the appearance of jet civil and military aircraft, including those reaching speeds many times faster than sound, is associated. It is also widely used and is indispensable in the creation of space technology, modern sea vessels, ocean liners, and in many other industries.

- Tungsten. A very hard, most refractory metal, which also has great resistance to any external influences. Highly in demand by humanity.

- Chromium, vanadium, manganese. This trio of metals, together and separately, as well as with the adjoining nickel, has been actively used by metallurgists for decades to create new types of steel, special hard alloys with various unique properties.

Although the hardest metal in the world, or rather two of them - iridium and osmium, have shown their unique properties only in laboratory conditions, and also as insignificant percentage additions to alloys, other compounds should be used to create new materials needed by humans be grateful to nature and for this gift. At the same time, there is no doubt that the inquisitive minds of talented scientists and brilliant inventors will come up with new substances with unique properties, as has already happened with the synthesis of fullerenes, which turned out to be harder than diamond, which is already surprising.

Osmium

The list of the hardest metals also includes osmium. It is an element belonging to the platinum group, and its properties are similar to iridium. This refractory metal is resistant to aggressive environments, has a high density, and is difficult to process. It was discovered by the scientist Smithson Tennant from England in 1803. This metal is widely used in medicine. Elements of pacemakers are made from it, and it is also used to create the pulmonary valve. It is also widely used in the chemical industry and for military purposes.

Osmium

Features of a pure substance and its impurities

Another characteristic feature of the material is paramagneticity. Such a substance is not attracted by a magnetic field, but is also not capable of being pushed out of it. For production processes, they try to use titanium in the most pure form without adding impurities, since this is how it can withstand maximum loads.

Any non-metal impurities added to titanium make the standard material more brittle. Metal impurities significantly reduce its heat resistance. Titanium, even with a minimum of impurities, is technical. Typically, this type is the most resistant to corrosion.

Important. An amazing property of the material is that minimal additions of other substances radically change the known characteristics of titanium.

Compared to other commonly used elements, titanium is 2 times stronger than iron and 6 times stronger than aluminum. The metal in question resists corrosion very easily. Its anti-corrosion performance is significantly better than that of aluminum and stainless steel.

How is titanium obtained?

In terms of distribution in nature, the material in question is in 10th place. However, it is most often found in the form of titanic acid in minerals. Such titanium ores include:

- brookite;

- anatase;

- rutile;

- pervoksit.

These minerals are most common in Russia, the USA, Great Britain, Japan, as well as Spain, Belgium, and France.

There are 4 known ways to obtain this material:

- Electrolysis method. The compounds of the substance in question are exposed to enormous current, which separates the mineral into its components.

- Magnesium-thermal method. At the first stage, titanium dioxide is obtained. Then it should be chlorinated in the presence of a special catalyst, since the process itself is too inhibited and sluggish. The result is a gas that is reduced with magnesium or sodium. The compound is heated, and then titanium is smelted from the resulting substance.

- Refining. A method where titanium dioxide is treated using iodine vapor. The result is titanium iodide, which is heated as much as possible and exposed to electric current. After the end of the effect, two substances are obtained: iodine and titanium itself.

- Calcium hydride method. First you need to get titanium hydride. After this, the substance is separated into all its components.

In mass industry, methods 2 and 4 are most often used, since they help obtain pure material at low cost.

Rhenium

The transition silver metal rhenium takes the seventh position on our list. The assumption about the existence of this element was made by D.I. Mendeleev in 1871, and chemists from Germany managed to discover it in 1925. Just 5 years after this, it was possible to establish the extraction of this rare, durable and refractory metal. At that time, it was possible to obtain 120 kg of rhenium per year. Now the amount of annual metal production has increased to 40 tons. It is used for the production of catalysts. It is also used to make electrical contacts that can self-clean.

Rhenium

How Nitinol Became SM-100

Interest in this metal came many years later and, as usual, “from where we were not expecting it.” Guess once who might be interested in a high-hardness and rare alloy that gives a bright and unpredictable pattern during heat treatment?

Knife designer Duane Dwyer of Strider Knives became interested in nitinol back in 2005, when he was looking for a super-hard metal alloy that would not rust. He approached metallurgist and friend Scott Devanna, vice president of technology at SB Specialty Metals, and inquired about the possibility of producing nitinol using a technology that had never been used.

Shortly thereafter, Scott introduced Duane to Eric Bono, a metallurgist and knife maker who was also interested in nitinol, and the three of them began exploring the possibilities of creating blades from the alloy.

With his knowledge and experience in metallurgy, Bono developed a working version of the alloy, called "SM-100", in powder metal form in 2006. Several more years were spent refining the alloy and processes, and in 2009 Bono and his business partner Fred Yolton formed Summit Metals LLC to produce SM-100.

Since then, the SM-100 (60% nickel and 40% titanium), which the company markets under the name "HIPTiNite", has gained interest not only from the knife industry, but also from the US space agency NASA and representatives of various Formula 1 teams.

Tungsten

Silver-gray tungsten is not only one of the hardest metals, it also leads in refractoriness. It can only be melted at a temperature of 3422 °C. Due to this property, it is used to create incandescent elements. Alloys made from this element have high strength and are often used for military purposes. Tungsten is also used to make surgical instruments. It is also used to make containers in which radioactive materials are stored.

Tungsten

How are metals produced?

Metals are extracted from ores. To determine their deposits, various established methods and calculation systems are used. Metal production is carried out in several stages:

- Development of an ore deposit. It can be open or closed. Sometimes ore mining methods are combined. The open method is less dangerous.

- Ore beneficiation. This is carried out to isolate useful components (ore concentrate) from it, which will be used in further production.

- Metal extraction. It is carried out using electrolytic or chemical reduction.

- Metal smelting. It is performed in industrial ovens when heating consumable raw materials to maximum temperatures. Additionally, a reducing agent is used.

Ore deposit development

Uranus

One of the hardest metals is uranium. It was discovered in 1840 by the chemist Peligo. D.I. Mendeleev made a great contribution to the study of the properties of this metal. The radioactive properties of uranium were discovered by the scientist A. A. Becquerel in 1896. Then a chemist from France called the detected metal radiation Becquerel rays. Uranium is often found in nature. The countries with the largest deposits of uranium ore are Australia, Kazakhstan and Russia.

Uranus

History of discovery

The concept of “metal” appeared in the Russian language in the 15th–16th centuries. It came from the German language. Since the 16th century, this concept has appeared in various books. This word began to gain popularity under Peter 1. Initially, it was used to describe various ores, alloys, and minerals. Lomonosov shared these concepts.

It is very difficult to find pure metal in nature. More often they are found in various ores and minerals. They can form various natural compounds - carbonates, oxides, sulfides.

Peter I

Titanium

The final place in the top ten hardest metals goes to titanium. For the first time this element was obtained in its pure form by the chemist J. Ya. Berzelius from Sweden in 1825. Titanium is a lightweight silver-white metal that is highly durable and resistant to corrosion and mechanical stress. Titanium alloys are used in many branches of mechanical engineering, medicine and the chemical industry.

Titanium

Assortment of metal products “Ruler - S”

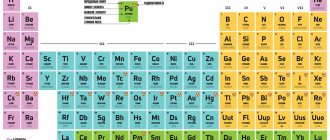

The hardest metal is chromium and titanium.

Chromium is an element of the secondary subgroup of the sixth group of the fourth period of the periodic system of chemical elements of D.I. Mendeleev, with atomic number 24. It is designated by the symbol Cr (Latin: Chromium). The simple substance chromium (CAS number: 7440-47-3) is a hard metal of a bluish-white color.

Chromium occurs in nature mainly in the form of chromium iron ore Fe(CrO2)2 (iron chromite). Ferrochrome is obtained from it by reduction in electric furnaces with coke (carbon): FeO Cr2O3 + 4C → Fe + 2Cr + 4CO↑

Chromium is a fairly common element; its content in the earth's crust is approximately 0.02% (22nd place). Ferrochrome is used for the production of alloy steels. To obtain pure chromium, the reaction is carried out as follows: 1) iron chromite is fused with sodium carbonate (soda ash) in air: 4Fe(CrO2)2 + 8Na2CO3 + 7O2 → 8Na2CrO4 + 2Fe2O3 + 8CO2↑ 2) sodium chromate is dissolved and separated from iron oxide; 3) convert the chromate to dichromate, acidifying the solution and crystallizing the dichromate; 4) pure chromium oxide is obtained by reduction of dichromate with coal: Na2Cr2O7 + 2C → Cr2O3 + Na2CO3 + CO↑ 5) metallic chromium is obtained using aluminothermy: Cr2O3+ 2Al → Al2O3 + 2Cr + 130 kcal 6) electrolytic chromium is obtained from a solution of chromic anhydride using electrolysis in water containing sulfuric acid. In this case, mainly 3 processes take place at the cathodes: reduction of hexavalent chromium to trivalent chromium with its transition into solution; discharge of hydrogen ions with the release of hydrogen gas; discharge of ions containing hexavalent chromium with precipitation of metallic chromium; Cr2O72− + 14Н+ + 12е− = 2Cr + 7H2O

Production of chromium The raw material for the industrial production of chromium is chromium iron ore. Its chemical processing leads to Cr2O3. Reduction of Cr2O3 with aluminum or silicon produces chromium metal of low purity: Cr2O3+Al=Al2O3+2Cr 2Cr2O3+3Si=3SiO2+4Cr Purer metal is obtained by electrolysis of concentrated solutions of chromium compounds.

Titanium - (Latin Titanium; denoted by the symbol Ti) - an element of the secondary subgroup of the fourth group, the fourth period of the periodic table of chemical elements of D.I. Mendeleev, with atomic number 22. The simple substance titanium (CAS number: 7440-32-6) - light metal of silvery-white color. Exists in two crystal modifications: α-Ti with a hexagonal close-packed lattice, β-Ti with cubic body-centered packing, α↔β transition temperature 883 °C

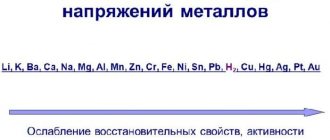

The softest metals are potassium, rubidium, cesium .

Potassium is an element of the main subgroup of the first group, the fourth period of the periodic system of chemical elements of Mendeleev D.I., with atomic number 19. Denoted by the symbol K (Latin Kalium). The simple substance potassium (CAS number: 7440-09-7) is a soft alkali metal with a silvery-white color. In nature, potassium is found only in combination with other elements, for example, in sea water, as well as in many minerals. It oxidizes very quickly in air and very easily enters into chemical reactions, especially with water, forming an alkali. In many respects, the chemical properties of potassium are very similar to sodium, but in terms of biological function and use by the cells of living organisms, they are still different.

Rubidium is an element of the main subgroup of the first group, the fifth period of the periodic table of chemical elements of Mendeleev D.I., with atomic number 37. It is designated by the symbol Rb (lat. Rubidium). The simple substance rubidium (CAS number: 7440-17-7) is a soft alkali metal with a silvery-white color.

Cesium is an element of the main subgroup of the first group of the sixth period of the periodic table of chemical elements of Mendeleev D.I., atomic number 55. Denoted by the symbol Cs (lat. Caesium). The simple substance cesium (CAS number: 7440-46-2) is a soft alkali metal of a silvery-yellow color. Cesium received its name for the presence of two bright blue lines in the emission spectrum (from the Latin caesius - sky blue).

From the Why column...

- First of all, tell me, Panama, what kind of metals ? - Iron. - And what else? - More? No, I don't know anymore. - You know, you know. Think carefully, remember. Okay, I'll give you a hint. So tell me, what is the fishing rod sinker made of? - Made of lead. - What is mom’s ring made of? - Made of gold. - Right. But both lead and gold are metals. The pan is aluminum, which means it’s metal, the mortar and pestle are brass, the metal wires, if you scrape off the plastic from them, are copper, metal. There are many more different metals in the world! And many of them have amazing properties. Which? But answer my questions: do metals sink in water? - Necessarily. Even the needle sinks. I have seen. - So, Panama, there are such light metals that float in water like a cork. One of them is called lithium. It is lighter than water... I don’t remember how much. Bumka probably knows. - HELLO, TURNING ON. LITHIUM IS TWICE LIGHTER THAN WATER AND 15 TIMES LIGHTER THAN IRON. LITHIUM IS A COMPONENT OF MORE THAN 150 MINERALS IT IS IN ALMOST EVERY STONE AND THAT IS WHY IT GOT THIS NAME: THE GREEK WORD “LITHOS” MEANS “STONE”. THIS SILVER-WHITE METAL IS MELT IN HOT OVENS AND MIXED WITH OTHER METALS. ALLOYS ARE OBTAINED. ALUMINUM IS NOT VERY STRONG, BUT IF YOU ALLOY IT WITH LITHIUM, THE RESULTS ARE A MUCH STRONGER METAL. - Thank you, Bumka. I ask a new question: do metals get sick? - Are they sick?! That's funny! So, a water tap can cause a runny nose, and a penknife can cause whooping cough? Hilarious! - Metals still hurt. Isn't the rust we talked about recently a disease of metals? They even “die” from it and are destroyed. There was steel, but it lay in the water for a long time - it collapsed and became covered with red rust. Tron will crumble into powder. No wonder people say: rust (that is, rust) eats iron. So I ate it. Now answer - is metal liquid? Not when it is melted in a hot oven, but always liquid? - Liquid metal, grandfather Do you know? Yes, it’s like “hot ice”! “So you’re saying it doesn’t happen?” Have you forgotten about mercury, which shows the temperature in a thermometer? This is real liquid metal ! If you accidentally drop or break the thermometer, the mercury will spread across the floor in small balls. If you collect them, they will instantly merge into one. This liquid metal hardens only in very severe frost. By the way, mercury is needed not only for thermometers. It is also necessary for tube lamps that provide bright daylight. Mercury is part of the paints that cover the bottoms of ships. After this, ships do not rust as much even in salty sea water and their bottoms are less overgrown with shells and algae. Well, in the end, let's answer the question: which metal is the strongest, which is the softest? First, about the most durable. It is silvery-white in color and is called titanium. Titanium is 12 times harder than aluminum, 4 times harder than iron and copper. If you heat other metals, they will immediately lose their strength. But titanium ... the temperature is 500 degrees, and it is still as strong as it was. It’s not for nothing that many parts of jet aircraft are made of titanium. This metal is so strong that it can only be crushed by the most powerful hammer machines. But sodium (also silvery-white), even though it is metal, doesn’t cost anything to flatten with your fingers. And magnesium is famous for its good combustion. Yes, yes - metal, but it burns! He brought a lit match to the thin shavings of magnesium and it flared up.

Here is the answer to the question: Which metal is the hardest and which is the softest?